Professional Documents

Culture Documents

Conveyor Belt Storage and Installation

Conveyor Belt Storage and Installation

Uploaded by

jonodo89Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conveyor Belt Storage and Installation

Conveyor Belt Storage and Installation

Uploaded by

jonodo89Copyright:

Available Formats

Index Page

Conveyor Belt Storage and Installation

Index Page

Conveyor Belt Storage and Installation

Receiving the Roll

Upon delivery, check the factory packaging for damage, punctures, etc. Make any appropriate claim against the carrier at that time.

Storage

When storing a new conveyor belt, leave it hoisted or stand it upright, preferably on a dry surface (do not lay the roll on its side). A wooden skid is best. Block it safely so it cant accidentally roll. Extreme temperature variations can have an adverse affect on a belt over long periods of time. The ideal storage range is between 50F and 70F. Long exposure at temperatures even slightly below 40F can harden or stiffen the compounds. If installed on a conveyor in this stiffened state, the belt may not train well until it adjusts or warms up to the system. Neoprene, for example, is especially sensitive to low temperatures and should never be stored at less than 40F. Stiffened neoprene belting is different than other constructions. It wont loosen up until its had a lengthy exposure to relatively mild temperatures. Temperatures over 90F have an adverse effect, too, and should be avoided. Sunlight and ozone can also deteriorate any exposed rubber over time. Store your belt out of the direct sunlight whenever possible. Electrical generators or arc welders can sometimes generate ozone. It is best to store your belt some distance away from this type of equipment. In general, its wise to keep any unused belt stored in its protective factory packaging until its ready for installation. Used belt should be thoroughly cleaned and dried prior to storage. A dry place out of direct sunlight is preferred for storage, excessive temperature variations or extremes being avoided. Belts should not be stored in excessively wet places or in areas where oils, gasoline, paint

Handling the Roll

Factory packaging is designed to protect your conveyor belt during normal shipping and handling. When a belt arrives, be careful unloading it. Dont drop it or handle it roughly. This could break the packaging and cause the belt to telescope. Once a belt telescopes, it is almost impossible to re-roll. Try not to roll it, but if you must, roll in the direction the belt is wound. Rolling a belt in the opposite direction can cause it to loosen and telescope. The best way to move a belt is to slip a sturdy hoisting bar through the center core. Then, lift it with a sling or with strong cables. Be careful that these hoist cables dont damage the outer wraps at the belt edges. Protect the edges with special spreader bars, or short wooden planks. Never apply a sling around the circumference of a roll of belting. . .it isnt safe! You can also move a belt safely by laying the roll flat on a skid and hoisting the skid with a forklift. Just be sure the forks on the lift dont come in contact with the belt itself.

Index Page

materials, acids and chemicals are also stored or used. Motor-control rooms, welding shops, and other places where ozone is generated should likewise be avoided. A belt should not be permitted to rest on a concrete floor. If it is necessary to lay a belt on the floor, use a pallet or a cradle. Belts which are not endless should be stored in rolls. Once thoroughly cleaned and dried, it is good practice to dust a belt with tire talc or to insert kraft paper between the layers when rolling it up. Care should be taken not to roll a belt too tightly. Be sure the interior diameter of the roll is sufficiently large to avoid any possible carcass damage or warping. The belt should be rolled evenly to avoid telescoping and warping. Excessive flexing or sharp bends of any sort are to be avoided. Rolls should not be stood on edge or leaned against a wall. Small endless belts may be hung up on a dowel or a peg for storage. It is advisable to rotate the belt occasionally to avoid a constant flex or bend at one point. Larger endless belts may be stored flat, doubling them over as necessary. It is advisable when doubling a belt over to be sure that the edges of the belt are in line to avoid any warping. As above, it is good practice to rotate and repile the belt occasionally to avoid constant flexing or bending at any point. Bends should be made as large as possible to avoid cracking the carcass.

Installation

Once the roll of belting has been transported to the point of installation it should be mounted on a suitable shaft for unrolling and threading onto the conveyor. Conveyor belting is normally rolled at the factory with the carrying side out. Consequently, in mounting the roll, the belt must lead off the top of the roll if it is being pulled onto the troughing or carrying idlers but off the bottom of the roll if it is being pulled onto the return idlers. The illustrations below represent suitable methods of mounting and stringing belt for each case.

Left: Temporary flat roll at bend point Below: Threading through return strand

Note: Temporary flat roll at bend point, as roll is pulled onto troughing idlers

Reefing the Belt No weight to be placed on top

In some cases, such as in the mines where head room does not permit maneuvering a roll, the belt may have to be pulled off the roll and reefed (Left). Extreme care should be exercised to see that the loops have large bends to avoid kinking or placing undue strain on the belt. No weight should ever be placed on the belt when it is in this position. Another method of handling belting under such conditions is to lay the roll on a turntable with a vertical spindle.

Keep bends large to prevent breaking carcass

Index Page

C O N V E Y O R

B E L T I N G

A M E R I C A S

21 Laredo Drive Scottdale, Georgia 30079 USA Phone: (404) 297-3170 Fax: (404) 296-5165 www.fennerdunlopamericas.com

IS O 9001: 2000 C ertified

10/03

You might also like

- TrestlesDocument6 pagesTrestlesozcan100% (1)

- ENG ECI ELC SPC 004 Electrical InstallationDocument68 pagesENG ECI ELC SPC 004 Electrical Installationjonodo89No ratings yet

- Surface Preparation and Paint SpecificationDocument63 pagesSurface Preparation and Paint Specificationjonodo89No ratings yet

- ENG SOP 106 - Crusher MaintenanceDocument7 pagesENG SOP 106 - Crusher MaintenanceJohn Lawing100% (3)

- Astagah Iyo DiDocument94 pagesAstagah Iyo DiSpi Ishak Dorkneversaydie100% (1)

- Bogged Vehicle Recovery PDFDocument2 pagesBogged Vehicle Recovery PDFcityofdarwingis100% (1)

- The Useful Knots Book: How to Tie the 25+ Most Practical Rope Knots: Escape, Evasion, and SurvivalFrom EverandThe Useful Knots Book: How to Tie the 25+ Most Practical Rope Knots: Escape, Evasion, and SurvivalRating: 5 out of 5 stars5/5 (1)

- Screw Take UpsDocument7 pagesScrew Take Upsjonodo89No ratings yet

- Fire Protection Standard For Vehicles and Moving MachineryDocument39 pagesFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocument22 pagesEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- AATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & StructuralDocument68 pagesAATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & Structuraljonodo89No ratings yet

- Examiner and Learner Guide For Opencast MinesDocument58 pagesExaminer and Learner Guide For Opencast MinesJP Labuschagne100% (3)

- Conveyor Belt: Installation, Maintenance & Troubleshooting GuideDocument5 pagesConveyor Belt: Installation, Maintenance & Troubleshooting GuideGuru Raja Ragavendran Nagarajan100% (1)

- Conveyor Belt Maintenance Manual 2010 PDFDocument46 pagesConveyor Belt Maintenance Manual 2010 PDFkhuong_uno100% (3)

- Truco Belting CareDocument5 pagesTruco Belting Carejonodo89No ratings yet

- Care of Belting 02Document9 pagesCare of Belting 02jonodo89No ratings yet

- CLO2Document5 pagesCLO2saifNo ratings yet

- HW Installation Maintenance Troubleshooting Guide en PDFDocument48 pagesHW Installation Maintenance Troubleshooting Guide en PDFlukky prasetyoNo ratings yet

- Information For Safe Use and Maintenance of Flat Polyester Webbing SlingDocument4 pagesInformation For Safe Use and Maintenance of Flat Polyester Webbing Slingramy abazaNo ratings yet

- E 45 GP 005 - Installation of Belts On ConveyorsDocument11 pagesE 45 GP 005 - Installation of Belts On Conveyorsthiru_jsrNo ratings yet

- Synthetic Webbing SlingsDocument5 pagesSynthetic Webbing Slingssapi_buntekNo ratings yet

- Assembly Instructions For A Tetragon Two Pole Dome Tent:: Component ListDocument2 pagesAssembly Instructions For A Tetragon Two Pole Dome Tent:: Component ListDavid FrommeNo ratings yet

- Sling SafetyDocument20 pagesSling SafetySrijit Puthen100% (1)

- Care of Belting Rev 01Document10 pagesCare of Belting Rev 01jonodo89No ratings yet

- CMCO Catalog - Cosmo Petra - Safe Lifting Solutions - Textile Lifting SlingsDocument58 pagesCMCO Catalog - Cosmo Petra - Safe Lifting Solutions - Textile Lifting SlingsSafe Lifting SolutionsNo ratings yet

- Sling SafetyDocument17 pagesSling Safetymichol2014No ratings yet

- Skoot Lifting DeviceDocument4 pagesSkoot Lifting DevicechandankrdumkaNo ratings yet

- VRD User Manual Webbing Slings RoundslingsDocument3 pagesVRD User Manual Webbing Slings RoundslingsAlfonsus W.M.No ratings yet

- CAT-11 Hoist, Sling, and Chain Safety-EnglishDocument21 pagesCAT-11 Hoist, Sling, and Chain Safety-EnglishGemNo ratings yet

- Safe Slinging PracticeDocument2 pagesSafe Slinging PracticebudoNo ratings yet

- Uso Globos CerradosDocument2 pagesUso Globos CerradosMiguel CantóNo ratings yet

- Introduction To Belt ConveyorsDocument35 pagesIntroduction To Belt ConveyorsashokjeetprasadNo ratings yet

- Military MountaineeringDocument21 pagesMilitary MountaineeringSean Ben Kadusale100% (1)

- Chain Block Do's & Dont'sDocument7 pagesChain Block Do's & Dont'sRajanbabu100% (3)

- Instruksi Penggunaan Webbing SlingDocument7 pagesInstruksi Penggunaan Webbing SlingRusdiana PertiwiNo ratings yet

- Troubleshooting ConveyorDocument7 pagesTroubleshooting Conveyorsapu11jagat5855No ratings yet

- Lecture Preparation Unit 4Document50 pagesLecture Preparation Unit 4Prem VikasNo ratings yet

- Chain, Sling, Hook, InspectionDocument3 pagesChain, Sling, Hook, InspectionHeru Hermansyah100% (1)

- Mac21 22 25 ManualDocument9 pagesMac21 22 25 Manualfredericneveu2012No ratings yet

- Instructions For The Safe Use Of: Flat Woven Webbing SlingsDocument2 pagesInstructions For The Safe Use Of: Flat Woven Webbing SlingsMontadhar SaeedNo ratings yet

- Mon TazaDocument7 pagesMon TazapipilipipiNo ratings yet

- Sling SafetyDocument16 pagesSling SafetyanjireddyNo ratings yet

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNo ratings yet

- Instructions For The Safe Use Of: Fibre Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Fibre Rope SlingsMontadhar SaeedNo ratings yet

- Conveyor Belt Maintenance & Trouble Shooting ManualDocument48 pagesConveyor Belt Maintenance & Trouble Shooting ManualMichael D. Torres100% (1)

- Kreator Belt Install - 1490728195Document11 pagesKreator Belt Install - 1490728195Cassio Thome de FariaNo ratings yet

- Unloading and Handling Guide 2015Document7 pagesUnloading and Handling Guide 2015ampofodarko37No ratings yet

- EOTcrane SafetyDocument54 pagesEOTcrane SafetyRafique AjmeriNo ratings yet

- Roundslings: ManualDocument2 pagesRoundslings: ManualPernando SagaNo ratings yet

- 4D Pouches User GuideDocument2 pages4D Pouches User GuideSamuel GleisnerNo ratings yet

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

- Bucket Elevator Chain InstallationDocument27 pagesBucket Elevator Chain Installationm s sankar raoNo ratings yet

- Warn Service ManualDocument16 pagesWarn Service Manualadrianram1100% (1)

- ABKManual PDFDocument75 pagesABKManual PDFGus PolentaNo ratings yet

- Seguridad en El Izaje Dentro de PlantaDocument30 pagesSeguridad en El Izaje Dentro de PlantaChNo ratings yet

- Fibre Ropes, Knots, HitchesDocument26 pagesFibre Ropes, Knots, HitchesMaricris de GuzmanNo ratings yet

- Handling Transportation Storage ProcedureDocument6 pagesHandling Transportation Storage ProcedureAlexandru AndreiNo ratings yet

- Manual de Rio Tirfor T 532DDocument2 pagesManual de Rio Tirfor T 532DraulguardaNo ratings yet

- Flat Woven Webbing SlingsDocument2 pagesFlat Woven Webbing SlingsYosses Sang NahkodaNo ratings yet

- User Manual Wire Rope SlingDocument4 pagesUser Manual Wire Rope SlingRashid Ghani100% (1)

- Manual Carpa Instant TentDocument2 pagesManual Carpa Instant TentBermans Olivares LayNo ratings yet

- Hoists & Chain HoistDocument1 pageHoists & Chain HoistnespakkhNo ratings yet

- Rigging The Weta TrimaranDocument6 pagesRigging The Weta TrimaranunforyoppableNo ratings yet

- Summary of RiggingDocument7 pagesSummary of RiggingMahmoud Abdallah100% (1)

- Trouble Shooting On Conveyor BeltingsDocument17 pagesTrouble Shooting On Conveyor BeltingsVimal Bhansali100% (1)

- Crane Maintenance and Check PointDocument12 pagesCrane Maintenance and Check Pointspsl5100% (4)

- A Guide to the Use of Climbing Rope - A Collection of Historical Mountaineering Articles on Rope TechniqueFrom EverandA Guide to the Use of Climbing Rope - A Collection of Historical Mountaineering Articles on Rope TechniqueNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Illustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringFrom EverandIllustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringNo ratings yet

- Fire Protection Standard For Electrical Equipment and InstallationsDocument27 pagesFire Protection Standard For Electrical Equipment and Installationsjonodo89100% (1)

- Fire Protection Standard For Use of Plastic PipesDocument6 pagesFire Protection Standard For Use of Plastic Pipesjonodo89No ratings yet

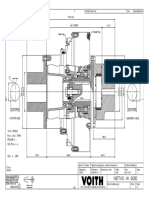

- Static Shaft Pulleys With Internal BearingsDocument14 pagesStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Sole PlatesDocument12 pagesSole Platesjonodo89No ratings yet

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocument15 pagesK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89No ratings yet

- Generic Geared ReducersDocument12 pagesGeneric Geared Reducersjonodo89No ratings yet

- Mechanical StandardsDocument10 pagesMechanical Standardsjonodo890% (1)

- Belt Conveyor Idlers and RollsDocument14 pagesBelt Conveyor Idlers and Rollsjonodo89No ratings yet

- 2RVRETURNS25Document1 page2RVRETURNS25jonodo89No ratings yet

- M&T Risk & AssuranceDocument39 pagesM&T Risk & Assurancejonodo89No ratings yet

- DWG 415-008 REV 0Document1 pageDWG 415-008 REV 0jonodo89No ratings yet

- SolidwovendatasheetDocument1 pageSolidwovendatasheetjonodo89No ratings yet

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89No ratings yet

- G - 1 - A1 General Arrangment DrawingDocument1 pageG - 1 - A1 General Arrangment Drawingjonodo89No ratings yet

- DWG 424-012 REV 1Document1 pageDWG 424-012 REV 1jonodo89No ratings yet

- BB Design ReportDocument79 pagesBB Design Reportjonodo89No ratings yet

- DWG 415-009 REV 0Document1 pageDWG 415-009 REV 0jonodo89No ratings yet

- Aa Spec 114005Document45 pagesAa Spec 114005jonodo8950% (2)

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89No ratings yet

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Document4 pagesMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89No ratings yet

- v487tvvs - Ha - Sx260Document1 pagev487tvvs - Ha - Sx260jonodo89No ratings yet

- DWG 415-007 REV 0Document1 pageDWG 415-007 REV 0jonodo89No ratings yet

- DWG 415-006 REV 0Document1 pageDWG 415-006 REV 0jonodo89No ratings yet

- DWG 415-012 REV 2Document1 pageDWG 415-012 REV 2jonodo89No ratings yet

- 2014 Convention Belt LineDocument32 pages2014 Convention Belt LineNIBA- The Belting AssociationNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- Concrete Business in A BOXDocument35 pagesConcrete Business in A BOXDessalegn GaminiNo ratings yet

- Loma Systems - IQ2F Ferrousin Foil User Manual PDFDocument110 pagesLoma Systems - IQ2F Ferrousin Foil User Manual PDFYani Mamani de SáezNo ratings yet

- IBR4005 Pulleys A4 0314 WebDocument12 pagesIBR4005 Pulleys A4 0314 Webkosmc123No ratings yet

- BMHS Specifications of EquipmentDocument43 pagesBMHS Specifications of Equipmentmdakram145No ratings yet

- DCI Yearbook 2011 PDFDocument256 pagesDCI Yearbook 2011 PDFGaetan DufourNo ratings yet

- Coal Handling PlantDocument47 pagesCoal Handling PlantRajat Sharma100% (1)

- Pulley Idler Shaft F9265C65B8F87Document3 pagesPulley Idler Shaft F9265C65B8F87souvonik100% (1)

- Recommendations For The Installation Planning of Belt WeighersDocument4 pagesRecommendations For The Installation Planning of Belt Weighersloli2323No ratings yet

- SLPP Lhs-Q&aDocument7 pagesSLPP Lhs-Q&arameshNo ratings yet

- TS 5 Transfer SystemDocument246 pagesTS 5 Transfer SystemSantosh DengleNo ratings yet

- Cement Project HistoryDocument28 pagesCement Project HistoryRaji Suri100% (1)

- Cost Effective Recognition and Classification of Moving Objects Using SimulinkDocument10 pagesCost Effective Recognition and Classification of Moving Objects Using Simulinknam bachNo ratings yet

- Bulk Material Handling Systems - All You Need To Know - Processing MagazineDocument9 pagesBulk Material Handling Systems - All You Need To Know - Processing MagazineSaiNo ratings yet

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 pagesGearless Drives For Medium-Power Belt Conveyors: MotionchalogdNo ratings yet

- Indus Conveyor Belt Brochure-CatalougeDocument19 pagesIndus Conveyor Belt Brochure-Catalougepmf engineering limitedNo ratings yet

- P139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)Document6 pagesP139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)CongOanh PHAN100% (1)

- Conveyor Belt Design Manual Contitech - EngDocument140 pagesConveyor Belt Design Manual Contitech - Engcanito73100% (12)

- Energy Requirements and Optimization The Transport Route of Belt ConveyorsDocument6 pagesEnergy Requirements and Optimization The Transport Route of Belt ConveyorsGogyNo ratings yet

- Belt Conveyor1Document187 pagesBelt Conveyor1Anshul yadavNo ratings yet

- Catalogo 2500SM ENGDocument12 pagesCatalogo 2500SM ENGAntonio Quispe Patiño100% (1)

- Palm Oil Equipment and Machineries Lubrication 2 Oct 2014Document2 pagesPalm Oil Equipment and Machineries Lubrication 2 Oct 2014engrsurifNo ratings yet

- 2.1. Attachment 1 - Equipment DatasheetDocument5 pages2.1. Attachment 1 - Equipment DatasheetCongOanh PHANNo ratings yet

- Correa de SacrificioDocument22 pagesCorrea de Sacrificiomatias vargas apablazaNo ratings yet

- Hytrol Basic Training Manual KonveijeriDocument36 pagesHytrol Basic Training Manual KonveijeriArtūrs VēversNo ratings yet

- (Take Up) IS 4776-1977 Part-1Document10 pages(Take Up) IS 4776-1977 Part-1Deepjyoti DasNo ratings yet