Professional Documents

Culture Documents

Engineering Bill of Materials

Engineering Bill of Materials

Uploaded by

inboxsweetsCopyright:

Available Formats

You might also like

- Electric Screw Driver M 54-2823 English Rev 1.5Document17 pagesElectric Screw Driver M 54-2823 English Rev 1.5Dina NadeemNo ratings yet

- HMK300EDocument9 pagesHMK300EkbenjikaNo ratings yet

- Function AnalysisDocument4 pagesFunction AnalysisWanAtikatulAsmaNo ratings yet

- Module 07 B1 Mechanical Book 1 PDFDocument341 pagesModule 07 B1 Mechanical Book 1 PDFSohaib Aslam ChaudharyNo ratings yet

- Manage Bill of MaterialsDocument18 pagesManage Bill of MaterialsSoft bridgesNo ratings yet

- Milling OperationsDocument4 pagesMilling Operationsinboxsweets100% (1)

- E1817 PDFDocument3 pagesE1817 PDFalfonso_comimsaNo ratings yet

- Major Repair Alteration Job-Aid PDFDocument118 pagesMajor Repair Alteration Job-Aid PDFJuan BalderasNo ratings yet

- Aviation CSIHandbookDocument186 pagesAviation CSIHandbookxclublifestyleNo ratings yet

- Formability Training Dec2012 PDFDocument111 pagesFormability Training Dec2012 PDFShrikrishna BirajdarNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.2 (Workshop Practices) PDFDocument34 pagesModule 7 (Maintenance Practices) Sub Module 7.2 (Workshop Practices) PDFshareyhouNo ratings yet

- 03 - Drafting Manual - Decimal Inch Sheet Size and FormatDocument51 pages03 - Drafting Manual - Decimal Inch Sheet Size and FormatKakoDaNo ratings yet

- 14 CFR Part 25 Subpart C FARDocument9 pages14 CFR Part 25 Subpart C FARnurek2No ratings yet

- Introduction To Design For Assembly and Manufacturing: (Cost Effective)Document81 pagesIntroduction To Design For Assembly and Manufacturing: (Cost Effective)maladcondomNo ratings yet

- Topic 2 - Formats & Title BlockDocument21 pagesTopic 2 - Formats & Title BlockAmir DanialNo ratings yet

- FAI by Numbers For NI V5 - Rev. GDocument80 pagesFAI by Numbers For NI V5 - Rev. GRicardoNo ratings yet

- Project Scheduling: PERT/CPMDocument37 pagesProject Scheduling: PERT/CPMShruti KaushikNo ratings yet

- ENG Change Order ProcessDocument2 pagesENG Change Order Processsoureddy1981No ratings yet

- MTBF Calculator (Reliability Calculation System)Document233 pagesMTBF Calculator (Reliability Calculation System)Polimore100% (1)

- Lockheed Tooling Manual Tms - MC - 015 - Rev29 PDFDocument114 pagesLockheed Tooling Manual Tms - MC - 015 - Rev29 PDFjimNo ratings yet

- CHAPTER-1 Introduction To Aircraft DrawingDocument12 pagesCHAPTER-1 Introduction To Aircraft DrawingGhifaris VashaNo ratings yet

- CNC Design FeaturesDocument10 pagesCNC Design Featuresaqtu12fuc100% (1)

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltNo ratings yet

- Foreign Object Damage (Fod) Prevention PlanDocument14 pagesForeign Object Damage (Fod) Prevention PlanJolyeTorresNo ratings yet

- Partmaker Tech Note #081505: Using Config-By-Click'™ in PartmakerDocument9 pagesPartmaker Tech Note #081505: Using Config-By-Click'™ in Partmaker123anthonyNo ratings yet

- 1 Purpose and ScopeDocument5 pages1 Purpose and ScopeSivananthaa MurtheeNo ratings yet

- Aero Presentation: Aerospace PracticeDocument56 pagesAero Presentation: Aerospace Practicerajagopalkrg0% (1)

- Bill of Material Basics: PDH Course G288Document33 pagesBill of Material Basics: PDH Course G288Ajay Menon100% (2)

- Automotive Body in White FasteningDocument61 pagesAutomotive Body in White Fasteningsurisri1No ratings yet

- Faa ConformityDocument34 pagesFaa ConformityJuan Ali RojasNo ratings yet

- DFMA On Desktop StaplerDocument15 pagesDFMA On Desktop Staplerranjithkraj100% (1)

- Framework Procedure For DDPMASDocument112 pagesFramework Procedure For DDPMASzach rogersNo ratings yet

- Integrated Maintenance Management SystemsDocument37 pagesIntegrated Maintenance Management SystemsUbalamaheshwaran100% (1)

- What Are Bend Allowance, Bend Deduction and K-FactorDocument11 pagesWhat Are Bend Allowance, Bend Deduction and K-Factoritsme5616No ratings yet

- NPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QADocument441 pagesNPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QAPirasanth VithuNo ratings yet

- ME2037 Maintenance EngineeringDocument46 pagesME2037 Maintenance Engineeringrp0212100% (2)

- Aircraft Maintenance and TypesDocument12 pagesAircraft Maintenance and TypesRaamaChandiranNo ratings yet

- Introduction To DFMA: Objectives of This CourseDocument37 pagesIntroduction To DFMA: Objectives of This Coursevenkat4No ratings yet

- Ahmed Atef Abdulghani Base Edge / Base Edge Assembly: Base Edge (45mm Straight) - Straight (3405mm X 304.8mm X 44.5mm)Document2 pagesAhmed Atef Abdulghani Base Edge / Base Edge Assembly: Base Edge (45mm Straight) - Straight (3405mm X 304.8mm X 44.5mm)Ahmed AtefNo ratings yet

- DMU PaperDocument9 pagesDMU Papersathiyam007No ratings yet

- Failure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Document3 pagesFailure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Vishnu RoyNo ratings yet

- Maintenance PhilosophiesDocument8 pagesMaintenance PhilosophiesZainNo ratings yet

- Design ControlsDocument18 pagesDesign Controlstrungthanhnguyen_83No ratings yet

- 4Training-Material CATIA V5 Assembly Design Ch11 PDFDocument57 pages4Training-Material CATIA V5 Assembly Design Ch11 PDFMohammad Rizal RamlyNo ratings yet

- Dial Test IndicatorsDocument20 pagesDial Test IndicatorsbabusadhaNo ratings yet

- Chapter 12 - Warehousing and Material HandlingDocument22 pagesChapter 12 - Warehousing and Material HandlingMohamed Hashi AhmedNo ratings yet

- IATF16949+Chapter+21 +Automotive+Core+ToolsDocument18 pagesIATF16949+Chapter+21 +Automotive+Core+ToolsNhựt Nguyễn HữuNo ratings yet

- Production Drawing: 3 Basic Principles of Dimensioning in Production DrawingsDocument5 pagesProduction Drawing: 3 Basic Principles of Dimensioning in Production DrawingsManoj KbNo ratings yet

- EjectionDocument32 pagesEjectionsk9145No ratings yet

- Design For X: Design and Engineering KTU Module-4Document15 pagesDesign For X: Design and Engineering KTU Module-4Naseel Ibnu AzeezNo ratings yet

- Design For AssemblyDocument34 pagesDesign For AssemblySreeharan100% (1)

- Trailer Seminar PDFDocument73 pagesTrailer Seminar PDFstefanovicana1No ratings yet

- 5021,42 Part List in Design-Engineering DocumentationDocument3 pages5021,42 Part List in Design-Engineering DocumentationGarry Taylor100% (1)

- Manufacturing and Operations ManagementDocument52 pagesManufacturing and Operations ManagementRohit Dhaware100% (1)

- Di Sess 81248BDocument2 pagesDi Sess 81248BBre TroNo ratings yet

- Design For Plastics Unit 7Document10 pagesDesign For Plastics Unit 7Harinath GowdNo ratings yet

- Design and Application GuidelinesDocument391 pagesDesign and Application GuidelinesonspsnonsNo ratings yet

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionFrom EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNo ratings yet

- Catia Digital Mock UpDocument31 pagesCatia Digital Mock UpslitantNo ratings yet

- Airbus Wing Rib DesignDocument12 pagesAirbus Wing Rib DesignSayee ChandrasekaramouliNo ratings yet

- Material Management 1Document6 pagesMaterial Management 1riskyindraNo ratings yet

- BOMDocument1 pageBOMMirza RahilNo ratings yet

- Routing Unit 3 PPCDocument21 pagesRouting Unit 3 PPCRajbir SinghNo ratings yet

- How To Fix A Cyclic Redundancy Check Error - 9 Steps PDFDocument6 pagesHow To Fix A Cyclic Redundancy Check Error - 9 Steps PDFinboxsweetsNo ratings yet

- Browning Fricke Negele (2006) - Process Modeling ConceptsDocument25 pagesBrowning Fricke Negele (2006) - Process Modeling ConceptsinboxsweetsNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- Astrid Baumgardner - How To Set Priorities - 3 Steps For Taking Control of Your TimeDocument5 pagesAstrid Baumgardner - How To Set Priorities - 3 Steps For Taking Control of Your TimeinboxsweetsNo ratings yet

- Weld SymbolsDocument2 pagesWeld SymbolsinboxsweetsNo ratings yet

- 3 Introduction To Engineering DrawingDocument14 pages3 Introduction To Engineering DrawinginboxsweetsNo ratings yet

- 1 Cadcaecam ReviewDocument59 pages1 Cadcaecam ReviewAtsis PapadopoulosNo ratings yet

- Ibrahim Raja August 2022 Theraplay ReportDocument6 pagesIbrahim Raja August 2022 Theraplay Reportfatma522No ratings yet

- PRACTICA 3 - Holguino ErnestoDocument6 pagesPRACTICA 3 - Holguino ErnestoErnesto HolguinoNo ratings yet

- Sop For H3i Nefpa Simo To Mimo 251 - V1.0-JabotabekDocument14 pagesSop For H3i Nefpa Simo To Mimo 251 - V1.0-JabotabekAril GozaliNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- AOS Injury Classification Systems Poster 20200327 THORACOLUMBARDocument1 pageAOS Injury Classification Systems Poster 20200327 THORACOLUMBARRakhmat RamadhaniNo ratings yet

- Final Health EducDocument139 pagesFinal Health EducsprrwgoldenNo ratings yet

- Make Predictions Using TransitsDocument2 pagesMake Predictions Using Transitscnugoud2011100% (1)

- TridentDocument24 pagesTridentPrajod ThiruvambattilNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

- GSX R600k7e3 PDFDocument104 pagesGSX R600k7e3 PDFAdolfoNo ratings yet

- 04 Prescription InterpretationDocument32 pages04 Prescription InterpretationBalsam Zahi Al-HasanNo ratings yet

- Haryana at A Glance: Geographical AreaDocument1 pageHaryana at A Glance: Geographical AreasonuNo ratings yet

- Sika CoolCoat BrochureDocument2 pagesSika CoolCoat BrochureSanjeev KumarNo ratings yet

- Nature of Research (FIRST)Document18 pagesNature of Research (FIRST)JEMNA PITOGONo ratings yet

- Maths Coursework Mark SchemeDocument4 pagesMaths Coursework Mark Schemef5d7ejd0100% (2)

- Motor Nuron Disease and The Life of Motor Neurones.Document1 pageMotor Nuron Disease and The Life of Motor Neurones.mjkenneallyNo ratings yet

- Sma 6512H 2017Document9 pagesSma 6512H 2017jieNo ratings yet

- Company Profile PDFDocument9 pagesCompany Profile PDFSamir WalunjNo ratings yet

- Syriac Unicode U0700Document4 pagesSyriac Unicode U0700ygurseyNo ratings yet

- Review Exercises DAY 3Document4 pagesReview Exercises DAY 3Heba Abd-AllahNo ratings yet

- PPT5-S5 - Problem & Change ManagementDocument29 pagesPPT5-S5 - Problem & Change ManagementDinne RatjNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- Treasure Trove Workbook Answers Daffodils: Passage-1Document4 pagesTreasure Trove Workbook Answers Daffodils: Passage-1Rohan CharlesNo ratings yet

- 2017 Somali English ABC Bridge PrimerDocument230 pages2017 Somali English ABC Bridge PrimerSky somaliNo ratings yet

- Ethics QuizDocument2 pagesEthics QuizLegogie Moses AnoghenaNo ratings yet

- SPM30 PDF Eng PDFDocument0 pagesSPM30 PDF Eng PDFValdemar Miguel SilvaNo ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Notes Receivable and Loan ReceivableDocument21 pagesNotes Receivable and Loan ReceivableLady BelleNo ratings yet

Engineering Bill of Materials

Engineering Bill of Materials

Uploaded by

inboxsweetsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Bill of Materials

Engineering Bill of Materials

Uploaded by

inboxsweetsCopyright:

Available Formats

Engineering bill of materials

http://www.ciras.iastate.edu/publications/CIRASNews/fall97/bom.html

by Jon Clancy, CIRAS

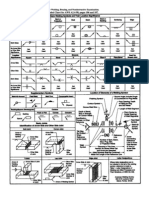

An engineering bill of materials (BOM) is often compared to a cake recipe. Both identify and list the components of a finished product. While the cake recipe identifies ingredients such as flour, sugar, and eggs, the BOM identifies and lists all raw materials, subassemblies, and even intangibles that contribute to the costs of manufacturing a product. While a recipe and a BOM are similar, the consequences of inaccuracy are not. The wrong ingredient in a cake recipe may create a "flop" that ends up in the garbage, a loss, but one that could be resolved in a matter of hours by baking a second cake. Producing product with a wrong component in an engineering BOM is not so easily resolved. It can negatively impact your company's performance through incorrect costing of product, inaccurate inventory levels, accounting variances, customer returns, production of out-of-spec units, potential product liability claims. An accurate engineering BOM is a prerequisite to developing other operating systems. It's a "building block," a central source of information that supports product costing, inventory control, and engineering documentation. A bill of materials may be in a tree form, or more typically in a printed document indented to the lowest level required to accurately describe all material and subassemblies of the parent (or level one) product (Table 1). Whether you utilize the tree or indented method, the key to understanding BOMs is their leveled structure with a "bottoms up" or "goes into" organization. For example, level three components always "go into" level two components, level two components always "go into" the parent (or level one) finished product. However, not all components at a given level require a supporting or lower level. If a sub-assembly at level two is a purchased part, there is no need for a lower, or supporting level (For example, PN15476-62009 [I] Control). Conversely, if a level two component is fabricated in-house, all materials that "go into" the level two component must be identified and listed at a lower or supporting level (For example, PN14644-38389 [AA] Precipitator Assembly). The BOM should be considered an engineering document that accurately identifies and lists the components required to produce a given product at a given revision level. BOMs can be designed to reflect varying degrees of complexity, depending upon the company needs. Utilized as a basic engineering document, the minimal requirements for BOM information should include structure level, part number, revision level, quantity required, unit of measure, description, and make or buy indicator.

1 of 2

3/22/2013 1:44 PM

Engineering bill of materials

http://www.ciras.iastate.edu/publications/CIRASNews/fall97/bom.html

BOM's may be single or multi-level, depending upon company inventory and marketing policies. BOMs can be enhanced to include costing information by including labor and material costs in each lower level component and adding these costs from the bottom to the parent level. Application of overhead rates will then provide fully burdened manufacturing costs. Caution must be exercised when converting engineering BOMs to cost BOMs. Labor and material standards on cost BOMs are an estimate, and provide an accounting standard for the fiscal year. Consequently, they are a reference that must be adjusted by both labor and material variances to obtain actual costs. The accuracy of BOMs is paramount when considering a switch to computerized MRP systems. Basic guidelines for BOM structure include: Each part number must be uniqueno duplication allowed. Part number identification system must be compatible with software. For example, some software requires numeric identification only. Units of measure on BOM must be as purchased. For example, if purchased in feet, express usage in feet. Material use must be adjusted for predictable shrinkage. The engineering BOM and routing sheets are two of the most important documents associated with the manufacturing process. The importance of maintaining accuracy cannot be overemphasized when considering the substantial impact that they have on product costing, inventory, and production management. Table 1: Level 1 ..2 ..2 ....3 ....3 ....3 ..2 ....3 ....3 ....3 ....3 Part # 16844-23003 15476-62009 16763-87001 18701-19302 12000-14273 09000-16001 14644-38389 52010-48007 57002-55100 98002-66600 12000-14267 Revision B J C B D F AA E E D G Quantity Parent 1 1 4 4 1 2 2 2 8 2 Unit Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Description Field Adapter Control Moisture Tester Enclosure Machine Screw Encapsulant Precipitator Assy. Element Housing Machine Screw Precipitator Make/buy Make Buy Make Buy Buy Buy Make Buy Buy Buy Buy

CIRAS News, Vol. 32, No. 1, Fall 1997

Back to the table of contents.

2 of 2

3/22/2013 1:44 PM

You might also like

- Electric Screw Driver M 54-2823 English Rev 1.5Document17 pagesElectric Screw Driver M 54-2823 English Rev 1.5Dina NadeemNo ratings yet

- HMK300EDocument9 pagesHMK300EkbenjikaNo ratings yet

- Function AnalysisDocument4 pagesFunction AnalysisWanAtikatulAsmaNo ratings yet

- Module 07 B1 Mechanical Book 1 PDFDocument341 pagesModule 07 B1 Mechanical Book 1 PDFSohaib Aslam ChaudharyNo ratings yet

- Manage Bill of MaterialsDocument18 pagesManage Bill of MaterialsSoft bridgesNo ratings yet

- Milling OperationsDocument4 pagesMilling Operationsinboxsweets100% (1)

- E1817 PDFDocument3 pagesE1817 PDFalfonso_comimsaNo ratings yet

- Major Repair Alteration Job-Aid PDFDocument118 pagesMajor Repair Alteration Job-Aid PDFJuan BalderasNo ratings yet

- Aviation CSIHandbookDocument186 pagesAviation CSIHandbookxclublifestyleNo ratings yet

- Formability Training Dec2012 PDFDocument111 pagesFormability Training Dec2012 PDFShrikrishna BirajdarNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.2 (Workshop Practices) PDFDocument34 pagesModule 7 (Maintenance Practices) Sub Module 7.2 (Workshop Practices) PDFshareyhouNo ratings yet

- 03 - Drafting Manual - Decimal Inch Sheet Size and FormatDocument51 pages03 - Drafting Manual - Decimal Inch Sheet Size and FormatKakoDaNo ratings yet

- 14 CFR Part 25 Subpart C FARDocument9 pages14 CFR Part 25 Subpart C FARnurek2No ratings yet

- Introduction To Design For Assembly and Manufacturing: (Cost Effective)Document81 pagesIntroduction To Design For Assembly and Manufacturing: (Cost Effective)maladcondomNo ratings yet

- Topic 2 - Formats & Title BlockDocument21 pagesTopic 2 - Formats & Title BlockAmir DanialNo ratings yet

- FAI by Numbers For NI V5 - Rev. GDocument80 pagesFAI by Numbers For NI V5 - Rev. GRicardoNo ratings yet

- Project Scheduling: PERT/CPMDocument37 pagesProject Scheduling: PERT/CPMShruti KaushikNo ratings yet

- ENG Change Order ProcessDocument2 pagesENG Change Order Processsoureddy1981No ratings yet

- MTBF Calculator (Reliability Calculation System)Document233 pagesMTBF Calculator (Reliability Calculation System)Polimore100% (1)

- Lockheed Tooling Manual Tms - MC - 015 - Rev29 PDFDocument114 pagesLockheed Tooling Manual Tms - MC - 015 - Rev29 PDFjimNo ratings yet

- CHAPTER-1 Introduction To Aircraft DrawingDocument12 pagesCHAPTER-1 Introduction To Aircraft DrawingGhifaris VashaNo ratings yet

- CNC Design FeaturesDocument10 pagesCNC Design Featuresaqtu12fuc100% (1)

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltNo ratings yet

- Foreign Object Damage (Fod) Prevention PlanDocument14 pagesForeign Object Damage (Fod) Prevention PlanJolyeTorresNo ratings yet

- Partmaker Tech Note #081505: Using Config-By-Click'™ in PartmakerDocument9 pagesPartmaker Tech Note #081505: Using Config-By-Click'™ in Partmaker123anthonyNo ratings yet

- 1 Purpose and ScopeDocument5 pages1 Purpose and ScopeSivananthaa MurtheeNo ratings yet

- Aero Presentation: Aerospace PracticeDocument56 pagesAero Presentation: Aerospace Practicerajagopalkrg0% (1)

- Bill of Material Basics: PDH Course G288Document33 pagesBill of Material Basics: PDH Course G288Ajay Menon100% (2)

- Automotive Body in White FasteningDocument61 pagesAutomotive Body in White Fasteningsurisri1No ratings yet

- Faa ConformityDocument34 pagesFaa ConformityJuan Ali RojasNo ratings yet

- DFMA On Desktop StaplerDocument15 pagesDFMA On Desktop Staplerranjithkraj100% (1)

- Framework Procedure For DDPMASDocument112 pagesFramework Procedure For DDPMASzach rogersNo ratings yet

- Integrated Maintenance Management SystemsDocument37 pagesIntegrated Maintenance Management SystemsUbalamaheshwaran100% (1)

- What Are Bend Allowance, Bend Deduction and K-FactorDocument11 pagesWhat Are Bend Allowance, Bend Deduction and K-Factoritsme5616No ratings yet

- NPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QADocument441 pagesNPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QAPirasanth VithuNo ratings yet

- ME2037 Maintenance EngineeringDocument46 pagesME2037 Maintenance Engineeringrp0212100% (2)

- Aircraft Maintenance and TypesDocument12 pagesAircraft Maintenance and TypesRaamaChandiranNo ratings yet

- Introduction To DFMA: Objectives of This CourseDocument37 pagesIntroduction To DFMA: Objectives of This Coursevenkat4No ratings yet

- Ahmed Atef Abdulghani Base Edge / Base Edge Assembly: Base Edge (45mm Straight) - Straight (3405mm X 304.8mm X 44.5mm)Document2 pagesAhmed Atef Abdulghani Base Edge / Base Edge Assembly: Base Edge (45mm Straight) - Straight (3405mm X 304.8mm X 44.5mm)Ahmed AtefNo ratings yet

- DMU PaperDocument9 pagesDMU Papersathiyam007No ratings yet

- Failure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Document3 pagesFailure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Vishnu RoyNo ratings yet

- Maintenance PhilosophiesDocument8 pagesMaintenance PhilosophiesZainNo ratings yet

- Design ControlsDocument18 pagesDesign Controlstrungthanhnguyen_83No ratings yet

- 4Training-Material CATIA V5 Assembly Design Ch11 PDFDocument57 pages4Training-Material CATIA V5 Assembly Design Ch11 PDFMohammad Rizal RamlyNo ratings yet

- Dial Test IndicatorsDocument20 pagesDial Test IndicatorsbabusadhaNo ratings yet

- Chapter 12 - Warehousing and Material HandlingDocument22 pagesChapter 12 - Warehousing and Material HandlingMohamed Hashi AhmedNo ratings yet

- IATF16949+Chapter+21 +Automotive+Core+ToolsDocument18 pagesIATF16949+Chapter+21 +Automotive+Core+ToolsNhựt Nguyễn HữuNo ratings yet

- Production Drawing: 3 Basic Principles of Dimensioning in Production DrawingsDocument5 pagesProduction Drawing: 3 Basic Principles of Dimensioning in Production DrawingsManoj KbNo ratings yet

- EjectionDocument32 pagesEjectionsk9145No ratings yet

- Design For X: Design and Engineering KTU Module-4Document15 pagesDesign For X: Design and Engineering KTU Module-4Naseel Ibnu AzeezNo ratings yet

- Design For AssemblyDocument34 pagesDesign For AssemblySreeharan100% (1)

- Trailer Seminar PDFDocument73 pagesTrailer Seminar PDFstefanovicana1No ratings yet

- 5021,42 Part List in Design-Engineering DocumentationDocument3 pages5021,42 Part List in Design-Engineering DocumentationGarry Taylor100% (1)

- Manufacturing and Operations ManagementDocument52 pagesManufacturing and Operations ManagementRohit Dhaware100% (1)

- Di Sess 81248BDocument2 pagesDi Sess 81248BBre TroNo ratings yet

- Design For Plastics Unit 7Document10 pagesDesign For Plastics Unit 7Harinath GowdNo ratings yet

- Design and Application GuidelinesDocument391 pagesDesign and Application GuidelinesonspsnonsNo ratings yet

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionFrom EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNo ratings yet

- Catia Digital Mock UpDocument31 pagesCatia Digital Mock UpslitantNo ratings yet

- Airbus Wing Rib DesignDocument12 pagesAirbus Wing Rib DesignSayee ChandrasekaramouliNo ratings yet

- Material Management 1Document6 pagesMaterial Management 1riskyindraNo ratings yet

- BOMDocument1 pageBOMMirza RahilNo ratings yet

- Routing Unit 3 PPCDocument21 pagesRouting Unit 3 PPCRajbir SinghNo ratings yet

- How To Fix A Cyclic Redundancy Check Error - 9 Steps PDFDocument6 pagesHow To Fix A Cyclic Redundancy Check Error - 9 Steps PDFinboxsweetsNo ratings yet

- Browning Fricke Negele (2006) - Process Modeling ConceptsDocument25 pagesBrowning Fricke Negele (2006) - Process Modeling ConceptsinboxsweetsNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- Astrid Baumgardner - How To Set Priorities - 3 Steps For Taking Control of Your TimeDocument5 pagesAstrid Baumgardner - How To Set Priorities - 3 Steps For Taking Control of Your TimeinboxsweetsNo ratings yet

- Weld SymbolsDocument2 pagesWeld SymbolsinboxsweetsNo ratings yet

- 3 Introduction To Engineering DrawingDocument14 pages3 Introduction To Engineering DrawinginboxsweetsNo ratings yet

- 1 Cadcaecam ReviewDocument59 pages1 Cadcaecam ReviewAtsis PapadopoulosNo ratings yet

- Ibrahim Raja August 2022 Theraplay ReportDocument6 pagesIbrahim Raja August 2022 Theraplay Reportfatma522No ratings yet

- PRACTICA 3 - Holguino ErnestoDocument6 pagesPRACTICA 3 - Holguino ErnestoErnesto HolguinoNo ratings yet

- Sop For H3i Nefpa Simo To Mimo 251 - V1.0-JabotabekDocument14 pagesSop For H3i Nefpa Simo To Mimo 251 - V1.0-JabotabekAril GozaliNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- AOS Injury Classification Systems Poster 20200327 THORACOLUMBARDocument1 pageAOS Injury Classification Systems Poster 20200327 THORACOLUMBARRakhmat RamadhaniNo ratings yet

- Final Health EducDocument139 pagesFinal Health EducsprrwgoldenNo ratings yet

- Make Predictions Using TransitsDocument2 pagesMake Predictions Using Transitscnugoud2011100% (1)

- TridentDocument24 pagesTridentPrajod ThiruvambattilNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

- GSX R600k7e3 PDFDocument104 pagesGSX R600k7e3 PDFAdolfoNo ratings yet

- 04 Prescription InterpretationDocument32 pages04 Prescription InterpretationBalsam Zahi Al-HasanNo ratings yet

- Haryana at A Glance: Geographical AreaDocument1 pageHaryana at A Glance: Geographical AreasonuNo ratings yet

- Sika CoolCoat BrochureDocument2 pagesSika CoolCoat BrochureSanjeev KumarNo ratings yet

- Nature of Research (FIRST)Document18 pagesNature of Research (FIRST)JEMNA PITOGONo ratings yet

- Maths Coursework Mark SchemeDocument4 pagesMaths Coursework Mark Schemef5d7ejd0100% (2)

- Motor Nuron Disease and The Life of Motor Neurones.Document1 pageMotor Nuron Disease and The Life of Motor Neurones.mjkenneallyNo ratings yet

- Sma 6512H 2017Document9 pagesSma 6512H 2017jieNo ratings yet

- Company Profile PDFDocument9 pagesCompany Profile PDFSamir WalunjNo ratings yet

- Syriac Unicode U0700Document4 pagesSyriac Unicode U0700ygurseyNo ratings yet

- Review Exercises DAY 3Document4 pagesReview Exercises DAY 3Heba Abd-AllahNo ratings yet

- PPT5-S5 - Problem & Change ManagementDocument29 pagesPPT5-S5 - Problem & Change ManagementDinne RatjNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- Treasure Trove Workbook Answers Daffodils: Passage-1Document4 pagesTreasure Trove Workbook Answers Daffodils: Passage-1Rohan CharlesNo ratings yet

- 2017 Somali English ABC Bridge PrimerDocument230 pages2017 Somali English ABC Bridge PrimerSky somaliNo ratings yet

- Ethics QuizDocument2 pagesEthics QuizLegogie Moses AnoghenaNo ratings yet

- SPM30 PDF Eng PDFDocument0 pagesSPM30 PDF Eng PDFValdemar Miguel SilvaNo ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Notes Receivable and Loan ReceivableDocument21 pagesNotes Receivable and Loan ReceivableLady BelleNo ratings yet