Professional Documents

Culture Documents

Silicone Rubber Cold Shrink Connector Insulators 8440 Series

Silicone Rubber Cold Shrink Connector Insulators 8440 Series

Uploaded by

hendrabudimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silicone Rubber Cold Shrink Connector Insulators 8440 Series

Silicone Rubber Cold Shrink Connector Insulators 8440 Series

Uploaded by

hendrabudimanCopyright:

Available Formats

Silicone Rubber Cold Shrink Connector Insulators 8440 Series

Data Sheet

1.0 Product Description

3M Cold Shrink Connector Insulators 8440 Series are open ended, silicone rubber, tubular sleeves. The sleeves are factory expanded and assembled on a removable supporting plastic core. Each rubber assembly is supplied for field installation in this pre-stretched condition. As the core is unwound, the insulating sleeve shrinks to form a tight seal. Three sizes of Cold Shrink Insulators cover terminal lug barrels and three sizes of Cold Shrink Insulators cover inline connectors. Each insulator type, collectively has an application range of 0.35" (8,86 mm) to 0.95" (24,13 mm) for installations on #6 AWG to 3/0 AWG.

3.0 Data: Physical & Electrical Properties High Stretch Silicone Rubber Typical Physical Properties

Test Method Color 100% Modulus ASTM D412-75 Ultimate Tensile ASTM D412-75 Die B Tear ASTM D624B-73 Shore A Hardness ASTM D2240-75 Specific Gravity Permanent Set 100% Strain - 22 hours @ 212 F/100 C Dielectric Strength ASTM D149-75 @1.78 mm thickness Dielectric Strength 168 hours in H2O @194F/90C Typical Values Grey 180 psi (1.24MPa) 1240 psi (8.55 MPa) 185 psi (1.28 MPa) 48 1.23 7.1%

Simple installation, requires only workman's hands. No tools required. No heat required for installation. Seals tight, retains its resiliency and pressure even after years of aging and exposure. Resists moisture. Wide range, size accommodation. Resists acids and alkalies. Resists ozone and ultraviolet light. Resists fluid splashes. Resists fire - will not support flame. Operating temperature range - 66 F/ - 55 C to 500F/260C.

554 Volts/mil (21.8 MV/m) 543 Volts/mil (21.4 MV/m)

2.0 Applications

Primary electrical insulation for all solid dielectric (rubber and plastic) insulated wire and cable splices rated to 1000 volts. Electrical Aircraft cables. For indoor, outdoor, in cable tray for overhead use. Physical protection and moisture sealing for high voltage, air insulated connectors and lugs. Insulation of secondary splices, copper and aluminum conductors. Sheath repairs. Insulation for inline conductor transition connector.

Page 1 of 4

78-8124-5813-7

Expanded Silicone Rubber Tube Loose Core End

B

Plastic supporting core

3/8" (9,5 mm) min.

Part Number 8443-2 8443-6.5 8445-2.5 8445-7.5 8447-3.2 8447-8

Cable Range AWG 6-2 6-2 2 - 1/0 2 - 1/0 1/0 - 3/0 1/0 - 3/0

Application Range

Inches (mm)

Dimensions

Inches (mm)

Min. Dia.* for Seal .350 (8.86) .350 (8.86) .420 (10.7) .420 (10.7) .550 (14) .550 (14)

Max. Dia.** Insulator Covers .560 (14.22) .560 (14.22) .720 (18.29) .720 (18.29) .950 (24.13) .950 (24.13)

A Length 1.4 (36) 5.2 (132) 1.7 (43) 6.2 (158) 2.3 (57) 6.8 (172)

B I.D. (Core) 0.68 (17.3) 0.68 (17.3) 0.84 (21.3) 0.84 (21.3) 1.07 (27.2) 1.07 (27.2)

Table 1

4.0 Specifications Product

Exposed metallic connectors joining power cable conductors rated 1000 volts or less shall be covered with 3M 8440 Series Silicone Cold Shrink tubular rubber insulation. The inline connections shall be insulated in accordance with the instructions provided with the 3M Cold Shrink Connector Insulator 8443-6, 8445-7.5, and 8447-8. The connecting barrel portion of terminal lugs shall be insulated in accordance with the instructions provided with the 3M Cold Shrink Connector Insulators 8443-2, 8445-2.5, and 8447-3.2.

Engineering/Architectural

5.0 Performance Tests

A. Flammability Test

The test for flammability of the 3M Cold Shrink Insulators 8440 Series was conducted with specimens positioned both vertically and horizontally per specification BSS 7230. The silicone rubber insulation passed the Flammability Test of BSS 7230 without supporting a flame. In addition, these insulators were also subjected to a gas flame test as outlined in paragraph 4.4.15 of MIL-C-24643A and met the passing criteria as specified. No fuse was blown during the one hour flame exposure.

B. Humid Environment

A silicone Cold Shrink Connector Insulators must be capable of normal operation through a temperature range of -66F/ -55C to 500F/260C. It must be usable without additional covering or adhesive both indoors and outdoors, in cable tray or overhead applications on cables rated up to 1000V. It must be applied without additional heat or flame and, when applied according to manufacturer's directions, be immediately energizable. It must not support flame or be adversely affected by moisture, mild acids or alkalies, ozone or ultraviolet light. It must provide resistance to aircraft fluids and be compatible with all rubber and plastic insulated power cables.

Test Before After Insulation Resistance 3.0 x 1012 2.5 x 10

12

Tests to verify electrical integrity through conditions of high humidity were run per Mil Standard 202Method B. The test duration was for 10 days at 104F/40C and 95% RH. Typical test values are found in Table 2.

C. Ultraviolet Resistance

After 1000 hours of testing in a Weather-O-Meter according to Specifications ASTM D750 and ASTM G23, the silicone rubber insulation exhibited no crazing, cracking or change in surface appearance.

Withstand 2500 V-rms 2500 V-rms

Result Pass Pass

Table 2

78-8124-5813-7 Page 2 of 4

D. Thermal Shock

Assembled units from the fluid resistance test were used for the thermal shock evaluation. The units were subjected to 15 cycles of the following thermal shock sequence: 1. 2. 3. 4. 30 minutes at -66F/ -55C. 5 minutes at 74F/23C. 30 minutes at 500F/260C. 5 minutes at 74F/23C.

The insulation resistance values and results of test are found in Table 3.

Fluid Monsanto L.D. Jet A MIL-L-7808 MIL-L-23699 5% Saline Test Before After Before After Before After Before After Before After Insulation Resistance 1.5 x 1013 ohms 1.0 x 1012 ohms 7.0 x 1012 ohms 1.7 x 1012 ohms 3.5 x 1012 ohms 6.5 x 1012 ohms 8.0 x 1012 ohms 3.5 x 1012 ohms 9.0 x 1012 ohms 6.5 x 1012 ohms Withstand 2500 2500 2500 2500 2500 2500 2500 2500 2500 2500 V-rms V-rms V-rms V-rms V-rms V-rms V-rms V-rms V-rms V-rms Result Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass

Table 3

E. Altitude

Electrical integrity at high altitudes was determined by testing to Mil Standard 1344A, Test method 1004.1. Typical test values are found in Table 4.

Insulation Resistance 1.0 x 1011 ohms 1.8 x 10 ohms

12

Altitude 50,000 70,000

Withstand 2500 V-rms 2500 V-rms

Result Pass Pass

Table 4

F. Heat Aging

Installed silicone rubber insulators were subjected to an eight hour heat aging test at 500F/260C. Other units were subjected to 401F/205C for 30 days. The silicone rubber remained resilient and showed no sign of deterioration.

Page 3 of 4

78-8124-5813-7

G. Fluid Resistance

6.0 Maintenance

Components of 3M Silicone PST Cold Shrink Connector Insulators are stable under normal storage conditions for a period of three years from the date of manufacture. The Cold Shrink Insulators are not impaired by freezing or overheating due to the ambient temperatures found in storage or shipping. Normal storage and stock rotation are recommended.

To determine the affect of a fluid splash on insulated connected assemblies, the units were subjected to ten cycles of the following test sequence. 1. 2. 3. 4. One minute fluid soak. 24 hour, 74F/23C ambient dry. Insulation resistance measurement. 2.4 kV-rms withstand.

Results from the fluid resistance test are found in table 5.

7.0 Availability

3M Silicone PST Cold Shrink Connector Insulators 8440 Series are available through your local authorized 3M electrical distributor.

Insulation Resistance/2500 V-rms Withstand

Fluid Splash Test

Fluid Initial 1 2 3 4 5 6 7 8 9 10 Monsanto L.D. 1.5 x 1013/Pass 3.0 x 109 ohms 1.2 x 109 ohms 4.0 x 107 ohms 1.8 x 107 ohms 8.0 x 106 ohms 6.0 x 106 ohms 5.0 x 106 ohms 4.0 x 106 ohms 4.0 x 106 ohms 3.5 x 106 ohms

Jet A 7.2 x 1012/Pass 2.0 x 1012 ohms 1.2 x 1012 ohms 1.2 x 1012 ohms 8.0 x 1011 ohms 3.0 x 1011 ohms 2.0 x 1011 ohms 1.8 x 1011 ohms 1.0 x 1011 ohms 1.0 x 1011 ohms 7.0 x 1010 ohms

MIL-L-7808 3.5 x 1012/Pass 8.0 x 1012 ohms 2.0 x 1012 ohms 2.5 x 1012 ohms 3.0 x 1012 ohms 2.0 x 1012 ohms 1.8 x 1012 ohms 1.0 x 1012 ohms 1.0 x 1011 ohms 6.5 x 1011 ohms 5.0 x 1011 ohms

MIL-L-23699 8.0 x 1012/Pass 2.5 x 1012 ohms 5.0 x 1012 ohms 4.0 x 1012 ohms 3.0 x 1012 ohms 2.5 x 1012 ohms 2.0 x 1012 ohms 2.5 x 1012 ohms 1.4 x 1012 ohms 1.0 x 1012 ohms 1.2 x 1012 ohms

5% Saline 9.0 x 1012/Pass 3.5 x 1012 ohms 5.0 x 1012 ohms 3.5 x 1012 ohms 4.0 x 1012 ohms 6.0 x 1012 ohms 7.0 x 1012 ohms 9.0 x 1012 ohms 3.0 x 1012 ohms 3.0 x 1012 ohms 5.0 x 1012 ohms

Table 5

Approximate Installed Weight Terminal Lug Insulators Part No. 8443-2 8445-2.5 8447-3.2 Weight oz. (gm) 0.123 (3.5) 0.190 (.54) 0.335 (9.5) Inline Connector Insulators Part No. 8443-6.5 8445-7.5 8447-8 Weight oz. (gm) 0.388 (11.0) 0.564 (16.0) 0.776 (22.0)

Table 6

IMPORTANT NOTICE Before using this product, you must evaluate it and determine if it is suitable for your intended application. You assume all risks and liability associated with such use. Warranty; Limited Remedy; Limited Liability. This product will be free from defects in material and manufacture as of the date of purchase. 3M MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above, your exclusive remedy shall be, at 3Ms option, to replace or repair the 3M product or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be liable for any loss or damage arising from this 3M product, whether direct, indirect, special, incidental or consequential regardless of the legal theory asserted.

Electrical Products Division 6801 River Place Blvd. Austin, TX 78726-9000 800/245-3573 www.3M.com/elpd

Printed on 50% recycled paper with 10% post-consumer

Litho in USA 3M 2003 78-8124-5813-7 Rev. B

Page 4 of 4

You might also like

- Office 365 Serial Key Plus Product KeyDocument3 pagesOffice 365 Serial Key Plus Product Keyhendrabudiman46% (13)

- Afico Faceed InsulationDocument4 pagesAfico Faceed Insulationhello1230No ratings yet

- 147 Scu RadaflexDocument8 pages147 Scu RadaflexMartin R NilssonNo ratings yet

- Silicone Rubber Cold Shrink Lug and Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Lug and Connector Insulators 8440 SeriesFrancis Jay ManaloNo ratings yet

- Guantes Trifurcacion 8560-Series HTDocument4 pagesGuantes Trifurcacion 8560-Series HTVanessa Alicia Catazi AnampaNo ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Cold Shrink Silicone RubberDocument4 pagesCold Shrink Silicone RubberNoex Xeon100% (1)

- EG Tech Bulletin ASTM C1695Document3 pagesEG Tech Bulletin ASTM C1695AuburnMfgNo ratings yet

- 3M™ Cold Shrink Silicone Rubber 3/C Cable Breakout Boots 8560 SeriesDocument7 pages3M™ Cold Shrink Silicone Rubber 3/C Cable Breakout Boots 8560 SeriesLizbeth Lizbeth AmesquitaNo ratings yet

- Electrical TapeDocument2 pagesElectrical TapemmartincikNo ratings yet

- 3M Pipeline Tape Coating System Data SheetDocument4 pages3M Pipeline Tape Coating System Data SheetWarlexNo ratings yet

- 22 Ohm ResistorDocument11 pages22 Ohm ResistorDwp BhaskaranNo ratings yet

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65No ratings yet

- Olex Nexan HandbookDocument112 pagesOlex Nexan Handbook322399mk7086No ratings yet

- Okoguard - Okoseal Type MV-105: Compact Strand ConstructionDocument2 pagesOkoguard - Okoseal Type MV-105: Compact Strand ConstructionHong TrungNo ratings yet

- 3ek7 Iec Ansi enDocument12 pages3ek7 Iec Ansi enReynaldo Flores AncietaNo ratings yet

- AFICO Heavy Density Pipe Insulation - NewDocument4 pagesAFICO Heavy Density Pipe Insulation - NewNickolas HeadNo ratings yet

- Cam LockDocument7 pagesCam LockBrant AkkanNo ratings yet

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- Cold InsulatorDocument2 pagesCold Insulatoranil4u29No ratings yet

- Polyken 936 TapeDocument2 pagesPolyken 936 TapeKyaw Kyaw AungNo ratings yet

- SpecificationsDocument4 pagesSpecificationsDeepa DevarajNo ratings yet

- Sealing and BondingDocument4 pagesSealing and BondingLovv InNo ratings yet

- Multi-B Busduct FeaturesDocument30 pagesMulti-B Busduct FeaturesSourp VartanNo ratings yet

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- Heat Shrink Cable Repair Sleeves, 25 80mm Cable Dias 3M HDCW8025Document2 pagesHeat Shrink Cable Repair Sleeves, 25 80mm Cable Dias 3M HDCW8025ELHUSSEIN TAHANo ratings yet

- Wrekin Woven Fastrack SG RangeDocument2 pagesWrekin Woven Fastrack SG Rangeryleeha07No ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Document2 pagesScotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Kishan MohtaNo ratings yet

- DF PDFDocument8 pagesDF PDFAtif JaveadNo ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- PAL Polyurethane Panel Spec 31102008Document4 pagesPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaNo ratings yet

- AS 312 SealentDocument2 pagesAS 312 SealentbhavinNo ratings yet

- Covalence WPC100M Shrink Sleeves PDFDocument2 pagesCovalence WPC100M Shrink Sleeves PDFJMROMANTNo ratings yet

- Hollow Core BushingDocument4 pagesHollow Core BushingAkhileshkumar PandeyNo ratings yet

- Tape Scotch 27Document2 pagesTape Scotch 27Victor Javier Reyes NavarroNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- Ultrasil Polymer-Housed Evolution (10 Ka) Surge ArrestersDocument12 pagesUltrasil Polymer-Housed Evolution (10 Ka) Surge ArrestersAlfonso Franco De ArcoNo ratings yet

- C 509 - 94 R99 - Qzuwos1sruqDocument6 pagesC 509 - 94 R99 - Qzuwos1sruqGustavo Adolfo Vargas MorantesNo ratings yet

- 22 Dead-End & Suspension InsulatorsDocument16 pages22 Dead-End & Suspension Insulatorsrye_eeNo ratings yet

- Raychem Spec 44Document8 pagesRaychem Spec 44zakariiNo ratings yet

- Xtreme 10 Mil Vapor Barrier Submittal - 06JUN13Document6 pagesXtreme 10 Mil Vapor Barrier Submittal - 06JUN13Binhscbm BinhscbmNo ratings yet

- 3M CtalogueDocument54 pages3M CtalogueMasoud Baig100% (1)

- Model 5000 Prefco Damper-4Document4 pagesModel 5000 Prefco Damper-4Inventor SolidworksNo ratings yet

- Insulation Application GuideDocument33 pagesInsulation Application GuideNath BoyapatiNo ratings yet

- 3M - Scotchcast - LV Hazard Area-Armoured Technical Data SheetDocument4 pages3M - Scotchcast - LV Hazard Area-Armoured Technical Data SheetMuhammad AlshafiNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- 3m qtII 5623kDocument4 pages3m qtII 5623kcerachuckNo ratings yet

- 3M Power Industry SolutionsDocument44 pages3M Power Industry Solutionstony6868No ratings yet

- 3 M Electrical CatalogDocument377 pages3 M Electrical CatalogClifton JamisonNo ratings yet

- FOAM GLASS UG Piping Insulation Underground BrochureDocument12 pagesFOAM GLASS UG Piping Insulation Underground BrochureSethuraman SaravanakumarNo ratings yet

- Insulators & TypesDocument48 pagesInsulators & Typesdilleh50% (2)

- Cable Terminal KitDocument10 pagesCable Terminal KitJohn ThomasNo ratings yet

- 5 1 Calpak Products Mark5 ManualDocument55 pages5 1 Calpak Products Mark5 ManualΑΝΑΣΤΑΣΙΟΣ ΣΑΦΡΙΔΗΣ100% (1)

- Pipe InsulationDocument50 pagesPipe InsulationSam WeberNo ratings yet

- Industrial SocketsDocument38 pagesIndustrial SocketsAyman RamzyNo ratings yet

- Connector Product Locations: GermanyDocument56 pagesConnector Product Locations: Germanywww.erwer9No ratings yet

- NewAge Silicone Catalog PDFDocument8 pagesNewAge Silicone Catalog PDFRahman FatahNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Control of Nonconformance ProcedureDocument3 pagesControl of Nonconformance ProcedurehendrabudimanNo ratings yet

- En - Fds Genlub TDXDocument6 pagesEn - Fds Genlub TDXhendrabudimanNo ratings yet

- Method Repair of Damaged Galvanized Coating For FencingDocument6 pagesMethod Repair of Damaged Galvanized Coating For FencinghendrabudimanNo ratings yet

- Attachment XXXDocument1 pageAttachment XXXhendrabudimanNo ratings yet

- Critchley Z MarkersDocument1 pageCritchley Z MarkershendrabudimanNo ratings yet

- Drager Flame 1300Document17 pagesDrager Flame 1300Mohan ArumugavallalNo ratings yet

- Size of BoltDocument1 pageSize of BolthendrabudimanNo ratings yet

- Ultrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkioDocument4 pagesUltrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkiohendrabudimanNo ratings yet

- Main Electrical Earthing Conductor Tag: As Required Under AS/NZS 3000:2007 Clause 5.5.1.3Document1 pageMain Electrical Earthing Conductor Tag: As Required Under AS/NZS 3000:2007 Clause 5.5.1.3hendrabudimanNo ratings yet

- DM GL1002-2008r0 PSDDocument5 pagesDM GL1002-2008r0 PSDhendrabudimanNo ratings yet

- E-Z-Code: "Mr. Ouch" - NEMA Safety LabelsDocument1 pageE-Z-Code: "Mr. Ouch" - NEMA Safety LabelshendrabudimanNo ratings yet

- Terminal Blocks: NEMA TypeDocument24 pagesTerminal Blocks: NEMA TypehendrabudimanNo ratings yet

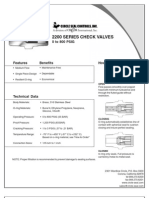

- 2200 Series PDFDocument3 pages2200 Series PDFhendrabudimanNo ratings yet

- Terminal Blocks: IEC TypeDocument20 pagesTerminal Blocks: IEC TypehendrabudimanNo ratings yet

- CVH Series PDFDocument9 pagesCVH Series PDFhendrabudimanNo ratings yet

- 2100 2800 Series PDFDocument2 pages2100 2800 Series PDFhendrabudimanNo ratings yet

- 100 Series PDFDocument2 pages100 Series PDFhendrabudimanNo ratings yet

- Different Types of PliersDocument5 pagesDifferent Types of PliersBhanuka Srikantha100% (1)

- MEGGERDocument2 pagesMEGGERHMBPNo ratings yet

- Group 1, Double Bedroom WiringDocument19 pagesGroup 1, Double Bedroom WiringAarthi RashmiNo ratings yet

- Al 38/66kV: HV Cables With Longitudinal Water-Blocking SystemDocument4 pagesAl 38/66kV: HV Cables With Longitudinal Water-Blocking SystemCarlos PlaceresNo ratings yet

- Water Cooled Copper Magnet CoilsDocument1 pageWater Cooled Copper Magnet Coilstsram90No ratings yet

- ELEC9712 - Lec5 - Overhead Lines PDFDocument60 pagesELEC9712 - Lec5 - Overhead Lines PDFsauravkafle1No ratings yet

- Insulator Quantity Required For IsolatorsDocument2 pagesInsulator Quantity Required For IsolatorsNavaneetha KrishnanNo ratings yet

- IEC Stdandards 1 3Document77 pagesIEC Stdandards 1 3Shanmuga Baskar0% (2)

- Physics Art Integration Project: ElectrostaticsDocument16 pagesPhysics Art Integration Project: ElectrostaticsCHIEF VISHAAL 45No ratings yet

- Spec SheetDocument2 pagesSpec SheetArmando Huaraya ReinozoNo ratings yet

- Panel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFDocument14 pagesPanel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFENGMNo ratings yet

- Electrical Safe Work PracticeDocument138 pagesElectrical Safe Work PracticeIjaz HussainNo ratings yet

- FR3 Change From Mineral Oil in Transformer Na3072835Document4 pagesFR3 Change From Mineral Oil in Transformer Na3072835classicalgasNo ratings yet

- Sc1200ud-Us/sc1375ud-Us/ Sc1575ud-Us/sc1725ud-UsDocument73 pagesSc1200ud-Us/sc1375ud-Us/ Sc1575ud-Us/sc1725ud-UsGopi Laal BahadurNo ratings yet

- IEEE STD 1050-2004 IEEE Guide For Instrumentation and Control Equipment Grounding in Generating StationsDocument101 pagesIEEE STD 1050-2004 IEEE Guide For Instrumentation and Control Equipment Grounding in Generating Stationsleonel100% (2)

- Abb Switch Disconnectors 1Document3 pagesAbb Switch Disconnectors 1Farid GergesNo ratings yet

- TClad Selection GuideDocument27 pagesTClad Selection GuideTheBergquistCompanyNo ratings yet

- Schneider Electric XUB0BPSNL2 DatasheetDocument2 pagesSchneider Electric XUB0BPSNL2 DatasheetFouad NadjiNo ratings yet

- SAG Mill Drive Motor InspectionDocument8 pagesSAG Mill Drive Motor InspectionMauritz RoniNo ratings yet

- Makalah Seminar Omicron 24-25 Juli 2018Document90 pagesMakalah Seminar Omicron 24-25 Juli 2018Budi Norton100% (1)

- IECEx BAS 06.0028X R3Document5 pagesIECEx BAS 06.0028X R3cday10126No ratings yet

- RTA52 (U) - RTA62 (U) - RTA72 (U) Cylinder Liner With Insulation Tubes and Insulation BandagesDocument10 pagesRTA52 (U) - RTA62 (U) - RTA72 (U) Cylinder Liner With Insulation Tubes and Insulation BandagescarmaNo ratings yet

- DC Hi-Pot Testing Rev 1Document6 pagesDC Hi-Pot Testing Rev 1Muhammad Taufiq100% (2)

- High Voltage Insulation Coatings.Document2 pagesHigh Voltage Insulation Coatings.Vinay TungeNo ratings yet

- 02 Abb PM Inst Book-Tank Density MTRDocument64 pages02 Abb PM Inst Book-Tank Density MTRDean BartlettNo ratings yet

- G. Transmission LineDocument16 pagesG. Transmission LineJosNo ratings yet

- 3 M Fire Barrier Duct Wrap 15 ADocument20 pages3 M Fire Barrier Duct Wrap 15 ArasheedillikkalNo ratings yet

- Electrical System Data SheetDocument9 pagesElectrical System Data SheetpmlikrishnaNo ratings yet

- Proposed Tentative Standard For High Expansion Foam Systems (Expansion Ratios Over 100:1)Document26 pagesProposed Tentative Standard For High Expansion Foam Systems (Expansion Ratios Over 100:1)krivitskiNo ratings yet

- Pilz 773500MDocument24 pagesPilz 773500MprajwalNo ratings yet