Professional Documents

Culture Documents

Workshop Practice Series The Definitive Library For The Small Workhsop

Workshop Practice Series The Definitive Library For The Small Workhsop

Uploaded by

Peanut d. DestroyerCopyright:

Available Formats

You might also like

- Hot Rolling of Steel - William L. RobertDocument13 pagesHot Rolling of Steel - William L. RobertAon Hemmatad0% (2)

- A1018 A1011Document5 pagesA1018 A1011Gedalías MartínezNo ratings yet

- Workshop Practice Series The Definitive Library For The Small WorkhsopDocument1 pageWorkshop Practice Series The Definitive Library For The Small WorkhsopceljkoNo ratings yet

- Argus - Workshop Practice SeriesDocument8 pagesArgus - Workshop Practice Seriesविशाल पुडासैनीNo ratings yet

- Metalworking: Tools, Materials, and Processes for the HandymanFrom EverandMetalworking: Tools, Materials, and Processes for the HandymanRating: 5 out of 5 stars5/5 (1)

- Workshop Practice Series - BooksDocument8 pagesWorkshop Practice Series - BooksPuran Singh LabanaNo ratings yet

- Electro-Plating For The AmateurDocument114 pagesElectro-Plating For The AmateurmangyanNo ratings yet

- Oxy-Acetylene Welding and CuttingDocument96 pagesOxy-Acetylene Welding and CuttingGutenberg.orgNo ratings yet

- Workshop Practice Series 07 The Art of WeldingDocument47 pagesWorkshop Practice Series 07 The Art of WeldingJHANGIR KHANNo ratings yet

- The Practical Metal-Worker's AssistantDocument504 pagesThe Practical Metal-Worker's Assistantrazno001100% (1)

- Johnlei Aaron B Rauza g11 Try3Document1 pageJohnlei Aaron B Rauza g11 Try3Johnlei Aaron RauzaNo ratings yet

- A Practical Guide to Iron and Steel Works Analyses being Selections from "Laboratory Notes on Iron and Steel AnalysesFrom EverandA Practical Guide to Iron and Steel Works Analyses being Selections from "Laboratory Notes on Iron and Steel AnalysesNo ratings yet

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Metal Spinning PDFDocument86 pagesMetal Spinning PDFloosenut100% (1)

- Electric Welding 003709 MBPDocument429 pagesElectric Welding 003709 MBPAulia Haq AqobyNo ratings yet

- Gen 26883 A FMDB02 2012 PDFDocument653 pagesGen 26883 A FMDB02 2012 PDFgrimaguil100% (1)

- Workshop Practice Series 07 The Art of WeldingDocument47 pagesWorkshop Practice Series 07 The Art of WeldingSemnalmecNo ratings yet

- RunoutDocument14 pagesRunoutMajid SattarNo ratings yet

- Workshop Practice Series - BooksDocument8 pagesWorkshop Practice Series - Bookscatapix100% (5)

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Steel Heat Treatment Handboook Metalluurgy and TechnologiesDocument850 pagesSteel Heat Treatment Handboook Metalluurgy and Technologiestien100% (1)

- PW TD Arc Welding ENDocument67 pagesPW TD Arc Welding ENduniaadnanNo ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Welding ArihantDocument12 pagesWelding ArihantArihant SharmaNo ratings yet

- Research Paper On Welding CareerDocument8 pagesResearch Paper On Welding Careerfvgh9ept100% (1)

- Cutting and Grinding Equipment: Module For First Quarter Week 1Document11 pagesCutting and Grinding Equipment: Module For First Quarter Week 1JayNo ratings yet

- Engineering Workshop Lab ManualDocument74 pagesEngineering Workshop Lab ManualAnkushNo ratings yet

- Welding CompleteDocument579 pagesWelding CompleteSergioNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Reference Tables For I Ron. Const Ant An and Copper. Constantan ThermocouplesDocument19 pagesReference Tables For I Ron. Const Ant An and Copper. Constantan Thermocouplesken410309No ratings yet

- resweld-용접 변천사Document62 pagesresweld-용접 변천사Kyeong Cheol LeeNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Electron Beam Welding Steel and CopperDocument9 pagesElectron Beam Welding Steel and CopperVarma DantuluriNo ratings yet

- Electric Arc Furnace ThesisDocument6 pagesElectric Arc Furnace Thesish0dugiz0zif3100% (2)

- Ge Runout BasicsDocument14 pagesGe Runout BasicsRajagopal100% (1)

- Resistance Welding ThesisDocument5 pagesResistance Welding Thesisdwt3zbkq100% (2)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Chapter 14 WeldingDocument22 pagesChapter 14 WeldingRiian ApriansyahNo ratings yet

- Welding DictionaryDocument18 pagesWelding DictionaryEswar Enterprises QcNo ratings yet

- Friction Stir WeldingDocument30 pagesFriction Stir WeldingDilip Patel100% (1)

- Application of EbwDocument11 pagesApplication of Ebwsuman kumarNo ratings yet

- The Pattern Makers Handybook - Paul HasluckDocument198 pagesThe Pattern Makers Handybook - Paul Hasluckhbpr9999100% (3)

- FSW of Aluminium AlloysDocument45 pagesFSW of Aluminium AlloysAlexandre Lourenção CaselattoNo ratings yet

- Welding Superalloys For Aerospace ApplicationsDocument5 pagesWelding Superalloys For Aerospace ApplicationsakaretlerNo ratings yet

- Full Download Book Clinical Neuroanatomy 2 PDFDocument22 pagesFull Download Book Clinical Neuroanatomy 2 PDFruth.brown422100% (22)

- Arc - Wleding Final Exam PDFDocument13 pagesArc - Wleding Final Exam PDFronaldo de guzmanNo ratings yet

- Arc - Wleding Final ExamDocument13 pagesArc - Wleding Final ExamJhonalyne Estioco CamachoNo ratings yet

- Blacksmith's Craft: An Introduction to Smithing for Apprentices & CraftsmenFrom EverandBlacksmith's Craft: An Introduction to Smithing for Apprentices & CraftsmenNo ratings yet

- Term Paper-Sheet Metal WeldingDocument6 pagesTerm Paper-Sheet Metal Welding11gargdinesh7No ratings yet

- 1-Properties and Classification of Welding ProcessesDocument10 pages1-Properties and Classification of Welding ProcessesabastosuaptNo ratings yet

- WP Page5Document1 pageWP Page5Peanut d. DestroyerNo ratings yet

- Sheet Metal Research PaperDocument5 pagesSheet Metal Research Papergvym06g6100% (1)

- Syllabus For The Trade of Wireman: Week No:1Document43 pagesSyllabus For The Trade of Wireman: Week No:1Mohammed Abdul KaderNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Joining of Aa1050 Sheets Via Two Stages of Friction Spot TechniqueDocument13 pagesJoining of Aa1050 Sheets Via Two Stages of Friction Spot Techniquemunaf.h.ridhaNo ratings yet

- Website White Paper - Welding of Dissimilar Materials With 1KW Fiber LaserDocument12 pagesWebsite White Paper - Welding of Dissimilar Materials With 1KW Fiber LaserPardeepNo ratings yet

- "Age Ain't Nothin' But A Number": (Chorus: x2)Document1 page"Age Ain't Nothin' But A Number": (Chorus: x2)Peanut d. DestroyerNo ratings yet

- Street ThingDocument1 pageStreet ThingPeanut d. DestroyerNo ratings yet

- "Stones": (Feat. My Favorite Enemy)Document1 page"Stones": (Feat. My Favorite Enemy)Peanut d. DestroyerNo ratings yet

- PricelistDocument1 pagePricelistPeanut d. DestroyerNo ratings yet

- "Livin' The Dream": (Pre-Chorus:)Document1 page"Livin' The Dream": (Pre-Chorus:)Peanut d. DestroyerNo ratings yet

- HeartbrokenDocument1 pageHeartbrokenPeanut d. DestroyerNo ratings yet

- Rett0022 PB Purmo UkDocument183 pagesRett0022 PB Purmo UkPeanut d. DestroyerNo ratings yet

- Pricelist 2012 RRPDocument2 pagesPricelist 2012 RRPPeanut d. DestroyerNo ratings yet

- 2007 Evolve Price ListDocument194 pages2007 Evolve Price ListPeanut d. DestroyerNo ratings yet

- AC UPS SizingDocument8 pagesAC UPS SizingOlanrewaju Matthew OlabisiNo ratings yet

- Corliss Tax Price List 2011: Federal Tax Forms-Base FeeDocument1 pageCorliss Tax Price List 2011: Federal Tax Forms-Base FeePeanut d. DestroyerNo ratings yet

- PricelistDocument2 pagesPricelistPeanut d. DestroyerNo ratings yet

- Steps To Designing Structured Cabling SystemsDocument6 pagesSteps To Designing Structured Cabling SystemsPeanut d. DestroyerNo ratings yet

- Acadia Hospital Smoking Policy 7.09Document2 pagesAcadia Hospital Smoking Policy 7.09Peanut d. DestroyerNo ratings yet

- Northern Maine Medical Center Smoking Policy 2008Document2 pagesNorthern Maine Medical Center Smoking Policy 2008Peanut d. DestroyerNo ratings yet

- Smokefree Policy v2Document9 pagesSmokefree Policy v2Peanut d. DestroyerNo ratings yet

- Mayo Regional Hospital Smoke-Free 7.09Document2 pagesMayo Regional Hospital Smoke-Free 7.09Peanut d. DestroyerNo ratings yet

- Design and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyDocument69 pagesDesign and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyPartth VachhaniNo ratings yet

- OrganometallicsDocument58 pagesOrganometallicsRohit ChaudharyNo ratings yet

- Technology Multiple Choice Exam Få Fò - HWPDocument39 pagesTechnology Multiple Choice Exam Få Fò - HWPMark Darrel Aranas100% (3)

- 1.4742 enDocument2 pages1.4742 enGoran ErakovicNo ratings yet

- Steel Reference GuideDocument36 pagesSteel Reference GuideCésar VenegasNo ratings yet

- Kranich 2Document17 pagesKranich 2Rob CollisNo ratings yet

- Sleeve Anchor Data Sheet - For SubmittalDocument3 pagesSleeve Anchor Data Sheet - For SubmittalvtalexNo ratings yet

- 8J Magnets and ElectromagnetsDocument21 pages8J Magnets and ElectromagnetsPoornimaNo ratings yet

- Coolant System MaintenanceDocument2 pagesCoolant System MaintenanceDarmawan PutrantoNo ratings yet

- Pakistan Steel Marketing DepartmentDocument6 pagesPakistan Steel Marketing DepartmentHamid NaveedNo ratings yet

- Power CablesDocument48 pagesPower CablesIuliu Grad100% (1)

- Asme Section Ii A Sa-29 Sa-29m PDFDocument26 pagesAsme Section Ii A Sa-29 Sa-29m PDFHyunjong MoonNo ratings yet

- 1.9.1.2-10T - Aluminum BronzeDocument4 pages1.9.1.2-10T - Aluminum BronzechonubobbyNo ratings yet

- KSSC 3 2007 7 4 297 (C)Document13 pagesKSSC 3 2007 7 4 297 (C)ismael.lorandi623No ratings yet

- 198 Faf2500 Flanged y Type StrainerDocument4 pages198 Faf2500 Flanged y Type Strainerinfo8176No ratings yet

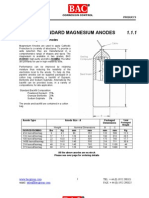

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- Rack and Pinion AcutatorsDocument4 pagesRack and Pinion AcutatorsRAHEEMNo ratings yet

- Spec Schedule40 Pipe Galvanized PDFDocument2 pagesSpec Schedule40 Pipe Galvanized PDFSahil SharmaNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- 484 Welding Guidelines For Design EngineersDocument4 pages484 Welding Guidelines For Design EngineersPham Song Hong100% (1)

- MetalJacket Overview CapabilitiesDocument17 pagesMetalJacket Overview CapabilitiesRajaSekarsajjaNo ratings yet

- 4.uses of Metals - 1-32 For StudentsDocument13 pages4.uses of Metals - 1-32 For StudentsnergisalihpasaogluNo ratings yet

- Unit I ' Theory of Metal CuttingDocument19 pagesUnit I ' Theory of Metal CuttingThulasi RamNo ratings yet

- RailwayDocument47 pagesRailwayusler4u94% (17)

- Strain Hardening Exponent-Sep-Oct 2005Document2 pagesStrain Hardening Exponent-Sep-Oct 20056541646No ratings yet

- C75C - Ck75 Steel DataDocument2 pagesC75C - Ck75 Steel DatavinibeNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- 20 MN CR 5Document4 pages20 MN CR 5Pulkit GururaniNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5754 H111 Treadplate 142Document2 pagesAalco Metals LTD Aluminium Alloy 5754 H111 Treadplate 142Ramon AraujoNo ratings yet

Workshop Practice Series The Definitive Library For The Small Workhsop

Workshop Practice Series The Definitive Library For The Small Workhsop

Uploaded by

Peanut d. DestroyerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop Practice Series The Definitive Library For The Small Workhsop

Workshop Practice Series The Definitive Library For The Small Workhsop

Uploaded by

Peanut d. DestroyerCopyright:

Available Formats

WORKSHOP PRACTICE SERIES The Definitive Library for the Small Workhsop

1. Hardening, Tempering & Heat Treatment

By Tubal Cain. A comprehensive exposition of the structure of steels and effects of different heat treatments, particularly in respect to tools. Contains accurate color temperature charts. 128 pages, illustrated paperback.

6. Measuring and Marking Metals by Ivan Law

Model engineers and many small workshops do not need, or have access to, much of the sophisticated measuring equipment used in industry. Accurate marking out and measurement by more basic means at all stages of work are described comprehensively by an expert engineer. 112 pg, illustrated.

#837-5A

$21.50

#841-3A 2. Vertical Milling in The Workshop

By Arnold Throp. Small workshops, including those of model engineers, are making increasing use of small vertical milling machines. This book explains how to use them (and lathe milling attachments) in clear terms. 96 pages, illustrated paperback.

$21.50

7. Art of Welding

By W.A. Vause. This book sets out the basic techniques for oxyacetylene welding, brazing, flame cutting and electric arc welding with mild steel, cast iron, stainless steel, copper, brass, etc. in sheet, plate or cast form. 96 pages, illustrated paperback.

#834-XA

$21.50

#846-4A 8. Sheet Metalwork

$21.50

3. Screwcutting in The Lathe

By Martin Cleeve. A fully comprehensive survey of the use of a lathe for all forms of screwcutting in all thread forms, inch and metric. Calculations, gear trains, conversions, etc. are all explained and set out in tabular form. 176 pages, illustrated paperback.

By R. E. Wakeford. The author is an instructor in metal work and allied crafts. He describes clearly all the processes likely to be encountered by the hobbyist in a model or light engineering workshop. 152 pages, illustrated paperback.

#845-6A

$21.50

#838-3A

$21.50 9. Soldering and Brazing

By Tubal Cain. Joining metal by soft and hard soldering, or brazing with various alloys, are run-of-themill jobs in model and light engineering workshops. Tubal Cain examines the processes, equipment, and materials. He explains what is happening in the joints as they are made. 126 pages, illustrated paperback.

4. Foundry Work for the Amateur

By B. Terry Aspin. This book is regarded as the perfect introduction to casting work in common metals. The new edition brings everything right up to date. 112 pages, illustrated paperback.

#842-1A

$21.50

5. Milling Operations in The Lathe

By Tubal Cain. A thorough and practical discourse on how to use the lathe for all types of milling work. Next to turning, the most valuable use of the lathe is for milling operations, whether using the lathe itself to drive the cutters or by extending its scope by adding a separate milling attachment. 128 pages, illustrated paperback.

#845-6AA 10.Saws & Sawing

$21.50

By Ian Bradley. This book examines all types of saws, hand and machine, their use and maintenance along with useful tables relating to various applications. 96 pages, illustrated paperback.

#840-5A

$21.50

#887-1A

$21.50

FOR MORE INFORMATION OR TO PLACE AN ORDER CALL 800-872-6500 PAGE 1

You might also like

- Hot Rolling of Steel - William L. RobertDocument13 pagesHot Rolling of Steel - William L. RobertAon Hemmatad0% (2)

- A1018 A1011Document5 pagesA1018 A1011Gedalías MartínezNo ratings yet

- Workshop Practice Series The Definitive Library For The Small WorkhsopDocument1 pageWorkshop Practice Series The Definitive Library For The Small WorkhsopceljkoNo ratings yet

- Argus - Workshop Practice SeriesDocument8 pagesArgus - Workshop Practice Seriesविशाल पुडासैनीNo ratings yet

- Metalworking: Tools, Materials, and Processes for the HandymanFrom EverandMetalworking: Tools, Materials, and Processes for the HandymanRating: 5 out of 5 stars5/5 (1)

- Workshop Practice Series - BooksDocument8 pagesWorkshop Practice Series - BooksPuran Singh LabanaNo ratings yet

- Electro-Plating For The AmateurDocument114 pagesElectro-Plating For The AmateurmangyanNo ratings yet

- Oxy-Acetylene Welding and CuttingDocument96 pagesOxy-Acetylene Welding and CuttingGutenberg.orgNo ratings yet

- Workshop Practice Series 07 The Art of WeldingDocument47 pagesWorkshop Practice Series 07 The Art of WeldingJHANGIR KHANNo ratings yet

- The Practical Metal-Worker's AssistantDocument504 pagesThe Practical Metal-Worker's Assistantrazno001100% (1)

- Johnlei Aaron B Rauza g11 Try3Document1 pageJohnlei Aaron B Rauza g11 Try3Johnlei Aaron RauzaNo ratings yet

- A Practical Guide to Iron and Steel Works Analyses being Selections from "Laboratory Notes on Iron and Steel AnalysesFrom EverandA Practical Guide to Iron and Steel Works Analyses being Selections from "Laboratory Notes on Iron and Steel AnalysesNo ratings yet

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Metal Spinning PDFDocument86 pagesMetal Spinning PDFloosenut100% (1)

- Electric Welding 003709 MBPDocument429 pagesElectric Welding 003709 MBPAulia Haq AqobyNo ratings yet

- Gen 26883 A FMDB02 2012 PDFDocument653 pagesGen 26883 A FMDB02 2012 PDFgrimaguil100% (1)

- Workshop Practice Series 07 The Art of WeldingDocument47 pagesWorkshop Practice Series 07 The Art of WeldingSemnalmecNo ratings yet

- RunoutDocument14 pagesRunoutMajid SattarNo ratings yet

- Workshop Practice Series - BooksDocument8 pagesWorkshop Practice Series - Bookscatapix100% (5)

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Steel Heat Treatment Handboook Metalluurgy and TechnologiesDocument850 pagesSteel Heat Treatment Handboook Metalluurgy and Technologiestien100% (1)

- PW TD Arc Welding ENDocument67 pagesPW TD Arc Welding ENduniaadnanNo ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Welding ArihantDocument12 pagesWelding ArihantArihant SharmaNo ratings yet

- Research Paper On Welding CareerDocument8 pagesResearch Paper On Welding Careerfvgh9ept100% (1)

- Cutting and Grinding Equipment: Module For First Quarter Week 1Document11 pagesCutting and Grinding Equipment: Module For First Quarter Week 1JayNo ratings yet

- Engineering Workshop Lab ManualDocument74 pagesEngineering Workshop Lab ManualAnkushNo ratings yet

- Welding CompleteDocument579 pagesWelding CompleteSergioNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Reference Tables For I Ron. Const Ant An and Copper. Constantan ThermocouplesDocument19 pagesReference Tables For I Ron. Const Ant An and Copper. Constantan Thermocouplesken410309No ratings yet

- resweld-용접 변천사Document62 pagesresweld-용접 변천사Kyeong Cheol LeeNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Electron Beam Welding Steel and CopperDocument9 pagesElectron Beam Welding Steel and CopperVarma DantuluriNo ratings yet

- Electric Arc Furnace ThesisDocument6 pagesElectric Arc Furnace Thesish0dugiz0zif3100% (2)

- Ge Runout BasicsDocument14 pagesGe Runout BasicsRajagopal100% (1)

- Resistance Welding ThesisDocument5 pagesResistance Welding Thesisdwt3zbkq100% (2)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Chapter 14 WeldingDocument22 pagesChapter 14 WeldingRiian ApriansyahNo ratings yet

- Welding DictionaryDocument18 pagesWelding DictionaryEswar Enterprises QcNo ratings yet

- Friction Stir WeldingDocument30 pagesFriction Stir WeldingDilip Patel100% (1)

- Application of EbwDocument11 pagesApplication of Ebwsuman kumarNo ratings yet

- The Pattern Makers Handybook - Paul HasluckDocument198 pagesThe Pattern Makers Handybook - Paul Hasluckhbpr9999100% (3)

- FSW of Aluminium AlloysDocument45 pagesFSW of Aluminium AlloysAlexandre Lourenção CaselattoNo ratings yet

- Welding Superalloys For Aerospace ApplicationsDocument5 pagesWelding Superalloys For Aerospace ApplicationsakaretlerNo ratings yet

- Full Download Book Clinical Neuroanatomy 2 PDFDocument22 pagesFull Download Book Clinical Neuroanatomy 2 PDFruth.brown422100% (22)

- Arc - Wleding Final Exam PDFDocument13 pagesArc - Wleding Final Exam PDFronaldo de guzmanNo ratings yet

- Arc - Wleding Final ExamDocument13 pagesArc - Wleding Final ExamJhonalyne Estioco CamachoNo ratings yet

- Blacksmith's Craft: An Introduction to Smithing for Apprentices & CraftsmenFrom EverandBlacksmith's Craft: An Introduction to Smithing for Apprentices & CraftsmenNo ratings yet

- Term Paper-Sheet Metal WeldingDocument6 pagesTerm Paper-Sheet Metal Welding11gargdinesh7No ratings yet

- 1-Properties and Classification of Welding ProcessesDocument10 pages1-Properties and Classification of Welding ProcessesabastosuaptNo ratings yet

- WP Page5Document1 pageWP Page5Peanut d. DestroyerNo ratings yet

- Sheet Metal Research PaperDocument5 pagesSheet Metal Research Papergvym06g6100% (1)

- Syllabus For The Trade of Wireman: Week No:1Document43 pagesSyllabus For The Trade of Wireman: Week No:1Mohammed Abdul KaderNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Joining of Aa1050 Sheets Via Two Stages of Friction Spot TechniqueDocument13 pagesJoining of Aa1050 Sheets Via Two Stages of Friction Spot Techniquemunaf.h.ridhaNo ratings yet

- Website White Paper - Welding of Dissimilar Materials With 1KW Fiber LaserDocument12 pagesWebsite White Paper - Welding of Dissimilar Materials With 1KW Fiber LaserPardeepNo ratings yet

- "Age Ain't Nothin' But A Number": (Chorus: x2)Document1 page"Age Ain't Nothin' But A Number": (Chorus: x2)Peanut d. DestroyerNo ratings yet

- Street ThingDocument1 pageStreet ThingPeanut d. DestroyerNo ratings yet

- "Stones": (Feat. My Favorite Enemy)Document1 page"Stones": (Feat. My Favorite Enemy)Peanut d. DestroyerNo ratings yet

- PricelistDocument1 pagePricelistPeanut d. DestroyerNo ratings yet

- "Livin' The Dream": (Pre-Chorus:)Document1 page"Livin' The Dream": (Pre-Chorus:)Peanut d. DestroyerNo ratings yet

- HeartbrokenDocument1 pageHeartbrokenPeanut d. DestroyerNo ratings yet

- Rett0022 PB Purmo UkDocument183 pagesRett0022 PB Purmo UkPeanut d. DestroyerNo ratings yet

- Pricelist 2012 RRPDocument2 pagesPricelist 2012 RRPPeanut d. DestroyerNo ratings yet

- 2007 Evolve Price ListDocument194 pages2007 Evolve Price ListPeanut d. DestroyerNo ratings yet

- AC UPS SizingDocument8 pagesAC UPS SizingOlanrewaju Matthew OlabisiNo ratings yet

- Corliss Tax Price List 2011: Federal Tax Forms-Base FeeDocument1 pageCorliss Tax Price List 2011: Federal Tax Forms-Base FeePeanut d. DestroyerNo ratings yet

- PricelistDocument2 pagesPricelistPeanut d. DestroyerNo ratings yet

- Steps To Designing Structured Cabling SystemsDocument6 pagesSteps To Designing Structured Cabling SystemsPeanut d. DestroyerNo ratings yet

- Acadia Hospital Smoking Policy 7.09Document2 pagesAcadia Hospital Smoking Policy 7.09Peanut d. DestroyerNo ratings yet

- Northern Maine Medical Center Smoking Policy 2008Document2 pagesNorthern Maine Medical Center Smoking Policy 2008Peanut d. DestroyerNo ratings yet

- Smokefree Policy v2Document9 pagesSmokefree Policy v2Peanut d. DestroyerNo ratings yet

- Mayo Regional Hospital Smoke-Free 7.09Document2 pagesMayo Regional Hospital Smoke-Free 7.09Peanut d. DestroyerNo ratings yet

- Design and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyDocument69 pagesDesign and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyPartth VachhaniNo ratings yet

- OrganometallicsDocument58 pagesOrganometallicsRohit ChaudharyNo ratings yet

- Technology Multiple Choice Exam Få Fò - HWPDocument39 pagesTechnology Multiple Choice Exam Få Fò - HWPMark Darrel Aranas100% (3)

- 1.4742 enDocument2 pages1.4742 enGoran ErakovicNo ratings yet

- Steel Reference GuideDocument36 pagesSteel Reference GuideCésar VenegasNo ratings yet

- Kranich 2Document17 pagesKranich 2Rob CollisNo ratings yet

- Sleeve Anchor Data Sheet - For SubmittalDocument3 pagesSleeve Anchor Data Sheet - For SubmittalvtalexNo ratings yet

- 8J Magnets and ElectromagnetsDocument21 pages8J Magnets and ElectromagnetsPoornimaNo ratings yet

- Coolant System MaintenanceDocument2 pagesCoolant System MaintenanceDarmawan PutrantoNo ratings yet

- Pakistan Steel Marketing DepartmentDocument6 pagesPakistan Steel Marketing DepartmentHamid NaveedNo ratings yet

- Power CablesDocument48 pagesPower CablesIuliu Grad100% (1)

- Asme Section Ii A Sa-29 Sa-29m PDFDocument26 pagesAsme Section Ii A Sa-29 Sa-29m PDFHyunjong MoonNo ratings yet

- 1.9.1.2-10T - Aluminum BronzeDocument4 pages1.9.1.2-10T - Aluminum BronzechonubobbyNo ratings yet

- KSSC 3 2007 7 4 297 (C)Document13 pagesKSSC 3 2007 7 4 297 (C)ismael.lorandi623No ratings yet

- 198 Faf2500 Flanged y Type StrainerDocument4 pages198 Faf2500 Flanged y Type Strainerinfo8176No ratings yet

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- Rack and Pinion AcutatorsDocument4 pagesRack and Pinion AcutatorsRAHEEMNo ratings yet

- Spec Schedule40 Pipe Galvanized PDFDocument2 pagesSpec Schedule40 Pipe Galvanized PDFSahil SharmaNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- 484 Welding Guidelines For Design EngineersDocument4 pages484 Welding Guidelines For Design EngineersPham Song Hong100% (1)

- MetalJacket Overview CapabilitiesDocument17 pagesMetalJacket Overview CapabilitiesRajaSekarsajjaNo ratings yet

- 4.uses of Metals - 1-32 For StudentsDocument13 pages4.uses of Metals - 1-32 For StudentsnergisalihpasaogluNo ratings yet

- Unit I ' Theory of Metal CuttingDocument19 pagesUnit I ' Theory of Metal CuttingThulasi RamNo ratings yet

- RailwayDocument47 pagesRailwayusler4u94% (17)

- Strain Hardening Exponent-Sep-Oct 2005Document2 pagesStrain Hardening Exponent-Sep-Oct 20056541646No ratings yet

- C75C - Ck75 Steel DataDocument2 pagesC75C - Ck75 Steel DatavinibeNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- 20 MN CR 5Document4 pages20 MN CR 5Pulkit GururaniNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5754 H111 Treadplate 142Document2 pagesAalco Metals LTD Aluminium Alloy 5754 H111 Treadplate 142Ramon AraujoNo ratings yet