Professional Documents

Culture Documents

Jurgen Dorm, Christian Doppler Laboratory For Expert Systems

Jurgen Dorm, Christian Doppler Laboratory For Expert Systems

Uploaded by

fernndOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jurgen Dorm, Christian Doppler Laboratory For Expert Systems

Jurgen Dorm, Christian Doppler Laboratory For Expert Systems

Uploaded by

fernndCopyright:

Available Formats

Jurgen Dorm, Christian Doppler laboratory for Expert Systems

EEL PRODUCTION INVOLVES A number of stages, such as melting, casting, rolling, and forging, that entail complex chemical and thermic reactions as well as intricate mechanical operations. Because these processes do not lend themselves to exact mathematical modeling, steel manufacturers must turn to techniques for reasoning with incomplete and uncertain data. Their decisions often rely on the experience of individual experts. Nearly all steelmakers worldwide now use expert systems, fuzzy logic, and neural nets to improve quality assurance and production efficiency. This special track of IEEE Expert looks at several typical, successfully fielded systems. For many years, the steel industrys main objective has been to maximize production by automating processes and streamlining plant organization. As with the Republic of Koreas Kwangyang Works, steel manufacturers have been erecting new plants from

18

scratch, locating them near the sea to make the delivery of steel from blast furnace to final shipment as direct as possible. Because they restricted the diversity of their products, such new plants have become very competitive. Asias steel industry, in particular, used these approaches in the 1980s to produce high-quality steel cheaper than its Western competitors. (See the sidebar for historical overview of steel production.) However, the continuing improvement of substitutes for steel has raised the demand for even higher-quality steel with dedicated characteristics. By using different alloying metals and various heat and surface treatments, steelmakers now can offer a manifold of products. Ongoing research into new steel qualities has produced a broad range of products, which present many newcontrol problems. Although other industries reflect the same tendency toward processing in smaller lot sizes, the steelmaking environment shows more diversity than most be0885-9000/96/$4 00 0 1996 IEEE

cause of the particular characteristics of its matenal and manufactunng technology Furthermore, the capital-intensive nature of the industry can make unanticipated violakons of technological constraints extremely costly A look at several typical factors will illustrate these considerations Most steelmaking processes are temperature-sensitive For each process, the steel must have aprescribed temperature, and any time it spends waiting on the next processing step will incur a costly reheating. Moreover, because chemical reactions depend on temperature, any loss of heat during processing may degrade the steels quality Iithe prescribed sohkfication temperature profile is violated, an incorrect internal structure of the steel might result Although process ames are difficult to predict precisely, steelmakers do exercise some degree of control. Treatment time in furnaces depends on the temperature, which can be controlled through heat input, generally subIEEE EXPERT

Historical overview on steelmaking

j e c t to w i n e global energy constraint. Steel-

maher\ c;in a l s o control casting and rolling tiiiic\ to w i n e extciit by varying the speed at \\ hich they run thc caster or rolling mill. By slouing ;I process down if it appears that an ordei- uill arrive too early at the next riggre, g r r i i , . 01\peeding it up if it appears it will arr i \ c too late. they can also use real-time proce\s control t o meet requirements for synchronicity. (An aggregate is a common steelmahing term lor machine.) Tec h no Iogical cons ide i-at ions in the proeltiction of' highei- grades of steel impose reqiiireincnts on the sequence in which orders arc pi-oduccd. Chemicals added to steel to ;ichie\ c certain charucterirtics react with the \teelmahiny aggregate. Residuals remain in the agyrcgate and may be absorbed by one of the n e x t orders. which inay be corrupted by thi\ infiltration. The width and thickness ot the stccl product also constrain sequences i n the ca9ring and rolling processes. Production-run ciigineers will avoid some obviously incompatible sequences, but sometimes \chediilc incompatible ones anyway for lack o f a closed tractable causal model that would prei ent them from doing s o . Afterward, cau\al models can explain these errors, and this negative experience will lead to a modification of the production process.

Compared to other industries,iron and steel production has a very long history. Archaeologists have found iron tools, weapons, and omaments in prehistoric tombs, and between 1350 and 1100 BC early societies in various parts of the world had begun smelting iron ore into iron on a large scale. The earliest smelting was done in primitive, charcoal-fueledhearths that used wind power to provide combustion.This direct reduction produced a soft, malleable wrought iron. which early ironworkers then forged by hammering. Hearths soon gave way to simple blast furnaces. Reaching a height of 16 feet by I350 AD, these fumaces were continuously charged with iron ore and charcoal,and later limestone, ;I\ the smelting process evolved. Because the produced high-carbon iron was rather brittle, i t could neither be rolled nor forged. The first indirect reduction occurred in Belgium about 1620. The two-step procedure first used an initial smelting to eliminate the ore's oxygen content. The second step purified the resulting pig iron, removing carbon and other elements.Later improvements involved the u s ~ ing and handling of the steel. Because improvements in steelmaking usually entail huge investments,the modern steel plant evolves slowly over decades. A new fundamental technology seems to arise every I O t o 15 years that requires a reorganization of the production process. The introduction olcontinuous casters in the late 1970s marked a such great turning point. Casters have enhanced the productivity significantly, but the need to continuously feed them creates new problems. Minimills for rolling small lots are the latest profound innovation.

Automating production

The nature of these problems that complicate production control-the vagueness and a h ;iy\-changing nature of the knowledgeha\ prevented steelmakers from making c l o \ e d control loops for steel production. Thi\ industry has always been very innovat i l e i n the application of new production technologic\ and the latest computer technology. I t was one of the first. for example, to :ipply fault-tolerant computer systems to fulfill the high requirements for availability and reliability o f control systems. Despite t h i \ I-apid automation. the process operator ha\ remained ;in important link in the production proce\s. and with the introduction of thew new control \ystems. operators are being overloaded with proce5s data. (Sec tht: moclern steel production sidebar, next page.) The stecl industry adopted expert systems relatively early lor further automating production. The five leading Japanese steel companic\ reported the first successful applicat i o n s . ' The designers o f the Scheplan whecluling system. for instance, claimed that

~~

its operation saved $ 1 million a year by reducing the time that ladles carrying hot steel to the casters must wait.' Although quality optimization and energy consumption are important aims, the most important motivation for applying expert systems seems to be production standardization. In the steelmaking plant, for example, it is more important to have a safe and continuous supply from the blast furnace than a high, but irregular, supply. Because there is so much freedom in production decisions, it is better for quality assurance purposes to have formal rules about how to proceed, even if they are less than optimal. Having an expert system that acts as a consultant or even as a decision maker will make decisions more transparent.

impossible to iiieii\urc the teinperaiurc 111side the furnace. so htincli-eel\ 01' \cti\ot.\ O I I the walls indirectly nic;i\tii-c tlic hol iiict:il.\ temperature. Existing expert $1\teiiij addre\\ t~ o problerns: predicting abnormal \ittiation\ \tic11 ;I\ slips (abnormal and \tidclcn de\cciicliiig\ of the raw matcrinl\ charged i n tlic l u i nace) and channeling (tlic heated g;i\ reache\ the top ofthe l'iiriiace \\ i t l i o i i t rc'action) and keeping the thermal coliclition stahlc,. Operator\ can adjii\t furnace lieat IC\e l \ and hot-metal temperattire\ t>> 1ii;in 1 pi1x1I 112 such variables a s ore-to-cokc ratio\. hla\t temperature\, fuel-iii,jection IC\ cl \. iiiicl t>la\t moisture levels. If the hot-rnctal \ i l i c o i i falls below the desired \ alue. the hot-iiictal temperature will ; i I w he below i t \ goal. 'l'lic operator will need to iiicrciw the heat l c \ e l . The problems i n controlling t h i \ procc\\ ~ r c the long reaction time\ a n c l the tlil'lcren~I-cactions of human operators. I n d i \ idual operatorb use dillerent ;ictioiis. art tlieiii ;II (111ferent times. and apply clillcrcnl magiiitutle\ of change\. Thcy also I'rcqucritly u\c old tliita from previou\ c;i\es to clccitle irc~ictioii\. Mos t bl a\ t I'Llr1i:lce\ 111a~iagcI'\ t hc I'C' I (11 c aim not to optimic.e hut to \(ariclardi/e t h i \ control. The unccrtninty ol'iiian) clata \ ;iluc\ makes it difficult to find ;I \iiiiplc control ZIIgorithm. An cxpcrt \) \ t c i i i lei\ ii1;iiiuI;ictiircrs build ;I moclel o l the ph) \ic;iI and c,liL>iiiical prows\ in the I'tirti;ice u i t l i \! tiiholic values. abs tract ing from t lie [ Ii() ti \:iiicl\ o 1

19

Applying expert systems

Steelmakers apply expert systems instead of conventional software because the controlling software has to reason with existing uncertainties and master the inherent complexity of typical control problems. The control ofthe blast furnace illustrates i\sut.s motivating the iniplernentation of expert systems. The main focus of the blast furnace quality improvement effort is hot-metal silicon variability. This is controlled by the heat levels inside the furnace. If the furnace is too hot, the silicon will increase; too cool, s i l i con levels will decrease. Unfortunately. it is

FEBRUARY 1996

~~ ~

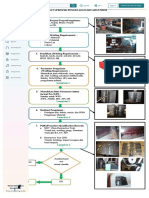

Modern steel production and control

Steel production requires different groups of processes often involvproducts up to 1200C in a reheat furnace eliminates surface defects ing different plants. In the iron-making stage, steelworkers charge iron and prepares them for hot rolling. This process also poses many control oxide (pellets, sintered ore, or iron ore), coke, and limestone in layers problems, both in combustion efficiency and steel exit temperature. into a blastfurnace to produce pig iron. Typically, a blast furnace can Steelmakers control the reheating process with mathematical models, hold several thousand cubic meters and operates continuously for about linear programming, and expert systems. The control of the reheating IO years before shutting down for repairs. process is closely linked with the hot-metal process. Starting at the top of the furnace, the charge takes about eight hours Other steps involve rolling the cast goods in the rolling mills, first to descend through the shaft. Solid, liquid, and gas coexist in the blast rolling the steel warm and then cold to achieve high accuracies in surfurnace, with heat exchanges and reduction reactions governing the face structure, dimensions, compression, and impact strength. These phenomena inside. These are expressed in terms of furnace conditions stages each involve several passes. The rolling process greatly affects and heat. Changes in the properties of the raw materials and the changthe quality of the final product, so the thickness, shape, and chemical ing profile of the furnace body disturb the furnaces operation. The properties of the rolled steel require highly accurate control. Controlprocess consumes huge amounts of energy. ling the pace of the mill presents another problem, one that involves deSpecial torpedo cars transport the liquid pig iron tapped from the termining the optimum reheating furnace discharge interval to allow blast furnace (up to 10,000tons of hot metal per day for large blast furthe hot rolling mill to run continuously. naces) to the steelmaking shop. Here, basic oxygenfumaces (BOF) reFinally, the rolling mill produces a variety of steel products. Batch or tine the iron steel to the desired composition by blowing oxygen into continuous annealing completes the processing of the steel and deterthe hot metal, which oxidizes impurities. During each run, or hear, the mines the properties of the final products. Here, the mill heats steel processing of up to 300 tons of pig iron takes about 20 to 30 minutes. products to a predetermined, closely controlled temperature for a given Steelworkers must control molten steels composition and temperalength of time to obtain the desired quality. The final stage may involve ture. Such control is especially critical in the oxygen-blowing step. a variety of operations such as pickling (descaling coils with acid), Recently, because of the increased use of continuous casting and widetempering, or coating of the produced coils, pipes, wires, and plates, before shipment to customers. (Figure A shows the cross section of a spread use of hot-metal pretreatment, the requirements for blowing control have become stricter. If no direct charging from the blast typical high-grade steel.) furnace is possible or if huge amounts of (cold) scrap iron are charged, plants must use electric arc furnaces to smelt the metal, a process that requires a huge amount of energy and takes considerably longer than the BOF converter process. Next comes ladle refinement, where the liquid steel is poured into ladles, before cranes transport it to various refinement aggregates (machines).In making the various grades of steel that customers order, these aggregates eliminate further impurities and add further alloying metals. The last stage in the steelmaking shop either uses continuous casters to cast the steel into billets, blooms, or slabs, or a more traditional process that involves making ingots, soaking the ingots, and passing them through a slabbingblooming mill. In continuous casting, real-time control is very important. Fluctuations in the level of molten steel in the mold of the caster cause inclusions of gas in the metal Figure A. Cross section (x600) of K1OO steel produced at Austrias Bohler Uddeholm plant. An ocid-treated austenit, it and surface defects. Heating the cast contains 1.23% carbon, 0.4% silicon, and 12.5% manganese.

measured data values. Rules allow the specification of certain standards-when and how an operator should react. One of the first well-described systems in this domain was Nippon Steels Artificial and Logical Intelligence System (ALIS), which controls several blast furnaces. Comparisons between human and expert system performance showed that in 25% of the cases studied. the expert system performed better and only in 7% did the human excel. Fur-

thermore, the system is continually modified to improve its competence.

This issue

Today, as the latest conferences on production control in steelmaking show, almost every steelmaker-from developing countries to the traditional steelmakers-applies expert systems.4 O n e great challenge now

facing the steel industry is to improve the self-adapting capabilities of expert systems. A s mentioned, modifications of the production process are quite regular. and the tendency is to adopt even more flexibility. Intelligent steelmaking aggregates that adapt themselves to new steel compositions and requirements for the produced good are i n portant research topics now. Kcscarch into intelligent organizers that can learn ne& strategies if the manufacturing objective or I E E E EXPERT

~ ~~

the production technology changes is also ongoing. The first article, by Nicolas Pican, Frkdkric Alexandre, and Patrick Bresson, addresses this issue. They have developed a system that incorporates an artificial neural network to preset the parameters of a steel temper mill. They also show that a combination ofAI and conventional techniques often solves industrial problems best. An intermediate step in self-learning systems are systems that assist human experts. Because users of expert systems are not familiar with expert system techniques, they need simple techniques to adapt a system to new production facilities and strategies. The article by Jiirgen Dorn and Reza Shams describes experience along these lines and makes propositions for improving this capability. A focus of future research is the cooperation between expert systems in the steel industry. At the moment, expert systems are singleuser, front-end computer systems dedicated to one function. Their integration with the existing organization is very simplistic. Most systems couple to a process computer or a production-planning system to obtain required input data. However, stronger coupling would increase the benefits of expert systems. The simplest solution is an expert system that performs this cooperation as its main task. However, a more generic approach would let expert systems cooperate in an open framework. For example, a steelmaking shop scheduling system should receive knowledge of the status of the blast furnace, because the supply situation will influence the scheduling strategy. More useful would be cooperation between a scheduling system and an intelligent machine such as a caster that can decide which sequences are good and when maintenance operations should occur. Negotiations are also necessary between a steelmaking plant and its customersthe rolling mills and other plants. Because these plants operate under different sequencing criteria, a best sequence for one plant is not necessarily good for the other. Despite even more pervasive automation in the future, human experts will remain unavoidable for production control in the steel industry, because new production failures that cannot be handled adequately by a system occur quite regularly.

Jiirgen Dorn is a senior researcher at the Chris-tian Doppler Laboratory for Expert Systems in Vienna, a basic research laboratory established by the Austrian steel industry to improve technology transfer from universities to steel industry. He received his MS and PhD in computer science from the Technical University of Berlin. He was involved in the development of two scheduling expert systems for the Austrian steel industry and works as a consultant for the international steel industry in the field of expert systems. He is member of the AAAI. Readers can contact him at the Christian Doppler Laboratory for Expert Systems, Vienna Univ. of Technology,Paniglgasse 16,A-1040 Vienna, Austria; dom@dbai.tuwien.ac.at.

Real World Artificial Intelligence

The leader in Reasoning Technologies

THE provides a completefamily of high performance, embeddable AI software components.

References

1. T. Saito, Application ofArtificial Intelligence in the Japanese Iron and Steel Industry, Proc. Sixth Intl Federation ofAutomatic Control Symp. Automation in Mining, Mineral andMetal Processing, 1989,pp. 30-38. 2. M. Numao and S. Morishita, Scheplan-AScheduling Expert for Steelmaking Process, Proc. Fourth C o f Artificial Intelligence Applications, AIAAPress, Menlo Park, Calif., 1988, pp. 467472.

3. S. Amano et al., Expert System for Blast Furnace Operation at Kimitsu Works, J. Iron and Steel Inst. of Japan, Vol. 30, No. 2, 1990, pp. 105-1 10.

4.

Preprints ofthe Intl Con$ on Computerized Production Control in Steel Plant, The Korean Institute of Metals and Materials, Seoul, 1993.

Call (800) 233-2622for afree trial

Fax: [I] (412) 741-6457, E-Mail : info@Haley.COM The Haley Enterprise, Inc., 413 Orchard St., Sewickley PA 15143, USA

FEBRUARY 1996

Reader Service Number 2

You might also like

- Casting Project ReportDocument47 pagesCasting Project ReportMohak60% (5)

- What Pipeliners Need To Know About Induction Bends PDFDocument20 pagesWhat Pipeliners Need To Know About Induction Bends PDFmarcos2dami2o2de2azeNo ratings yet

- Standards For High Integrity and Structural Die CastingDocument204 pagesStandards For High Integrity and Structural Die CastingThomas S R100% (1)

- Magnetic BRGDocument147 pagesMagnetic BRGVijayTijare100% (1)

- (Ksw?Tl3Utlon QF This Document Is Unlim!TedDocument9 pages(Ksw?Tl3Utlon QF This Document Is Unlim!TedAlfian PangestuNo ratings yet

- Concepts of Electric Arc Furnace Fume ControlDocument5 pagesConcepts of Electric Arc Furnace Fume ControlAshutosh SinghNo ratings yet

- Unesco - Eolss Sample Chapters: Automation and Control in Iron and Steel IndustriesDocument8 pagesUnesco - Eolss Sample Chapters: Automation and Control in Iron and Steel IndustriesShatrughna SamalNo ratings yet

- Blast Furnace Design of The FutureDocument10 pagesBlast Furnace Design of The FutureSamanway DasNo ratings yet

- The New Copper Casting-Machine: Experiences at FerroatlanticaDocument8 pagesThe New Copper Casting-Machine: Experiences at FerroatlanticaJuan Bautista HernándezNo ratings yet

- CHE 410 Fundamentals in Plants Equipment InstrumentationDocument34 pagesCHE 410 Fundamentals in Plants Equipment InstrumentationEilyza AballaNo ratings yet

- Metallurgical Changes in SteelsDocument16 pagesMetallurgical Changes in SteelsJafer Sathiq JaferNo ratings yet

- Casting1 PDFDocument76 pagesCasting1 PDFahmedNo ratings yet

- Steel Alerts Vol.5 No.3Document24 pagesSteel Alerts Vol.5 No.3Learnscoop Inc.No ratings yet

- Hot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFDocument11 pagesHot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFradinasrNo ratings yet

- Roller Hearth Kiln - IjoeDocument6 pagesRoller Hearth Kiln - IjoeSunit AroraNo ratings yet

- TMTDocument52 pagesTMTAtulNo ratings yet

- Safety and Health in Iron and Steel Industry: Faculty In-Charge: ASHWIN C ADocument7 pagesSafety and Health in Iron and Steel Industry: Faculty In-Charge: ASHWIN C ArameshNo ratings yet

- Steel Industry Research PaperDocument4 pagesSteel Industry Research Papers0l1nawymym3100% (1)

- The Fracture of Brittle Materials: Testing and Analysis, First Edition. Stephen W. FreimanDocument5 pagesThe Fracture of Brittle Materials: Testing and Analysis, First Edition. Stephen W. Freimandarebusi1No ratings yet

- 02 Whole X XXXXXXXXXXXXXX 80Document109 pages02 Whole X XXXXXXXXXXXXXX 80Danem HalasNo ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- Induction BendingDocument20 pagesInduction BendingAnoop N Kutty100% (4)

- Integration of Continuous Caster and Hot Strip Mill Planning For Steel ProductionDocument28 pagesIntegration of Continuous Caster and Hot Strip Mill Planning For Steel Productionusama_ahmedNo ratings yet

- Latas Eletrosoldadas Aspectos Tecnológicos e Avaliação Da QualidadeDocument85 pagesLatas Eletrosoldadas Aspectos Tecnológicos e Avaliação Da QualidadeSandro Sene100% (1)

- Remaining Life Assessment of RefineryDocument36 pagesRemaining Life Assessment of RefineryCostynha100% (2)

- Electrohydraulic FormingDocument4 pagesElectrohydraulic Formingtlolor833No ratings yet

- 00emerging Technologies For Iron and SteelmakingDocument16 pages00emerging Technologies For Iron and Steelmakingvasundhara singhNo ratings yet

- Failure Analysis of Tube and Shell Heat ExchangerDocument5 pagesFailure Analysis of Tube and Shell Heat ExchangerIJRASETPublicationsNo ratings yet

- CryostatDocument45 pagesCryostatSubhajit MondalNo ratings yet

- Arc Furnace - Electric - Arc - Furnace - Modelling - and - Contr PDFDocument12 pagesArc Furnace - Electric - Arc - Furnace - Modelling - and - Contr PDFsaiko_searchNo ratings yet

- Steel Plant Case StudyDocument8 pagesSteel Plant Case StudyShabeerNo ratings yet

- Control of Slopping in Basic Oxygen Steel MakingDocument72 pagesControl of Slopping in Basic Oxygen Steel MakingNarasimha Murthy InampudiNo ratings yet

- TP 77 Pap PDFDocument8 pagesTP 77 Pap PDFJaved MohammedNo ratings yet

- Fundamentals of The EAF ProcessDocument54 pagesFundamentals of The EAF ProcessradynasrNo ratings yet

- Otegui 2015Document18 pagesOtegui 2015CHONKARN CHIABLAMNo ratings yet

- Aluminium Pressure Die CastingDocument11 pagesAluminium Pressure Die CastingMarcos100% (1)

- Some Characteristics of Weld Repair For Creep ApplicationsDocument32 pagesSome Characteristics of Weld Repair For Creep ApplicationsXNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- Fine Production in Steelmaking Plants: SciencedirectDocument10 pagesFine Production in Steelmaking Plants: Sciencedirecthalla kerkacheNo ratings yet

- SIC Refractory CastableDocument5 pagesSIC Refractory CastableJagadeesh GuttiNo ratings yet

- Process Control Is Vital To Heat-TreatingDocument2 pagesProcess Control Is Vital To Heat-TreatingJader PitangueiraNo ratings yet

- GSC Steam Turbine CastingsDocument10 pagesGSC Steam Turbine CastingsJozsef Magyari100% (1)

- Ksbsig LIGs KV Eq AajcrDocument6 pagesKsbsig LIGs KV Eq AajcrRaphael Damasceno MarottaNo ratings yet

- Failures of BoilersDocument7 pagesFailures of BoilersTeuku Rizal El SilencioNo ratings yet

- 9 Strip Casting Technology PYMenetDocument5 pages9 Strip Casting Technology PYMenetNikolas Kolasni Lakenir Ckerde DockosNo ratings yet

- Manufacturing Process Crucible FurnaceDocument6 pagesManufacturing Process Crucible FurnaceCristian MosqueraNo ratings yet

- 20Document55 pages20José Arlindo FrancoNo ratings yet

- Hot Rolling ThesisDocument8 pagesHot Rolling ThesisClaire Webber100% (1)

- Basic Machining Operations: 1. Table of ContentsDocument7 pagesBasic Machining Operations: 1. Table of Contentsdjdjfj123No ratings yet

- How Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingDocument4 pagesHow Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingTS WongNo ratings yet

- 2012GEPESZET Dynamic Mass Balance For AaiDocument12 pages2012GEPESZET Dynamic Mass Balance For AaiLukas DionNo ratings yet

- Preheating and Start-Up of Prebaked Aluminium Reduction CellsDocument11 pagesPreheating and Start-Up of Prebaked Aluminium Reduction CellsNitin RautNo ratings yet

- Metallurgy and Mechanics of Welding: Processes and Industrial ApplicationsFrom EverandMetallurgy and Mechanics of Welding: Processes and Industrial ApplicationsRegis BlondeauNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionFrom EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Charpy Impact TestDocument2 pagesCharpy Impact TestShakthibalan MagalingamNo ratings yet

- Conplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionDocument3 pagesConplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionAditya KrisnandaNo ratings yet

- Material Safety Data Sheet: Section 1: Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1: Product and Company IdentificationIka KusumawatiNo ratings yet

- 7.1 - Cooling Water SystemDocument8 pages7.1 - Cooling Water SystemSayem kaifNo ratings yet

- Structural Rietveld Refinement, Morphological and Magnetic Features of Cudoped CoeCe Nanocrystalline Ferrites For High Frequency ApplicationsDocument11 pagesStructural Rietveld Refinement, Morphological and Magnetic Features of Cudoped CoeCe Nanocrystalline Ferrites For High Frequency ApplicationsAhad Ali KhanNo ratings yet

- Catalog - Norton Abrasive Product Solutions For The Full Line Stock Industrial Market - 7362 - 2017 BA IndustrialDocument37 pagesCatalog - Norton Abrasive Product Solutions For The Full Line Stock Industrial Market - 7362 - 2017 BA IndustrialCătălin BăicoianuNo ratings yet

- Unit Cost Analysis: Project: St. Luke's Medical Center 1 3. UNIT: MDocument22 pagesUnit Cost Analysis: Project: St. Luke's Medical Center 1 3. UNIT: MJamalNo ratings yet

- MI Renewable Methanol Pathways White Paper FinalDocument26 pagesMI Renewable Methanol Pathways White Paper Finalthajoka23No ratings yet

- TDS - Zeolite GranularDocument1 pageTDS - Zeolite GranularErik YerzyNo ratings yet

- 1.4418-Stainless Soft Martensitic Chromium-Nickel-Molybdenum SteelDocument2 pages1.4418-Stainless Soft Martensitic Chromium-Nickel-Molybdenum SteelwholenumberNo ratings yet

- Culvert Construction (Boq)Document3 pagesCulvert Construction (Boq)Siddiqur RahmanNo ratings yet

- Research On Effluent-Oxidation PondDocument6 pagesResearch On Effluent-Oxidation PondCHIN FelleNo ratings yet

- Uc2610 - Schottky BridgeDocument13 pagesUc2610 - Schottky BridgePaulo ReginattoNo ratings yet

- Tugas Destructive Test Welding UNY 2017Document10 pagesTugas Destructive Test Welding UNY 2017G. YUDHA FATRIA EGIANSYAH gyudha.2019No ratings yet

- Teaching How To Determine The Charpy Impact - UG-84 of The ASME VIII-1Document14 pagesTeaching How To Determine The Charpy Impact - UG-84 of The ASME VIII-1Mario MolinaNo ratings yet

- LOCTITE 2422-tdsDocument4 pagesLOCTITE 2422-tdsIndo KalbarNo ratings yet

- Sans2001 DP4 2010 - Ed1 SewerDocument37 pagesSans2001 DP4 2010 - Ed1 SewerRoland BritzNo ratings yet

- Gubwe - TVCCDocument1 pageGubwe - TVCCAnonymous 9rM4GbfuQKNo ratings yet

- CDPO RajupalemDocument161 pagesCDPO RajupalemCharan ReddyNo ratings yet

- Walksum Caster Wheel 230120 160857Document43 pagesWalksum Caster Wheel 230120 160857pratham surgicalNo ratings yet

- Project Mba 1ST SemDocument9 pagesProject Mba 1ST SemJyoti GaurNo ratings yet

- Clearance For Plaster by MEPDocument63 pagesClearance For Plaster by MEPAnonymous LnJVtahyRNo ratings yet

- 1.apexior 3 PDFDocument1 page1.apexior 3 PDFTolias EgwNo ratings yet

- Process For The Manufacturing of Copper SulphateDocument3 pagesProcess For The Manufacturing of Copper Sulphaterajesh80% (5)

- Tridol Atf 3-3Document2 pagesTridol Atf 3-3mario.No ratings yet

- Troubles of Heating CD: Processing ErrorsDocument14 pagesTroubles of Heating CD: Processing ErrorsOsama Fadel ahmedNo ratings yet

- Concepts in Structural Steel DesignDocument14 pagesConcepts in Structural Steel DesignMelchizedek EllNo ratings yet

- Weak InteractionsDocument9 pagesWeak InteractionsShridevi RaviNo ratings yet

- ReologiaDocument13 pagesReologiaRomuloNo ratings yet

- Compounds: Introduction To Bonding: Prepared By: Romaenia S. Salazar, RMT, MATDocument44 pagesCompounds: Introduction To Bonding: Prepared By: Romaenia S. Salazar, RMT, MATKat JornadalNo ratings yet