Professional Documents

Culture Documents

Axial Transport and Residence Time of MSW in Rotary Kilns

Axial Transport and Residence Time of MSW in Rotary Kilns

Uploaded by

jimmy_burgos_11Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axial Transport and Residence Time of MSW in Rotary Kilns

Axial Transport and Residence Time of MSW in Rotary Kilns

Uploaded by

jimmy_burgos_11Copyright:

Available Formats

Powder Technology 126 (2002) 217 227 www.elsevier.

com/locate/powtec

Axial transport and residence time of MSW in rotary kilns Part I. Experimental

S.-Q. Li a,b,*, J.-H. Yan a, R.-D. Li a, Y. Chi a, K.-F. Cen a

a b

Department of Energy Engineering, Zhejiang University, Hangzhou 310027, PR China Department of Thermal Engineering, Tshinghua University, Beijing, 100084, PR China

Received 17 October 2000; received in revised form 28 December 2001; accepted 31 December 2001

Abstract Experiments on the influences of operational variables on the axial transport of both heterogeneous municipal solid waste (MSW) and homogenous sand are conducted in a continuous lab-scale rotary kiln cold simulator. Compared with sand, the residence time of MSW has a relatively large discrepancy with the ideal normal distribution due to the trajectory segregation of MSW components. The residence time at different axial zone is quite different due to the varied bed depth profile along the kiln length. MSW has a longer mean residence time (MRT) and a lower material volumetric flow (MVF) than sand because of the higher hd than sand. The increment of both rotating speed and kiln slope reduces MRT, and increases MVF. Exit dam has a significant impact on the MRT and the influence of internal structure group consisting of various axial ribs and circular ribs is mainly determined by the height of circular ribs. Inside wall roughness also has effect on MRT through changing the bed regimes. For a case with the certain inlet and exit bed depths, the product of MRT and MVF holds at a constant within the limits of experimental errors in spite of the changing experimental variables. D 2002 Published by Elsevier Science B.V.

Keywords: Rotary kiln; MSW; Axial transport; Mean residence time; Material volumetric flow

1. Introduction Rotary kilns have been widely employed in chemical and metallurgical industries as heterogeneous noncatalytic gas solid reactors. The typical applications include drying or heating of wet solids, mixing or grinding of powders, calcining of limestone, clinkering of cementitious materials, reducing of iron ore or ilmenite, etc. [1 3]. Rotary kilns continue to find new applications in such gas solid reactions, despite challenges from newer and more specialized reactors such as fluidized bed and spouted bed. In recent years, rotary kilns have played an important role in the thermochemical treatment of municipal solid wastes (MSW). Rotary kiln system is one of the most promising incineration processes since it can simultaneously treat wastes as liquids or solids of various shapes and sizes and easily achieve the flexible adjustment by altering kiln inclination, rotational speed, etc. Rotary kiln as a primary gasification chamber, followed by a secondary combustion chamber, can fulfil the complete destruc*

Corresponding author. Tel.: +86-10-62782108. E-mail address: lishuiqing@hotmail.com (S.-Q. Li).

tion and detoxification of hazardous wastes, meanwhile minimize emissions of dioxins and heavy mental. All these unique features enable rotary kiln irreplaceable in MSW incineration. Siemens Schwelbrenn, Noell Conversion and Westinghouse OConnor processes are updated representatives of rotary kiln incinerators [4,5]. Pyrolysis, on the other hand, is an attractive alternative to incineration as a waste treatment option with respect to minimum environmental emissions and maximum resource recovery [6,7]. Rotary kiln pyrolyser also has many unique advantages over other types of reactors. For instance, slow rotation of inclined kiln enables the well mixing of wastes, thereby the more uniform pyrolytic products. Also, the flexible adjustment of residence time can make pyrolysis reaction perform at a perfectly optimum condition conveniently. With a view to different resource recovery option, rotary kiln can be properly designed to yield mainly the synthesis gas, e.g., Landgard Process [8], or to make the high calorific tars as well as porous carbon black, e.g., Kobe Steel Process [9]. Mean residence time (MRT) of solids through rotary kiln is one of the most important parameters, which not only directly influences mass and heat transfer, but also deter-

0032-5910/02/$ - see front matter D 2002 Published by Elsevier Science B.V. PII: S 0 0 3 2 - 5 9 1 0 ( 0 2 ) 0 0 0 1 4 - 1

218

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

mines chemical reaction degree of gas and solid phase. In order to optimize the design and operation of rotary kiln, it is necessary to develop the simplified empirical expressions to enable the proper predicting of the volumetric flow of material (MVF) as well as MRT. Sullivan et al. [10] originally conducted the experimental research on the solids MRT in rotary cylindrical kiln and derived the empirical equation of MRT correlating various operational variables, kiln geometry parameters and material properties. Subse` hl and Kingma [11] and Kramers and Kroockquently, Va ewit [12] made further experiments on the holdup as well as MRT in a horizontal or inclined cylinder, respectively. The effect of internal structures is one of remarkable research community. Chatterjee et al. [13] studied the effect of ring formation, Matchett and Sheikh [14] studied the effect of both number and angle of axial flight, and Rutgers [15] considered the influences of shapes of kiln entrance and exit end faces. Furthermore, the residence time distribution (RTD) in rotary drums were researched by Abouzeid and Fuerstenau [16] and Sai et al. [17] adopting tracer stimulusresponse techniques, or by Wes et al. [18] using atomic absorption spectroscopy methods. In addition, as the practical field-scale rotary kiln was concerned, Groen et al. [19] performed corresponding investigations in a high-temperature kiln, while Schofield and Glikin [20] studied them in an intensive gas-flow fleeting kiln. More recently, Wightman and Muzzio [21] emphasized that a research community focusing on the segregation of multimixed particles in rotary cylinder. Donald and Rosseman [22] firstly performed experimental studies in a horizontal system and identified three patterns of segregation: radial, axial and end longitudinal. Gupta et al. [23] described qualitative mechanisms of axial segregation, stating that a difference in the dynamic reposing angles of two pure components is a necessary (though not sufficient) condition of band formation. Nakagawa et al. [24] recently employed magnetic resonance imaging to study axial segregation. Boateng and Barr [25] and Bridgewater et al. [26] studied the mechanism of radial segregation, respectively. However, previous researches on axial transport in rotary kilns are mostly concentrated on the studies of small

cementitious and metallurgical particles, which are relatively homogeneous in nature. Although rotary kilns have been extensively used as reactors for MSW incineration or pyrolysis, so far, there have been few attempts on extrapolating the experiences and correlation developed from homogeneous materials to heterogeneous MSW. In this part, comparative studies are conducted between homogeneous sand and irregular MSW in a rotary kiln cold simulator (I.D. 0.3 1.8 m). Impacts of material characteristics (in terms of the dynamical angle of repose), kiln geometry characteristics (i.e., roughness of kiln wall, exitend dam and internal structures) and operational parameters (i.e., kiln inclination and rotational speed) on both MRT and MVF are examined. Simplified formulas of MRT and MVF are proposed on the basis of the experiment results in Part II of this work.

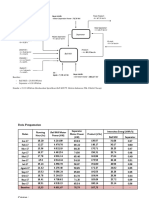

2. Experimental 2.1. Setup A cold simulator of rotary kiln, 0.3 mm in diameter and 1.8 mm in length, shown schematically in Fig. 1, was employed for the experiments. The cylinder was made of plexiglass so that the solid motion can be viewed. The rotational speed is variable within the range of 0.5 10 rpm (revolution per minute). The angle of kiln inclination can be easily adjusted between 0j and 5j by altering the height of the supporter at kiln inlet end. The feed rate of materials was adjusted to a certain amount that keeps the inlet depth of the solids on a desired value during each run. That is, the inlet depth of solid bed responds to the feed rate of materials, which is practically equal to the flow rate of materials under the steady state, one to one, under the same operational conditions. Therefore, the inlet bed depth instead of material feed rate were selected as one of the operating parameters, which was kept at 70 mm in all runs. In order to study the impact of internal structures on solid material motion, axial ribs and circular ribs were specially designed, as shown in Fig. 2. The grouped types and

Fig. 1. Schematic of rotary kiln cold simulator ((1) Funnel, (2) Belt conveyor, (3) Tracer addition point, (4) Feed chute, (5) Rotary cylinder, (6) Position plate, (7) Belt wheel, (8) Position wheel, (9) Jockey wheel, (10) Slope angle adjustor, (11) Supportor, (12) Varible motor, (13) Exit chute, (14) Sample collector).

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

219

geometric factors of the different kinds of axial ribs and circular ribs are listed in Table 1. 2.2. Materials Two categories of materials were employed for experiments. One was reconstituted MSW consisting of 49.9 wt.% wood chips, 17.0 wt.% paper plates and 33.1 wt.% waste tyres. The mixture has irregular shape, size and heterogeneous property. Also, homogeneous sand was used as another category for a contrast, which has higher density, regular shape and similar size. The physical properties of both kinds of materials are given in Table 2. As was reported in earlier literatures [11 20], the bulk characteristics of solids in terms of the dynamic angle of repose, hd, exert significant influences on the transport and mixing of the solids in the kiln. Here hd is measured according to the Rotating Drum-Method (Henein et al. [27]). This measurement is done under one of the most general bed rotation cases of the kiln, rolling regime, and it can reflect the real dynamical bulk characteristics of solids in kiln. For all hd measuring of various materials, the kiln rotates at 4 rpm and fill ratio of solids in the kiln is about 15% 20%. hd of sand is about 29.7j while that of MSW mixture is 48.5j. In order to study the influence of wall roughness on MRT and MVF, the inside kiln wall are covered by the finer or coarser emery cloths. The wall friction factor of solids is defined as the tangent function of the wall friction angle. The latter is measured by a special shear-plateanalyzer with an easy adjusting shear angle. A plate, which has the same roughness with the tested wall, is fixed on the adjustable shear plate. A layer of tested solids is laid on the plate. Then, the plate is gradually tilted until the solids begin to fall along it. At that time, the slope of the plate with respect to the horizontal line is just the wall friction angle of solids. As shown in Table 2, compared to the smooth inside wall, the friction coefficient, f, increased dramatically (69 243%) with finer emery cloth setting. However, f increased only about 6 25% from the finer emery cloth to the coarser one.

Table 1 The grouped types and geometric factors of internal structures Group No. Axial ribs Number Exit dam 1 Exit dam 2 12b-4n 12b-7n 12n-4n 12b-4b 12 12 12 12 Height (mm) 20 20 10 20 Circular ribs Number 1 1 4 7 4 4 Height (mm) 30 50 30 30 30 50

2.3. Experimental methods To determine MRT and MVF, the system must be adjusted to achieve the steady state, which is reached when the output of materials is equal to the feed rate of materials. The steady-state flow rate of materials, volumetric or molar, was measured by collecting sample successively within a certain time and quantifying it. As is widely known, the residence time of solids through rotary kiln is not a constant, but a probability distribution. Hence, the mean and variance of residence time are experimentally obtained by the stimulus-response techniques of tracers. Generally, the method for RTD measurement of MSW is hardly available in current literatures, though that of homogeneous sand has been described in detail [16 18]. In this work, experiments were taken by introducing the dyed tracers consisting of 9 wood chips, 15 paper plates and 36 waste tyres. The ratios of three kinds of tracers are 47.9, 16.9 and 35.2 wt.%, which are quite similar to those of original mixed wastes (i.e., 49.9 wt.% wood chips, 17.0 wt.% papers and 33.1 wt.% tyres). In fact, it is difficult to feed all tracers to kiln inlet end at the same time. Also, it is infeasible to label every tracer and measure its time one by one in such a short time interval. Thus, all tracers are divided into three groups and dyed red, white and yellow (each of which consists of 3 wood chips, 5 papers and 12 tyres). As the steady state is reached, three groups of tracers are successively fed to the kiln inlet and the corresponding inlet time for each group is recorded. At the kiln outlet, they were collected after a certain time interval, until all tracers finished their excursion through the kiln. Meanwhile, the residence time of tracers in each sample interval was recorded (here, the inlet-time differences of three group were taken into account). The mean and variance of residence time of the tracers are expressed below: MRTc

I X i1 I X ti MRT2 EDti ; i1

ti E Dti ;

Fig. 2. Schematic of internal structures ((1) Cylinder, (2) Circular ribs, (3) Longitudinal ribs).

r 2c

220

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

Table 2 Summary of properties, bulk characteristic and wall friction factors of materials Materials Wood chips Paper plates Waste tyre Mixed MSW * Sand Shapes Cylindrical Tabulate Arcuate Nodular Bulk density (kg/m3) 371.5 104.5 278.7 225 1342 True density (kg/m3) 646.0 691.7 1020.0 777.6 2660 Sizes (mm) U25 30 30 30 3 10 5 30 1.0 2.0 hd (j) 47.3 51.9 52.9 48.5 29.7 f1 0.525 0.563 0.421 0.480 0.407 f2 0.902 1.930 0.941 1.003 0.724 f3 * * 0.941 2.331 1.102 1.251 0.768

* Mixed MSW consist 49.9 wt.% woods, 17.0 wt.% papers and 33.1 wt.% tyres. ** f1, f2, f3 are wall friction factor of solids with none, finer and coarser emery cloth setting on inside wall.

where I is the sequence of sampling interval, Dti is the interval of the ist sampling interval, and ti is the retention time of tracers in the ist interval. E(Dti) can be expressed as the ratio of the number of tracers in ist sampling interval to that of the total tracers, i.e.: E Dti N Dti =

I X i1

N Dti :

Usually, the relative variance is used to express the dispersing extent of RTDs, which satisfies the relation: rr2 r 2 =MRT2 : 4

3. Results and discussions Table 3 summarizes the detailed experimental results for MRT (together with r and rr) and MVF of the MSW in rotary kiln simulator with various rotating speeds, kiln slopes, exit-end dams, internal structures and walls of different roughness. In the following sections, the effect of each variable both on MRT and MVF will be discussed accordingly. 3.1. Residence time distribution of MSW and sand The previous studies on residence time of solids in rotary kiln are scarcely concentrated on the heterogeneous MSW, but on the homogeneous particles instead. For instance, Abouzeid and Fuerstenau [16] concluded that residence time of dolomites in rotary kiln is approximately subjected to a normal distribution by employing the axial dispersion model. The comparison between experimental results and theoretical calculation for RTD of both sand and MSW are shown in Figs. 3 and 4, respectively. As for sand, the probability of tracers by experiment in each sample interval (Dti) fits well with the theoretical normal distribution function. However, it is noted that, for MSW, there exists a relatively large discrepancy between experimental value and theoretical curve, other than rr2 of MSW is much larger than that of sand under the same

condition. It can be explained that, as tracers consist of three components with various shapes, sizes and densities, the variance in residence time would arise from axial segregation instead of axial mixing (particle collision). In fact, the axial segregation causes the deviation of measured RTD from the normal distribution (this view will be further verified in Part II of this work). In addition, the alternate band formation of the various components (i.e., the visible axial segregation) that has been studied and emphasized in a batch kiln system by some investigators [21 24] does not occur in this experiment. According to Donald and Rosseman [22], the alternate band formation in batch system may not arise in continuous system where the length of system is not adequate for particles to demix. Gupta et al. [23] stated that a difference in hd of all pure components at a particular rotation speed is one of the necessary (though not sufficient) conditions of band formation. From Table 2, the hd difference among three components of MSW is not significant. The rotating speed is only an order of magnitude smaller than that in the study of Gupta et al. Thus, it is induced that the axial segregation of MSW in kiln wont be violent enough to form alternate bands, especially for such a system with a limited ratio of length to diameter (L/D = 6). The detailed r and rr of RTD of MSW under various rotating speeds, kiln slopes, exit-end dams, internal structures and wall roughness are given in Table 3. Much valuable information can be obtained as follows. (1) Increasing rotating speed or kiln slope leads to relatively slight increment of r, while rr varies or keeps in a narrow range from 0.02 to 0.05. (2) The usage of exit dam can also increases r or rr; but the impact on variance is less appreciable than that on MRT. (3) Employment of internal structures promotes both r and rr remarkably by one order of magnitude (e.g., rr from range [0.02, 0.05] to range [0.2, 0.4]). However, it must be stated that the measuring error of RTDs r and rr is quite high due to the segregation of MSW properties. Meanwhile, the measuring precision of both MRT and MVF can doubtlessly reach an expected level because of their statistical averaged characteristics. Therefore, more attention is paid to discussions on MRT/MVF rather than r/rr in the following paper.

S.-Q. Li et al. / Powder Technology 126 (2002) 217227 Table 3 Overall experimental data for MRT and MVF of MSW with different variables Run number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 Internal structure Smooth wall Rotated rate (rpm) 2 3 4 4 4 6 8 3 4 4 4 6 8 3 4 4 4 6 8 3 4 4 8 4 2 3 4 4 4 2 3 4 4 4 2 3 4 4 4 2 3 4 4 4 Inclination (j) 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 2.40 1.81 2.40 2.40 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 1.81 0.62 2.40 2.40 2.40 1.81 0.62 MRT (min) 11.53 8.25 5.58 7.05 11.28 4.07 3.27 10.98 8.87 8.78 16.80 6.20 4.20 11.83 8.40 9.47 12.30 6.15 4.95 13.15 9.93 12.27 5.92 14.80 19.67 13.90 9.75 12.67 24.67 16.95 15.90 11.62 15.12 21.67 19.67 12.08 9.78 15.20 22.37 24.92 15.85 12.03 15.95 26.75 MVF (l/min) 1.56 2.62 3.73 2.53 2.18 4.24 5.50 2.04 3.09 2.09 1.16 4.58 4.62 1.60 2.80 1.96 1.69 3.82 4.27 1.64 2.44 1.47 4.22 1.56 1.27 1.71 2.16 2.00 1.18 1.02 1.69 2.33 2.13 0.98 1.33 1.84 2.71 1.91 1.20 0.87 1.47 2.04 1.38 0.84 r 0.26 0.20 0.18 0.23 0.54 0.16 0.12 2.65 2.02 1.75 3.84 1.19 0.85 2.10 1.70 2.23 3.82 1.43 0.97 0.43 0.37 0.37 0.30 0.67 4.48 3.29 2.26 3.56 8.26 4.36 4.11 2.45 4.34 7.32 5.57 3.24 2.14 4.67 6.89 6.27 2.94 2.61 3.92 7.65

221

rr 0.023 0.024 0.026 0.043 0.049 0.042 0.037 0.24 0.23 0.20 0.24 0.19 0.20 0.18 0.20 0.24 0.23 0.23 0.20 0.033 0.037 0.030 0.051 0.045 0.23 0.24 0.23 0.28 0.34 0.26 0.27 0.21 0.29 0.33 0.28 0.27 0.22 0.31 0.33 0.25 0.19 0.22 0.25 0.27

Finer emery cloth setting

Coarser emery cloth setting

Exit dam 1 (30 mm)

Exit dam 2 12b-4n

12b-7n

12n-4n

12b-4b

* The inlet depth of solid bed in all runs is 70mm (23% of inner diameter).

3.2. Axial velocity distribution along kiln length For end-open system, as the bed depth and the fill ratio of solids in cross-section are different at the different axial position, the axial cascading velocity of solids is not constant along the kiln axis. That is, the residence time in different zone along kiln length is quite different. Figs. 5 and 6 give the axial velocity of sand and MSW under different axial points, respectively. It can be seen that the axial velocity of particles increases along the axial direction. It is due to the decrement of the bed depth or the fill ratio along the kiln axis. Thus, according to the mass

conservation theory, d(quA)/dx = 0, the axial velocity along kiln length increases gradually. By the way, as for the practical rotary kiln reactor, it has various reaction zones along the axis and the solids have different properties in every zone. Thus, it is essential to know the detailed residence time of the solids in each zone. However, up to now, nearly all the experimental/theoretical works of solid transport are concentrated on the overall residence time through the kiln inlet to outlet. The residence time of solid passing a special reaction zone can be obtained by integration of the bed axial velocity along the age of this i zone, ti mz zi1 dz=uz where z represents kiln axis and i

222

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

Fig. 3. Residence time distribution of sand.

Fig. 5. Axial speed distribution of sand along kiln axis.

the zones sequence. Axial velocity, u(x), can be calculated through the empirical correlations (Lebas et al. [28], Perron and Bui [29]). 3.3. Influences of particle characteristics on MRT and MVF The comparison of MRT and MVF between sand and MSW under the same conditions is shown in Figs. 7 and 8, respectively. The MRT of MSW is greater than that of sand for all runs. From the regress curve in Fig. 7, it is obtained that the former is about 1.43 times of the latter. Contrarily, MVF of MSW is less than that of sand with the multiple of 0.625 (1/1.48). From Table 2, it can be seen that sinhd of MSW is 1.50 times of that of sand. Thus, the conclusion is drawn: the materials characteristics exerts its influences on the MRT and MVF mainly in terms of hd; MRT increases approximately in linear fashion as sinhd of material increases, while MVF is subjected to the inverse proportional function of sinhd. These conclusions will be

verified subsequently by the theoretical analysis in Part II of this work. 3.4. Influences of rotating speed and kiln slope The impact of rotating speed on the MRT and MVF of heterogeneous MSW is shown in Fig. 9. As rotational speed increases from 2 to 8 rpm, MRT decreases nearly in inverse proportional fashion of rotating speed, while MVF increases gradually. These conclusions are consistent with those acquired from the homogenous small particles by others [11,30]. It may be explained that the axial transport of solids mainly occurs in the active layer of bed surface, while solids in the stagnant region under bed surface only turn around the kiln axis without any axial displacement. As the rotational speed increases, the times of a particle entering the active layer per unit time increases, which further results in the increase of the particles axial displacement per unit time (namely, particles axial velocity) [18,31]. Therefore, MRT decreases and MVF increases.

Fig. 4. Residence time distribution of MSW.

Fig. 6. Axial speed distribution of MSW along kiln axis.

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

223

Fig. 9. Effect of rotational speed on MSW transport behavior. Fig. 7. Comparison of MRT between MSW and sand.

Fig. 10 indicates the effect of kiln slope on the transport behavior of MSW. When kiln slope angle increases from 0.62j to 2.40j, the MRT decreases in an approximately linear fashion from 11.28 to 5.58 min, while MVF rises from 2.18 to 3.73 l/min. It is possible that the increasing kiln inclination causes the increment of the gravitational force component in the axial direction of individual particle during its cascading, i.e., the increment of the solid axial velocity, which finally causes MRT to decrease and MVF to increase. 3.5. Influences of exit-end dams The exit-end dam exerts significant influences on the MRT and MVF of solids in a rotary kiln. As shown in Fig. 11, MRT of MSW and sand with the 30-mm dam (about 10% of inner kiln diameter) are 78.0% and 71.4% longer than that with no end constriction, respectively. As for a higher 50-mm dam (about 16.7% of inner diameter), the

corresponding augment is 165% and 138% for MSW and sand, respectively. The higher height of dam has, the more remarkable effect it has on MRT. The affecting extent made by the 50-mm dam is almost twice of that made by the 30mm dam. The reasons for above conclusions lie in two aspects. First, the usage of exit dam reduces the slope of the solid bed and then the axial cascading velocity of particles. On the other hand, it causes the increment of bed depth in kiln. This increment of flow area in cross-section will decrease axial cascading velocity, either. Finally, the combination of two reasons above cause the remarkable increase of MRT. In addition, MVF decreases when employing exitend dam. As for the 30-mm dam, the reduction of MVF of MSW and sand are 34.5% and 27.9%, respectively, and for the 50-mm dam, the corresponding reduction is 58.3% and 35.2% (shown in Fig. 12). It is doubtless that the usage of exit dam is an effective method to control the MRT and MVF of solids. However, it is noted that exit dam has no such apparent impacts on relative variance rr as it has on MRT, as seen from Table 3.

Fig. 8. Comparison of MVF between MSW and sand.

Fig. 10. Effect of kiln slope angle on MSW transport behavior.

224

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

Fig. 11. Effect of exit end dam on MRT.

Fig. 13. Effect of various internal structures on MRT of MSW.

3.6. Influences of the internal structures The internal structures inevitably affect the axial transport of solids [13,14]. The impacts of internal structures on MRT are different with various groups consisting of a certain number of axial ribs or circular ribs. Figs. 13 and 14 illustrate the influences of four groups of internal structures (listed in Table 2) on the MRT of MSW and sand, respectively. It is found that all these four kind of internal structures seriously increase MRT of solids. The detailed conclusions are drawn: as the number of circular ribs in an internal structure group increases (12b-4n ! 12b-7n), the MRT in 12b-7n case is slightly longer than that in 12b-4n case for both MSW and sand; as the height of circular ribs increases from 30 to 50 mm (12b-4n ! 12b-4b), the increment of MRT from 12b-4n to 12b-4b case is more remarkable. However, with the increasing height of axial ribs from 10 to 20 mm (12n-4n ! 12b-4n), the MRT changing tendency of MSW and sand is inconsistent or inexplicit.

According to above, it is concluded that influences of the internal structure group on MRT are dependent on the height of circular ribs, while the impacts of the height of axial ribs is inexplicit. The influence of circular ribs on MRT can be explained by their similarity to the exit dam whose influence has been already tested to be remarkable. The impact of axial ribs on MRT is quite complicated, which not only changes the solids dynamic angle of repose, but also kicks up some particles from the bed surface to the freeboard space. These conclusions can be verified by the experiments. For instance, the 30-mm exit dam promotes MRT with 78.0%; however, the internal structure groups labeled 12b-4n, 12b-7n and 12n-4n, whose circular ribs is also 30mm height, only promote the MRT in range of 75% to 108% with MSW under an condition of rotating speed at 4 rpm and inclination at 2.40j (Fig. 14). Since the exit dam (regarded as one special circular rib) does not exert the same apparent effects on rr as it does on MRT, here, the great promotion by one-order of magni-

Fig. 12. Effect of exit end dam on MVF.

Fig. 14. Effect of various internal structures on MRT of sand.

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

225

Fig. 15. Effect of inside wall roughness on MRT of MSW.

Fig. 17. Relationship between MRT and MVF.

tude of rr may be attributed to the presence of axial ribs (Table 3). 3.7. The influences of inside wall roughness The inside walls roughness, designated by the wall friction factors of solids ( f), has significant effects on axial transport. Fig. 15 presents the variation of MRT with the various f. When the inside wall is smooth with f at 0.480, MRT is rather short. When f increases to 1.003 (viz. the finer emery cloth is set on inside wall), MRT increases significantly. However, with further increase of f from 1.003 to 1.251 (the coarser emery cloth setting), the increment of MRT is not apparent. It can be explained that the variation of f greatly changes the bulk characteristics (in terms of variation of hd) and further changes the bed regimes of solids. As observed, the solid bed in a case of smooth wall may perform at a slumping regime, in which the solids cascade as periodic avalanche through the kiln and have a short MRT. When f increases to 1.003, hd increases from 48.5j to 58j and the rolling regime is well

formed. The variation of both hd and bed regimes greatly increases MRT. When f continues to increase to 1.251, hd slowly increases up to about 59.5j, the rolling regime also dominates the bed behavior (that is, the advanced cataracting regime is not yet formed). Thus, the variation of MRT is small. In addition, the impact of f on MVF of MSW is shown in Fig. 16. MVF decreases gradually with the increasing f, and its changing tendency is contrary to that of MRT. 3.8. The relationship between MRT and MVF As discussed above, when one of the variables, such as rotational speed, kiln slope, dynamic angle of repose and internal-structures, changes, the variation of MRT has the reverse tendency with that of MVF. It is apparent that the product of MRT and MVF is just the holdup of solids in kiln, which is expressed as Holdup = MRT MVF. Fig. 17 shows the product of MRT and MVF (i.e. holdup) under different run, in which the values of MRT and MVF are obtained from Table 3. In a case of smooth wall with open exit end, in spite of the changing of rotational speed or kiln slope, the product of MRT and MVF keeps around 19.7 l, which implies that the overall fill ratio of solids to kiln vessel is a constant at 15%. As far as the internal-structures, such as 12b-4n, 12b-7n and 12n-4n are considered, it holds around 25 l (thats, overall fill of solids reaches about 18 f 19%). The employment of 12b-4n, 12b-7n or 12n-4n not only similarly enlarges the exit-end bed depth from 0 to 30 mm (while the bed depth at kiln inlet holds 70 mm), but also expands the bulk characteristics of solids along all kiln length. Thus, the holdup increases from 19.7 to 25.3 l. Finally it is drawn that the overall fill ration or holdup of solids within kiln is just relevant to the inlet bed depth, exit bed depth and usage of internal structures, but independent of some operational parameters such as rotational speed or kiln slope. This conclusion is much meaningful to the scaleup or design rotary kiln reactor.

Fig. 16. Effect of inside wall roughness on MVF of MSW.

226

S.-Q. Li et al. / Powder Technology 126 (2002) 217227

4. Conclusion (1) The reconstituted MSW consists of 49.9 wt.% wood chips, 17.0 wt.% paper plates and 33.1 wt.% waste tyres. The dynamic angle of repose (hd) reflects the bulk characteristics of solids in kiln. hd of MSW is 48.5j and hd of the contrastive sand is about 29.3j. The value of hd increases with the enhancement of wall roughness, but is independent of the drum rotation speed. (2) The distribution of residence time of MSW arises from the axial segregation of different components, but not the axial collisions. It results in a relatively large discrepancy of experimental RTD with ideal normal distribution. The variance (r or rr) of MSW is greater than that of sand. It is noted that the known phenomenon of alternate band formation does not occur in such a continuous system. (3) The axial cascading velocity of particles increases along the axial direction due to the decrement of the bed depth or the fill area along the kiln axis. Thus, it is essential to know the detailed residence time of the solids in each divided zone besides that of the whole kiln, which implies incoming research intensive. (4) The difference of the MRT/MVF between the heterogeneous MSW and regular sand is related to their dynamic angles of repose. MRT is approximately a proportion function of sin hd, while MVF is an inverse proportion function of sin hd. (5) Increasing either rotating speed or kiln slope results in the decreasing MRT and increasing MVF. These variables are both considered as flexible parameters to adjust the kiln peformance in the practice. The r of RTD shows the same fashion as MRT with various rotating speed or kiln slope, while rr keeps in a narrow range from 0.02 to 0.05. (6) The exit dam has remarkable impact on MRT of solids; thus, it can also be used as an adjusting tool of the kiln. Impact of internal structures, which are composed of axial ribs and circular ribs, on MRT mainly depends on height of circular ribs. However, exit dam (or circular ribs) does not exert the same apparent impact on rr as it does on MRT. It is implied that the axial ribs will have great effect on rr. (7) The effect of roughness of inside wall on MRT and MVF can be explained by that the variation of f between the wall and the solids directly changes the bulk characteristics of the solids in kiln and further changes the motion regime of the bed. (8) For a case with given inlet and exit bed depths, the holdup in terms of the product of MRT and MVF holds at a constant within the limits of experimental errors. The presence of internal structures increases the holdup of solids.

Zhejiang provincial National Science Funds of China (No. RC99041). We are grateful to Dr. A. -M. Li for helpful discussion about rotary kiln transport processes. The contribution of Dr. J. T. Huang and Z. X. Zhang to this work is gratefully acknowledged.

References

[1] S.J. Porter, The design of rotary driers and coolers, Trans. Inst. Chem. 41 (1963) 272 280. [2] A.P. Watkinson, J.K. Brimacombe, Limestone calcination in rotary kiln, Metall. Trans. B 13B (1982) 369 378. [3] A. Chatterjee, A.V. Sathe, M.P. Srivastava, P.K. Mukhopadhyay, Flow of materials in rotary kilns used for sponge iron manufacture: Part I. Effect of some operational variables, Metall. Trans. B 14B (1983) 375 381. [4] E. Henrich, S. Bu rkle, Z.I. Meza-Renken, S. Rumpel, Combustion and gasification kinetics of pyrolysis chars from waste and biomass, J. Anal. Appl. Pyrolysis 49 (1999) 221 241. [5] W.-C. Yang, Dynamics of simulated municipal solid waste in a rotating device, Powder Technol. 72 (1992) 139 147. [6] A.M. Li, X.D. Li, S.Q. Li, Pyrolysis of solid waste in a rotary kiln: influence of final pyrolysis temperature on pyrolysis products, J. Anal. Appl. Pyrolysis 50 (1999) 149 162. [7] A.M. Li, X.D. Li, S.Q. Li, Experimental studies on municipal solid waste pyrolysis in a laboratory-scale rotary kiln, Energy 24 (1999) 209 218. [8] W.D. Schaefer, Disposing of solid wastes by pyrolysis, Environ. Sci. Technol. 9 (1975) 98 99. [9] P.W. Dufton, The Value and Use of Scrap Tyre, Rapra Technology, England, 1987. [10] J.D. Sullivan, C.G. Maier, O.C. Ralson, Passage of solid particles through rotary cylindrical kilns, U. S. Bur. Mines Tech. Pap. 384 (1927). ` hl, W.G. Kingma, Transport of solids through horizontal rotary [11] L. Va cylinders, Chem. Eng. Sci. 1 (1952) 253 258. [12] H. Kramers, P. Croockewit, The passage of granular solids through inclined rotary kilns, Chem. Eng. Sci. 1 (1952) 259 265. [13] A. Chatterjee, A.V. Sathe, M.P. Srivastava, Flow of materials in rotary kilns used for sponge iron manufacture: Part III. Effect of ring formation within the kiln, Metall. Trans. B 14B (1983) 393 399. [14] A.J. Matchett, M.S. Sheikh, An improved model of particle motion in cascading rotary dreyers, Chem. Eng. Res. Des. 68 (1990) 139 148. [15] R. Rutgers, Longitudinal mixing of granular material flowing through a rotary cylinder: Part I. Descriptive and theoretical, Chem. Eng. Sci. 20 (1965) 1079 1087. [16] A.Z.M. Abouzeid, D.W. Fuerstenau, A study of the hold-up in rotary drums with discharge end constrictions, Powder Technol. 25 (1980) 21 29. [17] P.S.T. Sai, G.D. Surender, A.D. Damodaran, V. Suresh, Z.G. Philip, K. Sankaran, Residence time distribution and material flow studies in a rotary kiln, Metall. Trans. B 21B (1990) 1005 1011. [18] G.W.J. Wes, A.A.H. Drinkenburg, S. Stemerding, Solids mixing and residence time distribution in a horizontal rotary drum reactor, Powder Technol. 13 (1976) 177 184. [19] G. Groen, J. Ferment, M.J. Grorneveld, J. Decleer, A. Delva, Scaling down of the calcination process for industrial catalyst manufacturing, Proc. Int. Symp. Sci. Basis for the Preparation of Heterogeneous Catalysts, Elsevier, Amsterdam, 1986. [20] F.R. Schofield, P.G. Glikin, Rotary dryers and coolers for granular fertilizers, Trans. Inst. Chem. Eng. 40 (1962) 183 190. [21] C. Wightman, F.J. Muzzio, Mixing of granular material in a drum undergoing rotating and rocking motions part II segregating particles, Powder Technol. 98 (1998) 125 134.

Acknowledgements This research was supported mainly by Nation Natural Science Funds of China (No. 50076037) and partially by

S.-Q. Li et al. / Powder Technology 126 (2002) 217227 [22] M.B. Donald, B. Rosseman, Mixing and de-mixing of solid particles part III industrial aspects of mixing and de-mixing, Br. Chem. Eng. 7 (1962) 922 924. [23] S.D. Gupta, D.V. Khakhar, S.K. Bhatia, Axial segregation of particles in a horizontal rotating cylinder, Chem. Eng. Sci. 46 (1991) 1517. [24] M. Nakagawa, S.A. Altobelli, A. Caprihan, E. Fukushima, NMRI study: axial segregation of radially segregated core of granular mixtures in a horizontal rotating cylinder, Chem. Eng. Sci. 52 (1997) 4423 4428. [25] A.A. Boateng, P.V. Barr, Modelling of particle mixing and segregation in the transverse plane of rotary kiln, Chem. Eng. Sci. 51 (1996) 4167 4181. [26] J. Bridgewater, W.S. Foo, D.J. Stephens, Particle mixing and segregation in failure zonetheory and experiments, Powder Technol. 41 (1985) 147 158.

227

[27] H. Henein, J.K. Brimacombe, A.P. Watkinson, Experimental study of transverse bed motion in rotary kilns, Metall. Trans. B 14B (1983) 191 204. [28] E. Lebas, F. Hanrot, D. Ablitzer, J.L. Houzelot, Experimental study of residence time, particle movement and bed depth profile in rotary kilns, J. Can. Chem. Eng. 73 (1995) 173 179. [29] J. Perron, R.T. Bui, Rotary cylinder: solid transport predicted by dimensional and rheological analysis, J. Can. Chem. Eng. 68 (1990) 61 68. [30] R. Rogers, A Monte Carlo method for simulating dispersion and transport through horizontal rotating cylinder, Powder Technol. 23 (1979) 159 167. [31] G.R. Woodle, J.M. Munro, Particle motion and mixing in a rotary kiln, Powder Technol. 76 (1993) 241 245.

You might also like

- 1 s2.0 S136403212300179X MainDocument12 pages1 s2.0 S136403212300179X Mainjimmy_burgos_11100% (1)

- DYNOmite Dynamometer Catalog 2014Document37 pagesDYNOmite Dynamometer Catalog 2014jimmy_burgos_11No ratings yet

- Static Fluid Bed Dryers, Vibrating Fluid Bed Dryers and Exhaust TechnologyDocument8 pagesStatic Fluid Bed Dryers, Vibrating Fluid Bed Dryers and Exhaust TechnologyOscar Alvitez DominguezNo ratings yet

- Mechanical Size Reduction SLIDEDocument26 pagesMechanical Size Reduction SLIDEaziziNo ratings yet

- Your Digital AfterlivesDocument273 pagesYour Digital AfterlivesVitor Moura Visoni100% (1)

- Problem Sheet 12-13 QuestionsDocument1 pageProblem Sheet 12-13 QuestionsWill Morgan-EvansNo ratings yet

- Doosan Daewoo Dx225lcDocument4 pagesDoosan Daewoo Dx225lcrayendra100% (3)

- Power Drawn by Grinding MediaDocument5 pagesPower Drawn by Grinding MediaanruloNo ratings yet

- Enhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersDocument5 pagesEnhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersD S VenkateshNo ratings yet

- Cyclone Separator LucasDocument28 pagesCyclone Separator LucasAnonymous zOo2mbaVANo ratings yet

- Lesson 7 NumericalsDocument11 pagesLesson 7 Numericalssurya kiranNo ratings yet

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenNo ratings yet

- Piston RingsDocument7 pagesPiston RingsMudassir HussainNo ratings yet

- Modulare Systems For Conveyor PlantsDocument36 pagesModulare Systems For Conveyor Plantsado31No ratings yet

- CMD 124 Class 5 Comminution - Crushing CircuitsDocument32 pagesCMD 124 Class 5 Comminution - Crushing CircuitsKabo Abednico PhuthegoNo ratings yet

- TER201 Lecture 6Document66 pagesTER201 Lecture 6lnxxNo ratings yet

- Gear Motors: Achieving The Perfect Motor & Gearbox MatchDocument16 pagesGear Motors: Achieving The Perfect Motor & Gearbox MatchJohn LeeNo ratings yet

- Media Charge - Ball Size & DensityDocument3 pagesMedia Charge - Ball Size & DensityIrving Dirzo CarrilloNo ratings yet

- Design and Structural Analysis of Spur Gear Using Various MaterialsDocument15 pagesDesign and Structural Analysis of Spur Gear Using Various MaterialsprajeeshNo ratings yet

- Materi PPT Secondary EngDocument5 pagesMateri PPT Secondary EngFanya arifantiNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Calculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)Document11 pagesCalculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)RAVI1972No ratings yet

- Entropy ChangeDocument13 pagesEntropy Changeنبيل محمد عيد ابوميراNo ratings yet

- Literature ReviewDocument6 pagesLiterature ReviewIrfan FadzailahNo ratings yet

- Short Course On Comminution & Semi-Autogenous Grinding: Session 8 Functional PerformanceDocument26 pagesShort Course On Comminution & Semi-Autogenous Grinding: Session 8 Functional PerformanceFredy Peña100% (1)

- Ball Mill OperatingDocument14 pagesBall Mill OperatingCao Ngoc Anh100% (1)

- Shimpo Circulute 3000 CatalogDocument36 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignDocument13 pagesPaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980No ratings yet

- Design Guide For Air Slide PDFDocument2 pagesDesign Guide For Air Slide PDFAhmedRizk100% (1)

- 11,42 Catti: EquationDocument17 pages11,42 Catti: EquationMohit MehtaNo ratings yet

- Spiral Classifier Brochure - Triveni EnggDocument4 pagesSpiral Classifier Brochure - Triveni Enggrajeevup2004No ratings yet

- Entropy Rate Balance For Closed Systems: ExampleDocument26 pagesEntropy Rate Balance For Closed Systems: ExampleDaniel García100% (1)

- Bearings FinalDocument8 pagesBearings FinalThiyagarajan RajkumarNo ratings yet

- Machinary For Crushing & GrindingDocument75 pagesMachinary For Crushing & GrindingAsad Imran MunawwarNo ratings yet

- Intake SystemDocument13 pagesIntake SystemSanyam Madaan100% (1)

- StanexDocument2 pagesStanexSamehibrahemNo ratings yet

- Finance Project On ACC CEMENTDocument87 pagesFinance Project On ACC CEMENTShilpan Shah80% (5)

- High Performance: Vertical Machining CentersDocument6 pagesHigh Performance: Vertical Machining CentersSandeep SNo ratings yet

- Analysis of The Effect of Counter-Cone Location On Cyclone SeparatorDocument12 pagesAnalysis of The Effect of Counter-Cone Location On Cyclone SeparatorAnonymous NxpnI6jCNo ratings yet

- Brochure BriquettingDocument24 pagesBrochure Briquettingssmith2007No ratings yet

- 2011 Flsmidth Terms and ConditionsDocument2 pages2011 Flsmidth Terms and ConditionsIrving Dirzo CarrilloNo ratings yet

- japonesesCR PDFDocument7 pagesjaponesesCR PDFJavier Antonio Cardenas OliverosNo ratings yet

- Ball MillDocument10 pagesBall MillLuthfanNo ratings yet

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocument3 pagesA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresNo ratings yet

- Preheater Lores PDFDocument8 pagesPreheater Lores PDFamjed_de_enimNo ratings yet

- Review BeamsDocument11 pagesReview BeamsAiswarya Ramesh me21b011No ratings yet

- Filter & Size ReductionDocument20 pagesFilter & Size ReductionMuhammad Putra RamadhanNo ratings yet

- 3 Experience and Case Studies 12.5.05Document3 pages3 Experience and Case Studies 12.5.05Sikander Girgoukar100% (1)

- Hpgrsim OpenDocument83 pagesHpgrsim OpenCarlos DiazNo ratings yet

- Thermal Expansion Settings in GleebleDocument4 pagesThermal Expansion Settings in GleeblePranav TripathiNo ratings yet

- FEECO Seal OptionsDocument1 pageFEECO Seal OptionsFernando MilmanNo ratings yet

- Gears Their Designs & Uses: Andrei Lozzi 2012Document23 pagesGears Their Designs & Uses: Andrei Lozzi 2012atulsemiloNo ratings yet

- Ecuaciones en DiferenciaDocument57 pagesEcuaciones en DiferenciaJuan PabloNo ratings yet

- PCS Algebra I Quiz 4 Chapter Review KEYDocument1 pagePCS Algebra I Quiz 4 Chapter Review KEYTim Ricchuiti100% (1)

- Bijur Delimon KatalogDocument24 pagesBijur Delimon Katalogdamian_k19No ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Vibrating Mill PDFDocument6 pagesVibrating Mill PDFPhanHathamNo ratings yet

- Catalogue V20 PDFDocument404 pagesCatalogue V20 PDFUstad Remy0% (1)

- Equation TX: ParametricDocument3 pagesEquation TX: ParametricNguyễn Lê Quốc HưngNo ratings yet

- MathDocument15 pagesMathapi-439869462No ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Selected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionFrom EverandSelected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionNo ratings yet

- 1 s2.0 S0165237007001489 MainDocument6 pages1 s2.0 S0165237007001489 MainU.G.No ratings yet

- Sau WorkDocument16 pagesSau WorkMuhammad AdnanNo ratings yet

- 1 s2.0 S0955598621001485 MainDocument10 pages1 s2.0 S0955598621001485 Mainjimmy_burgos_11No ratings yet

- Exercise 1: Inventor 2010.ipj. A Check MarkDocument7 pagesExercise 1: Inventor 2010.ipj. A Check Markjimmy_burgos_11No ratings yet

- GeothermalEnergy ReulDocument75 pagesGeothermalEnergy Reuljimmy_burgos_11No ratings yet

- Electromagnetic Diffraction in Optical Systems. I. An Integral Representation of The Image FieldDocument8 pagesElectromagnetic Diffraction in Optical Systems. I. An Integral Representation of The Image Fieldjimmy_burgos_11No ratings yet

- Comsol TutorialDocument40 pagesComsol Tutorialjimmy_burgos_11100% (3)

- Coal Combustion in A Rotary Kiln: Application Briefs From FluentDocument2 pagesCoal Combustion in A Rotary Kiln: Application Briefs From Fluentjimmy_burgos_11No ratings yet

- Partial Differantial Equation GregoryanDocument96 pagesPartial Differantial Equation GregoryanMelike UzunNo ratings yet

- Thermochemical StoverDocument1 pageThermochemical Stoverjimmy_burgos_11No ratings yet

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 pagesPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNo ratings yet

- STS Lesson 2Document30 pagesSTS Lesson 2Reymond Lupoz IINo ratings yet

- Manually and Mechanically Actuated Directional Control Valves Sturdy and Reliable!Document66 pagesManually and Mechanically Actuated Directional Control Valves Sturdy and Reliable!lojzemulec5966No ratings yet

- Law of MotionDocument4 pagesLaw of MotionRose GilaNo ratings yet

- New Inventions - Exercises 1Document2 pagesNew Inventions - Exercises 1Natálie DědečkováNo ratings yet

- Linear Algebra NotesDocument93 pagesLinear Algebra NotesalijazizaibNo ratings yet

- MJE16204 NPN DatasheetDocument12 pagesMJE16204 NPN DatasheetMaximus ByamukamaNo ratings yet

- Drawing of Melt Spun FibresDocument20 pagesDrawing of Melt Spun FibresSuraj RaghvNo ratings yet

- Acid Base and Solubility of Organic Compounds PDFDocument31 pagesAcid Base and Solubility of Organic Compounds PDFPaolo NaguitNo ratings yet

- Cam Lab 1Document40 pagesCam Lab 1Madhusudhan Rao KNo ratings yet

- Gen MathDocument19 pagesGen MathMiraflorNo ratings yet

- Thin Lenses: Prepared By: Jenno S. Lantaya, OdDocument31 pagesThin Lenses: Prepared By: Jenno S. Lantaya, OdKwenzie FortalezaNo ratings yet

- Discrete ControlDocument24 pagesDiscrete Controlcontrol_613No ratings yet

- Amc CR 650 PDSDocument1 pageAmc CR 650 PDSShooWin Allen JohnNo ratings yet

- BSMT Q3 - Set A Answer KeyDocument3 pagesBSMT Q3 - Set A Answer KeyJohn Dennis Tijam100% (1)

- Application of Laplace Transform in ControlsDocument31 pagesApplication of Laplace Transform in ControlshportezNo ratings yet

- Geometrically Exact Extreme Vibrations of CantileversDocument15 pagesGeometrically Exact Extreme Vibrations of Cantileversmohdsolihat1No ratings yet

- MVohra TNaeem Proposal Base IsolationDocument26 pagesMVohra TNaeem Proposal Base IsolationTalha NaeemNo ratings yet

- Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodDocument7 pagesDesign and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodIJAERS JOURNALNo ratings yet

- Closed-Loop Electronic Fuel Injection For Spark-Ignited EnginesDocument9 pagesClosed-Loop Electronic Fuel Injection For Spark-Ignited EnginesSukma FirdausNo ratings yet

- The Catenary PDFDocument5 pagesThe Catenary PDFChandra PrakashNo ratings yet

- Função de GudermannDocument3 pagesFunção de GudermannElaine MoratoNo ratings yet

- Appendix E Tensile Strength of Roller Compacted Concrete: EP 1110-2-12 30 Sep 95Document15 pagesAppendix E Tensile Strength of Roller Compacted Concrete: EP 1110-2-12 30 Sep 95nywd806033No ratings yet

- SKF3013 - Manual Amali PDFDocument26 pagesSKF3013 - Manual Amali PDFhazwani safuraNo ratings yet

- Phantoms of The Human BrainDocument360 pagesPhantoms of The Human BrainAlex Ciobotaru100% (12)

- Quality Grades, Guidelines For SelectionDocument10 pagesQuality Grades, Guidelines For SelectionAhmad ShujaNo ratings yet

- ConcreteDocument132 pagesConcreteThái TrầnNo ratings yet