Professional Documents

Culture Documents

Procedure Painting Mps Epoxcy - Final - PT Khi

Procedure Painting Mps Epoxcy - Final - PT Khi

Uploaded by

sinambeladavidCopyright:

Available Formats

You might also like

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- RC Vs Steel PiperackDocument4 pagesRC Vs Steel PiperacksinambeladavidNo ratings yet

- Control Building Users Guide EXDOC-XX19-en-110 PDFDocument756 pagesControl Building Users Guide EXDOC-XX19-en-110 PDFsinambeladavidNo ratings yet

- A Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeDocument3 pagesA Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeWang TianyangNo ratings yet

- Linear ProgrammingDocument76 pagesLinear ProgrammingHanna Grace Honrade0% (1)

- LINE 100 RFQ CV 004 - Requisition Steel Structure ErectionDocument97 pagesLINE 100 RFQ CV 004 - Requisition Steel Structure ErectionACHMAD.KAMALNo ratings yet

- RFI Chipping & PaddingDocument80 pagesRFI Chipping & Paddingcrys suryo prayogoNo ratings yet

- Master Document Register ListDocument10 pagesMaster Document Register ListcrysNo ratings yet

- INQUIRY SHEET ////////////: Hyosung CorporationDocument7 pagesINQUIRY SHEET ////////////: Hyosung CorporationervanjovanNo ratings yet

- GR5HRM-CIVIL-ITP-ENGLISH VersionDocument66 pagesGR5HRM-CIVIL-ITP-ENGLISH VersionGaneshNo ratings yet

- 3.1 Fabrication and Installation of PipingDocument45 pages3.1 Fabrication and Installation of PipingArie100% (1)

- Jms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2Document39 pagesJms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2amir hakimNo ratings yet

- Body of Requisition - ROW Work Package PDFDocument60 pagesBody of Requisition - ROW Work Package PDFmahandhieNo ratings yet

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDocument4 pagesA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- QC Documents & Procedures (20!6!2019)Document2 pagesQC Documents & Procedures (20!6!2019)Billy Kurniawan100% (1)

- Weldlok Steel GratingDocument16 pagesWeldlok Steel GratingDivyang241088No ratings yet

- Sakuti Method - Statement - For - HRSG - Works CrsherDocument32 pagesSakuti Method - Statement - For - HRSG - Works CrsherMIL RABNo ratings yet

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocument4 pagesMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNo ratings yet

- Erection Tank Settlement Check Schedule 103 110 165Document8 pagesErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- Work Method Bridge Sleeper Replacement - 2014Document8 pagesWork Method Bridge Sleeper Replacement - 2014Irham M AFNo ratings yet

- Project: Fuel Storage Tank 20.000KL With Facilty Loc.Document9 pagesProject: Fuel Storage Tank 20.000KL With Facilty Loc.basukiNo ratings yet

- Fabrication Method For HSM 2 ProjectDocument14 pagesFabrication Method For HSM 2 ProjectMikiRoniWijayaNo ratings yet

- GK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureDocument15 pagesGK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureElias EliasNo ratings yet

- Fabrication of Steel Structure and Steel Equipment (Itp)Document4 pagesFabrication of Steel Structure and Steel Equipment (Itp)Javed MANo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- GCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Document19 pagesGCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Dwiadi Cahyabudi100% (1)

- 6.9. Handling Storage & Preservation ProcedureDocument10 pages6.9. Handling Storage & Preservation Procedurerendra syamNo ratings yet

- General Work Method Statement.2Document26 pagesGeneral Work Method Statement.2Novita SariNo ratings yet

- Cy3 - Te MeteringDocument22 pagesCy3 - Te MeteringSilpa Asti Nura100% (1)

- Method Statement Steel Structure 1 4 MegDocument26 pagesMethod Statement Steel Structure 1 4 MegNick LawNo ratings yet

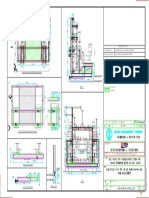

- ACID DOSING PUMP FOR UF CEB SKID (426-P-812AB) CIVIL ARRANGEMENT-Model PDFDocument1 pageACID DOSING PUMP FOR UF CEB SKID (426-P-812AB) CIVIL ARRANGEMENT-Model PDFJehangir MoosNo ratings yet

- Tank Lifting ProcedureDocument18 pagesTank Lifting ProcedureRicardo NapitupuluNo ratings yet

- 1 Civil Document Pertamina EpDocument13 pages1 Civil Document Pertamina EpDwiadi Cahyabudi100% (1)

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Lifting Lug CalculatorDocument5 pagesLifting Lug CalculatorJOHNNo ratings yet

- Besi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2Document4 pagesBesi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2didiNo ratings yet

- General Information G-0002: Description On Material JIS-ASTMDocument4 pagesGeneral Information G-0002: Description On Material JIS-ASTMEko Indra SaputraNo ratings yet

- 5-Mooring Buoy KEMENANGAN BrosurDocument2 pages5-Mooring Buoy KEMENANGAN Brosurdody andiNo ratings yet

- Field Joint Coating Installation ProcedureDocument2 pagesField Joint Coating Installation Procedureunix manNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- G05.4 - Civil WorksDocument107 pagesG05.4 - Civil WorksLandon Mitchell100% (1)

- Format MTODocument1 pageFormat MTOHermantoro PradanaNo ratings yet

- Summary Materials: Project Time of Issue Nien Made Project Factory 3-6Document11 pagesSummary Materials: Project Time of Issue Nien Made Project Factory 3-6thang TranNo ratings yet

- Itp Structural Steel Work Erection BlogDocument6 pagesItp Structural Steel Work Erection BlogIndwell RaigarhNo ratings yet

- 105-Structural Steel ErectionDocument7 pages105-Structural Steel Erectionzaki fadl100% (1)

- Standard PracticeDocument14 pagesStandard PracticeRomi Abdul RahmanNo ratings yet

- Specification For Fabrication and Erection ofDocument26 pagesSpecification For Fabrication and Erection ofEdgargarNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Training Schedule 2021 - SLVDocument4 pagesTraining Schedule 2021 - SLVFerdie OSNo ratings yet

- ITP Steel StructureDocument2 pagesITP Steel StructureEndy0% (1)

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - ADocument9 pagesENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- BRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Document10 pagesBRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Ponaryo AnggaraNo ratings yet

- Bailey Bridge ScheduleDocument4 pagesBailey Bridge ScheduleFernandoPintoMachacaNo ratings yet

- Presentasi Welding Prosedur Specification (WPS) Pre QualifiedDocument8 pagesPresentasi Welding Prosedur Specification (WPS) Pre QualifiedDeri Agung WicaksonoNo ratings yet

- Blasting Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting Coating Procedure For Fabricated Steel StructureSalman Alfarisi100% (1)

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Method Statement For APCS-113A (1) 22-6-2011Document7 pagesMethod Statement For APCS-113A (1) 22-6-2011sharif339No ratings yet

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- Working Procedure Ls1-Ls4Document9 pagesWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

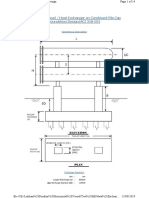

- HE Exchanger PilecapDocument14 pagesHE Exchanger PilecapsinambeladavidNo ratings yet

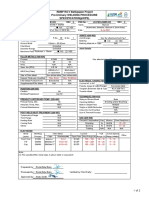

- STAAD Foundation%2Document10 pagesSTAAD Foundation%2sinambeladavidNo ratings yet

- Input Data: 2.1 Strength of An AnchorDocument3 pagesInput Data: 2.1 Strength of An Anchorsinambeladavid100% (1)

- Pile Stress Ratio CalculationDocument23 pagesPile Stress Ratio CalculationsinambeladavidNo ratings yet

- C Keyplan: South Sumatera NGL ProjectDocument5 pagesC Keyplan: South Sumatera NGL ProjectsinambeladavidNo ratings yet

- Excavation and Trenching ProcedureDocument12 pagesExcavation and Trenching Proceduresinambeladavid100% (1)

- PDA CheckDocument2 pagesPDA ChecksinambeladavidNo ratings yet

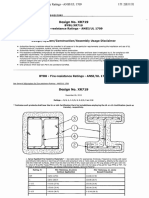

- Ul Certi (Promat)Document2 pagesUl Certi (Promat)sinambeladavidNo ratings yet

- New J100-MC-001 Piled FDN Existing Sewer For Site PreparationDocument1 pageNew J100-MC-001 Piled FDN Existing Sewer For Site PreparationsinambeladavidNo ratings yet

- Rfcc-c-qc-pr-002 Site Itp Procedure Rev 3Document114 pagesRfcc-c-qc-pr-002 Site Itp Procedure Rev 3sinambeladavid100% (3)

- HSE PlanDocument52 pagesHSE Plansinambeladavid100% (3)

- Rfcc-c-qc-pr-002 Site Itp Procedure Rev 3Document114 pagesRfcc-c-qc-pr-002 Site Itp Procedure Rev 3sinambeladavid100% (3)

- Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC ProjectDocument6 pagesCilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Projectsinambeladavid100% (1)

- RFCC-T-GCPC-0024 Submit Result Bending Test Spun Pile Dia 500 and 600Document46 pagesRFCC-T-GCPC-0024 Submit Result Bending Test Spun Pile Dia 500 and 600sinambeladavidNo ratings yet

- Summary of PDA Test ResultDocument8 pagesSummary of PDA Test Resultsinambeladavid0% (1)

- RFCC-T-PCGC-0264 Requsition Fire Proofing Material (ISOLATEX)Document11 pagesRFCC-T-PCGC-0264 Requsition Fire Proofing Material (ISOLATEX)sinambeladavidNo ratings yet

- RFCC-T-PCGC-0265 Requsition Fire Proofing Material (PROMAT)Document98 pagesRFCC-T-PCGC-0265 Requsition Fire Proofing Material (PROMAT)sinambeladavid100% (1)

- Yokogawa Universal IODocument6 pagesYokogawa Universal IOsinambeladavidNo ratings yet

- Name For Correspondence From PMI:: David Sinambela 62 821 75884403Document2 pagesName For Correspondence From PMI:: David Sinambela 62 821 75884403sinambeladavidNo ratings yet

- 1 Motor Protection Single SessionDocument27 pages1 Motor Protection Single Sessionmubarakkirko100% (1)

- Annual Report 2013Document48 pagesAnnual Report 2013Shankar DasNo ratings yet

- Faster Planes and Cheaper Flights: B. It Can Be Destroyed by Too Many VisitorsDocument6 pagesFaster Planes and Cheaper Flights: B. It Can Be Destroyed by Too Many VisitorsGermainNo ratings yet

- Astronomic TarotDocument17 pagesAstronomic TarotNancy ZecchelNo ratings yet

- FIFA Video Game - Players ClassificationDocument26 pagesFIFA Video Game - Players Classificationimmi1989No ratings yet

- IT Checklist For Successful Mergers and Acquisitions PDFDocument8 pagesIT Checklist For Successful Mergers and Acquisitions PDFAli AlwesabiNo ratings yet

- Early Childhood and Children's Rights: A Critical PerspectiveDocument21 pagesEarly Childhood and Children's Rights: A Critical PerspectiveOyibokure OlufunmilolaNo ratings yet

- Lect 3c The Lean EnterpriseDocument52 pagesLect 3c The Lean EnterpriseAvantika SarafNo ratings yet

- Declamation ScriptDocument1 pageDeclamation Scriptglaide lojeroNo ratings yet

- Engineers Weekly Report InstructionsDocument4 pagesEngineers Weekly Report InstructionsashifNo ratings yet

- Yellow GroupDocument14 pagesYellow Groupavxenogenesis03No ratings yet

- Uml Lecture PDFDocument4 pagesUml Lecture PDFMuhammad MoizNo ratings yet

- SANSUI Hdlcd1955 enDocument25 pagesSANSUI Hdlcd1955 enMelanie HoodNo ratings yet

- Ethics and Organisational CultureDocument2 pagesEthics and Organisational CultureSonika MishraNo ratings yet

- Manajemen OperasiDocument37 pagesManajemen OperasiHELWAH AMINAH ACHMADNo ratings yet

- Alana Robertson PDFDocument7 pagesAlana Robertson PDFKshitij SinghNo ratings yet

- How To Implement ABAP Kernel UpdateDocument4 pagesHow To Implement ABAP Kernel Updateabhisona76No ratings yet

- TemarioDocument4 pagesTemarioLina GordilloNo ratings yet

- CJ Relays (Acj) : Features Typical ApplicationsDocument7 pagesCJ Relays (Acj) : Features Typical ApplicationsFranciscoMedinaNo ratings yet

- WW2 Military Bldgs PDFDocument102 pagesWW2 Military Bldgs PDFone-eyed fat manNo ratings yet

- "Flexible Manufacturing System": Department of Mechanical EngineeringDocument32 pages"Flexible Manufacturing System": Department of Mechanical EngineeringGoutham ReddyNo ratings yet

- General SpecificationsDocument6 pagesGeneral SpecificationsMaire Joy E. AzañaNo ratings yet

- Impact of Chronic Illness On ChildrenDocument6 pagesImpact of Chronic Illness On ChildrenDeepa ThomasNo ratings yet

- Health8 - q1 - Mod5 - Family Health Comes First - FINAL07282020Document21 pagesHealth8 - q1 - Mod5 - Family Health Comes First - FINAL07282020Rose Marie NaboNo ratings yet

- ICDL Module 6 PresentationDocument40 pagesICDL Module 6 PresentationcaphilNo ratings yet

- VUMAT For Fabric Reinforced Composites: Figure 1: Schematic Representation of WovenDocument10 pagesVUMAT For Fabric Reinforced Composites: Figure 1: Schematic Representation of Wovenjunjie yiNo ratings yet

- Modular ExponentiationDocument2 pagesModular ExponentiationflaksherNo ratings yet

- Kinematics: Distance Vs DisplacementDocument7 pagesKinematics: Distance Vs DisplacementTorettoNo ratings yet

Procedure Painting Mps Epoxcy - Final - PT Khi

Procedure Painting Mps Epoxcy - Final - PT Khi

Uploaded by

sinambeladavidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Painting Mps Epoxcy - Final - PT Khi

Procedure Painting Mps Epoxcy - Final - PT Khi

Uploaded by

sinambeladavidCopyright:

Available Formats

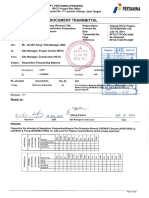

DOC. NO.

: RFCC-A-CV-VP-PO029-SP007

Cilacap Resid Fluid Catalytic Cracking (RFCC) Project PT. PERTAMINA (Persero)

REV. NO. : 02 PAGE NO. :1 / 12

Manufacturing Procedure Specification of Paint Epoxy Coating

PROJECT

: CILACAP RESID FLUID CATALYTIC CRACKING (RFCC) PROJECT

LOCATION OWNER CONTRACTOR PO. NO.

: PERTAMINA RU-IV, CILACAP, CENTRAL JAVA, INDONESIA : PT. PERTAMINA (PERSERO) : CONSORTIUM ADHI-GSEC : RFCC-A-CV-PO-029

REQUISITION NO. : RFCC-A-CV-RQ-029 VENDOR NAME : PT. KHI PIPE INDUSTRIES

VENDOR DOC. NO. : 042/KHI/MPS/EXC/VIII/2012

02

Issued For Final

October 24, 2014

01 0 Rev.

Re-Issued for Approval Issued for Approval Description

September 24, 2012

August 15, 2012 Date

Edi Jumialdi Prepared by

Suprapto Reviewed by

Tri Wahono Approved by

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC) Project PT. PERTAMINA (Persero) MANUFACTURING PROCEDURE SPECIFICATION OF PAINT EPOXY COATING

DOC. NO. : RFCC-A-CV-VP-PO029-SP007

REV. NO. : 02

PAGE

:2 /12

REVISION HISTRORICAL SHEET Rev.

01 02

Page / Paragraph

PAGE 2 & 3 PAGE 2 & 3

Item

Description of Change

INPUT/TYPEDOCNO.FORCOVERDOCUMENT

ISSUEDFORFINAL

CONSORTIUM ADHI GS E&C

MPS No.

042/KHI/MPS/EXC/VIII/2012

MANUFACTURING PROCEDURE SPECIFICATION

of

PAINTEPOXYCOATING

Customer Client Project

: PT. ADHI KARYA (Persero) Tbk. : PT. PERTAMINA (Persero) : Resid Fluid Catalytic Cracking (RFCC) - Cilacap

14-Aug-12

Issued for Approval

TW

WS

AA

QA

Checked by

AHS

Prod

Reviewed by For Customer Approval Remarks

Rev.

Date

Description

Prepared by

This MPS is the property of KHI and must not be handed to a third party or reproduced completely or in a part without the explicit written consent of KHI

PT. KHI PIPE INDUSTRIES

PIPE & COATING

CILEGON - BANTEN

Doc. No

042/KHI/MPS/EXC/VIII/2012 1 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

1 Table Of Content

Section

Description

Page No

1 2 3 4 5 6 7 8 9

Table of Contents Scope Manufacturing Process Code, Specifications, Standard and References Responsibilities Receiving Inspection Blasting, Primer & Coating Application Inspection and Repair Coating Stock Yard

1 2 3 4 5 6 7 8 9

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 2 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

2 Scope

This document covers MANUFACTURING PROCEDURE SPECIFICATION including Testing and Inspection procedure specification of application of paint epoxy on pipe external surface.

This procedure is written with the intention of being a working instruction for shop floor personnel by detailing the standard of workmanship and acceptance criteria throughout each phase of the process.

Pipe epoxy coating activities will be conducted at PT. KHI Pipe Industries Cigading Factory.

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 3 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

3 Manufacturing Process

Material & Pipe Receiving Inspection

BLASTING

Good Not Good

COATING APPLICATION

Not Good

REPAIR

Good

Accept

RE-INSPECTION

Accept

THICKNESS MEASUREMENT

Good

RE-COATING

Not Good

MARKING

STOCK YARD

PACKING

DELIVERED

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 4 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

Code, Specifications, Standard and References

The following code, specifications, standards and reference are relevant to this document:

a. SSPC-SP10/NACE No.2 : Surface Preparation Standards for Painting Steel Surface b. ISO 8501-1-1988 : International Organization for Standard Blast Cleaning. c. ISO 8503-2 -1998 :Method for the grading of surface profile of abrasive blast- cleaned steel Comparator procedure

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 5 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

5 Responsibilities

5.1.

Coating Superintendent shall be responsible for all labor and equipment necessary for the required operation. He shall also ensure that the operations are performed in a safe manner and that the product meets the requirements specified herein. QA Manager responsible for ensuring that the Customers agreed quality requirements are satisfied. He shall also ensure that the Q.C. inspectors inspect and control the quality of the product in accordance with this document.

5.2.

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 6 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

6 Receiving Inspection

1. Pipe Receiving Inspection All pipes shall be visually examined for defect such as slag, arc strike, weld spatter, porosity, sharp edge, pit, lamination, slivers, crevice and internal ridges or welds that have not been properly scarfed. Pipes containing these defects shall be segregated if the defects are to the extent they would reduce the coating quality. If pipes are received from other pipe manufacturer the marking shall be recorded and kept for identification and the bevel end protector shall be kept and installed later after coating application has finished.

2. Coating Material Receiving Inspection a. Receiving coating material shall be checked as per delivery sheet. b. Check, verify and reported every batch of coating with the following items: Coating Manufacturers name address Product Type Batch No Quantity Certificate Date of Manufacture / expire date Packing Condition

c. Keep the coating material as per manufacturer specification. d. Only the coating materials which have been approved shall be used for coating process. e. Coating material as per Customer Purchase Order.

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 7 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

7 Blasting, Primer & Coating Application

Blasting

Before blasting the pipe surface shall be cleaned to remove dirt or grease. All traces of oil and grease shall be brushed and wiped off using detergent/water cleaning (Aqueous solutions of household detergent) and a clean cloth. All moisture, if any shall be removed by heating using a gas burner or a hot air blower. Weld spatter, scale, sliver, lamination and surface defect which are not remove during blasting shall be edges smoothed or rendered flush or removed by grinding and re-blast. Any pipe which has been blasted but not primed and then wet by rain moisture shall be re-blasted. All moisture, if any shall be removed by heating using a gas burner or a hot air blower. Every pipe is blasted to meet Sa 2 standard by grit blasting, sand blasting or abrasive blasting. Blasting shall not be commenced when humidity is greater than 85% or surface temperature shall not less 3C above dew point, work in outside when it rain, any visible moisture is on the surface, the abrasive is wet, when painting is being done or coating is drying and curing in adjacent areas, and the lighting is poor and equipment is in improper working condition, at night. The finishing surface of blasting shall be Sa 2 or SSPC SP-10 It is compared to the pictorial standard. The roughness value shall be 30 - 80 microns as per ISO 8503-2. The roughness profile depth shall be checked using a calibrated Elcometer roughness gauge or Keane-Tator profile comparator.

Coating Application

Epoxy coating which is applied shall be use High Build Epoxy Coating or as per PO. Coating thickness as follows:

1st coat : minimum 50 microns with Zinc Rich Epoxy 2nd coat : minimum 200 microns with coal tar epoxy 3rd coat : minimum 200 microns with coal tar epoxy Total coating thickness is 450 microns

The pipe surface temperature shall always be minimum of 3C above dew point.

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 8 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

8 Inspection and Repair Coating

Inspection Procedure

Report the ambient condition (Humidity, Dew Point) before and any change of weather

condition during surface preparation.

Visual surface cleanliness shall be checked as per ISO 8501 and spot checks for dust level

as per ISO 8502-3.

The surface preparation and surface profile shall be evaluate and reported at the beginning

of each production shift.

DFT measurement shall be performed on every coat and reported. DFT shall be checked as per SSPC-PA2 Standard. Visual Inspection of finish every coat shall be performed and reported. Specified Nominal Coating Thickness is 450 micron. Adhesion test shall be conducted at first day application as per ASTM D4541

Repair of Coating

Degrease if necessary. Spot blast and clean the damage area back to with SA 2.5 and sweep blast the others if over

coating time has exceeded.

Feather back the adjacent coating to minimum 20 mm and firm edge by sanding disc. Clean and apply at least 2 touch up coats with appropriate epoxy coating.

Remarks:

Doc. No

042/KHI/MPS/EXC/VIII/2012 9 of 9 August 14, 2012 0

MANUFACTURING PROCEDURE SPECIFICATION [ M. P. S. ]

Page Date Revision

Section Title

9 Stock Yard

A. Pipe storage : The pipe shall be stored under which do not have any effect detrimentally to its performance characteristic. 1. Pipes with difference wall thickness shall be stacked at separate locations. 2. Storage area shall be well drained and free from any materials which may damage the pipe coating. 3. Pipes shall be stockpiled on a horizontal surface. They may be stockpiled in a pyramidal shape. Soft dunnage or rubber shall be used to support the bottom layer and to eliminate contact of the coated pipe with any metallic surface. 4. The pipes shall be stacked with maximum 2 tiers during storage.

B. Handling : Pipe shall be handled in a manner to prevent damage to pipe walls beveled ends and coatings. 1. Padding shall be provided when loading for transfer to any location. 2. Pipes shall be raised or lowered to or from stock pile, ground, barge or truck by end hooks inserted in the ends of the pipe and carried by a wire rope with spreader bar between the lines. As alternative for coated pipe, sufficient strength of nylon sling can also be used. 3. Pipes shall not be dropped 4. Pipes shall not be rolled on a surface that can damage the pipe. 5. Pipes shall be picked up clear of the ground on deck of the barge and moved bodily, and not dragged over the ground of the barge deck.

6. Pipe shall not be subjected to jars or impact.

Remarks:

You might also like

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- RC Vs Steel PiperackDocument4 pagesRC Vs Steel PiperacksinambeladavidNo ratings yet

- Control Building Users Guide EXDOC-XX19-en-110 PDFDocument756 pagesControl Building Users Guide EXDOC-XX19-en-110 PDFsinambeladavidNo ratings yet

- A Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeDocument3 pagesA Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeWang TianyangNo ratings yet

- Linear ProgrammingDocument76 pagesLinear ProgrammingHanna Grace Honrade0% (1)

- LINE 100 RFQ CV 004 - Requisition Steel Structure ErectionDocument97 pagesLINE 100 RFQ CV 004 - Requisition Steel Structure ErectionACHMAD.KAMALNo ratings yet

- RFI Chipping & PaddingDocument80 pagesRFI Chipping & Paddingcrys suryo prayogoNo ratings yet

- Master Document Register ListDocument10 pagesMaster Document Register ListcrysNo ratings yet

- INQUIRY SHEET ////////////: Hyosung CorporationDocument7 pagesINQUIRY SHEET ////////////: Hyosung CorporationervanjovanNo ratings yet

- GR5HRM-CIVIL-ITP-ENGLISH VersionDocument66 pagesGR5HRM-CIVIL-ITP-ENGLISH VersionGaneshNo ratings yet

- 3.1 Fabrication and Installation of PipingDocument45 pages3.1 Fabrication and Installation of PipingArie100% (1)

- Jms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2Document39 pagesJms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2amir hakimNo ratings yet

- Body of Requisition - ROW Work Package PDFDocument60 pagesBody of Requisition - ROW Work Package PDFmahandhieNo ratings yet

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDocument4 pagesA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- QC Documents & Procedures (20!6!2019)Document2 pagesQC Documents & Procedures (20!6!2019)Billy Kurniawan100% (1)

- Weldlok Steel GratingDocument16 pagesWeldlok Steel GratingDivyang241088No ratings yet

- Sakuti Method - Statement - For - HRSG - Works CrsherDocument32 pagesSakuti Method - Statement - For - HRSG - Works CrsherMIL RABNo ratings yet

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocument4 pagesMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNo ratings yet

- Erection Tank Settlement Check Schedule 103 110 165Document8 pagesErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- Work Method Bridge Sleeper Replacement - 2014Document8 pagesWork Method Bridge Sleeper Replacement - 2014Irham M AFNo ratings yet

- Project: Fuel Storage Tank 20.000KL With Facilty Loc.Document9 pagesProject: Fuel Storage Tank 20.000KL With Facilty Loc.basukiNo ratings yet

- Fabrication Method For HSM 2 ProjectDocument14 pagesFabrication Method For HSM 2 ProjectMikiRoniWijayaNo ratings yet

- GK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureDocument15 pagesGK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureElias EliasNo ratings yet

- Fabrication of Steel Structure and Steel Equipment (Itp)Document4 pagesFabrication of Steel Structure and Steel Equipment (Itp)Javed MANo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- GCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Document19 pagesGCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Dwiadi Cahyabudi100% (1)

- 6.9. Handling Storage & Preservation ProcedureDocument10 pages6.9. Handling Storage & Preservation Procedurerendra syamNo ratings yet

- General Work Method Statement.2Document26 pagesGeneral Work Method Statement.2Novita SariNo ratings yet

- Cy3 - Te MeteringDocument22 pagesCy3 - Te MeteringSilpa Asti Nura100% (1)

- Method Statement Steel Structure 1 4 MegDocument26 pagesMethod Statement Steel Structure 1 4 MegNick LawNo ratings yet

- ACID DOSING PUMP FOR UF CEB SKID (426-P-812AB) CIVIL ARRANGEMENT-Model PDFDocument1 pageACID DOSING PUMP FOR UF CEB SKID (426-P-812AB) CIVIL ARRANGEMENT-Model PDFJehangir MoosNo ratings yet

- Tank Lifting ProcedureDocument18 pagesTank Lifting ProcedureRicardo NapitupuluNo ratings yet

- 1 Civil Document Pertamina EpDocument13 pages1 Civil Document Pertamina EpDwiadi Cahyabudi100% (1)

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Lifting Lug CalculatorDocument5 pagesLifting Lug CalculatorJOHNNo ratings yet

- Besi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2Document4 pagesBesi Kotak Pipa Hollow Square Tubes Rectangular Beyond Steel 2didiNo ratings yet

- General Information G-0002: Description On Material JIS-ASTMDocument4 pagesGeneral Information G-0002: Description On Material JIS-ASTMEko Indra SaputraNo ratings yet

- 5-Mooring Buoy KEMENANGAN BrosurDocument2 pages5-Mooring Buoy KEMENANGAN Brosurdody andiNo ratings yet

- Field Joint Coating Installation ProcedureDocument2 pagesField Joint Coating Installation Procedureunix manNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- G05.4 - Civil WorksDocument107 pagesG05.4 - Civil WorksLandon Mitchell100% (1)

- Format MTODocument1 pageFormat MTOHermantoro PradanaNo ratings yet

- Summary Materials: Project Time of Issue Nien Made Project Factory 3-6Document11 pagesSummary Materials: Project Time of Issue Nien Made Project Factory 3-6thang TranNo ratings yet

- Itp Structural Steel Work Erection BlogDocument6 pagesItp Structural Steel Work Erection BlogIndwell RaigarhNo ratings yet

- 105-Structural Steel ErectionDocument7 pages105-Structural Steel Erectionzaki fadl100% (1)

- Standard PracticeDocument14 pagesStandard PracticeRomi Abdul RahmanNo ratings yet

- Specification For Fabrication and Erection ofDocument26 pagesSpecification For Fabrication and Erection ofEdgargarNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Training Schedule 2021 - SLVDocument4 pagesTraining Schedule 2021 - SLVFerdie OSNo ratings yet

- ITP Steel StructureDocument2 pagesITP Steel StructureEndy0% (1)

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - ADocument9 pagesENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- BRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Document10 pagesBRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Ponaryo AnggaraNo ratings yet

- Bailey Bridge ScheduleDocument4 pagesBailey Bridge ScheduleFernandoPintoMachacaNo ratings yet

- Presentasi Welding Prosedur Specification (WPS) Pre QualifiedDocument8 pagesPresentasi Welding Prosedur Specification (WPS) Pre QualifiedDeri Agung WicaksonoNo ratings yet

- Blasting Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting Coating Procedure For Fabricated Steel StructureSalman Alfarisi100% (1)

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Method Statement For APCS-113A (1) 22-6-2011Document7 pagesMethod Statement For APCS-113A (1) 22-6-2011sharif339No ratings yet

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- Working Procedure Ls1-Ls4Document9 pagesWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- HE Exchanger PilecapDocument14 pagesHE Exchanger PilecapsinambeladavidNo ratings yet

- STAAD Foundation%2Document10 pagesSTAAD Foundation%2sinambeladavidNo ratings yet

- Input Data: 2.1 Strength of An AnchorDocument3 pagesInput Data: 2.1 Strength of An Anchorsinambeladavid100% (1)

- Pile Stress Ratio CalculationDocument23 pagesPile Stress Ratio CalculationsinambeladavidNo ratings yet

- C Keyplan: South Sumatera NGL ProjectDocument5 pagesC Keyplan: South Sumatera NGL ProjectsinambeladavidNo ratings yet

- Excavation and Trenching ProcedureDocument12 pagesExcavation and Trenching Proceduresinambeladavid100% (1)

- PDA CheckDocument2 pagesPDA ChecksinambeladavidNo ratings yet

- Ul Certi (Promat)Document2 pagesUl Certi (Promat)sinambeladavidNo ratings yet

- New J100-MC-001 Piled FDN Existing Sewer For Site PreparationDocument1 pageNew J100-MC-001 Piled FDN Existing Sewer For Site PreparationsinambeladavidNo ratings yet

- Rfcc-c-qc-pr-002 Site Itp Procedure Rev 3Document114 pagesRfcc-c-qc-pr-002 Site Itp Procedure Rev 3sinambeladavid100% (3)

- HSE PlanDocument52 pagesHSE Plansinambeladavid100% (3)

- Rfcc-c-qc-pr-002 Site Itp Procedure Rev 3Document114 pagesRfcc-c-qc-pr-002 Site Itp Procedure Rev 3sinambeladavid100% (3)

- Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC ProjectDocument6 pagesCilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Project Cilacap RFCC Projectsinambeladavid100% (1)

- RFCC-T-GCPC-0024 Submit Result Bending Test Spun Pile Dia 500 and 600Document46 pagesRFCC-T-GCPC-0024 Submit Result Bending Test Spun Pile Dia 500 and 600sinambeladavidNo ratings yet

- Summary of PDA Test ResultDocument8 pagesSummary of PDA Test Resultsinambeladavid0% (1)

- RFCC-T-PCGC-0264 Requsition Fire Proofing Material (ISOLATEX)Document11 pagesRFCC-T-PCGC-0264 Requsition Fire Proofing Material (ISOLATEX)sinambeladavidNo ratings yet

- RFCC-T-PCGC-0265 Requsition Fire Proofing Material (PROMAT)Document98 pagesRFCC-T-PCGC-0265 Requsition Fire Proofing Material (PROMAT)sinambeladavid100% (1)

- Yokogawa Universal IODocument6 pagesYokogawa Universal IOsinambeladavidNo ratings yet

- Name For Correspondence From PMI:: David Sinambela 62 821 75884403Document2 pagesName For Correspondence From PMI:: David Sinambela 62 821 75884403sinambeladavidNo ratings yet

- 1 Motor Protection Single SessionDocument27 pages1 Motor Protection Single Sessionmubarakkirko100% (1)

- Annual Report 2013Document48 pagesAnnual Report 2013Shankar DasNo ratings yet

- Faster Planes and Cheaper Flights: B. It Can Be Destroyed by Too Many VisitorsDocument6 pagesFaster Planes and Cheaper Flights: B. It Can Be Destroyed by Too Many VisitorsGermainNo ratings yet

- Astronomic TarotDocument17 pagesAstronomic TarotNancy ZecchelNo ratings yet

- FIFA Video Game - Players ClassificationDocument26 pagesFIFA Video Game - Players Classificationimmi1989No ratings yet

- IT Checklist For Successful Mergers and Acquisitions PDFDocument8 pagesIT Checklist For Successful Mergers and Acquisitions PDFAli AlwesabiNo ratings yet

- Early Childhood and Children's Rights: A Critical PerspectiveDocument21 pagesEarly Childhood and Children's Rights: A Critical PerspectiveOyibokure OlufunmilolaNo ratings yet

- Lect 3c The Lean EnterpriseDocument52 pagesLect 3c The Lean EnterpriseAvantika SarafNo ratings yet

- Declamation ScriptDocument1 pageDeclamation Scriptglaide lojeroNo ratings yet

- Engineers Weekly Report InstructionsDocument4 pagesEngineers Weekly Report InstructionsashifNo ratings yet

- Yellow GroupDocument14 pagesYellow Groupavxenogenesis03No ratings yet

- Uml Lecture PDFDocument4 pagesUml Lecture PDFMuhammad MoizNo ratings yet

- SANSUI Hdlcd1955 enDocument25 pagesSANSUI Hdlcd1955 enMelanie HoodNo ratings yet

- Ethics and Organisational CultureDocument2 pagesEthics and Organisational CultureSonika MishraNo ratings yet

- Manajemen OperasiDocument37 pagesManajemen OperasiHELWAH AMINAH ACHMADNo ratings yet

- Alana Robertson PDFDocument7 pagesAlana Robertson PDFKshitij SinghNo ratings yet

- How To Implement ABAP Kernel UpdateDocument4 pagesHow To Implement ABAP Kernel Updateabhisona76No ratings yet

- TemarioDocument4 pagesTemarioLina GordilloNo ratings yet

- CJ Relays (Acj) : Features Typical ApplicationsDocument7 pagesCJ Relays (Acj) : Features Typical ApplicationsFranciscoMedinaNo ratings yet

- WW2 Military Bldgs PDFDocument102 pagesWW2 Military Bldgs PDFone-eyed fat manNo ratings yet

- "Flexible Manufacturing System": Department of Mechanical EngineeringDocument32 pages"Flexible Manufacturing System": Department of Mechanical EngineeringGoutham ReddyNo ratings yet

- General SpecificationsDocument6 pagesGeneral SpecificationsMaire Joy E. AzañaNo ratings yet

- Impact of Chronic Illness On ChildrenDocument6 pagesImpact of Chronic Illness On ChildrenDeepa ThomasNo ratings yet

- Health8 - q1 - Mod5 - Family Health Comes First - FINAL07282020Document21 pagesHealth8 - q1 - Mod5 - Family Health Comes First - FINAL07282020Rose Marie NaboNo ratings yet

- ICDL Module 6 PresentationDocument40 pagesICDL Module 6 PresentationcaphilNo ratings yet

- VUMAT For Fabric Reinforced Composites: Figure 1: Schematic Representation of WovenDocument10 pagesVUMAT For Fabric Reinforced Composites: Figure 1: Schematic Representation of Wovenjunjie yiNo ratings yet

- Modular ExponentiationDocument2 pagesModular ExponentiationflaksherNo ratings yet

- Kinematics: Distance Vs DisplacementDocument7 pagesKinematics: Distance Vs DisplacementTorettoNo ratings yet