Professional Documents

Culture Documents

Barnett Shale Energy Education Council

Barnett Shale Energy Education Council

Uploaded by

zirimiaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Guideline For Industrial Track Projects - BNSF RailwayDocument67 pagesDesign Guideline For Industrial Track Projects - BNSF RailwayKhalil SaberNo ratings yet

- Basic Clinical Massage TherapyDocument654 pagesBasic Clinical Massage Therapykkism100% (11)

- Radiation Technologies Superfund PlanDocument11 pagesRadiation Technologies Superfund PlanLouis C. HochmanNo ratings yet

- Ascs To The Acr Standard Training Course Handouts - 2016 0 PDFDocument143 pagesAscs To The Acr Standard Training Course Handouts - 2016 0 PDFNhel AlvaroNo ratings yet

- New Concept in Fracturing - Al 119094Document8 pagesNew Concept in Fracturing - Al 119094Ali ZareeforoushNo ratings yet

- Mil STD 882eDocument104 pagesMil STD 882ezirimia100% (1)

- Methanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemDocument6 pagesMethanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemzirimiaNo ratings yet

- Design TipsDocument30 pagesDesign Tipsrvejner5253No ratings yet

- ct220130102 34a24006f9Document1 pagect220130102 34a24006f9zirimiaNo ratings yet

- Analytical Requirements For Hydrocarbon Dewpoint CalculationDocument13 pagesAnalytical Requirements For Hydrocarbon Dewpoint CalculationzirimiaNo ratings yet

- 0 Excelent HFDocument53 pages0 Excelent HFzirimiaNo ratings yet

- Individual Risk and Social Risk Analysis For Urban PipelineDocument6 pagesIndividual Risk and Social Risk Analysis For Urban Pipelinezirimia100% (1)

- Carrier RLC 2016 - enDocument58 pagesCarrier RLC 2016 - enAbseleam NurtenNo ratings yet

- Persidangan Pengarah2 Perhutanan SM 5 Sept 2022 - 220905 - 133501Document16 pagesPersidangan Pengarah2 Perhutanan SM 5 Sept 2022 - 220905 - 133501Arifhadi Johari AffandiNo ratings yet

- Macrobenthos of Meghna River Estuary, BangaldeshDocument7 pagesMacrobenthos of Meghna River Estuary, BangaldeshMohammad Belal HossainNo ratings yet

- 1992 National Waste Processing Conference 01Document8 pages1992 National Waste Processing Conference 01aymmon8950No ratings yet

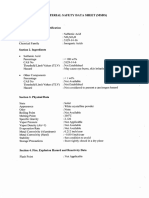

- Material Safety Data Sheet: Section 1: Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1: Product and Company IdentificationIka KusumawatiNo ratings yet

- Material Safety Data Sheet: D182 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument4 pagesMaterial Safety Data Sheet: D182 1. Identification of The Substance/Preparation and of The Company/UndertakingPranav DubeyNo ratings yet

- STP GuideDocument2 pagesSTP GuideFlow Dynamics IndiaNo ratings yet

- LEED V4.1 Score CardDocument1 pageLEED V4.1 Score CardAsad YousafNo ratings yet

- Gaza StripDocument39 pagesGaza StripFeras ObeidNo ratings yet

- Briefing Note 16 BREEAMDocument6 pagesBriefing Note 16 BREEAMalireza1023No ratings yet

- ĐỀ THI GIỮA KÌ ANH 9- 40 trắc nghiệmDocument2 pagesĐỀ THI GIỮA KÌ ANH 9- 40 trắc nghiệmTiếng Anh 7No ratings yet

- H2ICEDocument10 pagesH2ICElucasNo ratings yet

- Acid Rain and Transported Air Pollutants: Implications For Public PolicyDocument325 pagesAcid Rain and Transported Air Pollutants: Implications For Public Policydilsiam100% (4)

- Waste ManagementDocument5 pagesWaste ManagementDaveIversonSorianoNo ratings yet

- Waste Management FAQSDocument4 pagesWaste Management FAQSBelinda LapsitNo ratings yet

- Exam 1 - 001Document26 pagesExam 1 - 001Jose Carlos ArgeñalNo ratings yet

- Sở Giáo Dục Và Đào Tạo Vĩnh Phúc Trường Thpt Chuyên Vĩnh Phúc (Đềthigồm 5trang) Đề Kscl Các Môn Thi Thpt Quốc Gia - Lần 2 NĂM HỌC: 2020-2021 Môn: Anh 11Document6 pagesSở Giáo Dục Và Đào Tạo Vĩnh Phúc Trường Thpt Chuyên Vĩnh Phúc (Đềthigồm 5trang) Đề Kscl Các Môn Thi Thpt Quốc Gia - Lần 2 NĂM HỌC: 2020-2021 Môn: Anh 11lienanhcvpNo ratings yet

- p6 Man and Environment WorksheetDocument17 pagesp6 Man and Environment Worksheetapi-362831708100% (1)

- Sulphamic Acid MSDS PDFDocument3 pagesSulphamic Acid MSDS PDFSalsabilaAzisNo ratings yet

- Ashiq HossainDocument54 pagesAshiq HossainAshiq Hossain100% (1)

- FYP Allocation AY 2012-2013 Sem 1Document7 pagesFYP Allocation AY 2012-2013 Sem 1Yandi LayadiNo ratings yet

- Progress Report MemoDocument3 pagesProgress Report MemoKamaleeshwaran karthiNo ratings yet

- Nesrea ActDocument24 pagesNesrea Actkirandevi1981100% (1)

- E-00331 Vigon SDS US EnglishDocument9 pagesE-00331 Vigon SDS US EnglishDHe Vic'zNo ratings yet

- Global Warming & Acid RainDocument34 pagesGlobal Warming & Acid RainVikshit GanjooNo ratings yet

- Introduction To Environmental Studies: Unit 1Document8 pagesIntroduction To Environmental Studies: Unit 17992 B Ashutosh NagarNo ratings yet

- Designing of A Fire Tube Boiler: July 2020Document8 pagesDesigning of A Fire Tube Boiler: July 2020hamza abbasNo ratings yet

- Chrome On Silica Cataylst MSDSDocument4 pagesChrome On Silica Cataylst MSDSstavros7No ratings yet

Barnett Shale Energy Education Council

Barnett Shale Energy Education Council

Uploaded by

zirimiaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Barnett Shale Energy Education Council

Barnett Shale Energy Education Council

Uploaded by

zirimiaCopyright:

Available Formats

HYDRAULIC

FRACTURING

Unlocking Vast New Natural Gas

Resources for North America

BARNETT SHALE ENERGY EDUCATION COUNCIL

Clean, Domestic Natural Gas

Although geologists have known for years that shale formations hold vast

deposits of natural gas, the natural gas in these formations was not thought

to be recoverable until recently. Today, through a combination of hydraulic

fracturing and horizontal drilling, energy companies are safely producing

extraordinary amounts of natural gas from these formations.

Hydraulic fracturing is a proven process, and by using this advancing

technology, the U.S. has the potential to signifcantly reduce carbon dioxide

(CO2) emissions and to decrease our reliance on imported foreign fuel.

Developing the natural gas resources held by shale gas formations is critical

to Americas energy needs and its economic renewal.

Numerous federal regulations govern the

fracing process, and state oil and gas

regulatory programs are in place to protect

groundwater. The state regulatory programs

require that multiple layers of protective steel

casing, surrounded by cement, be installed to

protect freshwater aquifers.

What Is Hydraulic Fracturing?

Hydraulic fracturing (fracing) is the process

of creating fssures in underground formations

to allow natural gas to fow. During fracing,

water, sand and other additives are pumped

under high pressure into the shale formation

to create fractures. Frac fuid is approximately

99.5% water and sand, with a small amount

of special-purpose additives. The sand is used

to prop open the newly created fractures,

which allows the natural gas to fow into the

wellbore and up to the surface. Hydraulic

fracing is typically performed only once in

the life of a well.

Protecting Groundwater

The producible portions of shale formations

are more than a mile below the earths

surface and are separated from groundwater

aquifers by thousands of feet of protective

rock barriers. The average depth of a shale gas

well is more than 7,500 feet and can reach

depths greater than 13,000 feet.

Properly conducted, modern hydraulic

fracing is a highly controlled and safely

engineered process that has been used by the

oil and gas industry since the 1940s.

The process is a key tool in natural gas

production, and more than one million U.S.

wells have been safely produced using the

technology over the past 60 years.

How deep is 7,500 feet?

six Empire 5tate BuiIdings stacked end-to-end

1.5 times deeper than the deepest part of the

Grand Canyon

more than 25 footbaII heIds Iaid out

goalpost-to-goalpost

Shale Fractures

Average distance

from surface: 7,500 feet

Groundwater Aquifer

Protective

Steel Casing

Private Well

Municipal Water Well:

<1,000 ft.

Cement

Conductor Casing

Cement

Surface Casing

Intermediate Casing

Production Casing

Cement

Production Tubing

Hydrocarbons

0.49%

ADDITIVES

In addition to water and sand, other additives are

used to enhance frac fuids and improve the safety

and efectiveness of fracturing the rock. These

additives are used in extremely low concentrations

and include a number of compounds found in

common consumer products.

*The specific additives used in a given fracturing operation will vary depending on source water quality, site and

specific characteristics of the target formation. The additives listed above are typical components but other

additives are also common.

Typical Additives Used in Hydraulic Fracturing*

Compound* Purpose Common application

Frac Facts

- Hydraulic fracturing is essential for the production of natural gas from deep shale formations.

- Deep shale gas formations exist many thousands of feet underground.

- Multiple layers of protective steel casing surrounded by cement protect freshwater aquifers as administered

and enforced under state regulations.

- Frac uids are 99.5% water and sand.

Additive

Nitrogen

Guar

Bentonite

Borate Crosslinker

and Buffer

Ammonium Persulfate

Enzyme Breaker

Surfactants

Acetic Acid

Triethanolamine (TEA)

Ethylenediaminetetracetic

Acid (EDTA)

Purpose

gas phase in a foam

thickening agent so that the

water can carry sand

type of clay added to

suspend solids in the slurry

increase the viscosity of

the slickwater fluid

break up the guar and allow

it to flow out of the sand

after the fracture treatment

degrade the guar and clean

up the fracture

fracture fluid recovery or to

create and stabilize a foam

to lower pH in

frac fluid water

iron control, to prevent

damage in the formation

water mineral deposit

control

Common Use

79% of the air we breathe

ice cream, salad dressings

cat litter, cosmetics

hand soap (borate), baking

soda (pH buffer)

oxidizing agent, hydrogen

peroxide

meat tenderizers,

brewing beer

dishwashing soap,

household cleaners

vinegar

fabric softener

food preservative

The Barnett Shale Energy Education Council (BSEEC)

is a community resource that provides information to the

public about gas drilling and production in the Barnett

Shale region in North Texas.

777 Taylor Street, Suite 900

Fort Worth, Texas 76102

Phone: 817-338-3305 www.bseec.org

Clean-burning natural gas will continue to play a vital role in meeting U.S. energy needs. And,

U.S. natural gas supply is expected to come increasingly from domestic gas-flled shales. Key to

the emergence of shale gas production has been the refnement of horizontal drilling and

hydraulic fracturing technologies. These technologies enable industry to produce more natural

gas from the shale formations economically and with less disturbance of surface environments.

- U.S. Department of Energy

Natural Gas: Americas Abundant

Energy Source

- The natural gas industry is responsible for nearly

3 million American jobs and $181 billion in

wages and benets.

- 97% of the natural gas used in the U.S. comes

from North America, reducing reliance on

imported oil.

- We have more than a 100-year supply of natural gas.

- Compared to coal, natural gas emits nearly 50%

less CO2.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Guideline For Industrial Track Projects - BNSF RailwayDocument67 pagesDesign Guideline For Industrial Track Projects - BNSF RailwayKhalil SaberNo ratings yet

- Basic Clinical Massage TherapyDocument654 pagesBasic Clinical Massage Therapykkism100% (11)

- Radiation Technologies Superfund PlanDocument11 pagesRadiation Technologies Superfund PlanLouis C. HochmanNo ratings yet

- Ascs To The Acr Standard Training Course Handouts - 2016 0 PDFDocument143 pagesAscs To The Acr Standard Training Course Handouts - 2016 0 PDFNhel AlvaroNo ratings yet

- New Concept in Fracturing - Al 119094Document8 pagesNew Concept in Fracturing - Al 119094Ali ZareeforoushNo ratings yet

- Mil STD 882eDocument104 pagesMil STD 882ezirimia100% (1)

- Methanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemDocument6 pagesMethanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemzirimiaNo ratings yet

- Design TipsDocument30 pagesDesign Tipsrvejner5253No ratings yet

- ct220130102 34a24006f9Document1 pagect220130102 34a24006f9zirimiaNo ratings yet

- Analytical Requirements For Hydrocarbon Dewpoint CalculationDocument13 pagesAnalytical Requirements For Hydrocarbon Dewpoint CalculationzirimiaNo ratings yet

- 0 Excelent HFDocument53 pages0 Excelent HFzirimiaNo ratings yet

- Individual Risk and Social Risk Analysis For Urban PipelineDocument6 pagesIndividual Risk and Social Risk Analysis For Urban Pipelinezirimia100% (1)

- Carrier RLC 2016 - enDocument58 pagesCarrier RLC 2016 - enAbseleam NurtenNo ratings yet

- Persidangan Pengarah2 Perhutanan SM 5 Sept 2022 - 220905 - 133501Document16 pagesPersidangan Pengarah2 Perhutanan SM 5 Sept 2022 - 220905 - 133501Arifhadi Johari AffandiNo ratings yet

- Macrobenthos of Meghna River Estuary, BangaldeshDocument7 pagesMacrobenthos of Meghna River Estuary, BangaldeshMohammad Belal HossainNo ratings yet

- 1992 National Waste Processing Conference 01Document8 pages1992 National Waste Processing Conference 01aymmon8950No ratings yet

- Material Safety Data Sheet: Section 1: Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1: Product and Company IdentificationIka KusumawatiNo ratings yet

- Material Safety Data Sheet: D182 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument4 pagesMaterial Safety Data Sheet: D182 1. Identification of The Substance/Preparation and of The Company/UndertakingPranav DubeyNo ratings yet

- STP GuideDocument2 pagesSTP GuideFlow Dynamics IndiaNo ratings yet

- LEED V4.1 Score CardDocument1 pageLEED V4.1 Score CardAsad YousafNo ratings yet

- Gaza StripDocument39 pagesGaza StripFeras ObeidNo ratings yet

- Briefing Note 16 BREEAMDocument6 pagesBriefing Note 16 BREEAMalireza1023No ratings yet

- ĐỀ THI GIỮA KÌ ANH 9- 40 trắc nghiệmDocument2 pagesĐỀ THI GIỮA KÌ ANH 9- 40 trắc nghiệmTiếng Anh 7No ratings yet

- H2ICEDocument10 pagesH2ICElucasNo ratings yet

- Acid Rain and Transported Air Pollutants: Implications For Public PolicyDocument325 pagesAcid Rain and Transported Air Pollutants: Implications For Public Policydilsiam100% (4)

- Waste ManagementDocument5 pagesWaste ManagementDaveIversonSorianoNo ratings yet

- Waste Management FAQSDocument4 pagesWaste Management FAQSBelinda LapsitNo ratings yet

- Exam 1 - 001Document26 pagesExam 1 - 001Jose Carlos ArgeñalNo ratings yet

- Sở Giáo Dục Và Đào Tạo Vĩnh Phúc Trường Thpt Chuyên Vĩnh Phúc (Đềthigồm 5trang) Đề Kscl Các Môn Thi Thpt Quốc Gia - Lần 2 NĂM HỌC: 2020-2021 Môn: Anh 11Document6 pagesSở Giáo Dục Và Đào Tạo Vĩnh Phúc Trường Thpt Chuyên Vĩnh Phúc (Đềthigồm 5trang) Đề Kscl Các Môn Thi Thpt Quốc Gia - Lần 2 NĂM HỌC: 2020-2021 Môn: Anh 11lienanhcvpNo ratings yet

- p6 Man and Environment WorksheetDocument17 pagesp6 Man and Environment Worksheetapi-362831708100% (1)

- Sulphamic Acid MSDS PDFDocument3 pagesSulphamic Acid MSDS PDFSalsabilaAzisNo ratings yet

- Ashiq HossainDocument54 pagesAshiq HossainAshiq Hossain100% (1)

- FYP Allocation AY 2012-2013 Sem 1Document7 pagesFYP Allocation AY 2012-2013 Sem 1Yandi LayadiNo ratings yet

- Progress Report MemoDocument3 pagesProgress Report MemoKamaleeshwaran karthiNo ratings yet

- Nesrea ActDocument24 pagesNesrea Actkirandevi1981100% (1)

- E-00331 Vigon SDS US EnglishDocument9 pagesE-00331 Vigon SDS US EnglishDHe Vic'zNo ratings yet

- Global Warming & Acid RainDocument34 pagesGlobal Warming & Acid RainVikshit GanjooNo ratings yet

- Introduction To Environmental Studies: Unit 1Document8 pagesIntroduction To Environmental Studies: Unit 17992 B Ashutosh NagarNo ratings yet

- Designing of A Fire Tube Boiler: July 2020Document8 pagesDesigning of A Fire Tube Boiler: July 2020hamza abbasNo ratings yet

- Chrome On Silica Cataylst MSDSDocument4 pagesChrome On Silica Cataylst MSDSstavros7No ratings yet