Professional Documents

Culture Documents

DtEC Reactor Internals Brochure 170709 PDF

DtEC Reactor Internals Brochure 170709 PDF

Uploaded by

Aadam AryanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DtEC Reactor Internals Brochure 170709 PDF

DtEC Reactor Internals Brochure 170709 PDF

Uploaded by

Aadam AryanCopyright:

Available Formats

Distillation Equipment Company Ltd

The Boat Yard, Newcastle Road, Stone, Staffordshire, ST15 8JZ, United Kingdom

REACTOR INTERNALS

product

bulletin

Distillation Equipment Company Ltd

At DtEC we consider our business to be the insides of columns . This includes the design, manufacture, supply and installation of a full range of internals for reactors and Mechanical Design molecular sieve or activated carbon/alumina vessels.

Down Flow Reactors

Down Flow reactors are typically used in hydrocracking, hydrotreating and isomerization processes. A typical two bed reactor will have the following internals: Inlet Feed Diffuser Scale Catching Tray / Baskets Vapour - Liquid Distributor Tray Catalyst Support Grid Quench Distributor Pipe Remixing Assembly Vapour - Liquid Distributor Tray Outlet Collector (Basket) The internals for these reactors normally utilise licensed or proprietary know-how. At DtEC we have considerable experience in manufacturing reactor internals according to the stringent specifications of the major Process Licensors. Alternatively where required we can offer reactor internals to our own in-house design

A key aspect with reactor internals is the mechanical design. The loads for these types of internals are many times more than the loads for packed tower internals used in distillation and absorption columns. Hence detailed consideration needs to be given to the mechanical design. DtEC provides a full mechanical designs service including where necessary Finite Element Analysis.

Inlet Feed Diffusers

An inlet feed diffuser is used to distribute the incoming vapour and liquid onto a distributor tray underneath.

Finite Element Analysis Catalyst Support Grid - Reactor Diameter 1830mm

Catalyst Support Grids

For catalyst beds DtEC provides 3 types of support grids: Lattice Bar + Perforated Screen Type Lattice Bar + Mesh Screen Type Wedge Wire Type Catalyst Support Grid - Model 162 Wedge Wire Type

Inlet Feed Diffuser Nozzle 12nb HDS Reactor 2300mm

With the lattice type grids, for a given mechanical design load (including pressure drop) bars of an appropriate height and thickness on the required pitch are used. Typical grid height is 100 to 150mm. The perforation hole diameter and/or mesh size are selected taking into account the catalyst particle size. The wedge wire grids are constructed from screen made from a series of parallel V profile wire welded to perpendicular support rods or bars.

Scale Catching Trays / Baskets Scale catching trays or baskets are used to prevent fouling material entering the catalyst bed. The scale baskets can be either mesh type or wedge wire type and are usually held in a frame or tied together with chains. Scale Basket

Wedge Wire Type

Catalyst Support Grid - Model 160 Lattice Bar + Perforated Screen Type

REACTOR INTERNALS

product

bulletin

Distributor Trays

Distributor trays for reactors fall into 3 types: Sieve Type Bubble Cap Type Distribution Tube Type The most prominent is the distribution tube type with each Process Licensor having their own distinct features. The trays are designed for two phase co-current flow and ensure good vapour and liquid distribution so that the entire bed of catalyst is used effectively.

Leak Test + Trial Assembly of Collector Tray & Distributor Tray MDH Reactor - Diameter 4850mm MOC - 321 SS Vapour - Liquid Distributor Tray Diolefin Saturator Reactor 3200mm MOC - 304L SS

Remixing + Quench Assemblies

A remixing + quench assembly is used between the catalyst beds to ensure efficient heat and mass transfer between the cold quench gas and the vapour + liquid effluent from the upper catalyst bed. This results in efficient heat and mass transfer with uniform composition and an even temperature profile in the bottom (lower) catalyst bed.

Vapour - Liquid Distributor Tray Distribution Tube Type

Outlet Collectors (Baskets)

An outlet collector (basket) ensures even flow distribution in the bottom bed to achieve optimum catalyst utilisation and prevents escape of the catalyst. The collectors can be wedge wire type or perforated type c/w mesh screen.

Remixing + Quench Assembly c/w Major Beams HDS Reactor - Diameter 5400mm MOC - 321 SS

Outlet Collector (Basket) Wedge Wire Type

REACTOR INTERNALS

product

bulletin

Molecular Sieve Vessels

The internals for a molecular sieve vessel are very similar to a downflow reactor. A typical arrangement is shown below.

Inlet & Outlet Baffle Baskets

DtEC provides 3 types of inlet & outlet baffle baskets: Slotted - Plain Type Slotted + Mesh Type Wedge Wire Type

Floating Mesh Screens

Floating mesh screens are used as an effective and economic divider between the different media layers. The screen is usually made of overlapping segments tied together inside the vessel using tie wire. The segments are cut oversize relative to the vessel diameter to ensure sealing at the periphery.

Molecular Sieve Support Grids

The DtEC range of designs for molecular sieve support grids is the same as for catalyst beds in reactors: Lattice Bar + Perforated Screen Type Lattice Bar + Mesh Screen Type Wedge Wire Type

Molecular Sieve Support Grid - Model 161 Gas Dehydration Vessel - Diameter 2600mm MOC - Carbon Steel

Distillation Equipment Company Ltd

The Boat Yard, Newcastle Road, Stone, Staffordshire, ST15 8JZ, United Kingdom Tel: Fax: Email: Web: 0044 1785 602810 0044 1785 602811 sales@traysRus.com www.traysRus.com

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Equipment DetailsDocument33 pagesEquipment DetailsSaif Siddiqui100% (1)

- Underground Piping PDFDocument40 pagesUnderground Piping PDFAngelita Qtal100% (2)

- EEC Cat PDFDocument28 pagesEEC Cat PDFNermeen ElmelegaeNo ratings yet

- SX Mixer-Settler DesignDocument10 pagesSX Mixer-Settler Designmario_acevedoNo ratings yet

- Assignment 9 SolutionDocument6 pagesAssignment 9 SolutionBruce Matthew Fock-yat100% (1)

- (Very Short Introductions) Peter Atkins - Physical Chemistry - A Very Short Introduction-Oxford University Press (2014) PDFDocument149 pages(Very Short Introductions) Peter Atkins - Physical Chemistry - A Very Short Introduction-Oxford University Press (2014) PDFYogi Yogesh100% (2)

- Bubble Cap FucntionDocument4 pagesBubble Cap FucntionPujo PurwantoNo ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- Scraper TrapDocument6 pagesScraper TrapMayur PatelNo ratings yet

- Vessels Internals 2008 05 TFMDocument20 pagesVessels Internals 2008 05 TFMjannick86100% (1)

- TECOtubeexpanders BROCHUREDocument56 pagesTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESANo ratings yet

- Gas/Liquid Separation Technology: Sulzer ChemtechDocument24 pagesGas/Liquid Separation Technology: Sulzer ChemtechneversigNo ratings yet

- Refining Topsoe Reactor InternalsDocument8 pagesRefining Topsoe Reactor InternalsGopiNo ratings yet

- Hydrophore Set (Mectron Engineering)Document2 pagesHydrophore Set (Mectron Engineering)KelvinNo ratings yet

- Underground Fuel TanksDocument24 pagesUnderground Fuel TanksAlupole_AlbertLim100% (2)

- Fractional TraysDocument4 pagesFractional TraysNagwa MansyNo ratings yet

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologypentianNo ratings yet

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyLuevandresNo ratings yet

- AMACS Tray BrochureDocument4 pagesAMACS Tray BrochureahmadNo ratings yet

- Lost Foam Foundry SystemDocument28 pagesLost Foam Foundry SystemDeepak Khanna100% (1)

- Demister DistributerDocument10 pagesDemister DistributercavnqnNo ratings yet

- 300 - Tower Tray Bulletin - Eng PDFDocument28 pages300 - Tower Tray Bulletin - Eng PDFKamil MarszałekNo ratings yet

- Packed Tower Internals PDFDocument32 pagesPacked Tower Internals PDFmehul10941No ratings yet

- Gas Liquid Separation Technology SulzerDocument24 pagesGas Liquid Separation Technology SulzerCH1253100% (1)

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyCuong TranHungNo ratings yet

- Inune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Document30 pagesInune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Process EngineerNo ratings yet

- Dryplus EvaporatorDocument24 pagesDryplus EvaporatorsreekanthchemiNo ratings yet

- Completions Accessories BRDocument8 pagesCompletions Accessories BRfarotimitundeNo ratings yet

- Product Guide: "Container and Material Handling Solutions For Every Industry"Document16 pagesProduct Guide: "Container and Material Handling Solutions For Every Industry"nikkih1244No ratings yet

- Pintu KlepDocument12 pagesPintu KlepAndri KwinNo ratings yet

- ASCO Miniature Valve Products (AV017R5)Document96 pagesASCO Miniature Valve Products (AV017R5)vasudeva yasasNo ratings yet

- ControTrace Benefits SummaryDocument2 pagesControTrace Benefits SummaryYoung-seok Hwang100% (1)

- Tranter Platecoil ApplicationsDocument12 pagesTranter Platecoil ApplicationsShafqat AfridiNo ratings yet

- Vacuum CollectionDocument4 pagesVacuum CollectionLoganBohannonNo ratings yet

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- BB VerticalTrayDeaerator Jan11Document16 pagesBB VerticalTrayDeaerator Jan11GHEZELASHEGHINo ratings yet

- SFP Catalog 3 Fabric Exp JointsDocument32 pagesSFP Catalog 3 Fabric Exp JointsJosé MoránNo ratings yet

- Tubular Drag ConveyorsDocument8 pagesTubular Drag ConveyorsLuiz CostaNo ratings yet

- CSI Bolt-On Heating SystemsDocument12 pagesCSI Bolt-On Heating Systemspeubrandao100% (1)

- Wellhead Brochure - DP PDFDocument12 pagesWellhead Brochure - DP PDFmaso0140100% (1)

- Large-Tank Heating SystemsDocument4 pagesLarge-Tank Heating Systemsmayukhguha88No ratings yet

- H56886 TB Design 0807Document12 pagesH56886 TB Design 0807algotrNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet

- Catálogo HP Hoses - enDocument28 pagesCatálogo HP Hoses - enJavier Alfonso FernandezNo ratings yet

- Ground Steel Crude Oil Storage Tank Location and FoundationDocument20 pagesGround Steel Crude Oil Storage Tank Location and Foundationliz aldanaNo ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Wedge Wire ScreensDocument6 pagesWedge Wire Screenscumpio425428No ratings yet

- Distillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFDocument22 pagesDistillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFmehul10941100% (1)

- BAFFLESDocument9 pagesBAFFLESSalma ChakirNo ratings yet

- Specification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byDocument14 pagesSpecification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- Triton XR-70 HZP R2 FinalDocument16 pagesTriton XR-70 HZP R2 FinalErcan YilmazNo ratings yet

- Koch GlitschDocument36 pagesKoch Glitschdeepanagha100% (1)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Thermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilDocument4 pagesThermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilIoana StanciuNo ratings yet

- First Page PDFDocument2 pagesFirst Page PDFkmkmNo ratings yet

- Carbohydrate MetabolismDocument8 pagesCarbohydrate MetabolismChhan Kumar kalitaNo ratings yet

- Grade 07 Science 1st Term Test Paper 2018 English Medium Western ProvinceDocument6 pagesGrade 07 Science 1st Term Test Paper 2018 English Medium Western ProvinceFawzar Sabir75% (4)

- Laporan Anorganik Modul 7Document10 pagesLaporan Anorganik Modul 7Romario AbdullahNo ratings yet

- Gas-Liquid Mass Transfer Coefficient in Stirred Tanks InterpretedDocument8 pagesGas-Liquid Mass Transfer Coefficient in Stirred Tanks Interpretedlili100No ratings yet

- Compression Test On Cast IronDocument11 pagesCompression Test On Cast IronEvan BoaloyNo ratings yet

- v76 477 PDFDocument6 pagesv76 477 PDFmanikandan aNo ratings yet

- Grade 6 - Separating Mixtures Through Handpicking, Sieving, WinnowingDocument11 pagesGrade 6 - Separating Mixtures Through Handpicking, Sieving, Winnowingsimeon tayawaNo ratings yet

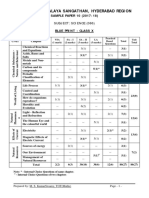

- Kendriya Vidyalaya Sangathan, Hyderabad Region: Subject: ScienceDocument5 pagesKendriya Vidyalaya Sangathan, Hyderabad Region: Subject: Sciencehweta173No ratings yet

- Liquid-Liquid ExtractionDocument5 pagesLiquid-Liquid ExtractionFahad ShakeelNo ratings yet

- AP Chem Syllabus 2021-2022Document2 pagesAP Chem Syllabus 2021-2022Urvi MohanNo ratings yet

- Revised Nata de CocoDocument7 pagesRevised Nata de CocoMae BernadetteNo ratings yet

- Lab 7 Paper ChromatographyDocument7 pagesLab 7 Paper ChromatographyAhmadNo ratings yet

- Physical Science - M1 - M5.1Document2 pagesPhysical Science - M1 - M5.1Janna PleteNo ratings yet

- Stainless Steel Pipes - Dimensions and Weights ANSI - ASME 36Document2 pagesStainless Steel Pipes - Dimensions and Weights ANSI - ASME 36Abhijit DekaNo ratings yet

- CASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDocument2 pagesCASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDijin MaroliNo ratings yet

- Glycerol Propylene. Reaction Scheme: EpichlorohydrinDocument3 pagesGlycerol Propylene. Reaction Scheme: EpichlorohydrinMUHAMMED BAQA ANWER100% (1)

- Electro Dialysis Demineralization of Whey: Water Technologies & SolutionsDocument2 pagesElectro Dialysis Demineralization of Whey: Water Technologies & SolutionsMirza SalkićNo ratings yet

- DLL Science 10 Jan. 20, 2020Document4 pagesDLL Science 10 Jan. 20, 2020ARVIN VILLANTINONo ratings yet

- Optical SourcesDocument33 pagesOptical SourcesAmit VermaNo ratings yet

- S5MT Ia B 1.1 - USEFULANDHARMFULMATERIALSDocument5 pagesS5MT Ia B 1.1 - USEFULANDHARMFULMATERIALSMa Marisa Arbalate100% (1)

- Daphne Magplus AM 30: Lubricant Product InformationDocument2 pagesDaphne Magplus AM 30: Lubricant Product InformationDewi Lanjarsari Purnama SastriNo ratings yet

- School of Engineering Department of Mechanical EngineeringDocument15 pagesSchool of Engineering Department of Mechanical EngineeringMohammed KawashNo ratings yet

- Sch4uc Unit 1 Lesson 01 PDFDocument36 pagesSch4uc Unit 1 Lesson 01 PDFEmeka ChukwuNo ratings yet

- ME 8792 PPE Unit - 1Document142 pagesME 8792 PPE Unit - 1UdamanNo ratings yet

- Composite MaterialsDocument399 pagesComposite MaterialsCharlton S.Inao100% (1)

- Energetic Materials - Physics and Chemistry of The Inorganic AzidesDocument8 pagesEnergetic Materials - Physics and Chemistry of The Inorganic AzidesangelofgloryNo ratings yet