Professional Documents

Culture Documents

History of Reverse Engineering

History of Reverse Engineering

Uploaded by

larokancoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

History of Reverse Engineering

History of Reverse Engineering

Uploaded by

larokancoCopyright:

Available Formats

History of Reverse Engineering The military served as an early platform for the application of the practice in question.

This application came in wars that incorporated new forms of technology. Thus, in modern conflicts like World War I or World War II, reverse engineering becomes vital in countries finding out how their enemies' new weaponry and transportation worked. An example of this is with the history of what is called the Jerry Can. The Jerry Can is a steel fuel container that was used throughout World War II. There were other fuel containers in use when this new can was introduced. But, the clever design of the Jerry Can allowed for greater transportability and more efficient pouring. The U.S. army and its British ally made great use of these Jerry Jugs thanks to their German enemies. Germany had invented these fuel containers as the Second World War approached. When the allied forces gained access to some of these containers (by either finding them or stealing them), they copied or reverse engineered the invention. However, many are unfamiliar with the origin of this common product. This is just one of hundreds of examples in which reverse engineering has been used to steal . History of Rapid Prototyping Rapid prototyping refers to physical objects that are automatically constructed with the aid of additive manufacturing technology. Rapid prototyping is quite a recent invention. The first machine of rapid prototyping hit the markets in the late 1980s. The early rapid prototyping process derived its name from the activities and the purpose for which the earlier machines were utilized. History of CMM ( Coordinate Measuring Machine) The coordinate measuring machine first appeared at the International Machine Tool exhibition in Paris in 1959 exhibited by the British company Ferranti having delivered the worlds first commercially available general purpose computer in 1951. The CMM quickly evolved with a plethora of CMM manufacturers from European Countries, USA and Japan entering the field in the mid 1960s; the uptake of coordinate measuring machines by manufacturing companies rapidly gathered pace after the introduction of the Touch Trigger Probe by Renishaw in the early 1970s. History of 3D Software Though there are many contributors to computer animation, 3D animation is often attributed to William Fetter. William Fetter worked for Boeing during the 1960s using computers to animate and design certain models. One of his projects involved making what came to be known as "The Boeing Man." It was a three-dimensional representation of the human body. It was then that Fetter coined the term "computer graphics."

Shrinkage Factor Percentage by which an output falls short of the estimated or planned output. Percentage of the total inventory by which a loss due to counting or recording errors, or from pilferage, spoilage, theft, or wastage occurs.

Roundness The measure of the sharpness of a particle's edges and corners.

Theoretical value for Roundness (2D) A single trace covering the full rotation is made and at each equally spaced angle, ,a

measurement, , of the radius or distance between the center of rotation and the surface point. A least-squares fit to the data gives the following estimators of the parameters of the circle:

The deviation is then measured as:

Calibration Calibration is a comparison between measurements one of known magnitude or correctness made or set with one device and another measurement made in as similar a way as possible with a second device. The formal definition of calibration by the International Bureau of Weights and Measures is the following: "Operation that, under specified conditions, in a first step, establishes a relation between the quantity values with measurement uncertainties provided by measurement standards and corresponding indications with associated measurement uncertainties (of the calibrated instrument or secondary standard) and, in a second step, uses this information to establish a relation for obtaining a measurement result from an indication."

Material Properties Strength - The ability of a material to stand up to forces being applied without it bending, breaking, shattering or deforming in any way. Elasticity - The ability of a material to absorb force and flex in different directions, returning to its original position. Plasticity - The ability of a material to be change in shape permanently. Ductility - The ability of a material to change shape (deform) usually by stretching along its length. Tensile strength - The ability of a material to stretch without breaking or snapping.

Traceability Traceability is the ability to verify the history, location, or application of an item by means of documented recorded identification. Other common definitions include to capability (and implementation) of keeping track of a given set or type of information to a given degree, or the ability to chronologically interrelate uniquely identifiable entities in a way that is verifiable.

Standard Tessellation Language

STL (STereoLithography) is a file format native to the stereolithography CAD software created by 3D Systems. STL is also known as Standard Tessellation Language. This file format is supported by many other software packages; it is widely used for rapid prototyping and computer-aided manufacturing. STL files describe only the surface geometry of a three dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both ASCII and binary representations. Binary files are more common, since they are more compact.

You might also like

- The Self-Taught Programmer - The Definitive Guide To Programming ProfessionallyDocument300 pagesThe Self-Taught Programmer - The Definitive Guide To Programming ProfessionallyLucas celestino100% (1)

- The History of CADDocument51 pagesThe History of CADPhillip DodsonNo ratings yet

- Chapter 2Document32 pagesChapter 2shellaNo ratings yet

- Research TitlesDocument7 pagesResearch TitlesAra Belle AgaremNo ratings yet

- Final Report 3D Chocolate PrintingDocument20 pagesFinal Report 3D Chocolate PrintingPrathamesh PatilNo ratings yet

- History of CAD: Drafting Machine and Used PDP-1 Computer From Digital Equipment Corp., A Vector - Refresh Display and ADocument24 pagesHistory of CAD: Drafting Machine and Used PDP-1 Computer From Digital Equipment Corp., A Vector - Refresh Display and ANina MiskovetsNo ratings yet

- CSE3013 Artficial IntelligenceDocument3 pagesCSE3013 Artficial Intelligencejeevan gangavarapuNo ratings yet

- AIESEC Product PricingDocument30 pagesAIESEC Product PricingMickaela Delos Santos100% (1)

- 3 Bit AdderDocument11 pages3 Bit AdderAvirup DasguptaNo ratings yet

- Activity 1 ME LabDocument6 pagesActivity 1 ME LabAlan Paolo SalazarNo ratings yet

- Wearable Computing: A Review: January 2005Document16 pagesWearable Computing: A Review: January 2005Umesh WalunjkarNo ratings yet

- 3D Printing For Artists Research and Creative PracticeDocument6 pages3D Printing For Artists Research and Creative Practicephd.meethaqNo ratings yet

- 3d PrintingDocument36 pages3d Printingahsonkhanmgm0% (1)

- Experiment DaryllDocument11 pagesExperiment DaryllSleepy SpettoNo ratings yet

- 3D PrintingDocument45 pages3D Printingbrian3442No ratings yet

- Comm ReportDocument15 pagesComm ReportAlpesh PatelNo ratings yet

- 3D PrintingDocument20 pages3D PrintingveeraraghavendrabalinaNo ratings yet

- Analysis of Product Using Reverse EngineeringDocument6 pagesAnalysis of Product Using Reverse EngineeringManthan PagareNo ratings yet

- Wearable Computing: A Review: Cliff RandellDocument15 pagesWearable Computing: A Review: Cliff Randellrobotz1791No ratings yet

- 3D PrintingDocument17 pages3D PrintingadimeghaNo ratings yet

- 3D Printing0Document36 pages3D Printing0Joydip PaulNo ratings yet

- The History, Trends, and Future of Infrared Technology - DSIACDocument21 pagesThe History, Trends, and Future of Infrared Technology - DSIACg c agnihotriNo ratings yet

- Metrology BasicsDocument113 pagesMetrology Basicsavutu_kunduru100% (1)

- A Short History of 3D Printing, A Technological Revolution Just StartedDocument8 pagesA Short History of 3D Printing, A Technological Revolution Just StartedzahidNo ratings yet

- Rapid Prototyping - WikipediaDocument15 pagesRapid Prototyping - WikipediaChalla varun KumarNo ratings yet

- 3D PrintingDocument15 pages3D PrintingKhushbu gaydhaneNo ratings yet

- The Wonder of 3D PrintingDocument64 pagesThe Wonder of 3D PrintingCătălin TenchiuNo ratings yet

- Design DocumentationDocument40 pagesDesign DocumentationHelenda May WongNo ratings yet

- Design-Documentation (Helenda's Edits)Document40 pagesDesign-Documentation (Helenda's Edits)Helenda May WongNo ratings yet

- Статья на АнглийскомDocument49 pagesСтатья на АнглийскомFrodo SumkinNo ratings yet

- Operations Research, or Operational Research in British Usage, Is A Discipline That Deals WithDocument4 pagesOperations Research, or Operational Research in British Usage, Is A Discipline That Deals WithMonika KshetriNo ratings yet

- Introduction in Engineering DrawingDocument3 pagesIntroduction in Engineering DrawingMaeriel AggabaoNo ratings yet

- Статья на АнглийскомDocument50 pagesСтатья на АнглийскомFrodo SumkinNo ratings yet

- Close-Range Photogrammetry Applications PDFDocument12 pagesClose-Range Photogrammetry Applications PDFDoc2005No ratings yet

- A Decomposition-Based Approach To Layered ManufacturingDocument35 pagesA Decomposition-Based Approach To Layered Manufacturingdangquang_k46No ratings yet

- V 8 Noi GL Yex 2Document1,033 pagesV 8 Noi GL Yex 2Hafiz Ipe100% (1)

- Stan Dad IzationDocument10 pagesStan Dad IzationJustin Alvin P. CaballaNo ratings yet

- HistoryDocument4 pagesHistoryRommel estrelladoNo ratings yet

- How To Make Almost Anything - Fabrication - Neil GershenfeldDocument16 pagesHow To Make Almost Anything - Fabrication - Neil GershenfeldLaura Gonzalez Fdez100% (1)

- 3D Printing TechnologyDocument43 pages3D Printing TechnologySushmaNo ratings yet

- Micro PrintingDocument4 pagesMicro PrintingJim KatNo ratings yet

- Toolroom: Storing ToolsDocument3 pagesToolroom: Storing Toolsசரவணகுமார் மாரியப்பன்No ratings yet

- Dynamic Vision For Perception and Control of Motion - Ernst D. Dickmanns PDFDocument490 pagesDynamic Vision For Perception and Control of Motion - Ernst D. Dickmanns PDFmxnoxnNo ratings yet

- A Computational Model The Human Hand 93-ERI-053: K. Hollerbach, P.I. T. Axelrod, Original P.IDocument14 pagesA Computational Model The Human Hand 93-ERI-053: K. Hollerbach, P.I. T. Axelrod, Original P.ISunčica Milan Otović BlagojevićNo ratings yet

- 3d Printing IndustryDocument20 pages3d Printing Industrydfman123No ratings yet

- Final Report 3D Chocolate PrintingDocument20 pagesFinal Report 3D Chocolate PrintingPrathamesh PatilNo ratings yet

- Visual Output Devices: Definitions, Uses and Examples by Group 8Document10 pagesVisual Output Devices: Definitions, Uses and Examples by Group 8Richard RhuleNo ratings yet

- 3D PrintingDocument21 pages3D Printinghellgate.vishesh25No ratings yet

- CA en Insights Issues Disruptive ManufacturingDocument20 pagesCA en Insights Issues Disruptive Manufacturingbloodterry2284No ratings yet

- Amft2009b-J IEEEPervComput PDFDocument6 pagesAmft2009b-J IEEEPervComput PDFAlexandru CozmaNo ratings yet

- Development Camera Calibration Methods ModelsDocument16 pagesDevelopment Camera Calibration Methods Modelsborza_diana8714No ratings yet

- Report 2Document28 pagesReport 2Flux PrimeNo ratings yet

- Dynamic Vision For Perception and Control of Motion - Ernst D. Dickmanns PDFDocument490 pagesDynamic Vision For Perception and Control of Motion - Ernst D. Dickmanns PDFCarlos Gonzalez RegNo ratings yet

- Up Decade Counter ProjectDocument17 pagesUp Decade Counter ProjectOhaneje UzomaNo ratings yet

- Starrett - Tools N RulesDocument80 pagesStarrett - Tools N Rules4U6ogj8b9snylkslkn3n100% (5)

- Context of Use Within Usability Activities: Artin AguireDocument31 pagesContext of Use Within Usability Activities: Artin AguireSergio Rodrigo Cardenas RiveraNo ratings yet

- Terminology: 3D Printing, Also Known As Additive Manufacturing (AM), Refers To Processes Used To CreateDocument14 pagesTerminology: 3D Printing, Also Known As Additive Manufacturing (AM), Refers To Processes Used To CreateErEeshanAcharyaNo ratings yet

- 23) 3d Printing in Organic Synthesis PDFDocument14 pages23) 3d Printing in Organic Synthesis PDFlolitica123456No ratings yet

- Thousandth of An Inch - WikipediaDocument4 pagesThousandth of An Inch - WikipediaAlemayehu JiruNo ratings yet

- Reverse Engineering of Mechanical Parts Full PaperDocument3 pagesReverse Engineering of Mechanical Parts Full Paperrramesh2k8712No ratings yet

- 5 SimplesDocument5 pages5 Simplesvalentin tudancaNo ratings yet

- Engineering Drawing: Unlocking Visual Perception in Engineering DrawingFrom EverandEngineering Drawing: Unlocking Visual Perception in Engineering DrawingNo ratings yet

- Shivam Garg: ResumeDocument2 pagesShivam Garg: ResumeShivamNo ratings yet

- 130 Jio Dongle List Handed Over To Traffic Dept MR - JadhavDocument22 pages130 Jio Dongle List Handed Over To Traffic Dept MR - JadhavPrashant KadamNo ratings yet

- Journal of Computer Science IJCSIS July 2015 Special IssueDocument132 pagesJournal of Computer Science IJCSIS July 2015 Special Issuereymee21No ratings yet

- Static MethodsDocument5 pagesStatic MethodsLokesh PawarNo ratings yet

- Android VersionsDocument7 pagesAndroid VersionsEdna Mae Salas GarciaNo ratings yet

- SSIS - Non-Blocking, Semi-Blocking and Fully-Blocking ComponentsDocument12 pagesSSIS - Non-Blocking, Semi-Blocking and Fully-Blocking ComponentsboyiniramanaNo ratings yet

- Intranet Mailing System: Project Report OnDocument60 pagesIntranet Mailing System: Project Report OnVigneshwaranRaveendran100% (1)

- PIC Base C 1Document24 pagesPIC Base C 1frank_grimesNo ratings yet

- Chandrasekar and Deming - 1949 - On A Method of Estimating Birth and Death Rates and The Extent of RegistrationDocument16 pagesChandrasekar and Deming - 1949 - On A Method of Estimating Birth and Death Rates and The Extent of RegistrationXING XING0% (1)

- Icdd PDFDocument17 pagesIcdd PDFJamil MisbahNo ratings yet

- Course Schedule 2016-17/2 Semester (Pr-Registration)Document38 pagesCourse Schedule 2016-17/2 Semester (Pr-Registration)AkhilNo ratings yet

- MATLAB Linear AlgebraDocument9 pagesMATLAB Linear Algebraapi-3728275100% (3)

- SQLRDD ManualDocument38 pagesSQLRDD ManualltspbrNo ratings yet

- HackDocument231 pagesHackKira KoorsenNo ratings yet

- Responsive Design and MoodleDocument9 pagesResponsive Design and MoodletrueradNo ratings yet

- Nash EquilibriumDocument25 pagesNash Equilibriumsubroto36No ratings yet

- EMC XtremIO - Smart Zoning Example - PDFDocument7 pagesEMC XtremIO - Smart Zoning Example - PDFRashid MahamoodNo ratings yet

- STAAD Pro V8iDocument140 pagesSTAAD Pro V8iVivek Gosavi67% (3)

- Backup Process For McAfee DevicesDocument11 pagesBackup Process For McAfee DevicesabbuasherNo ratings yet

- Sharifah Aznida Binti Syed Azin-ResumeDocument4 pagesSharifah Aznida Binti Syed Azin-ResumeSyed HafizNo ratings yet

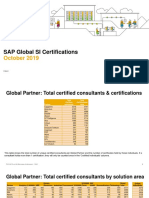

- SAP Global SI CertificationsDocument12 pagesSAP Global SI CertificationsDebi_Prasad_Go_5889No ratings yet

- 1 (1) IntroductionDocument7 pages1 (1) IntroductionSridhar VcNo ratings yet

- Neuroscience: Science of The Brain in ArmenianDocument70 pagesNeuroscience: Science of The Brain in ArmenianInternational Brain Research Organization100% (1)

- Denormalization in Databases: Recommended PostsDocument1 pageDenormalization in Databases: Recommended PostsAmrosy Bani BunsaNo ratings yet

- Mario Bunge - Semantics (II) - Interpretation and Truth PDFDocument223 pagesMario Bunge - Semantics (II) - Interpretation and Truth PDFioan dumitrescu100% (1)

- Project Report On Library Management System: Submitted byDocument32 pagesProject Report On Library Management System: Submitted byvjidiv26103dNo ratings yet