Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1K viewsBack Pressure Cal

Back Pressure Cal

Uploaded by

Roshan ShanmughanThe document calculates the exhaust back pressure of a Cummins 1650 KVA standby power generator. It provides the exhaust gas flow, pipe diameter, exhaust temperature and other data. It then shows the calculations for back pressure in the pipe, 90 degree elbow, flexible fitting, and rain cap. The total back pressure is calculated and compared to the maximum allowable back pressure per the engine specifications.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Back Pressure Calculation 1 PDFDocument2 pagesBack Pressure Calculation 1 PDFRanu Januar100% (8)

- Velocity Pressure Method Calculation SheetDocument7 pagesVelocity Pressure Method Calculation SheetPhyu Mar Thein Kyaw100% (1)

- Xby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09Document35 pagesXby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09llaiskonis2725100% (3)

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Manual For Toyota Hilux 3lDocument5 pagesManual For Toyota Hilux 3lArcadio Duron0% (1)

- VW MK5 Jetta Model Introduction SSP 891403Document86 pagesVW MK5 Jetta Model Introduction SSP 891403Alex Stirbu100% (6)

- Hydraulic Calculation For Transfer PumpDocument2 pagesHydraulic Calculation For Transfer PumpSopi LabuNo ratings yet

- Compressed Air CalculationDocument7 pagesCompressed Air Calculationlutfi awnNo ratings yet

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (2)

- Car Park CalcDocument1 pageCar Park CalcDesigner Forever0% (1)

- Back Pressure CalculatorDocument1 pageBack Pressure CalculatorJosé Morales100% (1)

- Venturi ScrubbersDocument47 pagesVenturi ScrubbersAnoop Sharma100% (1)

- Hazen Williams EquationDocument5 pagesHazen Williams Equationprabhjot123100% (1)

- John Hicks (Auth.) - Welded Joint Design-Woodhead Publishing (1997)Document92 pagesJohn Hicks (Auth.) - Welded Joint Design-Woodhead Publishing (1997)Roshan Shanmughan100% (1)

- VW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Document194 pagesVW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Mucowera AshaNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Friction Loss in Pipe LineDocument3 pagesFriction Loss in Pipe LineAvinash VasudeoNo ratings yet

- Pump Sizing CalculationDocument11 pagesPump Sizing CalculationvkumaranNo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- Gas Pipe SizingDocument3 pagesGas Pipe SizingthecodekingNo ratings yet

- Calculation of Air Duct Pressure Loss (Rectangular)Document15 pagesCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein Kyaw100% (1)

- Equivalent Length Pipe FittingsDocument2 pagesEquivalent Length Pipe Fittingsorganicspolybond50% (2)

- Sewer Pumpstation Design Calculations For AlqiDocument7 pagesSewer Pumpstation Design Calculations For AlqiTahirJabbarNo ratings yet

- 01 - Fresh Air Unit Esp CalculationDocument2 pages01 - Fresh Air Unit Esp Calculationmefaisal750% (1)

- Calculation of FlowDocument3 pagesCalculation of FlowPhyu Mar Thein Kyaw100% (1)

- Pipe Sizing and CalculationsDocument17 pagesPipe Sizing and CalculationsJaykumar100% (7)

- Calculation of Back Pressure On Elbows, Flex Connectors and PipesDocument1 pageCalculation of Back Pressure On Elbows, Flex Connectors and PipesShakerMahmoodNo ratings yet

- Exhaust System Back Pressure CalculationDocument1 pageExhaust System Back Pressure Calculationmazumdar_satyajitNo ratings yet

- PIPEFLOWDocument1 pagePIPEFLOWSana UllahNo ratings yet

- Jet Pump CalculationDocument4 pagesJet Pump CalculationTry SutrisnoNo ratings yet

- Pipe Size For Cooling Water SystemDocument5 pagesPipe Size For Cooling Water Systemnagu108No ratings yet

- ENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFDocument23 pagesENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFBkhari Haran0% (1)

- Calculation of Duct SizingDocument7 pagesCalculation of Duct SizingPhyu Mar Thein KyawNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- Pump Head CalculationDocument6 pagesPump Head CalculationThushan Madu100% (17)

- Valve Sizing CalculationsDocument10 pagesValve Sizing CalculationsMuhammad Imran100% (1)

- Sizing Calculations RW CW HD ADDocument32 pagesSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizingmazumdar_satyajit100% (3)

- Pressure Loss Calculation Ariobimo Project MGS 2300R & 3100RDocument4 pagesPressure Loss Calculation Ariobimo Project MGS 2300R & 3100RRangga SetaNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation Sheethasanadel88No ratings yet

- Design of Medical Waste Incinertor Integrated With DeasinlationDocument130 pagesDesign of Medical Waste Incinertor Integrated With DeasinlationMotaz ZgogoNo ratings yet

- Three Phase Separator Sizing - Submerged WierDocument2 pagesThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradNo ratings yet

- Tank SizingDocument2 pagesTank SizingsamehNo ratings yet

- Chilled Water Expansion TankDocument1 pageChilled Water Expansion TankRamiAl-fuqahaNo ratings yet

- Water Pipe Sizes & Loading Units Calculations TahaDocument44 pagesWater Pipe Sizes & Loading Units Calculations TahaWaqar Ahmed Shaikh0% (1)

- Venturi Scrubber Theory & ExperimentDocument6 pagesVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Boiler NG CalculationDocument9 pagesBoiler NG CalculationChirag DarjiNo ratings yet

- Calculo de CFM Pump Room Ventilation Calculation PDFDocument1 pageCalculo de CFM Pump Room Ventilation Calculation PDFsusansue50% (2)

- Diesel Drive Fuel Tank Sizing CalculationDocument1 pageDiesel Drive Fuel Tank Sizing CalculationDinesh100% (1)

- Design Calculation Sheet: 1-AbbreviationsDocument3 pagesDesign Calculation Sheet: 1-Abbreviationsmayukhguha1988No ratings yet

- Process Line SizingDocument21 pagesProcess Line Sizingsj_scribdNo ratings yet

- Blower CalculatorDocument1 pageBlower CalculatorAnonymous QiMB2lBCJLNo ratings yet

- Tank Design CalculatorDocument19 pagesTank Design CalculatorSunday PaulNo ratings yet

- Calculat Friction LossDocument2 pagesCalculat Friction LosssenghyNo ratings yet

- Calculation of Back Pressure On Elbows, Flex Connectors and PipesDocument1 pageCalculation of Back Pressure On Elbows, Flex Connectors and Pipestri engineeringNo ratings yet

- NPSHADocument5 pagesNPSHAjokishNo ratings yet

- Gas Pipe SizingDocument10 pagesGas Pipe SizingSanthosh Kumar100% (1)

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

- Boiler Size Chart (XLS)Document4 pagesBoiler Size Chart (XLS)Bhartendu PatniNo ratings yet

- Exhaust Back Pressure Calculation 2Document1 pageExhaust Back Pressure Calculation 2Waruna PasanNo ratings yet

- Nuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4Document6 pagesNuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4gutmontNo ratings yet

- From Table We KnowDocument5 pagesFrom Table We KnowTaha ZakiNo ratings yet

- Calculation of Air Duct Pressure Loss (Circular)Document5 pagesCalculation of Air Duct Pressure Loss (Circular)Phyu Mar Thein KyawNo ratings yet

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi Wa100% (1)

- Domestic Technology 17-18 en WoP S7 Mechanical Level IndicatorsDocument1 pageDomestic Technology 17-18 en WoP S7 Mechanical Level IndicatorsRoshan ShanmughanNo ratings yet

- GG4195 MarkedDocument8 pagesGG4195 MarkedRoshan ShanmughanNo ratings yet

- Antishiphon ValveDocument1 pageAntishiphon ValveRoshan ShanmughanNo ratings yet

- Governing Equations and AssumptionsDocument5 pagesGoverning Equations and AssumptionsRoshan ShanmughanNo ratings yet

- Figure Schematic of An Axial Flow TurbineDocument5 pagesFigure Schematic of An Axial Flow TurbineRoshan ShanmughanNo ratings yet

- L09 - Fortran Programming - Part 1 1. Compiled LanguagesDocument9 pagesL09 - Fortran Programming - Part 1 1. Compiled LanguagesRoshan ShanmughanNo ratings yet

- One Dimensional Heat Conduction FTCS Matlab ProgramDocument2 pagesOne Dimensional Heat Conduction FTCS Matlab ProgramRoshan Shanmughan100% (1)

- Adiabatic Expansion Process (Work Extracted From System - Sign Convention For Added Work +W)Document5 pagesAdiabatic Expansion Process (Work Extracted From System - Sign Convention For Added Work +W)Roshan ShanmughanNo ratings yet

- Axial Flow Compressor CharacteristicsDocument5 pagesAxial Flow Compressor CharacteristicsRoshan ShanmughanNo ratings yet

- Figure A Typical Multistage Axial Flow Compressor (Rolls-Royce)Document5 pagesFigure A Typical Multistage Axial Flow Compressor (Rolls-Royce)Roshan ShanmughanNo ratings yet

- From Eqs. (1) and (2) : Euler Turbine EquationDocument5 pagesFrom Eqs. (1) and (2) : Euler Turbine EquationRoshan ShanmughanNo ratings yet

- Turbo MachineryDocument4 pagesTurbo MachineryRoshan ShanmughanNo ratings yet

- Radial-Flow Compressors Can Not Be Staged: (CPR) Per Stage Overall CPRDocument4 pagesRadial-Flow Compressors Can Not Be Staged: (CPR) Per Stage Overall CPRRoshan Shanmughan100% (1)

- Fluid Machinery: Positive Displacement - DynamicDocument4 pagesFluid Machinery: Positive Displacement - DynamicRoshan ShanmughanNo ratings yet

- One Dimensional Heat Conduction BTCS Matlab ProgramDocument2 pagesOne Dimensional Heat Conduction BTCS Matlab ProgramRoshan ShanmughanNo ratings yet

- Bos 21652Document4 pagesBos 21652Roshan ShanmughanNo ratings yet

- B605U71AdmitCard PDFDocument1 pageB605U71AdmitCard PDFRoshan ShanmughanNo ratings yet

- MATLAB Scripts and Programming: Dr. Ugur GUVENDocument7 pagesMATLAB Scripts and Programming: Dr. Ugur GUVENRoshan ShanmughanNo ratings yet

- AcDocument44 pagesAcRoshan ShanmughanNo ratings yet

- Analysis of Vibratory Stress of Integral Shroud BladeDocument12 pagesAnalysis of Vibratory Stress of Integral Shroud BladeRoshan Shanmughan100% (1)

- Hardware Remove DPF FilterDocument4 pagesHardware Remove DPF FilterMaykel CruzNo ratings yet

- CTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentDocument3 pagesCTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentMarlon Geronimo100% (1)

- Instrument Cluster (Instrument Panel, Gauges and Warning Indicators) - ALLDATA Repair FiestaDocument2 pagesInstrument Cluster (Instrument Panel, Gauges and Warning Indicators) - ALLDATA Repair FiestaEDGAR ROSALES DUARTENo ratings yet

- Manual Chevrolet CucvDocument202 pagesManual Chevrolet Cucvervin100% (1)

- Vol 0027Document3 pagesVol 0027Kenki HuemuraNo ratings yet

- 한도샤프트2Document56 pages한도샤프트2Mirequip Mirequip100% (1)

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Electromagnetic Clutch: What Is It, Diagram, Working Principle (With PDF)Document3 pagesElectromagnetic Clutch: What Is It, Diagram, Working Principle (With PDF)sameerNo ratings yet

- Unit 2Document49 pagesUnit 2Ramanathan DuraiNo ratings yet

- A46JE/A46JRT: Articulated Boom LiftsDocument1 pageA46JE/A46JRT: Articulated Boom LiftsbejoythomasNo ratings yet

- Fgtech Galletto v54 Customer Tested Ecu ListDocument5 pagesFgtech Galletto v54 Customer Tested Ecu ListSonny Jendhool Setyawan0% (1)

- Component LocationDocument2 pagesComponent LocationLuis Antonio FuentesNo ratings yet

- P673-2 - LuggerDocument62 pagesP673-2 - Luggerfatma kuruNo ratings yet

- Transition To Turbopropeller-Powered AirplanesDocument14 pagesTransition To Turbopropeller-Powered AirplanesAditya Sinha100% (1)

- Test Report Englisch BlancoDocument3 pagesTest Report Englisch BlancoElio DiazNo ratings yet

- Excessive Crankcase PressureDocument8 pagesExcessive Crankcase PressureabelNo ratings yet

- HKT Glow Plugs 2015Document37 pagesHKT Glow Plugs 2015Andru Sulima100% (2)

- En List of Cars For CAN-BUS 1406Document10 pagesEn List of Cars For CAN-BUS 1406moh12109No ratings yet

- 2019 Chevy Malibu 2.0L Engine Torque Specs Chevy SpecsDocument1 page2019 Chevy Malibu 2.0L Engine Torque Specs Chevy Specsm9dx2fx52tNo ratings yet

- Wheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeDocument4 pagesWheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeRalf MaurerNo ratings yet

- Gen7 Level 1 - TroubleshootingDocument22 pagesGen7 Level 1 - TroubleshootingDrago LugonjaNo ratings yet

- 2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFDocument197 pages2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFGourish Bhandari100% (1)

- 700649en A 1217 M MH Range-BdDocument36 pages700649en A 1217 M MH Range-BdManitouNo ratings yet

- All New GS3 Leaflet - A4June23Document2 pagesAll New GS3 Leaflet - A4June23Renzel TamayoNo ratings yet

- Kohler XT675 Owner's Manual 14 - 590 - 22 - ENDocument8 pagesKohler XT675 Owner's Manual 14 - 590 - 22 - ENbunkmonkeyNo ratings yet

- List Sparepart KobelcoDocument1 pageList Sparepart Kobelcoargya AwangNo ratings yet

Back Pressure Cal

Back Pressure Cal

Uploaded by

Roshan Shanmughan0 ratings0% found this document useful (0 votes)

1K views1 pageThe document calculates the exhaust back pressure of a Cummins 1650 KVA standby power generator. It provides the exhaust gas flow, pipe diameter, exhaust temperature and other data. It then shows the calculations for back pressure in the pipe, 90 degree elbow, flexible fitting, and rain cap. The total back pressure is calculated and compared to the maximum allowable back pressure per the engine specifications.

Original Description:

Backpressure calculation

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document calculates the exhaust back pressure of a Cummins 1650 KVA standby power generator. It provides the exhaust gas flow, pipe diameter, exhaust temperature and other data. It then shows the calculations for back pressure in the pipe, 90 degree elbow, flexible fitting, and rain cap. The total back pressure is calculated and compared to the maximum allowable back pressure per the engine specifications.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

1K views1 pageBack Pressure Cal

Back Pressure Cal

Uploaded by

Roshan ShanmughanThe document calculates the exhaust back pressure of a Cummins 1650 KVA standby power generator. It provides the exhaust gas flow, pipe diameter, exhaust temperature and other data. It then shows the calculations for back pressure in the pipe, 90 degree elbow, flexible fitting, and rain cap. The total back pressure is calculated and compared to the maximum allowable back pressure per the engine specifications.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

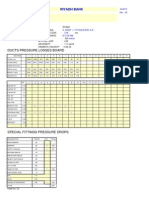

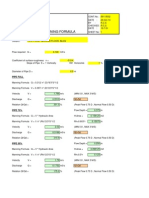

EXHAUST BACK PRESSURE CALCULATION

Project : University of sharjah teaching hospital Genset : Cummins 1650 KVA, STANDBY POWER GENSET DATA

Q (m3/min) = Exhaust gas flow (Dual outlet) Q (m /min) = Exhaust gas flow (single outlet) D (mm) = Diameter of pipe

T (DEG C) = Exhaust Stack Temp.

3

230 230 300 422 0.506906475 12 3 1

[ (L x S x Q^2 x 3.6 x 10^6) / (D5) ] 0.476717378 2.145228201 0.476717378 0.198632241 please refer muffler data sheet

S (kg/m3) L (m) Le (m) Lf (m)

= Density of gas = Total length of pipe = 90 Deg Elbow = flexible fitting

Backpressure of pipe (kPa) =

Back pressure in pipe (kpa) - A Back pressure in elbow (kpa) - B Back pressure in flexible fitting (kpa) - C Back pressure in rain cap (kpa) - D Back pressure in muffler (kpa) - E Total back pressure in exhaust system in single outlet (kpa) (A+B+C+D) Maximum allowable back pressure in exhaust system 6.7 kpa (As per cummins engine data sheet)

3.297295199

Note : Above calculation excluding exhaust muffler back pressure amount.

You might also like

- Back Pressure Calculation 1 PDFDocument2 pagesBack Pressure Calculation 1 PDFRanu Januar100% (8)

- Velocity Pressure Method Calculation SheetDocument7 pagesVelocity Pressure Method Calculation SheetPhyu Mar Thein Kyaw100% (1)

- Xby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09Document35 pagesXby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09llaiskonis2725100% (3)

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Manual For Toyota Hilux 3lDocument5 pagesManual For Toyota Hilux 3lArcadio Duron0% (1)

- VW MK5 Jetta Model Introduction SSP 891403Document86 pagesVW MK5 Jetta Model Introduction SSP 891403Alex Stirbu100% (6)

- Hydraulic Calculation For Transfer PumpDocument2 pagesHydraulic Calculation For Transfer PumpSopi LabuNo ratings yet

- Compressed Air CalculationDocument7 pagesCompressed Air Calculationlutfi awnNo ratings yet

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (2)

- Car Park CalcDocument1 pageCar Park CalcDesigner Forever0% (1)

- Back Pressure CalculatorDocument1 pageBack Pressure CalculatorJosé Morales100% (1)

- Venturi ScrubbersDocument47 pagesVenturi ScrubbersAnoop Sharma100% (1)

- Hazen Williams EquationDocument5 pagesHazen Williams Equationprabhjot123100% (1)

- John Hicks (Auth.) - Welded Joint Design-Woodhead Publishing (1997)Document92 pagesJohn Hicks (Auth.) - Welded Joint Design-Woodhead Publishing (1997)Roshan Shanmughan100% (1)

- VW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Document194 pagesVW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Mucowera AshaNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Friction Loss in Pipe LineDocument3 pagesFriction Loss in Pipe LineAvinash VasudeoNo ratings yet

- Pump Sizing CalculationDocument11 pagesPump Sizing CalculationvkumaranNo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- Gas Pipe SizingDocument3 pagesGas Pipe SizingthecodekingNo ratings yet

- Calculation of Air Duct Pressure Loss (Rectangular)Document15 pagesCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein Kyaw100% (1)

- Equivalent Length Pipe FittingsDocument2 pagesEquivalent Length Pipe Fittingsorganicspolybond50% (2)

- Sewer Pumpstation Design Calculations For AlqiDocument7 pagesSewer Pumpstation Design Calculations For AlqiTahirJabbarNo ratings yet

- 01 - Fresh Air Unit Esp CalculationDocument2 pages01 - Fresh Air Unit Esp Calculationmefaisal750% (1)

- Calculation of FlowDocument3 pagesCalculation of FlowPhyu Mar Thein Kyaw100% (1)

- Pipe Sizing and CalculationsDocument17 pagesPipe Sizing and CalculationsJaykumar100% (7)

- Calculation of Back Pressure On Elbows, Flex Connectors and PipesDocument1 pageCalculation of Back Pressure On Elbows, Flex Connectors and PipesShakerMahmoodNo ratings yet

- Exhaust System Back Pressure CalculationDocument1 pageExhaust System Back Pressure Calculationmazumdar_satyajitNo ratings yet

- PIPEFLOWDocument1 pagePIPEFLOWSana UllahNo ratings yet

- Jet Pump CalculationDocument4 pagesJet Pump CalculationTry SutrisnoNo ratings yet

- Pipe Size For Cooling Water SystemDocument5 pagesPipe Size For Cooling Water Systemnagu108No ratings yet

- ENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFDocument23 pagesENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFBkhari Haran0% (1)

- Calculation of Duct SizingDocument7 pagesCalculation of Duct SizingPhyu Mar Thein KyawNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- Pump Head CalculationDocument6 pagesPump Head CalculationThushan Madu100% (17)

- Valve Sizing CalculationsDocument10 pagesValve Sizing CalculationsMuhammad Imran100% (1)

- Sizing Calculations RW CW HD ADDocument32 pagesSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizingmazumdar_satyajit100% (3)

- Pressure Loss Calculation Ariobimo Project MGS 2300R & 3100RDocument4 pagesPressure Loss Calculation Ariobimo Project MGS 2300R & 3100RRangga SetaNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation Sheethasanadel88No ratings yet

- Design of Medical Waste Incinertor Integrated With DeasinlationDocument130 pagesDesign of Medical Waste Incinertor Integrated With DeasinlationMotaz ZgogoNo ratings yet

- Three Phase Separator Sizing - Submerged WierDocument2 pagesThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradNo ratings yet

- Tank SizingDocument2 pagesTank SizingsamehNo ratings yet

- Chilled Water Expansion TankDocument1 pageChilled Water Expansion TankRamiAl-fuqahaNo ratings yet

- Water Pipe Sizes & Loading Units Calculations TahaDocument44 pagesWater Pipe Sizes & Loading Units Calculations TahaWaqar Ahmed Shaikh0% (1)

- Venturi Scrubber Theory & ExperimentDocument6 pagesVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Boiler NG CalculationDocument9 pagesBoiler NG CalculationChirag DarjiNo ratings yet

- Calculo de CFM Pump Room Ventilation Calculation PDFDocument1 pageCalculo de CFM Pump Room Ventilation Calculation PDFsusansue50% (2)

- Diesel Drive Fuel Tank Sizing CalculationDocument1 pageDiesel Drive Fuel Tank Sizing CalculationDinesh100% (1)

- Design Calculation Sheet: 1-AbbreviationsDocument3 pagesDesign Calculation Sheet: 1-Abbreviationsmayukhguha1988No ratings yet

- Process Line SizingDocument21 pagesProcess Line Sizingsj_scribdNo ratings yet

- Blower CalculatorDocument1 pageBlower CalculatorAnonymous QiMB2lBCJLNo ratings yet

- Tank Design CalculatorDocument19 pagesTank Design CalculatorSunday PaulNo ratings yet

- Calculat Friction LossDocument2 pagesCalculat Friction LosssenghyNo ratings yet

- Calculation of Back Pressure On Elbows, Flex Connectors and PipesDocument1 pageCalculation of Back Pressure On Elbows, Flex Connectors and Pipestri engineeringNo ratings yet

- NPSHADocument5 pagesNPSHAjokishNo ratings yet

- Gas Pipe SizingDocument10 pagesGas Pipe SizingSanthosh Kumar100% (1)

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

- Boiler Size Chart (XLS)Document4 pagesBoiler Size Chart (XLS)Bhartendu PatniNo ratings yet

- Exhaust Back Pressure Calculation 2Document1 pageExhaust Back Pressure Calculation 2Waruna PasanNo ratings yet

- Nuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4Document6 pagesNuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4gutmontNo ratings yet

- From Table We KnowDocument5 pagesFrom Table We KnowTaha ZakiNo ratings yet

- Calculation of Air Duct Pressure Loss (Circular)Document5 pagesCalculation of Air Duct Pressure Loss (Circular)Phyu Mar Thein KyawNo ratings yet

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi Wa100% (1)

- Domestic Technology 17-18 en WoP S7 Mechanical Level IndicatorsDocument1 pageDomestic Technology 17-18 en WoP S7 Mechanical Level IndicatorsRoshan ShanmughanNo ratings yet

- GG4195 MarkedDocument8 pagesGG4195 MarkedRoshan ShanmughanNo ratings yet

- Antishiphon ValveDocument1 pageAntishiphon ValveRoshan ShanmughanNo ratings yet

- Governing Equations and AssumptionsDocument5 pagesGoverning Equations and AssumptionsRoshan ShanmughanNo ratings yet

- Figure Schematic of An Axial Flow TurbineDocument5 pagesFigure Schematic of An Axial Flow TurbineRoshan ShanmughanNo ratings yet

- L09 - Fortran Programming - Part 1 1. Compiled LanguagesDocument9 pagesL09 - Fortran Programming - Part 1 1. Compiled LanguagesRoshan ShanmughanNo ratings yet

- One Dimensional Heat Conduction FTCS Matlab ProgramDocument2 pagesOne Dimensional Heat Conduction FTCS Matlab ProgramRoshan Shanmughan100% (1)

- Adiabatic Expansion Process (Work Extracted From System - Sign Convention For Added Work +W)Document5 pagesAdiabatic Expansion Process (Work Extracted From System - Sign Convention For Added Work +W)Roshan ShanmughanNo ratings yet

- Axial Flow Compressor CharacteristicsDocument5 pagesAxial Flow Compressor CharacteristicsRoshan ShanmughanNo ratings yet

- Figure A Typical Multistage Axial Flow Compressor (Rolls-Royce)Document5 pagesFigure A Typical Multistage Axial Flow Compressor (Rolls-Royce)Roshan ShanmughanNo ratings yet

- From Eqs. (1) and (2) : Euler Turbine EquationDocument5 pagesFrom Eqs. (1) and (2) : Euler Turbine EquationRoshan ShanmughanNo ratings yet

- Turbo MachineryDocument4 pagesTurbo MachineryRoshan ShanmughanNo ratings yet

- Radial-Flow Compressors Can Not Be Staged: (CPR) Per Stage Overall CPRDocument4 pagesRadial-Flow Compressors Can Not Be Staged: (CPR) Per Stage Overall CPRRoshan Shanmughan100% (1)

- Fluid Machinery: Positive Displacement - DynamicDocument4 pagesFluid Machinery: Positive Displacement - DynamicRoshan ShanmughanNo ratings yet

- One Dimensional Heat Conduction BTCS Matlab ProgramDocument2 pagesOne Dimensional Heat Conduction BTCS Matlab ProgramRoshan ShanmughanNo ratings yet

- Bos 21652Document4 pagesBos 21652Roshan ShanmughanNo ratings yet

- B605U71AdmitCard PDFDocument1 pageB605U71AdmitCard PDFRoshan ShanmughanNo ratings yet

- MATLAB Scripts and Programming: Dr. Ugur GUVENDocument7 pagesMATLAB Scripts and Programming: Dr. Ugur GUVENRoshan ShanmughanNo ratings yet

- AcDocument44 pagesAcRoshan ShanmughanNo ratings yet

- Analysis of Vibratory Stress of Integral Shroud BladeDocument12 pagesAnalysis of Vibratory Stress of Integral Shroud BladeRoshan Shanmughan100% (1)

- Hardware Remove DPF FilterDocument4 pagesHardware Remove DPF FilterMaykel CruzNo ratings yet

- CTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentDocument3 pagesCTP Engine Oil & Fuel Filters: New CTP Replacement Parts For Heavy EquipmentMarlon Geronimo100% (1)

- Instrument Cluster (Instrument Panel, Gauges and Warning Indicators) - ALLDATA Repair FiestaDocument2 pagesInstrument Cluster (Instrument Panel, Gauges and Warning Indicators) - ALLDATA Repair FiestaEDGAR ROSALES DUARTENo ratings yet

- Manual Chevrolet CucvDocument202 pagesManual Chevrolet Cucvervin100% (1)

- Vol 0027Document3 pagesVol 0027Kenki HuemuraNo ratings yet

- 한도샤프트2Document56 pages한도샤프트2Mirequip Mirequip100% (1)

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Electromagnetic Clutch: What Is It, Diagram, Working Principle (With PDF)Document3 pagesElectromagnetic Clutch: What Is It, Diagram, Working Principle (With PDF)sameerNo ratings yet

- Unit 2Document49 pagesUnit 2Ramanathan DuraiNo ratings yet

- A46JE/A46JRT: Articulated Boom LiftsDocument1 pageA46JE/A46JRT: Articulated Boom LiftsbejoythomasNo ratings yet

- Fgtech Galletto v54 Customer Tested Ecu ListDocument5 pagesFgtech Galletto v54 Customer Tested Ecu ListSonny Jendhool Setyawan0% (1)

- Component LocationDocument2 pagesComponent LocationLuis Antonio FuentesNo ratings yet

- P673-2 - LuggerDocument62 pagesP673-2 - Luggerfatma kuruNo ratings yet

- Transition To Turbopropeller-Powered AirplanesDocument14 pagesTransition To Turbopropeller-Powered AirplanesAditya Sinha100% (1)

- Test Report Englisch BlancoDocument3 pagesTest Report Englisch BlancoElio DiazNo ratings yet

- Excessive Crankcase PressureDocument8 pagesExcessive Crankcase PressureabelNo ratings yet

- HKT Glow Plugs 2015Document37 pagesHKT Glow Plugs 2015Andru Sulima100% (2)

- En List of Cars For CAN-BUS 1406Document10 pagesEn List of Cars For CAN-BUS 1406moh12109No ratings yet

- 2019 Chevy Malibu 2.0L Engine Torque Specs Chevy SpecsDocument1 page2019 Chevy Malibu 2.0L Engine Torque Specs Chevy Specsm9dx2fx52tNo ratings yet

- Wheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeDocument4 pagesWheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeRalf MaurerNo ratings yet

- Gen7 Level 1 - TroubleshootingDocument22 pagesGen7 Level 1 - TroubleshootingDrago LugonjaNo ratings yet

- 2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFDocument197 pages2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFGourish Bhandari100% (1)

- 700649en A 1217 M MH Range-BdDocument36 pages700649en A 1217 M MH Range-BdManitouNo ratings yet

- All New GS3 Leaflet - A4June23Document2 pagesAll New GS3 Leaflet - A4June23Renzel TamayoNo ratings yet

- Kohler XT675 Owner's Manual 14 - 590 - 22 - ENDocument8 pagesKohler XT675 Owner's Manual 14 - 590 - 22 - ENbunkmonkeyNo ratings yet

- List Sparepart KobelcoDocument1 pageList Sparepart Kobelcoargya AwangNo ratings yet