Professional Documents

Culture Documents

A106 Pipe Specifications

A106 Pipe Specifications

Uploaded by

pundir_vineetOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A106 Pipe Specifications

A106 Pipe Specifications

Uploaded by

pundir_vineetCopyright:

Available Formats

A106 Pipe Specifications

A/SA106 Scope NPS 1/4"- 30" Schedules 10 through 160, STD, XH and XXH

Covers seamless carbon steel nominal wall pipe for high-temperature service, suitable for bending flanging and similar forming operations. NPS 1-1/2" and under may be either hot finished or cold drawn. NPS 2" and larger shall be hot finished unless otherwise specified.

Process

Killed steel, with primary melting process being open-hearth, basic-oxygen, or electric-furnace, possible combined with separate degassing or refining. Steel cast in ingots or strand cast is permissible. Hot-finished pipe need not be heat treated. Cold-drawn pipe shall be heat treated after the final cold draw pass.

Chemical Requirements

Carbon max. % Manganese % Phosphorous, max. % Sulfur, max. % Silicon, min.% Chrome, max. % Copper, max. % Molybdenum, max. % Nickel, max. % Vanadium, min.%

Grade A 0.25 0.27 to 0.93 0.035 0.035 0.10 0.40 0.40 0.15 0.40 0.08

Grade B 0.30 0.29 to 1.06 0.035 0.035 0.10 0.40 0.40 0.15 0.40 0.08

Grade C 0.35 0.29 to 1.06 0.035 0.035 0.10 0.40 0.40 0.15 0.40 0.08 Total of Cr, Cu, Mo, Ni, and V shall not exceed 1%

Permissible The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness Variations in specified. Wall Thickness

Permissible Weight of any length shall not vary more than 10% over and 3.5% under that specified. Variations in NOTE -- NPS 4 and smaller -- weighed in lots. Larger sizes shall be weighed separately by length. Weights per Foot

Permissible

Outside Diameter at any point shall not vary from standard specified more than:

Variations in Outside Diameter

Over NPS [DN Designator] in. 1/8 to 1-1/2 [6 to 40], incl Over 1-1/2 to 4 [40 to 100], incl Over 4 to 8 [100 to 200], incl Over 8 to 18 [200 to 450], incl Over 18 to 26 [450 to 650], incl Over 26 to 34 [650 to 859], incl Over 34 to 48 [850 to 1200], incl 1/64 (0.015) 1/32 (0.031) 1/16 (0.062) 3/32 (0.093) 1/8 (0.125) 5/32 (0.156) 3/16 (0.187) mm 0.4 0.8 1.6 2.4 3.2 4.0 4.8

Under in. 1/64 (0.015) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031) mm 0.4 0.8 0.8 0.8 0.8 0.8 0.8

Tensile Requirements

Grade A Tensile Strength, min., psi Yield Strength, min., psi 48,000 30,000

Seamless Grade B 60,000 35,000 Grade C 70,000 40,000

Number of Tests Required

NPS Tensile 5 and smaller 6 and larger Bending Flattening 2 and smaller 2 through 5 6 and over

On One Length from Each Lot of 400 or less 200 or less 400 or less 400 or less 200 or less

Hydrostatic Testing

Inspection test pressures produce a stress in the pipe wall equal to 60% of specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS3 and under 2800 psi for the larger sizes. Pressure is maintained for not less than 5 seconds.

Mechanical Tests Specified

Tensile Test -- NPS 8 and larger -- either transverse or longitudinal acceptable Smaller than NPS 8 -- weighed in lots. Larger sizes -- by length. Flattening Test -- NPS 2-1/2 and larger. Bending Test (Cold) -- NPS 2 and under. Degree of Bend For Normal A106 Uses For Close Coiling 90 180 Diameter of Mandrel 12 x nom dia. of pipe 8 x nom dia. of pipe

Lengths

Lengths required shall be specified on order. No "jointers" permitted unless otherwise specified. If no definite lengths required, following practice applies: Single Random -- 17' ~ 24' lengths Double Random -- 36' ~ 44' lengths

Rolled, Stamped, or Stenciled (Mfrs. Option) Required Markings on Manufacturer's name or brand. Each Length A106 A, A 106 B, A 106 C. (On Tags Hydrostatic test pressures and/or NDE; attached to each Bundle in or NH if neither is specified. case of Bundled Pipe)

Length of pipe. ANSI schedule number. Weight per foot (NPS 4 and larger) Additional "S" if tested supplementary requirements.

Referenced Documents

ASTM A 530/A 530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe ASTM E 213 Practice for Ultrasonic Examination of Metal Pipe and Tubing ASTM E 309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation ASTM E 381 Method of Macroetch testing Steel Bars, Billets, Blooms, and Forgings ASTM E 570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products ASME B26.10M Welded and Seamless Wrought Steel Pipe

General Information

Orders for material under this specification should include the following, as required, to describe the desired material adequately: Quantity Name of material Grade Manufacture Size Feet, centimeters, or number of lengths Seamless or Welded Pipe Grade A, Grade B, or Grade C Hot-finished or cold-drawn NPS or Outside Diameter and Schedule Number of Average Wall Thickness

Special outside diameter tolerance pipe Inside diameter tolerance pipe, over 10 in ID Length Supplementary requirements Test Report Required Specification designation Hydrostatic test Special requirements Specific or random

You might also like

- Dynamic Response of Deepwater Lazy Wave Catenary RiserDocument20 pagesDynamic Response of Deepwater Lazy Wave Catenary Risermghu70No ratings yet

- QMS Doc. Distribution MatrixDocument4 pagesQMS Doc. Distribution Matrixpundir_vineet83% (6)

- 15 - GreatWhiteDocument1 page15 - GreatWhiteBima MahendraNo ratings yet

- FPSO SpecificationDocument2 pagesFPSO SpecificationKim OanhNo ratings yet

- Riser Recoil Analysis Report For Acme DrillshipDocument21 pagesRiser Recoil Analysis Report For Acme DrillshipEdmo Das Virgens100% (1)

- Designofthe Aircraft Groundingand Mooring SystemDocument77 pagesDesignofthe Aircraft Groundingand Mooring SystemEvrenNo ratings yet

- Offpipe A&r 2 Excel Using Matlab-E - Rev1.4-2010Document9 pagesOffpipe A&r 2 Excel Using Matlab-E - Rev1.4-2010Peggy Jan QorbanNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Manual de Instrucciones CORUS - MID - V26Document64 pagesManual de Instrucciones CORUS - MID - V26Cristopher Lobos70% (10)

- New Company Profile Alkon After OTK (Part1)Document10 pagesNew Company Profile Alkon After OTK (Part1)henryNo ratings yet

- Catalogue 2014 en HDDocument58 pagesCatalogue 2014 en HDBrad BarnesNo ratings yet

- Technical Specifications of HDPE Pipes As Per Indian Standards InstituteDocument1 pageTechnical Specifications of HDPE Pipes As Per Indian Standards InstituteZacharia JohnNo ratings yet

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDocument2 pages4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaNo ratings yet

- MooringDocument151 pagesMooringHafizh AmazonNo ratings yet

- Flange Standard of ChinaDocument5 pagesFlange Standard of ChinaLaural MarshallNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- 2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimDocument15 pages2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimYoungtae KimNo ratings yet

- Allianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMDocument2 pagesAllianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMCyril J PadiyathNo ratings yet

- A Short Brief About Offshore Pipeline Installation EngineeringDocument13 pagesA Short Brief About Offshore Pipeline Installation EngineeringlsatchithananthanNo ratings yet

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDocument2 pages4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorena DávilaNo ratings yet

- Webforge Access 2020 Web 3 PDFDocument32 pagesWebforge Access 2020 Web 3 PDFFaris MahmoodNo ratings yet

- Japanese Industrial Standard-JIS Valve Standards: Page 1 / Total 9 Web: EmailDocument9 pagesJapanese Industrial Standard-JIS Valve Standards: Page 1 / Total 9 Web: EmailLê MinhNo ratings yet

- Fpso Cidade de Santos Mv20 - Modec Fpso - Fso ProjectDocument2 pagesFpso Cidade de Santos Mv20 - Modec Fpso - Fso ProjectjeffreymacaseroNo ratings yet

- Offshore Rope TestingDocument4 pagesOffshore Rope TestingYulkyung SungNo ratings yet

- Total Pms Scope of Work: Days Start Date End DateDocument6 pagesTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyNo ratings yet

- Bolt Preload CalculationDocument3 pagesBolt Preload Calculationmihai90No ratings yet

- Company Profile PT Tri Mulya GemilangDocument20 pagesCompany Profile PT Tri Mulya Gemilangdudi hidayatNo ratings yet

- OMAE2012 84121 PresentationDocument16 pagesOMAE2012 84121 PresentationsojanvasudevanNo ratings yet

- Pipeline Material & Installation CostDocument4 pagesPipeline Material & Installation Costmuhammad AzharNo ratings yet

- Weight Gate ValvesDocument1 pageWeight Gate ValvesBHARGAVNo ratings yet

- Mina PDFDocument144 pagesMina PDFJohari A. KasimNo ratings yet

- B23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8Document17 pagesB23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8HASHMI MAHMOODNo ratings yet

- Froude-Krylov Force CoefficientDocument20 pagesFroude-Krylov Force CoefficientLazaros NtoanidisNo ratings yet

- GL Pers Transfer Basket Inspection PDFDocument26 pagesGL Pers Transfer Basket Inspection PDFSteve Morrison100% (1)

- Burea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFDocument236 pagesBurea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFAnonymous 7tBrl8No ratings yet

- Great Waters - Business Track Record 2012-16Document16 pagesGreat Waters - Business Track Record 2012-16KK NairNo ratings yet

- Gandhi TubesDocument6 pagesGandhi TubesmukeshkumarjNo ratings yet

- Jurnal Offshore Semi SubmersibleDocument16 pagesJurnal Offshore Semi SubmersibleRidzkyNo ratings yet

- Asigmnet 1 - ShipyardDocument28 pagesAsigmnet 1 - Shipyardulzzang looNo ratings yet

- N-2409 - Flexible Pipes PDFDocument88 pagesN-2409 - Flexible Pipes PDFIgor BastosNo ratings yet

- Perform3d User GuideDocument336 pagesPerform3d User Guidepechak1No ratings yet

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Pig LaunchingDocument5 pagesPig Launchingdabir123No ratings yet

- Washers (JIS B 1256, 1251)Document7 pagesWashers (JIS B 1256, 1251)haharamesh0% (1)

- Pdfs Seaeye A Frame LARSDocument2 pagesPdfs Seaeye A Frame LARSMarigold SpellNo ratings yet

- Revised MS Pressure Test of Dn400 PipelieDocument4 pagesRevised MS Pressure Test of Dn400 PipelieMhando IgnasNo ratings yet

- D6316 141 RP PL 0005 - 1Document27 pagesD6316 141 RP PL 0005 - 1Anonymous rPV6LRE1No ratings yet

- Jack Up Drilling Rig Specifications SummaryDocument3 pagesJack Up Drilling Rig Specifications SummaryArturoNo ratings yet

- T 36Document6 pagesT 36Hariprasad RajannaNo ratings yet

- PSA SingaporeDocument40 pagesPSA Singaporekoib789No ratings yet

- C03-001-Structural Steel CalculationsDocument86 pagesC03-001-Structural Steel CalculationsNguyễnBìnhPhươngNo ratings yet

- RF PadDocument12 pagesRF PadVishnu TejaNo ratings yet

- G16 13 Applying Statistics To Analysis of Corrosion DataDocument14 pagesG16 13 Applying Statistics To Analysis of Corrosion DataAngélica Chavarro AvellanedaNo ratings yet

- EnerMech TrainingDocument4 pagesEnerMech TrainingZulhilmi ZalizanNo ratings yet

- Kurva HidrostatisDocument1 pageKurva HidrostatisMoch ArdiansyahNo ratings yet

- OTC-25134 Final - WatermarkDocument15 pagesOTC-25134 Final - WatermarkgenmikNo ratings yet

- Subsea Riser Base AnalysisDocument1 pageSubsea Riser Base Analysisgvsha88No ratings yet

- Pipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Document1 pagePipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Denise Koh Chin HuiNo ratings yet

- A/SA 106 Spec Sheet A106 Pipe Specifications: American Piping Products Stocks A Full Range of A106 Pipe (SA106 Pipe) inDocument8 pagesA/SA 106 Spec Sheet A106 Pipe Specifications: American Piping Products Stocks A Full Range of A106 Pipe (SA106 Pipe) inMostafizur RahmanNo ratings yet

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDocument7 pagesS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNo ratings yet

- MS 01 181Document4 pagesMS 01 181Mauricio Escobar LabraNo ratings yet

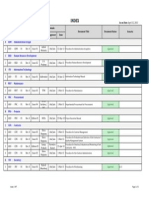

- HSEDocument2 pagesHSEpundir_vineetNo ratings yet

- Cover Page - Q11 NEWDocument1 pageCover Page - Q11 NEWpundir_vineetNo ratings yet

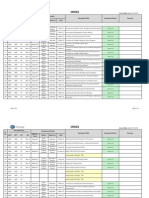

- Index: Sl. No. Document Status Document No. Document Title Document DetailsDocument1 pageIndex: Sl. No. Document Status Document No. Document Title Document Detailspundir_vineetNo ratings yet

- Index: Sl. No. Document Status Document No. Document Title Document DetailsDocument1 pageIndex: Sl. No. Document Status Document No. Document Title Document Detailspundir_vineetNo ratings yet

- Cover Page - Q12 NEWDocument1 pageCover Page - Q12 NEWpundir_vineetNo ratings yet

- Cover Page - Q09 NEWDocument1 pageCover Page - Q09 NEWpundir_vineetNo ratings yet

- Cover Page - Q10 NEWDocument1 pageCover Page - Q10 NEWpundir_vineetNo ratings yet

- Cover Page - IMS AuditsDocument1 pageCover Page - IMS Auditspundir_vineetNo ratings yet

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- Control Copy NumbersDocument2 pagesControl Copy Numberspundir_vineetNo ratings yet

- Control Copy Issue RegisterDocument30 pagesControl Copy Issue Registerpundir_vineetNo ratings yet

- Airanger DPL Plus: Instruction Manual PL-572 March 2001Document131 pagesAiranger DPL Plus: Instruction Manual PL-572 March 2001paras99No ratings yet

- Final Semester 3Document79 pagesFinal Semester 3Edwin BhakomeNo ratings yet

- Acer At2635Document32 pagesAcer At2635pisicafelixNo ratings yet

- Indian and ISO Standards For DimensioningDocument4 pagesIndian and ISO Standards For Dimensioningnishanth132No ratings yet

- Nonparametric StatisticsDocument22 pagesNonparametric StatisticsAbhee RajNo ratings yet

- Secure Premier 300 - Modbus MappingDocument10 pagesSecure Premier 300 - Modbus MappingRiyas MohamedNo ratings yet

- Optoma EX785 - DP-3638 & EW775 - DP-7606 ServiceManual - 20100105Document133 pagesOptoma EX785 - DP-3638 & EW775 - DP-7606 ServiceManual - 20100105hghamkharNo ratings yet

- V034E15 NT30 NT30C Operation Manual PDFDocument311 pagesV034E15 NT30 NT30C Operation Manual PDFsergioNo ratings yet

- Mauser K98 RiflesDocument252 pagesMauser K98 Riflesblowmeasshole1911100% (3)

- HTC VGF FuelDocument51 pagesHTC VGF FuelKarlosant MJNo ratings yet

- P14N TM en 6.1Document448 pagesP14N TM en 6.1Michael adu-boahenNo ratings yet

- Basic Universal Firewall Script - MikroTik Wiki PDFDocument2 pagesBasic Universal Firewall Script - MikroTik Wiki PDFDecio RamiresNo ratings yet

- EurocodesNews 07 - 10.2008 - 0139Document10 pagesEurocodesNews 07 - 10.2008 - 0139nebojsadj6411No ratings yet

- API 1104 Standard For Welding of Pipelines 1712387856Document39 pagesAPI 1104 Standard For Welding of Pipelines 1712387856Umair AnsariNo ratings yet

- Robots 447Document36 pagesRobots 447manishtopsecretsNo ratings yet

- JavaScript TutorialDocument2 pagesJavaScript Tutorialursu_padure_scrNo ratings yet

- 7776-1 DatasheetDocument2 pages7776-1 DatasheetMohamed B AliNo ratings yet

- Smart Complaint Registeration For Government Bodies by NasarDocument66 pagesSmart Complaint Registeration For Government Bodies by Nasarnasar_the_max100% (2)

- Neibour 4GDocument3,162 pagesNeibour 4GquyphamvanNo ratings yet

- Remote Access RF Modem Config 2.1Document39 pagesRemote Access RF Modem Config 2.1Jhon GrandezNo ratings yet

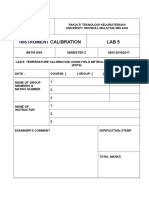

- Lab 5 - Thermocouple Temperature Calibration (PRTS)Document7 pagesLab 5 - Thermocouple Temperature Calibration (PRTS)Slim ShaddysNo ratings yet

- Basic Knowledge Requirements For Cybersecurity and HackinDocument65 pagesBasic Knowledge Requirements For Cybersecurity and Hackinshriram1082883No ratings yet

- Image File FormatsDocument10 pagesImage File FormatsJavhie LabiosNo ratings yet

- Trokraki On - Off VentilDocument12 pagesTrokraki On - Off VentilAdvokat HadziTonicNo ratings yet

- LVED210011EN-EasyPact CVS CatalogDocument122 pagesLVED210011EN-EasyPact CVS CatalogVicente Vixo Montero BustosNo ratings yet

- Centrifugal Compressor Notes Final Ver Rev1 Nov03-SymbolsDocument54 pagesCentrifugal Compressor Notes Final Ver Rev1 Nov03-SymbolsHarindharan Jeyabalan100% (9)

- DBX 1066 Lim SCHDocument13 pagesDBX 1066 Lim SCHmolinsonNo ratings yet

- TablerosDocument404 pagesTablerosJulian HurtadoNo ratings yet

- HD - 300 - T - Web - ManualDocument90 pagesHD - 300 - T - Web - ManualEsther Palomino MNo ratings yet