Professional Documents

Culture Documents

Rockwool LRB Mattresses: ROCKWOOL LRB Mattresses Are Not Hazardous To Health and Do Not Contain Asbestos. (See RIL MSDS)

Rockwool LRB Mattresses: ROCKWOOL LRB Mattresses Are Not Hazardous To Health and Do Not Contain Asbestos. (See RIL MSDS)

Uploaded by

Anwar SyedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rockwool LRB Mattresses: ROCKWOOL LRB Mattresses Are Not Hazardous To Health and Do Not Contain Asbestos. (See RIL MSDS)

Rockwool LRB Mattresses: ROCKWOOL LRB Mattresses Are Not Hazardous To Health and Do Not Contain Asbestos. (See RIL MSDS)

Uploaded by

Anwar SyedCopyright:

Available Formats

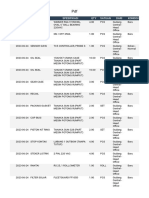

THERMAL CONDUCTIVITY

The thermal conductivity of ROCKWOOL LRB Mattresses as per ASTM, C 177, 518 is presented in the tables below:

ROCKWOOL LRB MATTRESSES

Mean Temperature

THERMAL CONDUCTIVITY IN W/m.K FOR THE FOLLOWING DENSITIES IN kg/m3

Mean Temperature

THERMAL CONDUCTIVITY IN BTU.in/ft2h.F FOR THE BELOW DENSITIES IN lbs/ft 3

C

50 100 150 200 250 300 350

80 0.038 0.044 0.053 0.062 0.070 0.086 0.102

96 0.037 0.043 0.050 0.059 0.068 0.081 0.095

100 0.037 0.043 0.051 0.060 0.069 0.082 0.095

120 0.038 0.045 0.051 0.060 0.070 0.083 0.091

128 0.039 0.046 0.052 0.060 0.070 0.082 0.091

144 0.039 0.046 0.051 0.059 0.069 0.081 0.091

150 0.039 0.046 0.052 0.059 0.069 0.081 0.091

F

122 212 302 392 482 572 662

5.0 0.263 0.305 0.367 0.430 0.485 0.596 0.707

6.0 0.257 0.298 0.347 0.409 0.471 0.562 0.659

6.25 0.257 0.298 0.354 0.416 0.478 0.569 0.659

7.5 0.263 0.312 0.354 0.416 0.485 0.575 0.631

8.0 0.270 0.319 0.361 0.416 0.485 0.569 0.631

9.00 0.270 0.319 0.354 0.409 0.478 0.562 0.631

9.375 0.270 0.319 0.361 0.409 0.478 0.562 0.631

APPLICATIONS

For wide range of thermal covers with re safety in industrial sector. ROCKWOOL LRB Mattresses are used where severe conditions of heat are involved like boilers, turbines, furnaces, larger diameter pipes, ues, curved surfaces, vessels and industrial ducts, irregular shaped pieces of equipment such as valves and anges. ROCKWOOL LRB Mattresses are also used where noise coupled with vibration and heat conditions are involved like heavy diesel engine exhaust systems / silencers and larger diameter pipe lines where high velocity uids or gases are transported. C

50

Mean These are typical values THERMAL CONDUCTIVITY IN W/m.K Mean subject to normal manufacturing and testing variances. Temperature Temperature FOR THE FOLLOWING DENSITIES IN kg/m3

THERMAL CONDUCTIVITY IN BTU.in/ft2h.F FOR THE BELOW DENSITIES IN Lbs/ft3

96 FIRE 80 SAFETY 0.038 0.037

100 0.037

120 0.038

128 0.039

144 0.039

150 0.039

5.0

6.0

6.25

7.5 0.263 0.312 0.354 0.416 0.485 0.575 0.631

8.0 0.270 0.319 0.361 0.416 0.485 0.569 0.631

9.00 0.270 0.319 0.354 0.409 0.478 0.562 0.631

9.375 0.319 0.361 0.409 0.478 0.562 0.631

ENVIRONMENT

ROCKWOOL LRB Mattresses are free from gases such as CFCs, HCFCs, HFCs, Pentane and any other ozone depletion material in their manufacture and represent no known threat to the environment. ROCKWOOL LRB Mattresses are classied as zero Ozone Depletion Potential (ODP) and zero Global Warming Potential (GWP) and help in reducing greenhouse effect.

0.263 0.257 0.2574), ROCKWOOL LRB Mattresses are non-combustible when tested in 122 accordance with BS 476 (part 0.044 0.043 0.043 0.046 0.046 0.046 100 the following 0.305 0.298 0.298 212 re safety rating 0.045 achievements: 0.053 0.050 0.051 0.052 0.051 0.052 0.051 0.367 0.347 150 0.354 302 0.062 surface 0.059 spread 0.059to BS 0.060 of ame 0.059 0.060 in 0.060 accordance 476 (part 7). 0.430 0.409 200 i). Class1 0.416 392

0.270 ISO 1182 and ASTM E 136 have

accordance BS 476 (part0.069 6 and part 7) and to 482 British Building 0.0700 in 0.068 0.069 to the 0.069 0.070 0.070 0.471 0.485 Regulations. 0.478 250 ii). Class in accordance European norms. 0.086A1 0.081 0.081 0.082 to0.083 300 iii). Class 0.081 0.082 0.596 0.562 0.569 572 iv). Surface in 0.091 accordance to ASTM E 84. 0.102 burning 0.095 characteristics 0.091 0.095 0.091 0.091 350 0.707 0.659 0.659 662 a). Fire Spread Index: b). Smoke Developed Index: Less than 25 Less than 50

DESCRIPTION

ROCKWOOL LRB Mattresses are exible, faced one side with wire mesh and manufactured from stable stone bers bonded with minimum quantity of thermosetting resin binder. ROCKWOOL LRB Mattresses are light in weight, strong, resilient, easy to handle and cut to suit intricate shapes.

MOISTURE ABSORPTION

PRODUCT at the octave frequencies ROCKWOOL LRB Mattresses absorb Absorption less thancoef 1%cient by volume when tested in HZ accordance with BS 2972, ASTM C 1104. ROCKINSUL LRB Mattresses do not absorb moisture from the ambient air nor water by capillary attraction. Only water under pressure can enter the Type however Thickness 125 out 250 1000 2000 of4000 NRC LRB Mattresses. insulation products, it quickly dries owing to500 the open cell structure ROCKWOOL mm

FACINGS

ROCKWOOL LRB Mattresses are available with a galvanized steel or stainless steel hexagonal wire netting(mesh) on one or two sides.

NON TOXIC 85

25

0.06

0.30

0.53

0.75

0.76

0.91

0.60

ROCKWOOL LRB hazardous and do not 1.0 contain0.85 Asbestos. 50 are not 0.28 0.89 to health 1.0 1.0 0.95(see RIL MSDS). 100 Mattresses

ACOUSTICS144

50

0.21

0.84

1.0

1.0

1.0

0.78

0.95

ROCKWOOL LRB Mattresses achieve following sound absorption coefcients when tested in accordance to ASTM C 423. PRODUCT Absorption coefcient at the octave frequencies HZ Thickness mm

25 50 50

STANDARD DIMENSIONS

STANDARD DENSITY

Type Density Code LRB 80 LRB 100 LRB 120 LRB 128 LRB 144 LRB 150 kg/m 80 100 120 128 144 150

3

125

0.06 0.28 0.21

250

0.30 0.89 0.84

500

0.53 1.0 1.0

1000

0.75 1.0 1.0

2000

0.76 1.0 1.0

4000

0.91 0.85 0.78

NRC

0.60 0.95 0.95

Thickness mm 40 to120

Width mm 1220

Length mm 1520

85

lbs/ft 3 5.0 6.25 7.5 8 9 9.375

100 144

Non-standard sizes may be available on request

These are typical values subject to normal manufacturing and testing variances.

CORROSIVITY

Non-corrosive to steel and austenitic stainless steel when tested in accordance to ASTM C 665 and ASTM C 795 & C 871 respectively.

Non-standard densities may be available on request

SHOT CONTENT

Less than 30% when tested in accordance to ASTM C 1335.

PERFORMANCES WORKING TEMPERATURE

Fibre: Upto 750 0C

RECOVERY AFTER COMPRESSION

ROCKWOOL LRB Mattresses are highly resilient and offer min. 90% recovery after compression when tested as per IS 3144.

CONFORMITY TO STANDARDS

ROCKWOOL LRB Mattresses comply with the following standards and are manufactured to a quality assurance system which complies with ISO 9001:2000. American Standards: British Standards: IS0: European Standards: Indian Standards: ASTM C 177, 411, 423, 518, 592, 665, 692, 795, 871, 1101, 1104, 1335, 1338, E 84, 136 BS 476 (parts 4,6 and 7) and 2972 1182 EN ISO 13501-1, EN/TS 15117 IS 8183, 3144

PERMANENCE

ROCKWOOL LRB Mattresses are dimensionally stable under varying conditions of temperature and humidity. ROCKWOOL LRB Mattresses are rot proof, odourless and non-hygroscopic. ROCKWOOL LRB Mattresses do not sustain vermin or fungus and will not encourage mould or bacteria. ROCKWOOL LRB Mattresses do not promote pitting corrosion nor stress corrosion cracking of austenitic stainless steel.

You might also like

- Material Alloy KHR35CLDocument2 pagesMaterial Alloy KHR35CLIebe Seventynine67% (3)

- Foam Glass Data SheetDocument2 pagesFoam Glass Data SheetMohamed KareemNo ratings yet

- Double Regulating Valves (2920W)Document8 pagesDouble Regulating Valves (2920W)Anwar SyedNo ratings yet

- Fire Fighting CourseDocument148 pagesFire Fighting CourseAnwar Syed100% (3)

- CNC DS0300 ProblemDocument7 pagesCNC DS0300 ProblemHairedinNo ratings yet

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- Rockwool SlabsDocument4 pagesRockwool SlabsBinu AyaniyattuNo ratings yet

- KBR Leaflet EngDocument1 pageKBR Leaflet EngAnwar SyedNo ratings yet

- Rockwool 159: 2.2 Insulation ProductsDocument1 pageRockwool 159: 2.2 Insulation ProductsZouhair AIT-OMARNo ratings yet

- Material Inconel 600Document16 pagesMaterial Inconel 600arvindgupta_2005100% (1)

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- 904LDocument5 pages904LManish542No ratings yet

- Fabrock 30: Board Insulation For OEM ApplicationsDocument2 pagesFabrock 30: Board Insulation For OEM ApplicationsCristhian RangelNo ratings yet

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocument4 pagesSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSNo ratings yet

- Vanpanel Wall: External and Internal SheetDocument3 pagesVanpanel Wall: External and Internal SheetMl JainNo ratings yet

- S2XX - 50 X 60Document3 pagesS2XX - 50 X 60mohamed hassanNo ratings yet

- Duplex Stainless Steel DetailDocument12 pagesDuplex Stainless Steel DetailessnelsonNo ratings yet

- Rockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsDocument3 pagesRockwool Slabs Thickness: 30 MM Density: 50 KG/M: ApplicationsFirst ChoiceNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetAscanio BarbosaNo ratings yet

- Nichrome Alloys For HeatingDocument10 pagesNichrome Alloys For HeatingRajaram GanesanNo ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- MCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080Document13 pagesMCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080willian GaldinoNo ratings yet

- Tabela ResistoreDocument13 pagesTabela Resistorewillian GaldinoNo ratings yet

- Carbon Film Fixed Resistor Axial Leaded: FeaturesDocument11 pagesCarbon Film Fixed Resistor Axial Leaded: FeaturesJonathan Llewellyn AndradaNo ratings yet

- Tech Rep 4-2011 Copper Zirkonium AlloysDocument14 pagesTech Rep 4-2011 Copper Zirkonium AlloysBahadır UysalNo ratings yet

- Inconel 601Document6 pagesInconel 601heanjiametalsNo ratings yet

- Rockwool Building Roll ENGDocument3 pagesRockwool Building Roll ENGAnwar SyedNo ratings yet

- Corrosion Guide - Stainless Internation NickelDocument20 pagesCorrosion Guide - Stainless Internation NickelJohn BurkeNo ratings yet

- Astm A743 Ca6nmDocument7 pagesAstm A743 Ca6nmMarlon Bombi100% (1)

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- Building Roll (KBR) : Light Weight, No Sagging Nor SettlingDocument8 pagesBuilding Roll (KBR) : Light Weight, No Sagging Nor SettlingPhan LongNo ratings yet

- Nicrofer6030 Alloy 690 eDocument12 pagesNicrofer6030 Alloy 690 eRizqi D. KurniantoNo ratings yet

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1No ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Rockwool Thermalrock S (Slab) : General Product InformationDocument2 pagesRockwool Thermalrock S (Slab) : General Product InformationMohsin RazaNo ratings yet

- Ultra-Green 45: Product DataDocument1 pageUltra-Green 45: Product DataWatashi Wa Abilene RockanLoverNo ratings yet

- Steel GKHDocument2 pagesSteel GKHAngel ZanottiNo ratings yet

- 254smo (Uns 31254)Document8 pages254smo (Uns 31254)Yang Gul LeeNo ratings yet

- MineralWoolInsulation (Rockwool) HotInsulation PDFDocument18 pagesMineralWoolInsulation (Rockwool) HotInsulation PDFPuneet MarwahaNo ratings yet

- 1 Ceramic Fiber BoardsDocument2 pages1 Ceramic Fiber BoardsMahesh MishraNo ratings yet

- The Corrosion of Superduplex SS in Different Types of SeawaterDocument9 pagesThe Corrosion of Superduplex SS in Different Types of SeawaterdevangmajithiaNo ratings yet

- Pubs 1049240Document12 pagesPubs 1049240cooki77No ratings yet

- SS 304Document5 pagesSS 304Nirav PatelNo ratings yet

- Rockwool Rocktech WM en DsDocument4 pagesRockwool Rocktech WM en DsZain Al AbidinNo ratings yet

- Incoloy Alloy 825Document4 pagesIncoloy Alloy 825Roman PaduaNo ratings yet

- QUIKGUN LC-SeriesDocument2 pagesQUIKGUN LC-SeriesGmail For ABT WorkNo ratings yet

- 380.1 PropiedadesDocument3 pages380.1 PropiedadesNini CortesNo ratings yet

- Carlson 904L Austenitic Stainless Steel: CategoriesDocument6 pagesCarlson 904L Austenitic Stainless Steel: CategoriesBagus PutraNo ratings yet

- CRDocument8 pagesCRErfan EffendyNo ratings yet

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Rockwool Rocktech Section Pipe Insulation: General Product InformationDocument4 pagesRockwool Rocktech Section Pipe Insulation: General Product Informationramy abazaNo ratings yet

- Do You Understand The Rogers AD1000 LaminatesDocument6 pagesDo You Understand The Rogers AD1000 LaminatesjackNo ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- 4.5.2 Product Selection Guide - Cold Insulation Glass Mineral Wool Glass Mineral Wool Needle Mat (E-Glass Textile Type) Thermal ConductivityDocument12 pages4.5.2 Product Selection Guide - Cold Insulation Glass Mineral Wool Glass Mineral Wool Needle Mat (E-Glass Textile Type) Thermal ConductivityOmar ObaidNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Is Downloading in Scribd Easy ?Document1 pageIs Downloading in Scribd Easy ?Anwar SyedNo ratings yet

- Hvac Factsheet BasicsDocument3 pagesHvac Factsheet BasicsAnwar SyedNo ratings yet

- TDSAlumRoll11 PDFDocument2 pagesTDSAlumRoll11 PDFAnwar SyedNo ratings yet

- 41 How To Calculate Air Temp in Unconditioned Spaces PDFDocument3 pages41 How To Calculate Air Temp in Unconditioned Spaces PDFAnwar SyedNo ratings yet

- Sanitary CatalogueDocument94 pagesSanitary CatalogueAnwar Syed100% (1)

- 62.191 SizingandSelectionDocument13 pages62.191 SizingandSelectionKo PaukNo ratings yet

- A S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentDocument2 pagesA S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentAnwar SyedNo ratings yet

- Potter OsysuDocument3 pagesPotter OsysuAnwar SyedNo ratings yet

- BY-CY Series PDFDocument36 pagesBY-CY Series PDFAnwar Syed0% (1)

- Check Valves (83BS)Document2 pagesCheck Valves (83BS)Anwar SyedNo ratings yet

- GV Osy E200 PDFDocument1 pageGV Osy E200 PDFAnwar SyedNo ratings yet

- Auto Flow Control Valve (AFCV)Document9 pagesAuto Flow Control Valve (AFCV)Anwar SyedNo ratings yet

- Rockwool Building Roll ENGDocument3 pagesRockwool Building Roll ENGAnwar SyedNo ratings yet

- KBR Leaflet EngDocument1 pageKBR Leaflet EngAnwar SyedNo ratings yet

- CHEMICAL COMPOSITION (In Weight %) DIN EN10088: Specification SheetDocument4 pagesCHEMICAL COMPOSITION (In Weight %) DIN EN10088: Specification SheetMohammad MaroufkhaniNo ratings yet

- 37 RelativityDocument39 pages37 RelativityAdam100% (1)

- G. Work Experience ListDocument58 pagesG. Work Experience ListRiyonda SuhalisNo ratings yet

- Dux Automatic ManualDocument17 pagesDux Automatic Manualcav4444No ratings yet

- Tolerance Fit ChartDocument1 pageTolerance Fit ChartHien Bui XuanNo ratings yet

- Induction Motor AnalysisDocument123 pagesInduction Motor AnalysisatmegamicroNo ratings yet

- ISO 9692-3-2002 Joint PreparationDocument16 pagesISO 9692-3-2002 Joint PreparationtndeshmukhNo ratings yet

- VABS ManualDocument22 pagesVABS ManualMohit GuptaNo ratings yet

- No Tanggal Material Spesifikasi QTY Satuan Dari KondisiDocument16 pagesNo Tanggal Material Spesifikasi QTY Satuan Dari KondisiAgus WinNo ratings yet

- KINETROL Actuators 1180006.0.820.0157.4.00 - Spare Parts ListDocument2 pagesKINETROL Actuators 1180006.0.820.0157.4.00 - Spare Parts Listritchie_ardaniNo ratings yet

- Sabp A 049 PDFDocument10 pagesSabp A 049 PDFWalid Megahed100% (1)

- Reaction VesselsDocument6 pagesReaction VesselsKim Christian Galaez100% (1)

- Diesel Genset Powered by SDEC: Generating Rates PrimeDocument3 pagesDiesel Genset Powered by SDEC: Generating Rates Primebalraj bawaNo ratings yet

- AN002 Application Note: What Is A Quaternion?Document3 pagesAN002 Application Note: What Is A Quaternion?kirancallsNo ratings yet

- Fan Za Gr56c-Zid-Gq - CR 2ND GenDocument6 pagesFan Za Gr56c-Zid-Gq - CR 2ND GenAlex SheinkmanNo ratings yet

- Gold ExercisesDocument26 pagesGold ExercisesJuan Carlos RuizNo ratings yet

- Diaphragm Accumulators: 1. DescriptionDocument8 pagesDiaphragm Accumulators: 1. DescriptionFelipe Pisklevits LaubeNo ratings yet

- Fourth Edition, February 2016: Piping Inspection Code: In-Service Inspection, Rating, Repair, andDocument79 pagesFourth Edition, February 2016: Piping Inspection Code: In-Service Inspection, Rating, Repair, andMiguel Antonio Bula PicónNo ratings yet

- Power Team PA50 Series Pumps - CatalogDocument2 pagesPower Team PA50 Series Pumps - CatalogTitanplyNo ratings yet

- 2P36606 Spring Loaded ERVDocument42 pages2P36606 Spring Loaded ERVYM Edwin Gil BeltranNo ratings yet

- Uflow Catalogue Poppet Valve SeriesDocument15 pagesUflow Catalogue Poppet Valve Seriesrupeshp1989No ratings yet

- Home Made Faceting MachineDocument7 pagesHome Made Faceting MachineGianluca Salvato100% (4)

- Lec 2 Best PPT On Jet EnginesDocument25 pagesLec 2 Best PPT On Jet Enginesahmet yıldızNo ratings yet

- Alfa Laval Visual Condition Assessment: Run Longer. Run Safer. Run BetterDocument2 pagesAlfa Laval Visual Condition Assessment: Run Longer. Run Safer. Run BetterMane FortanellNo ratings yet

- PneumaticsPneumatics, Air Conditioning, & PressurizationDocument9 pagesPneumaticsPneumatics, Air Conditioning, & PressurizationAnastasios Pavlou100% (3)

- ANNA UNIVERSITY Dts Two MarkDocument7 pagesANNA UNIVERSITY Dts Two MarkkarthisanNo ratings yet

- Mechanical Engineering ResumeDocument2 pagesMechanical Engineering ResumeZohaib KhanNo ratings yet

- SECTION 15180 Heating and Cooling Piping General 1.1: - Page 1 of 18Document18 pagesSECTION 15180 Heating and Cooling Piping General 1.1: - Page 1 of 18Munir RasheedNo ratings yet