Professional Documents

Culture Documents

Fixing Procedure For FRP-GRP Pipes

Fixing Procedure For FRP-GRP Pipes

Uploaded by

venka07Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixing Procedure For FRP-GRP Pipes

Fixing Procedure For FRP-GRP Pipes

Uploaded by

venka07Copyright:

Available Formats

Doc. No.

: TSPL-P143-WPS-812

Page 1 of 5

23.03.10 Date

PROJECT :

SUBMISSION FOR APPROVAL 0 SUBMISSION Rev.

SEPL Prepared

NC Checked

USY Approved

2 X 135MW THERMAL POWER PLANT (PHASE -1)

TAMMINAPATNAM & MUMMIDI VILLAGES, CHILLAKUR MANDAL SPSR NELLORE DISTRICT - 524121, ANDHRA PRADESH - INDIA

OWNER :

SIMHAPURI ENERGY PRIVATE LIMITED

MADHUCON GREENLANDS, BEGUMPET, HYDERABAD - 500 016, AP- INDIA

OWNER ENGINEER : EPC CONTRACTOR : ORIGINATOR : EPC ENGINEER VENDOR/ SUPPLIER : STATUS : FILE NO : UNITS : SCALE : NTS TITLE : DRG NO:

DEVELOPMENT CONSULTANTS PRIVATE LIMITED, KOLKATA MADHUCON PROJECTS LIMITED

ROAD NO.36, JUBILEE HILLS, HYDERABAD - 500 033, AP - INDIA

M.N.DASTUR & COMPANY (P) LIMITED, KOLKATA THERMOSYSTEMS PVT. LTD. HYDERABAD FIXING PROCEDURE OF GRP / FRP PIPES TSPL-P143-WPS-812

SHEET 01 OF 05 REV. 0

Doc. No. : TSPL-P143-WPS-812

Page 2 of 5

BELL & SPIGOT WITH RUBBER SEAL JOINT

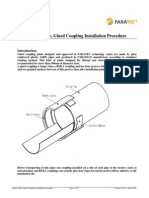

Bell and Spigot with elastomeric seal joint is used to connect two GRP pipes mainly used for underground application. Bell & Spigot joint has a groove on the Bell end to retain an elastomeric seal that shall be the sole element of the joint to provide the water-tightness. This flexible joint allows for axial movement of the spigot in the Bell and some angular deflection. The schematic arrangement of Bell & Spigot with rubber seal is shown in the sketch. The GRP pipe will have one end provided with Bell and other end provided with a matching Spigot. The essential requirements to accomplish this jointing are: Bell provided at one end of the pipe Spigot provided at other end of the pipe Elastomeric seals made of rubber

Fig. Bell & Spigot Joint with Elastomeric Seal.

Doc. No. : TSPL-P143-WPS-812

Page 3 of 5

Bell End: The Bell end is an integral filament wound part of the pipe The inner diameter of the bell end is manufactured perfectly to suit the spigot end with required tolerance.

Spigot End: The other end of the pipe will have the spigot. The spigot end is accurately machined to the required tolerance.

Rubber Seal: The rubber seal is made up of EPDM rubber. This rubber seal provides a very tight leak proof joint.

Joint Assembly:

Tools required for assembly of joint 1. Chain pulley block 2. Nylon slings. 3. Wooden supports Accessories / consumables required 1. Clothe. 2. Vegetable based lubricant.

Joining Method Step 1: Clean the Bell & Groove. Thoroughly clean the inside of Bell end and Groove with clean cloth. Make sure that any dirt or oil left on the surface. Do not use cotton waste in order to prevent thread or fibers stick on the sealing surface. Step 2: Install Gaskets Insert the gasket into the groove leaving loops (typically two to four) of rubber extending out of the groves. Do not use any lubricant in the groove or on the gasket at this stage of assembly. Water may be used to moisten the gasket and groove to ease positioning and insertion of the gasket.

Doc. No. : TSPL-P143-WPS-812

Page 4 of 5

With uniform pressure, push each loop of the rubber gasket into the gasket groove. When installed, pull carefully on the gasket in the radial direction around the circumference to distribute compression of the gasket. Check also that both sides of the gasket protrude equally above the top of the groove around the whole circumference. Tapping with a rubber mallet will be helpful to accomplish the above

Step 3: Lubricate Gasket Using a clean cloth, apply a thin film of lubricant to the rubber gaskets. Always use vegetable based lubricants, never use petroleum based lubricants. Step 4: Clean and Lubricate Spigot. Thoroughly clean pipe spigot to remove any dirt, grit, grease, etc. Using a clean cloth, apply a thin film of lubricant to the spigots from the end of the pipe. After lubricating, take care to keep the bell and spigot clean. Step 5: Fixing of Clamps Fix first clamp near to the bell end of one pipe or at the left in position to next joint. Fix Clamp B on the pipe to be connected in the correct position. Step 6: Pipe Placement The pipe to be connected is placed on the bed with sufficient distance from previously joined pipe to allow lowering the coupling into position.

Doc. No. : TSPL-P143-WPS-812

Page 5 of 5

FIELD HYDROTESTING OF GRP PIPELINES FOR BELL & SPIGOT JOINT WITH DOUBLE O-RINGS

The GRP pipes are tested at 1.5 times the pressure rating at our factory to ensure the leak tightness of the pipe. The hydraulic pressure testing along with other mechanical tests done on the pipe sections prove the capability of the pipe for its intended service. However, when the pipes are jointed to form a pipeline, it becomes necessary to do field hydro testing on the pipeline to ensure that joints constructed in the field do offer the required pressure tightness. This is done by either filling water in the constructed pipeline in segments by creating blinds at both ends and subjecting the selected segment to 1.5 times the working pressure or by carrying out a joint testing on the constructed pipeline. The joint testing method on the constructed pipeline is found to be more positive and it avoids the biggest problem of air entrapment and its associated technical issues during field hydro testing. The entrapped air in the pipeline filled with water for segmental field hydro testing cannot be fully removed practically as certain pockets of entrapped air in bends and fittings tend to remain the pipeline even with air valves fitted in the line. The entrapped air during pressurisation gets compressed and causes fluctuation in the line pressure and pipeline movement. The above problems are avoided in joint testing method. Also, the joint testing method is more suitable to wet trenches, since leakage can be checked on every joints and assessment done. Hence, Strategic Engineering is adopting the jointing testing procedure for field testing of constructed pipeline and the procedure is as shown in the sketch. Water is filled between the O rings through the nipple and subjected to the required pressure. On completion of testing, the nipple is closed with the male adaptor and laminated. Pipes are tested for joint testing at our factory by the above method and the joints are proved for its performance.

You might also like

- Summary - Granovetter (1985) Economic Action and Social StructureDocument2 pagesSummary - Granovetter (1985) Economic Action and Social StructureSimon Fiala100% (12)

- CBSE Happy Classrooms Workshop-FinalDocument54 pagesCBSE Happy Classrooms Workshop-FinalAman ambani100% (7)

- Method Statement - InsulationDocument2 pagesMethod Statement - Insulationjasonvent82% (11)

- Field Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsDocument8 pagesField Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsJoshua McAlisterNo ratings yet

- 008 - Field Hydrotest ProcedureDocument17 pages008 - Field Hydrotest Procedurekaruna346100% (2)

- Plant and Animal FibresDocument12 pagesPlant and Animal Fibresvenka07No ratings yet

- A Study On Employee MotivationDocument69 pagesA Study On Employee MotivationAnantha Vijayan100% (2)

- Method Statement For AC Units Pipe Installation and Drainage - CatDocument8 pagesMethod Statement For AC Units Pipe Installation and Drainage - CatakerimtuzunNo ratings yet

- Cylinder Change PurgingDocument16 pagesCylinder Change Purgingengg_mech77No ratings yet

- MS For Installation of GRE PipingDocument9 pagesMS For Installation of GRE PipingN P Srinivasarao100% (2)

- O & M-MannualDocument29 pagesO & M-MannualHadziq NaufalNo ratings yet

- English Solvent Welding Guide 12 2017Document24 pagesEnglish Solvent Welding Guide 12 2017Richard EddingtonNo ratings yet

- BestPractices Thermoplastic Sep08Document10 pagesBestPractices Thermoplastic Sep08geverett2765No ratings yet

- MOS For Water Supply Pipe Installation Inside ToiletDocument3 pagesMOS For Water Supply Pipe Installation Inside ToiletSherif M. ElgebalyNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- Cw213623-Sokaij-Qa-6050-00002-Sleeving ProcedureDocument7 pagesCw213623-Sokaij-Qa-6050-00002-Sleeving ProcedurejeszzymenNo ratings yet

- Piece Density by Mercury DisplacementDocument10 pagesPiece Density by Mercury DisplacementDavinNo ratings yet

- HDPE - PVC Heat Fusion Joining ProcedureDocument32 pagesHDPE - PVC Heat Fusion Joining Proceduresentunali100% (1)

- Sellos para Vacio Criterio de DiseñoDocument8 pagesSellos para Vacio Criterio de Diseñogabinho755416No ratings yet

- Nesl Training ManualDocument91 pagesNesl Training ManualSOUMYA DEEP CHATTERJEENo ratings yet

- CH9 Inst and Const ProceduresDocument65 pagesCH9 Inst and Const ProceduresSaad AliNo ratings yet

- Method Statement For GRP Pipe InstallationDocument8 pagesMethod Statement For GRP Pipe Installationdj_holo100% (1)

- GRE (Under-Ground) Pipe Erection ProcedureDocument9 pagesGRE (Under-Ground) Pipe Erection ProcedureHamada ELaraby100% (1)

- Pttchem SP P 121 000 - Wrapping PDFDocument12 pagesPttchem SP P 121 000 - Wrapping PDFCivil FriendNo ratings yet

- Mechanical PlugsDocument6 pagesMechanical Plugskategord0% (1)

- Method Statement For Repair of Underground 14rev 2Document10 pagesMethod Statement For Repair of Underground 14rev 2Boj MingiNo ratings yet

- Installation ManualDocument28 pagesInstallation ManualLuisa Fernanda Alvarez VillaNo ratings yet

- Rubber Lining ApplicationDocument9 pagesRubber Lining ApplicationeyslNo ratings yet

- Inspection Spark TestingDocument4 pagesInspection Spark TestingAshish PattanaikNo ratings yet

- Electrofusion Welding HDPE PipeDocument4 pagesElectrofusion Welding HDPE PipeTRISTAR TEKZONENo ratings yet

- PCT Patoqs Jolas Waterline&Sanitary&FcudrainDocument39 pagesPCT Patoqs Jolas Waterline&Sanitary&FcudrainRegine Dela Fuente100% (1)

- Method Statement For Installation of Ducted Split ACsDocument3 pagesMethod Statement For Installation of Ducted Split ACsofficialdonsonNo ratings yet

- IA Plumbing 9 Q3 LAS3 FINALDocument7 pagesIA Plumbing 9 Q3 LAS3 FINALRoniel BalverdeNo ratings yet

- GRP Pipe Adhesive Coupling InstallationDocument7 pagesGRP Pipe Adhesive Coupling InstallationMrinal Kanti BhaduriNo ratings yet

- Filtro Onga Series IIDocument24 pagesFiltro Onga Series IIRicardo Cesar Bueno BertichevicNo ratings yet

- Refrigeration PipelinesDocument2 pagesRefrigeration PipelinesDavidB1206No ratings yet

- ID-PRC 21 - Anti-Corrosion Wrapping UG Steel PipingDocument10 pagesID-PRC 21 - Anti-Corrosion Wrapping UG Steel Pipingcloud23No ratings yet

- MOS For Water Supply Pipe InstallationDocument3 pagesMOS For Water Supply Pipe InstallationDon Roseller Dumaya100% (1)

- Chapters Chapter 1 Introduction/ The OrganizationDocument11 pagesChapters Chapter 1 Introduction/ The OrganizationWag GeeNo ratings yet

- O - M ManualDocument27 pagesO - M ManualacpproductionNo ratings yet

- PVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsDocument2 pagesPVC & CPVC Basket Strainers: Installation & Maintenance Service InstructionsTheresa NguyenNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Electrofusion Jointing of Polyethylene (Pe) Pipe and Fittings For Pressure ApplicationsDocument3 pagesElectrofusion Jointing of Polyethylene (Pe) Pipe and Fittings For Pressure Applicationsarun100% (1)

- Tex 600JDocument44 pagesTex 600JLucio Rodriguez SifuentesNo ratings yet

- GPDS Connections Field InspectionDocument4 pagesGPDS Connections Field InspectiontheinmoeNo ratings yet

- N839EX PRA005 B HDPE Duct WeldingDocument17 pagesN839EX PRA005 B HDPE Duct Weldingocolon81No ratings yet

- Pipelines Leak RepairDocument6 pagesPipelines Leak Repairathar_abbas_1100% (2)

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDocument20 pagesA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNo ratings yet

- ATB 021 Flowtite Pipe Tapping PDFDocument10 pagesATB 021 Flowtite Pipe Tapping PDFRajadurai SinghNo ratings yet

- Manhole NasscoDocument9 pagesManhole NasscoAsmara KanthiNo ratings yet

- Jointing Instructions Dec 20123Document2 pagesJointing Instructions Dec 20123Gabi CristacheNo ratings yet

- Installation Checklist For The Petroplas Piping System (Page 1 of 2)Document2 pagesInstallation Checklist For The Petroplas Piping System (Page 1 of 2)Sami ThirunavukkarasuNo ratings yet

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- Inspection - Spark-Testing PDFDocument3 pagesInspection - Spark-Testing PDFanandtpe1No ratings yet

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

- 57-0057 InstDocument3 pages57-0057 Instvolvo297No ratings yet

- Guide To Special Operations: Maintaining The Grounding SystemDocument6 pagesGuide To Special Operations: Maintaining The Grounding SystemrolanditosanchezNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundFrom EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundNo ratings yet

- Lec 2 Refractories Kiln Design 2011Document36 pagesLec 2 Refractories Kiln Design 2011venka07No ratings yet

- Theni Notes - IbiboDocument7 pagesTheni Notes - Ibibovenka07No ratings yet

- History Amp Future - Plasma The Fourth State of MatterDocument2 pagesHistory Amp Future - Plasma The Fourth State of Mattervenka07No ratings yet

- Upcoming Power Projects in IndiaDocument41 pagesUpcoming Power Projects in Indiavenka07No ratings yet

- Data Sheet For Gate, Globe and Check ValvesDocument7 pagesData Sheet For Gate, Globe and Check Valvesvenka07No ratings yet

- Energy SavingsDocument2 pagesEnergy Savingsvenka07No ratings yet

- Evaporation: (I) Vapour PressureDocument15 pagesEvaporation: (I) Vapour Pressurevenka07No ratings yet

- Datasheet For Strainer.Document7 pagesDatasheet For Strainer.venka07No ratings yet

- Weather Data - APDocument10 pagesWeather Data - APvenka07No ratings yet

- Overall Heat Transfer CoefficientDocument4 pagesOverall Heat Transfer Coefficientvenka07No ratings yet

- Ni Hard (Wear Resistant) : PropertiesDocument1 pageNi Hard (Wear Resistant) : Propertiesvenka07No ratings yet

- Copper Plate CompDocument1 pageCopper Plate Compvenka07No ratings yet

- நவீன தமிழ் அருஞ்சொற்பொருள்Document47 pagesநவீன தமிழ் அருஞ்சொற்பொருள்venka07No ratings yet

- Pipe Support SpacingDocument2 pagesPipe Support Spacingvenka07No ratings yet

- EFX Approval DrawingDocument5 pagesEFX Approval Drawingvenka07No ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Documentvenka07No ratings yet

- Deck Slab Arrangements - 1Document1 pageDeck Slab Arrangements - 1venka07No ratings yet

- Telugu AlphabetsDocument3 pagesTelugu AlphabetsKowsik_JSNo ratings yet

- Seligram, IncDocument5 pagesSeligram, IncAto SumartoNo ratings yet

- CapstoneDocument16 pagesCapstoneKaithlyn LandichoNo ratings yet

- Leopard 2A4M CANDocument1 pageLeopard 2A4M CANMobil BoyNo ratings yet

- Sindh Government Promotion RulesDocument41 pagesSindh Government Promotion RulesseoresercherNo ratings yet

- Iso 14692 2Document8 pagesIso 14692 2Mayara AlvesNo ratings yet

- A Poison Tree: The Poet's Background William Blake (28 November 1757 - 12 August 1827) Was An English Poet, Painter, andDocument6 pagesA Poison Tree: The Poet's Background William Blake (28 November 1757 - 12 August 1827) Was An English Poet, Painter, andwan fadhilahNo ratings yet

- JADWAL KULIAH TPB SMT GASAL TA 2020 2021 Rev 5Document49 pagesJADWAL KULIAH TPB SMT GASAL TA 2020 2021 Rev 5shin yongriNo ratings yet

- (LIT) LS90 LS110 LS160 BrochureDocument20 pages(LIT) LS90 LS110 LS160 BrochureJuan Carlos Reinhold Niembro SuchowitzkiNo ratings yet

- A Project Proposal of Online Enrollment in WmsuDocument9 pagesA Project Proposal of Online Enrollment in WmsuClairole Marie Quilantang100% (2)

- Logix SERCOS Tuning Tips v1.02 1Document6 pagesLogix SERCOS Tuning Tips v1.02 1José AlanizNo ratings yet

- E. B. Magalona National High School Summative Test in CSS 10 Quarter 1 Week 1 Multiple Choice. Choose The Letter of The Correct AnswerDocument2 pagesE. B. Magalona National High School Summative Test in CSS 10 Quarter 1 Week 1 Multiple Choice. Choose The Letter of The Correct Answerric jason pedralNo ratings yet

- CD1 - P1 - Sentence TransformationDocument34 pagesCD1 - P1 - Sentence TransformationKhánh LinhNo ratings yet

- Modern Auditing Beynton Solution Manual Chapter 2Document21 pagesModern Auditing Beynton Solution Manual Chapter 2Sjifa AuliaNo ratings yet

- Soal Latihan Persiapan Us Bahasa InggrisDocument6 pagesSoal Latihan Persiapan Us Bahasa InggrisNurrul Hadhya ZaraNo ratings yet

- Consumer Behaviour Mod IIDocument50 pagesConsumer Behaviour Mod IIHarinder SinghNo ratings yet

- 2020 Wddty February 2020Document84 pages2020 Wddty February 2020San RajNo ratings yet

- Minebea Stepper Motor Part Number Decoding TableDocument5 pagesMinebea Stepper Motor Part Number Decoding TableWijebNo ratings yet

- Diagnosis of Hirschsprung Disease: Lusine Ambartsumyan, Caitlin Smith, and Raj P KapurDocument15 pagesDiagnosis of Hirschsprung Disease: Lusine Ambartsumyan, Caitlin Smith, and Raj P KapurGhina Mauizha WulandariNo ratings yet

- Test - Project Management Chapter 2 - QuizletDocument5 pagesTest - Project Management Chapter 2 - Quizletahmed mahmoudNo ratings yet

- Test Bank For Principles of Anatomy and Physiology 14th Edition Gerard J Tortora Bryan H Derrickson Isbn 10 1118774566 Isbn 13 9781118774564 Isbn 9781118808979 Isbn 9781118344392 IsbnDocument24 pagesTest Bank For Principles of Anatomy and Physiology 14th Edition Gerard J Tortora Bryan H Derrickson Isbn 10 1118774566 Isbn 13 9781118774564 Isbn 9781118808979 Isbn 9781118344392 Isbnjohnlipceqgkjnbt100% (53)

- Iterative Business Model Innovation A Conceptual Proc - 2023 - Journal of BusinDocument14 pagesIterative Business Model Innovation A Conceptual Proc - 2023 - Journal of Busintranhungduc1995No ratings yet

- Negor q3 Genbio2 Slkweek3 V2.finalDocument22 pagesNegor q3 Genbio2 Slkweek3 V2.finaljenicahazelmagahisNo ratings yet

- Apr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095Document1 pageApr 30 23:59:59 IST 2023 Sunil Kumar Bhardwaj: 3rd Floor, No - 165 Megh Towers PH Road Maduravoyal Chennai - 600095amanNo ratings yet

- Church GovernmentDocument28 pagesChurch Governmentchris NgonoMNo ratings yet

- 10 1 1 590 9326 PDFDocument13 pages10 1 1 590 9326 PDFsbarwal9No ratings yet

- E45 Laboratory4Document7 pagesE45 Laboratory4nickNo ratings yet

- Clat Mock Prime 10Document49 pagesClat Mock Prime 10Ritvikh RajputNo ratings yet