Professional Documents

Culture Documents

08 GRP04 All Engines

08 GRP04 All Engines

Uploaded by

eurospeed2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08 GRP04 All Engines

08 GRP04 All Engines

Uploaded by

eurospeed2Copyright:

Available Formats

08 GRP04 All Engines

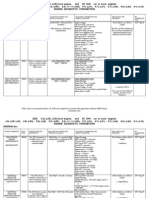

Component/ System Catalyst Bank 1 Fault Code P0420 Monitor Strategy Description oxygen storage of catalyst Primary Malfunction Signal and Criteria normalized oxygen storage less than normalized oxygen storage of a limit catalyst Threshold Logic < Threshold Value 1 Threshold Units factor Threshold Conditions <1factor Secondary Parameters exhaust gas mass flow exhaust gas mass flow catalyst temp. model catalyst temp. model engine speed engine speed engine load engine load modeled catalyst temp. gradient exhaust gas mass flow gradient fuel system closed loop time after engine start ambient temperature scheduled by System Manager secondary O2 sensor fuel adaptation fault short term fuel trim ( < max ) short term fuel trim ( > min ) transient fuel control critical misfire rate detected cat. damaging misfire rate exceeded cat oxygen storage neutralization Misfire crankshaft speed emissions relevant misfire rate > 1.4 % engine speed >1.4% (emission relevant misfire rate = 1.5%) engine speed indicated torque (idle, no drive) indicated torque (drive) (MISALUN) engine speed gradient volumetric efficiency gradient cylinder events after engine start Enabling delay when Coolant temp is below 7 C at start Delayed until Coolant temp > 21 C rough road traction control clutch switch press / release leak detection active handling ABS engine drag control fuel cut off fuel level OR fuel level AND solid misfire MIL OR fuel level error error: throttle position error: crankshaft sensor error: ref.mark of crank sensor Enable Logic > < < > > < > < < < active > > TRUE ready FALSE < > FALSE FALSE FALSE FALSE Enable Value 8.33 27.78 700 390 1000 3520 14 . 17 42.55 2.5 8.33 235 -48 Enable Units g/sec g/sec C C rpm rpm % % C / sec g/sec sec C Threshold Conditions >8.33g/sec <27.78g/sec <700 C >390 C >1040rpm <3520rpm >14 . 17% <42.55% <2.5 C / sec <8.33g/sec active->235sec >-48 C TRUE-ready FALSE <1.25factor >0.75factor FALSE FALSE FALSE FALSE Time Required approx. 1000 sec during active driving one test ( average of 4 checks ) per driving cycle one completed test per driving cycle Frequency of Checks 0.01 sec Criteria for Code 0.4 sec continuous or 4 sec cumulative MIL Illum. two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

1.25 0.75

factor factor

>

450

rpm

>450rpm

1000 revs

cylinder

immediate

Fault during

Emission Level Multiple Cylinder Cylinder #1 Cylinder #2 Cylinder #3 Cylinder #4 Cylinder #5 P0300 P0301 P0302 P0303 P0304 P0305

fluctuation cylinder 1 to cylinder 6

< > > < < > >

6500 3.91 3.91 . . . 17.19 12800 768 6 -7

rpm % % rpm/sec %/rev ignitions C

<6500rpm >3.91% >3.91 . . . 17.19% <12800rpm/sec (not active) <768%/rev (not active) >6ignitions >-7 C

firing frequency After continuous detection, the diagnostic can only

1st interval: 2 faults in 2 different drive cycles.

Fault during remaining

Cylinder #6

P0306

not detected off off off not active not active not active not active > < on set not set not set not set

5.9 5.9 -

% % -

not detected-off-transitionFALSEoff-not active not active-not active-not active-> 5.93 % > 5.93 % on-set-not set-not set-not set---

pass if similar conditions are encountered

intervals: 8 faults in 2 different drive cycles with at least 4 faults in each.

Page 1 of 32

08 GRP04 All Engines

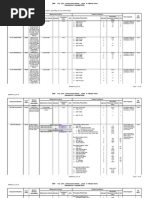

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Catalyst Damaging Level Multiple Cylinder Cylinder #1 Cylinder #2 Cylinder #3 Cylinder #4 Cylinder #5 Cylinder #6 OR Catalyst damaging misfire rate P0300 P0301 P0302 P0303 P0304 P0305 P0306 > 16.2 . . . 6.8 see Misfire supplementa l data (h) (2.5.1) % >16.2 . . . 6.8% see Misfire Includes all the above with the following exceptions: Enable Units Threshold Conditions ---1000 revs First interval 200 revs < >= < blinking -48 6.19 6.19 C % % <-48C > 6.19 % > 6.19 % blinking---all remaining intervals First occurance: immediate flashing while error present, then no MIL with no error. Time Required Frequency of Checks Criteria for Code MIL Illum.

supplemental First interval extention data (h) (2.5.1) engine coolant temperature fuel level OR fuel level AND blinking MIL AND NOT first blink event

Second occurance: immediate flashing while error present, then solid MIL with no error. evaporative system canister ventilation valve (AAV)

P0446

monitoring of tank pressure while AAV is open and CPV is closed

tank pressure too low because canister vent. defective & closed

<

-10.50049

hPa

< -10.50049 hPa

>= ambient temperature ambient temperature <= >= <= true >= <= >= <= true true true true true

-9.8 45 680.00 1,86 -18.00 10.00 10.45 18.00

C C hPa mph hPa hPa V V

>= -9.8 C <= 45 C >= 680.00 hPa <= 1,86 mph true >= -18.00 hPa <= 10.00 hPa >= 10.45 V <= 18.00 V true true true true true

< 20 sec

once per dcy

2,6 secs

2 dcy

canister purge valve (CPV)

P0496

monitoring of tank pressure while CPV and AAV are closed

final pressure too low because CPV defective and open

< -1.00098

hPa

ambient pressure vehicle speed engine is in idle mode unfiltered tank pressure and unfiltered tank pressure < -1.00098 hPa battery voltage and battery voltage lambda control is active secondary air pump inactive secondary air diagnosis inactive air bag hasn't been triggered no torque reduction (e.g. resulting from switched-off cylinder) critical misfire rate ratio intake manifold pressure /ambient pressure fault of canister purge valve in actual driving cycle

ca. 10 sec once per dcy

P0497

monitoring of tank pressure while CPV and AAV are closed

purge control stuck closed

false < 0.602

false < 0.602

false

false

tank leak large

P0455

AAV is closed and CPV vacuum pressure built up is open gradient too low because of large tank leakage (for example: open gas filler cap)

<

0.450039 ...0.750065

hPa/s

< 0.450039 ...0.750065 hPa/s

fault of canister ventilation valve in actual driving cycle tank fuel level and tank fuel level enabled by diagnostic scheduler fuel system adaptation has completed

false

false

ca. 18 sec once per dcy

>= <= true true

3.900 55.100

l l

>= 3.900 l <= 55.100 l true true

Page 2 of 32

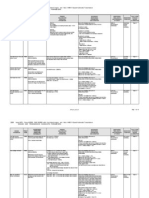

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters or time since engine start exceeds threshold Enable Logic > Enable Value 600 Enable Units sec Threshold Conditions > 600 sec Time Required Frequency of Checks Criteria for Code MIL Illum.

Fuel Evaporative System

P0456

Monitor fuel tank's pressure after engine shutdown

Engine off natural vacuum diagnosis has not been performed in this driving cyle. Fuel evaporative system monitor (at engine on) didn't run nor detect large leak nor a tight system. Engine coolant temperature at start. engine coolant temp. At start - intake air temp. intake air temperature intake air temperature ambient air temperature ambient air temperature engine has been running for a cal. min. time engine coolant temp. at engine stop driving distance (in current dcy) covered charcoal canister load factor ambient pressure driving distance (for vehicle lifetime) covered the fuel tank's level isn't at its minimum the fuel tank's level isn't at ist maximum battery's voltage no refueling activity the fuel tank pressure is within cal. range no intake air temperature faults no the purge control system faults no faults of the purge control valve's power stage no vehicle speed sensor faults no engine coolant temperature sensor faults no tank pressure sensor rationality faults no tank pressure sensor range faults no power supply voltage faults no main load sensor faults no canister vent valve faults no canister ventilation valve's power stage faults no ambient pressure sensor faults

true

100ms in

once per dcy

2.6 secs

2dcy

true

afterrun

<= <= <= >= < > > > >= < >= > true true > true true true true true

42.0 6.8 35.3 3.8 36.8 2.3 600.00 59.3 8100.0 10.00 680.0 20

C C C C C C s C m hPa Km

true true true true true true true true true true true true

11.00

true

true true true true true true true true true

Close canister ventilation valve. Look for maximum pressure. Abort if: - max. pressure >=

Page 3 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description threshold. Primary Malfunction Signal and Criteria max. pressure Threshold Logic >= Threshold Value volume & ambient temperature dependent Threshold Units hPa Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

- max. pressure current pressure >= threshold. max. pressure - current pressure - pressure stays in pressure range near zero for pressure a specific time. - pressure <= threshold

>= 0.30029 >= -0.69946 <= 0.69946 500

hPa hPa hPa s hPa -0.74951 30.00 s

>= 0.30029 hPa >= -0.69946 hPa <= 0.69946 hPa 500 s <= -0.74951 hPa 30.00 s

pressure

<=

for a specific time (vacuum build-up instead of pressure build-up) - pressure-phase-time >= threshold. pressure phase time - diagnostic-time >= threshold diagnostic time correct max. pressure.

>= >=

2400.00 2900.00

s s

>= 2400.00 s >= 2900.00 s

open canister ventilation valve for a calibrated time. Look for minimum pressure Abort if: - min pressure <= threshold

400.00

400.00 s

min. pressure

<=

<=

- diagnostic time >= threshold current pressure - min.

diagnostic time

>=

2900.00

>= 2900.00 s

- pressure >= threshold current pressure - min. pressure AND min. pressure <= threshold min. pressure

>= 0.30029

hPa

>= 0.30029 hPa

<= -0.69946

hPa

<= -0.69946 hPa >= -0.69946 hPa <= 0.69946 hPa 500.00 s

- pressure stays in ambient range for a specific time

pressure pressure

>= -0.69946 <= 0.69946 500.00

hPa hPa s

- canister vent valve reopened for a more than no. canister vent valve N times openings because the pressure exceeds a threshold pressure Calculate difference between corrected max. pressure and min. pressure. Calculate normalized result. First divide the

>

>2

0.74951

hPa

0.74951 hPa

Page 4 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description pressure difference by a parameter. Then subtract Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

volume & ambient temperature dependent

this result from 1. Filter the normalized result with an EWMA filter. Compare filtered result Filtered result with threshold. N results will be taken into account in order to determine a pass. A fault will be indicated immediately. Secondary air system P0411 passive functional check relative secondary air mass flow. Ratio from calculated secondary air mass by pressure sensor signal and secondary air mass model < > 0.844 1.156 < 0.844 > 1.156 start with catalyst heating secondary air system active active < 5s one 2.6 sec 2 dcy > 0.399994 4 4 > 0.399994

intake air temperature intake air temperature engine coolant temperature engine coolant temperature ratio: ( MAP Model / Baro ) no error on altitude detection error: intake air error: motor temperature error: secondary air pump (power stage) error: power supply voltage UB enabled by the diagnostic scheduler fuel cut off steady state mass airflow mass airflow change in air charge per working cycle

> < > < < avtive false false false false true false > < <=

0 80.3 5.3 120 0.7

C C C C

> 0 C < 80.3 C > 5.3 C < 120 C < 0.7

test per dcy (only, if secondaryair-system was active)

6 130 6

kg/h kg/h %

> 6 kg/h < 130 kg/h <= 6 %

Pressure sensor secondary air system

P2432 P2433

cirtcuit continuity - low measured sensor voltage cirtcuit continuity - high measured sensor voltage or open rationality during ECU init-

< >

0.498 4.501

V V

< 0,498 V > 4,501 V

0.5 sec

continuous

0.2 sec

2 dcy

P2431

< >

-50 50

hPa hPa

< -50 hPa > 50 hPa

comparisson between: difference SAI pressure vs BARO pressure SAI system pressure signal & Barometric pressure signal

Barometric pressure signal VALID secondary air injection during CAT heat executed secondary air injection during CAT heat finished

TRUE TRUE TRUE

TRUE TRUE TRUE

Page 5 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

Fuel System Rich/Lean Multiplicative and Additive

P2191 P2192

fuel trim limits exceeded range - multiplicative ( load > threshold and air flow > threshold ) range - additive low speed and low load

delta lambda correction or delta lambda correction

> <

1.175 0.825

factor factor

>1.175factor <0.825factor

fuel system status long term fuel trim status engine coolant temperature

closed loop active > not active <= > set >=

50.3 65.3 6.19 2800

C C % g

closed loop-active->50.3C not active-<=65.3C > 5.92 % set->=2800g

approx. 300 sec from engine start ( after adaptation has stabilized )

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec

P2187 P2188

delta fuel load correction or delta fuel load correction

> <

5.25 -5.25

% %

>5.25% <-5.25%

purge control intake air temperature fuel level or fuel level error integrated air mass

After detection, diagnostic can only pass if similar conditions are encountered

cumulative

demand controlled fuel supply (DECOS)

P0088

difference between fuel rail pressure measured difference and set-point fuel rail pressure difference between actual necessary and precontrol duty cycle

<

- 150

kPa

< - 150 kPa

DECOS fuel pump is active DECOS fuel control is enabled time after engine start time after hot start no fault of - fuel pressure sensor (DECOS) - power stage of demand controlled fuel pump

true true > > 1 6 sec sec

true true > 1 sec > 6 sec

5 sec

continuous

0.2 sec

2 dcy

P0089

< duty cycle difference

-25

< -25 %

true true true true > > 1 6 sec sec

true true true true > 1 sec > 6 sec

P0087

fuel rail pressure difference between difference measured and set-point fuel rail pressure difference between actual necessary and precontrol duty cycle

>

150

kPa

> 150 kPa

DECOS fuel pump is active DECOS fuel control is enabled time after engine start time after hot start no fault of - low pressure fuel sensor (DECOS) - power stage of demand controlled fuel pump no empty or almost empty fuel tank

P0089

> duty cycle difference

25

> 25 %

true true true

true true true

fuel pressure sensor (DECOS) P0193 P0192 cirtcuit continuity - high measured sensor voltage or open cirtcuit continuity - low measured sensor voltage > < 4.7 0.3 V V > 4.7 V < 0.3 V fuel supply system is active true true 0.5 sec continuous 0.2 sec 2 dcy

P0193

range check - high

measured fuel pressure

>

680

kPa

> 680 kPa

5 sec

P0192

range check - low measured fuel pressure

<

60

kPa

< 60 kPa

fuel supply system is active time after power fail

true >= 360 sec

true >= 360 sec

5 sec

Page 6 of 32

08 GRP04 All Engines

Component/ System Diagnosis of Power Control Module Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters general enabling conditions battery voltage locking request immobilizer P0092 diagnosis short circuit to battery voltage only active if powerstage on special enabling condition condition output duty cycle PCM for power on diagnosis Enable Logic Enable Value Enable Units Threshold Conditions Time Required 0.6 sec < > false 18 10 V V < 18 V > 10 V false Frequency of Checks continuous Criteria for Code 0.2 sec MIL Illum. 2 dcy

backward powerstage voltage of fuel pump diagnosis and backward powerstage voltage of fuel pump diagnosis and duty cycle PCM

>

3.9014

> 3.9014 V

true

true

2.7979 >

> 2.7979 V

<

100

< 100 % condition output duty cycle PCM for power off diagnosis false false

diagnosis short circuit to battery voltage only active if powerstage off P0091 diagnosis short circiut to ground only active if powerstage on

backward powerstage voltage of fuel pump diagnosis

>

3.9014

> 3.9014 V

backward powerstage voltage of fuel pump diagnosis and duty cycle PCM

<=

2.3486

<= 2.3486 V

condition output duty cycle PCM for power on diagnosis

true

true

>

>0% condition output duty cycle PCM for power on diagnosis true true

P0090

diagnosis wire interruption only active if powerstage on

diagnosis wire interruption only active if powerstage off

backward powerstage voltage of fuel pump diagnosis and duty cycle PCM and max-fault; powerstage diagnosis backward powerstage voltage of fuel pump diagnosis and backward powerstage voltage of fuel pump diagnosis condition fault message of PCM powerstage is locked

>

2.4414

> 2.4414 V

< false >

100

< 100 % false

2.4414

> 2.4414 V

condition output duty cycle PCM for power off diagnosis

false

false

<

3.9014

< 3.9014 V

P0090

powerstage locked

true

true

Air / Fuel Ratio Sensor (primary A/F) sensor voltage bank 1 sensor 1

P0130

A/F sensor voltage A/F sensor voltage exceeds threshold and but not out of full range A/F sensor voltage

> <

3.7 4.81

V V

>3.7V <4.81V

A/F sensor heater at operating temperature engine starting desired A/F all injectors activated scheduled by System Manager

TRUE complete < TRUE TRUE

1.6 -

lambda -

TRUE-complete-<1.6lambda TRUE-TRUE--

10 sec additional time if fuel level is low and not failed 600 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

or

AF sensor voltage and A/F sensor voltage ( if using rich calibration curve characteristic ) Air / Fuel Ratio Sensor (primary A/F) integrated circuit interface

> <

2.5 3.06

V V

>2.5V <3.06V

Page 7 of 32

08 GRP04 All Engines

Component/ System bank 1 Fault Code P0130 Monitor Strategy Description A/F sensor voltage IC correction too high Primary Malfunction Signal and Criteria A/F sensor voltage IC corrective value Threshold Logic > Threshold Value 0.1 Threshold Units V Threshold Conditions >0.1V Secondary Parameters battery voltage battery voltage engine engine starting Enable Logic < > running complete Enable Value 18 10.7 Enable Units V V Threshold Conditions <18V >10.7V running-complete-Time Required 10 sec Frequency of Checks 0.1 sec continuous Criteria for Code 0.4 sec continuous or 4 sec cumulative MIL Illum. two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

A/F sensor IC operating voltage too low

low voltage

TRUE

=TRUE-

battery voltage battery voltage engine engine starting

> < running complete

10.7 18 -

V V -

>10.7V <18V running-complete--

10 sec

A/F sensor IC SPI interface communication error A/F sensor IC circuit write error at INIT register

communication error

TRUE

=TRUE

> < running

10.7 18 -

V V -

>10.7V <18V running--

write error

TRUE

=TRUE

complete

complete--

Air / Fuel Ratio Sensor (primary A/F) pumping current circuit open bank 1 sensor 1

P2239

lambda control factor change above threshold

absolute value of lambda control factor change from the point when the secondary conditions are met

>

0.025

lambda

>0.025lambda battery voltage battery voltage engine engine starting A/F sensor voltage A/F sensor voltage A/F sensor electrical trimming A/F sensor heater at op.temp. A/F sensor warm up control lambda closed loop control forced fuel trim amplitude | fuel trim forced amplitude | catalyst warm up control sec. O2 sensor proportional trim lean mixture inhibit lambda closed loop control init closed loop control startup

< > running complete < > not active TRUE complete TRUE TRUE > stable stable stable FALSE FALSE

18 10.7 1.51 1.49 0.015 -

V V V V lambda -

<18V >10.7V running-complete-<1.51V >1.49V not active-TRUE-complete-TRUE-TRUE->0.015lambda stable-stable-stable-FALSE-FALSE--

1.5 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Air / Fuel Ratio Sensor (primary A/F) pumping current circuit open bank 1 sensor 1

P2237

A/F sensor voltage A/F sensor voltage within upper and lower thresholds and A/F sensor voltage and desired lambda is outside of upper or lower threshold

< >

1.51 1.49

V V

<1.51V >1.49V

battery voltage battery voltage engine engine starting target lambda above upper limit or below lower limit closed loop control A/F sensor heater at operating temperature A/F sensor electrical trimming

< > running complete > < TRUE TRUE not active

18 10.7 1.01 0.99 -

V V lambda lambda -

<18V >10.7V running-complete->1.01lambda <0.99lambda TRUE-TRUE-not active--

approx. 8 sec once the driving condition is met

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Page 8 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters A/F sensor dynamic response error: A/F sensor heating integrated exhaust gas mass Air / Fuel Ratio Sensor (primary A/F) pumping current circuit open bank 1 sensor 1 Enable Logic not slow not set > Enable Value 400 Enable Units g Threshold Conditions not slow-not set->400g Time Required Frequency of Checks Criteria for Code MIL Illum.

P2238

A/F sensor not lean enough during fuel shut off operation

A/F sensor voltage

<

1.7

<1.7V

battery voltage battery voltage engine engine starting time after fuel shut off A/F sensor heater at operating temperature

< > running complete > TRUE

18 10.7 3 -

V V sec -

<18V >10.7V running-complete->3sec TRUE--

5 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Air / Fuel Ratio Sensor (primary A/F) reference voltage circuit open bank 1 sensor 1

A/F sensor voltage P2243

A/F sensor voltage

< >

0.2 4.7

V V

<0.2V >4.7V

battery voltage battery voltage engine engine starting A/F sensor heating normal operation range for time error: A/F sensor heater circuit A/F sensor internal resistance

< > running complete >

18 10.7 10

V V sec

<18V >10.7V running-complete->10sec

2 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

above upper threshold A/F sensor voltage or below lower threshold for time

>

sec

>1sec

not set >

1500

Ohms

not set->1500Ohms

Air / Fuel Ratio Sensor (primary A/F) reference ground circuit open bank 1 sensor 1

P2251

measured A/F sensor A/F sensor internal internal resistance resistance above upper threshold for time

>

1500

Ohms

>1500Ohms

battery voltage battery voltage engine engine starting A/F sensor voltage A/F sensor voltage error: A/F sensor heater circuit A/F sensor pump voltage shut off A/F sensor warm up control A/F sensor heater operation time engine run time battery voltage below heater switch off voltage for time fuel cut in time for a fuel cut off time battery voltage exceed 11V time

< > running complete < > not set FALSE complete > >

18 10.7 1.48 1.36

V V V V

<18V >10.7V running-complete-<1.48V >1.36V not set FALSE-complete->28sec >28sec

5 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous

>

sec

>5sec

28 28

sec sec

> > > >

28 28 10 28

sec sec sec sec

>28sec >28sec >10sec >28sec

Air / Fuel Ratio Sensor (primary A/F) measuring (trim) current circuit open bank 1 sensor 1

A/F sensor voltage above threshold P2626

A/F sensor voltage

>

4.81

>4.81V

battery voltage battery voltage engine engine starting fuel cut off modeled exhaust temp in front of catalyst A/F sensor heater at operating temperature

< > running complete TRUE < TRUE

18 10.7 750 -

V V C -

<18V >10.7V running-complete-TRUE-<750 C TRUE--

2 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

additional time if fuel level is low and not failed 600 sec

Page 9 of 32

08 GRP04 All Engines

Component/ System Air / Fuel Ratio Sensor (primary A/F) general error causing open loop Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

P0130

general A/F sensor electrical fault

A/F sensor internal resistance

>

1500

Ohms

>1500Ohms

A/F sensor heater operation time fuel cut in time for a fuel cut off time battery voltage battery voltage A/F sensor A/F sensor heater pwr. stage err. A/F sensor IC internal error A/F sensor pin short circuit error modeled exhaust gas temp. invalid modeled exhaust gas temperature

> > > > < ready FALSE FALSE FALSE FALSE >

15 15 3 10.7 18

sec sec sec V V

>15sec >15sec >3sec >10.7V <18V ready FALSE FALSE FALSE FALSE

15 sec

0.1 sec continuous

immediate

two driving cycles

>0C

calculated A/F sensor temperature

<

640

<640C

A/F sensor heater operation time fuel cut in time for a fuel cut off time battery voltage battery voltage A/F sensor A/F sensor heater pwr. stage err. A/F sensor IC internal error A/F sensor pin short circuit error modeled exhaust gas temp. invalid modeled exhaust gas temperature

> > > > < ready FALSE FALSE FALSE FALSE >

15 15 3 10.7 18

sec sec sec V V

>15sec >15sec >3sec >10.7V <18V ready FALSE FALSE FALSE FALSE

15 sec

>0C

A/F sensor pin UN error set

= =

TRUE TRUE TRUE TRUE TRUE TRUE

=TRUE =TRUE =TRUE =TRUE =TRUE =TRUE

A/F sensor pin VM error set

= =

A/F sensor heater error set by after engine start diagnosis A/F sensor heater error set by maximum heater output diagnosis Air / Fuel Ratio Sensor (primary A/F) reference ground circuit; reference voltage circuit; or measuring current circuit bank 1 sensor 1 - low volt

= =

= =

TRUE TRUE

=TRUE =TRUE

P0131

A/F sensor signal at VM ( reference ground ) below lower limit or A/F sensor signal at UN ( reference voltage [Nernst voltage] ) below lower limit

IC Circuit Status shorted low

TRUE

=TRUE-

battery voltage battery voltage

< > running complete

18 10.7 -

V V -

<18V >10.7V running-complete--

25 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous

IC Circuit Status shorted low

TRUE

=TRUE-

engine engine starting

Page 10 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description or A/F sensor signal at IA ( measuring current trim circuit ) below lower limit bank 1 sensor 1 - high volt P0132 A/F sensor signal at VM ( reference ground ) above upper limit or A/F sensor signal at UN ( reference voltage [Nernst voltage] ) above upper limit or A/F sensor signal at IA ( measuring current trim circuit ) above upper limit Primary Malfunction Signal and Criteria IC Circuit Status shorted low Threshold Logic = Threshold Value TRUE Threshold Units Threshold Conditions =TRUESecondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum. or 4 sec cumulative

IC Circuit Status shorted high

TRUE

=TRUE-

IC Circuit Status shorted high

TRUE

=TRUE-

IC Circuit Status shorted high

TRUE

=TRUE-

Air / Fuel Ratio Sensor (primary A/F) response Bank 1 Sensor 1 P0133

dynamic response slow or low amplitude

A/F sensor dynamic value

<

0,2

ratio

< 0.2ratio

fuel trim forced amplitude A/F sensor short term fuel trim (o.k.) short term fuel trim (o.k.) measured A/F minus integral control of secondary O2 measured A/F minus integral control of secondary O2 engine speed engine speed volumetric efficiency volumetric efficiency volumetric efficiency gradient A/F sensor housing model temp filtered purge HC conc. factor or evap purge all fuel injectors active evap purge high HC conc. A/F pumping current circuit error: evap purge valve error: evap purge valve circuit scheduled by System Manager forced amplitude

active ready < MAX > MIN <

1.25 0.75 1,05

factor factor lambda

active-ready-< MAX1.25factor > MIN0.75factor <1.05lambda dynamic test sample count 0.01 sec continuous 0.4 sec continuous or 4 sec cumulative two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

( versus reference sensor )

( versus reference sensor )

>

0,95

lambda

>0.95lambda

>

< > < > < < < not active TRUE FALSE checked OK not set not set TRUE >

2800 1160 45 17.25 30 570 15

rpm rpm % % %/sec C factor

<2800rpm >1160rpm <45% >17.25% <30%/sec <570C <15factor not active TRUE FALSE-checked OK-not set-not set-TRUE->0.01lambda

35 samples then 2 sec

total time = approx. 600 sec

0.01

lambda

Oxygen Sensor (secondary O2) Trim of Air / Fuel Ratio Sensor (primary A/F) primary A/F signal RICH / secondary O2 signal LEAN Bank 1

P2096

A/F sensor long term secondary trim - rich shift - correction below threshold

secondary O2 sensor trim integral control

<

-0.03

lambda

<-0.03lambda engine starting secondary O2 trim active and secondary O2 oscillation check finished then timer

complete TRUE TRUE

complete- TRUE-TRUE- -

2 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec

primary A/F signal LEAN / secondary O2 signal RICH

>

25

sec

>25sec

Page 11 of 32

08 GRP04 All Engines

Component/ System Bank 1 Fault Code P2097 Monitor Strategy Description A/F sensor long term secondary trim - lean shift - correction above threshold Primary Malfunction Signal and Criteria secondary O2 sensor trim integral control Threshold Logic > Threshold Value 0.03 Threshold Units lambda Threshold Conditions Secondary Parameters Enable Logic TRUE FALSE FALSE FALSE checked OK Enable Value Enable Units Threshold Conditions TRUE FALSE FALSE FALSE checked OK Time Required Frequency of Checks Criteria for Code MIL Illum. cumulative

>0.03lambda scheduled by System Manager sec. O2 trim - fast lean correction sec. O2 trim - fast rich correction suspicion A/F sensor lean shift secondary O2 oscillation test

Oxygen Sensor (secondary O2) Trim of Air / Fuel Ratio Sensor (primary A/F) Bank 1

P2195

secondary O2 sensor operation too rich - strong correction A/F sensor measured too lean

secondary O2 sensor voltage

>

0.75

>0.75V

A/F sensor measured lambda short term fuel trim A/F sensor secondary O2 sensor then accumulated exhaust gas mass A/F sensor measured lambda secondary O2 sensor fuel trim proportional trim dominating secondary O2 aging diagnosis secondary O2 circuit diagnosis secondary O2 fuel trim active A/F sensor secondary O2 sensor then accumulated exhaust gas mass target lambda A/F sensor secondary O2 sensor lambda closed loop control secondary O2 circuit diagnosis short term fuel trim (o.k.) then accumulated exhaust gas mass

> = MAX ready ready

1.08008 1.25 -

lambda factor -

>1.08008lambda = MAX1.25factor ready-ready--

approx. 100 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

or

> > >

300 1.08008 0.014008

g lambda lambda

>300g >1.08008lambda >0.014008lambd a

secondary O2 sensor voltage

>

0.75

>0.75V

complete complete TRUE ready ready > > ready ready active complete > MIN >

300 1.04 0.75 800

g lambda factor g

complete-complete-TRUE-ready-ready->300g >1.04lambda ready-ready-active-complete-> MIN0.75factor >800g 0.9 sec

secondary O2 sensor voltage

>

0.75

>0.75V

Oxygen Sensor (secondary O2) Trim of Air / Fuel Ratio Sensor (primary A/F) Bank 1

P2196

secondary O2 sensor operation too lean - strong correction A/F sensor measured too rich

secondary O2 sensor voltage

<

0.2012

<0.2012V

A/F sensor measured lambda short term fuel trim A/F sensor secondary O2 sensor then accumulated exhaust gas mass A/F sensor measured lambda

< = MIN ready ready

0.92 0.75 -

lambda factor -

<0.92lambda = MIN0.75factor ready-ready--

approx. 100 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

> <

300 0.92

g lambda

>300g <0.92lambda

secondary O2 sensor voltage

<

0.2012

<0.2012V

Page 12 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters secondary O2 sensor fuel trim proportional trim dominating secondary O2 aging diagnosis secondary O2 circuit diagnosis secondary O2 fuel trim active A/F sensor secondary O2 sensor then accumulated exhaust gas mass target lambda A/F sensor secondary O2 sensor lambda closed loop control secondary O2 circuit diagnosis short term fuel trim (o.k.) then accumulated exhaust gas mass Enable Logic < Enable Value 0.014 Enable Units lambda Threshold Conditions <0.014lambda Time Required Frequency of Checks Criteria for Code MIL Illum.

complete complete TRUE ready ready > < ready ready active complete < MAX

300 0.96 1.25

g lambda factor

complete-complete-TRUE-ready-ready->300g <0.96lambda ready-ready-active-complete-< MAX1.25factor 0.9 sec

secondary O2 sensor voltage

<

0.2012

<0.2012V

>

800

>800g

Air / Fuel Ratio Sensor (primary A/F) electrical wire to wire short circuit bank 1 sensor 1

sensor short to heater P2231

filtered maximum pump current variation within every 10ms

>

0.00019

>0.00019A

all injectors activated battery voltage battery voltage A/F sensor IC diagnosis error: A/F sensor IC engine rpm modeled exhaust gas temperature heater duty cycle heater duty cycle A/F sensor heater at op.temp. after A/F sensor curve switching for time

TRUE < > complete not set < < > < TRUE

18 10,7 1800 800 20 80

V V rpm C % %

TRUE-<18V >10.7V complete-not set-<1800rpm <800 C >20% <80% TRUE

15 sec

0.01 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

>

0.06

sec

>0.06sec

Diagnosis of Heater upstream HO2S P0032 short circuit to battery voltage Voltage IC internal IC internal for time battery voltage via main relay battery voltage via main relay condition end of start condition engine speed: n > NMIN > <= >= True True 18 10,7 V V 5 sec > 5 sec <= 18 V >= 10,7 V True True 5 sec continous 0.2 sec 2 dcy

P0031

short circiut to ground

P0030

wire interruption

A/F Sensor Heating heater performance (primary A/F) bank 1 sensor 1

P0135

A/F sensor calculated temperature too low

A/F sensor temperature calculation

<

715

<715 C

battery voltage battery voltage internal resistance measurement all injectors activated

> < valid TRUE

10,7 18 -

V V -

>10.7V <18V valid-TRUE--

35 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous

Page 13 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters A/F sensor internal resistance excessive correction required engine stop time engine temperature at start A/F sensor heating ready A/F heater control shut off scheduled by System Manager heater performance (primary A/F) bank 1 sensor 1 (primary) Enable Logic FALSE Enable Value Enable Units Threshold Conditions FALSE-Time Required Frequency of Checks Criteria for Code MIL Illum. or 4 sec cumulative > > TRUE FALSE TRUE 5400 -9,8 sec C >5400sec >-9.8 C TRUE-FALSE-TRUE--

P0135

A/F sensor calculated temperature below threshold

A/F sensor temperature calculation

<

715

<715 C

A/F Heater at Maximum Power modeled exhaust temp. at sensor timer expires after either: fuel shut off >= 3 sec dur. ends or initial A/F heater turn on battery voltage battery voltage A/F heater control shut off modeled exhaust temp. valid scheduled by System Manager

TRUE > > > < FALSE TRUE TRUE 300 50 10,7 18 C sec V V -

TRUE >300 C >50sec ---->10.7V <18V FALSE-TRUE TRUE--

60 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

A/F Sensor Heating heater performance (secondary O2) bank 1 sensor 1 bank 2 sensor 1

P0053

correction value for A/F sensor internal resistance measurement too much

absolute value of correction value for A/F sensor internal resistance

>

45

Ohms

>45Ohms

battery voltage battery voltage engine starting

> < complete

10.7 18 -

V V -

>10.7V <18V complete--

40 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Oxygen Sensor sensor circuit (secondary O2) bank 1 sensor 2

P0137

short circuit to ground

secondary O2 sensor voltage

<

0.06

<0.06V

secondary O2 heating stable and mod. exhaust gas temp. for time engine running battery voltage mod. exhaust-gas temp. time after start engine temp at stop engine temp error: engine coolant temp secondary O2 heating stable and mod. Exhaust-gas temp. for time engine running battery voltage mod. exhaust-gas temp. secondary O2 heating stable and mod. Exhaust-gas temp. for time engine running

> > > TRUE > < < > < not set > > > TRUE > < > > > TRUE

10 250 90 10.7 800 1 60 40 10 250 90 10.7 800 10 250 90 -

sec C sec V C sec C C sec C sec V C sec C sec -

> 10sec >250 C >90sec TRUE->10.7V <800 C <1sec >60 C <40 C not set-> 10sec >250 C >90sec TRUE->10.7V <800 C > 10sec >250 C >90sec TRUE--

0.1 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

bank 1 sensor 2

P0138

short circuit to battery voltage

secondary O2 sensor voltage >

>

1.08

>1.08V

5.1 sec

bank 1 sensor 2

P0140

sensor line disconnection

secondary O2 sensor voltage and secondary O2 sensor voltage or

> <

0.401 0.499

V V

>0.401V <0.499V

600 sec

Page 14 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria secondary O2 sensor internal resistance when modeled exhaust gas temperature Oxygen Sensor sensor circuit (secondary O2) bank 1 sensor 2 Threshold Logic > > Threshold Value 40000 600 Threshold Units Ohm C Threshold Conditions >40000Ohm >600 C Secondary Parameters battery voltage mod. exhaust-gas temp. Enable Logic > < Enable Value 10.7 800 Enable Units V C Threshold Conditions >10.7V <800 C Time Required Frequency of Checks Criteria for Code MIL Illum.

P2232

sensor line short circuit secondary O2 sensor to heater output line voltage gradient within time after heater turn off for occurrences out of heater turn offs > < > = 2 0.04 4 6 V sec count count >2V <0.04sec >4count =6count

secondary O2 heating stable and mod. Exhaust-gas temp. for time engine running battery voltage mod. exhaust-gas temp. time after dew point exceeded

> > > TRUE > < >

10 250 90 10.7 800 10

sec C sec V C sec

> 10sec >250 C >90sec TRUE->10.7V <800 C >10sec

10 sec

0.01 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Oxygen Sensor Heating heater performance (secondary O2) bank 1 sensor 2 (secondary)

P0141

secondary O2 sensor internal resistance above threshold

measured secondary O2 sensor internal resistance nominal internal resistance multipy times degradation factor

battery voltage battery voltage engine running engine starting fuel cut off sec. O2 internal resistance intake air temperature engine off soak time modeled exhaust temp. at secondary O2 sensor suspicion of secondary O2 sensor open circuit secondary O2 voltage supply scheduled by System Manager for time

> < TRUE complete FALSE valid > > in range

10,7 18 -9,8 120 350 . . . 550

V V C sec C

>10.7V <18V TRUE-complete-FALSE-valid->-9.8C >120sec in range350 . . . 550C FALSE ON

6 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

>

88 . . . 408 KFRINH 3 . . . 20 FRINH

Ohms

>

factor

>88 . . . 408Ohms KFRINH >3 . . . 20factor FRINH >6sec

for time

>

sec

FALSE ON

>

120

sec

>120sec

sensor response (secondary O2) bank 1 sensor 2

P2270

oscillation check low

secondary O2 sensor voltage for time then ramping in enrichment by at gradient for time (after enrichment limit reached)

< >

0.499 . . . 0.603 5

V sec

= = >

0.25 0.0513 7

lambda l / sec sec

for time secondary O2 closed loop control =0.25lambda all injectors activated 0,0513 l / sec engine air flow (intrusive test) >7sec and engine air flow

<0.499 . . . 0.603V >5sec

secondary O2 sensor

ready > active TRUE > <

10 9.72 33.33

sec g/sec g/sec

ready - >10sec active - TRUE - 9.72g/sec 33.33g/sec

approx. 600 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

additional time if fuel level

bank 1 sensor 2

P2271

oscillation check high

secondary O2 sensor voltage

>

0.499 . . . 0.603

>0.499 . . . 0.603V

for time engine air flow (passive monitor) sec. O2 trim - fast lean correction sec. O2 trim - fast rich correction engine scheduled by System Manager secondary O2 sensor

> > FALSE FALSE running TRUE ready

3 9.72

sec g/sec

>3sec 9.72g/sec FALSE FALSE running TRUE

is low and not failed 600 sec

ready - -

approx.

0.1 sec

0.4 sec

two driving

Page 15 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria for time then ramping in enleanment by at gradient for time (after enleanment limit reached) Threshold Logic > Threshold Value 5 Threshold Units sec Threshold Conditions >5sec Secondary Parameters Enable Logic > active TRUE > < 9.72 33.33 g/sec g/sec Enable Value 10 Enable Units sec Threshold Conditions >10sec active TRUE 9.72g/sec 33.33g/sec Time Required 600 sec Frequency of Checks continuous Criteria for Code continuous or 4 sec cumulative MIL Illum. cycles each with: 0.4 sec continuous or 4 sec cumulative

= = >

0.07 0,0513 7

lambda l / sec sec

for time secondary O2 closed loop control =0.07lambda all injectors activated 0,0513 l / sec engine air flow (intrusive test) >7sec and engine air flow

bank 1 sensor 2

P2271

fuel cut off check high

secondary O2 sensor voltage time after fuel cut off

> >

0.202 2,5

V sec

>0.202V >2,5sec

for time engine air flow (passive monitor) sec. O2 trim - fast lean correction sec. O2 trim - fast rich correction engine scheduled by System Manager secondary O2 heating stable secondary O2 dew point exceeded for time air passed after fuel cut off modeled exhaust temp at secondary O2 sensor scheduled by System Manager error: cam sensor error: evap canister purge sys. error: evap purge valve ckt error: battery voltage secondary O2 heating stable secondary O2 dew point exceeded for time air passed after fuel cut off bank 1 sensor 2 voltage for time battery voltage

> > FALSE FALSE running TRUE > TRUE > > > TRUE not set not set not set not set > TRUE > >

3 9.72

sec g/sec

>3sec 9.72g/sec FALSE FALSE running TRUE

10 30 15 350 10 30 15

sec sec g C sec sec g

> 10sec TRUE - >30sec >15g >350 C TRUE - not set - not set - not set - not set - > 10sec TRUE - >30sec >20g >0,6 V > 3 sec > 10,7V

0.2 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

bank 1 sensor 2

P0139

fuel cut off check high

secondary O2 sensor voltage time after fuel cut off lambda actual value

> > >

0,152 3,0 2

V sec

>0.152V >3,0sec lambda >2

0.2 sec

0.1 sec continuous

0.4 sec continuous or 9,5 sec cumulative

two driving cycles each with: 0.4 sec continuous or 9,5 sec cumulative

Camshaft Control System - Locking Pin Bank 1 Intake Bank 2 Intake

P0011 P0021

rationality high

average of actual angle measurements versus locked position angle

>

10

degrees

>10degrees

engine speed engine run time camshaft control circuit test error: camshaft control circuit engine speed engine run time camshaft control circuit test error: camshaft control circuit coolant temperature coolant temperature

> > complete not set > > complete not set < > < >

560 1 560 1 143 -48 143 -48

rpm sec rpm sec C C C C

>560rpm >1sec complete-not set->560rpm >1sec complete-not set-< 143 C >-48 C <143 C >-48 C

10 sec

0.01 sec

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cum two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

System - Control Bank 1 Intake Bank 2 Intake

P000A P000C

rationality low / high

difference to start test (filtered actual angle versus filtered desired angle) (desired must remain above value to test to complete the evaluation) filtered actual angle remains filtered desired angle from test start within time (detects 5 sec slow [time constant])

>

6 . . . 11

degrees

> 6 . . . 11 degrees

approx. 20 sec

0.01 sec continuous

0.4 sec continuous or 4 sec

(4 times for 4 sec each )

cumulative

<

<

sec

=3sec

engine oil temperature engine oil temperature

Page 16 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters cam-crank alignment adaptation for multiple activation occurrences (decrements upon activations where > 4 count >4count ( same as stated in "time required" column ) Enable Logic complete Enable Value Enable Units Threshold Conditions complete-Time Required Frequency of Checks Criteria for Code MIL Illum.

no difference is seen between desired and actual) difference (filtered actual angle max versus actual at test start) ( to detect slow response versus stuck cam if above this limit ) at time (overlaps with time to detect above) (passes after multiple good activations in both cam phase rotation directions)

>

degrees

>3degrees

sec

=4sec

System - Cam - Crank Alignment Bank 1 Intake

P0016

Bank 2 Intake

P0018

cam-crank adapted angle limit check (applies for each camshaft)

adapted angle or adapted angle or actual angle with parked cams and adapted angle for both cams adapted angle for both cams

> < > < > <

10 -18 20 25 10 -18

degrees degrees degrees degrees degrees degrees

>10degrees <-18degrees >20degrees <25degrees >10degrees <-18degrees

engine run time > engine coolant temp > engine coolant temp < model: engine oil temp < error: camshaft sensor error: camshaft control circuit

> > < < not set not set

2 9.8 105 140 -

sec C C C -

>2sec >9.8 C <105 C <140 C not set-not set--

approx. 600 sec

0.2 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

fail after 2 adaptation cycles required

Bank 1 / Idler Sprocket Bank 2 / Idler Sprocket

P0008 P0009

Engine coolant

P0117

range check high

coolant temperature

>

138.8

>138.8 C

hot restart timer after engine start If Startup ECT+O155 | ECT-Startup ECT | (abs value) integrated air mass increases and air mass timer

>=

60

sec

>=60sec

0.1 sec

0.1 sec

0.4 sec

two driving

temperature sensor

P0118

range check low

coolant temperature

<

-38.3

<-38.3 C

< <= >= >=

-38.3 2.3 0 30

C C g sec

<-38.3 C <=2.3 C >=0g >=30sec

continuous or 4 sec cumulative

cycles each with: 0.4 sec cont. or 4 sec cum.

P0119

intermittent ( discontinuity )

delta coolant temperature or delta coolant temperature (between A/D read sample count offset)

<

-20.25

<-20.25 C

ignition

ON

=ON

approx. 150 sec

0.01 sec continuous

immediate

> =

20.25 3

C count

>20.25 C =3count

Engine coolant temperature sensor

P0116

plausibility check (low side check)

calculated coolant temperature model minus measured temperature

>

9.8

>9.8 C

the model temperature increases depending on air flow

or 0.4 sec continuous

two driving cycles each

Page 17 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value 9.8 Threshold Units C Threshold Conditions Secondary Parameters measured temperature engine speed Enable Logic < > Enable Value 93.8 520 Enable Units C rpm Threshold Conditions <93.8 C >520rpm or 4 sec with: 0.4 sec Time Required Frequency of Checks Criteria for Code MIL Illum.

plausibility check (high measured temperature side check) minus calculated coolant temperature model

Engine coolant temperature sensor

P050C

difference from intake air temperature after soaking

filtered difference ( ECT at key on - IAT at key on ) > 15 C >15 C

or filtered difference ( ECT at key on - IAT at key on )

<

-10

<-10 C

integrated air mass no error engine speed no error air mass flow meter key up IAT - previous min IAT key up IAT - previous min IAT previous accumulated air mass previous accumulated air mass previous engine run time or ECT at shut down Controller Shut Down at end of Strong Wind / Open Hood based on IAT rise at shut down Block Heater debouncing time error: engine coolant temp error: vehicle speed sensor

>

3000

> 3000g

cumulative

continuous or 4 sec cumulative two driving cycles each with: 0.4 sec cumulative

< > > > > > last cycle not detected

1.5 -24.75 2000 4000 500 84.75 -

C C g g sec C -

<1.5 C >-24.75 C >2000g >4000g >500sec >84.75 C last cycle-not detected--

160 sec for block heating

0.2 sec continuous

immediate additional after block heater check

not detected > not set not set > < >= > < >

15 -39.8 140 3.125 640 69.8 1000

sec C C mph rpm C g

not detected->15sec not set-not set-> -39.8C <140C >=3.125mph >640rpm < 69.8C > 1000g approx. 900 sec 0.1 sec continuous 0.4 sec continuous or 4 sec cumulative two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

Engine Coolant Thermostat Monitoring

P0128

Coolant Temperature (calculated reference Below model coolant temp Thermostat Regulating minus measured coolant temperature) Temperature (plausibility check) reference model calculation limit ( development vehicles indicated steady thermostat regulating temperatures of 89C, as measured by the engine coolant temp. sensor. The thermostat opening temp. is 82C. The thermostat is fully open by 95C. All critical OBD and emission functions are enabled above 60C. )

>

5.3

>5.3 C

74,3 ... 75,8

74,3 ... 75.8 C est. ambient temperature est. ambient temperature vehicle speed engine speed coolant temperature at start integrated air mass flow

Intake air temperature sensor

P0111

response check

max intake air temperature min intake air temperature

drive period - count > 2.3 C >2.3 C each with vehicle speed mass flow mass flow coolant temperature at start no fuel shut-off idle period - count each with vehicle speed coolant temperature at start coolant temperature ECT decrease since prior shutdown

>=

count

>=5count

2 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

>= < > <=

56.25 250 25.6 120

mph g / sec g / sec C

>=56.25mph <250g / sec > 25.6g/sec <=120 C

>= <= <= > >

4 1.5625 120 64.5 0

count mph C C C

>=4count <=1.5625mph <=120 C >64.5 C >0 C

Page 18 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

P0112 P0113

range check low range check high

intake air temperature intake air temperature

> <

125.3 -35.3

C C

>125.3 C <-35.3 C

time after start then time in idle and intake air temperature then | IAT change | (abs value) while integrated air mass increases

> > < <=

15 3 -35.3 2.3

sec sec C C

> 15sec >3sec <-35.3 C <=2.3 C

>=

>=0g

Mass air flow sensor

P0101

range check low

mass air flow

<

or and fuel trim limits exceded delta lambda correction range - multiplicative and correction factor correction factor air mass (modeled air mass at throttle / air mass measured by air mass flow meter) range check high mass air flow

>

1.83 . . . 78.9 KFMLDMN 0,16

g/sec

factor

<1.83 . . . 78.9 battery voltage g/sec KFMLDMN time after start >0.16factor crankshaft revolution counter error: throttle position sensor <0.83factor ratio: MAP to Baro air mass flow time after start errors:

> > > not set

10.5 0.4 150 0 0

V sec rev 0 g/s g/sec sec

>10.5V >0.4sec >150rev not set -00 0g/s <1 -

0.40 sec

0.01 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

<

0.83

factor

< > > not set

1 8.3 1

>

or and fuel trim limits exceded delta lambda correction range - multiplicative and correction factor correction factor air mass (modeled air mass at throttle / air mass measured by air mass flow meter) P0102 P0103 pressure sensor upstream throttle valve circuit check low circuit check high mass air flow mass air flow

<

26.9 . . . 312.5 KFMLDMX -0.175

g/sec

factor

> 26.9 . . . 312.5 g/sec KFMLDMX throttle body <-0.175factor Leak upstream throttle

--

>

1.1699

factor

>1.1699factor

< >

-10.3 333.3

g/sec g/sec

>10.3g/sec >33.3g/sec

battery voltage

>

7.5

>7.5V

0.2 sec

P0238 P0237

cirtcuit continuity - high measured sensor voltage or open cirtcuit continuity - low measured sensor voltage

> <

4.65 0.45

V V

> 4.65 V < 0.45 V

0.5 sec

continuous

0.2 sec

2 dcy

P0238 P0237

range check - high range check - low

measured pressure measured pressure

> <

300 50

kPa kPa

> 300 kPa < 50 kPa

enabled by diagnostic scheduler

2 sec true true

P0236

rationality -

measured fuel pressure lies below expected minimum comparison between pressure measured pressure and expected (calculated) pressure

true

true

P0236

rationality ('measured') compression ratio exceeds expected maximum comparison between compression ratio ('measured') compression ratio and expected (calculated) compression ratio

true

true

Page 19 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

boost pressure control P2281 comparison between ratio between MAF based pressure MAF based pressure ratio ratio over the throttle valve over the throttle valve and and throttle body based throttle body based pressure ratio pressure ratio over the throttle valve over the throttle valve > 0.098 to 1.25 > 0.098 to 1.25 engine speed time after engine start no fault of - pressure sensor upstream throttle valve - throttle position sensors - MAF sensor boost pressure control is active > 0.101 to 1.297 > 0.101 to 1.297 > > 1520 10 rpm sec > 1520 rpm > 10 sec 1 sec continuous 0.2 sec 2 dcy

true true true true

true true true true 1 sec

(detection of leakage)

(fine leakage)

ratio between MAF based pressure ratio over the throttle valve and throttle body based pressure ratio over the throttle valve (coarse leakage) ratio between MAF based pressure ratio over the throttle valve and throttle body based pressure ratio over the throttle valve

>

0.109 to 1.398

> 0.109 to 1.398

engine speed time after engine start no fault of - pressure sensor upstream throttle valve - throttle position sensors - MAF sensor - canister purge system boost pressure control is not active for time cruise control not active setpoint canister purge rate no dynamic engine condition

> >

1520 10

rpm sec

> 1520 rpm > 10 sec

1.8 sec

true true true true true > true < true

true true true true true > true < 0.03

(coarse leakage)

0.03

P0299

comparison between desired boost pressure and current boost pressure

difference (positive) between set-point boost pressure and current boost pressure

>

12

kPa

> 12 kPa

boost pressure control is active engine speed true > 2000 or 2800 66 base boost pressure + 5 rpm true > 2000 rpm or 2800 rpm > 66 kPa > base boost pressure + 5 kPa

6 sec

(boost pressure to low)

atmospheric pressure setpoint boost pressure

> >

rpm kPa

kPa

P0234

comparison between desired boost pressure and current boost pressure

difference (negative) between set-point boost pressure and current boost pressure

>

32 to 127.5

kPa

> 32 kPa to

pressure upstream throttle valve is valid true true

0.8 sec

kPa

127.5 kPa

(boost pressure to high)

Page 20 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

(Remark: for comparison the negative value is converted to an absolute value)

dump valve P2261 counting of increased normalized difference pulsation between in the intake manifold measured MAF sensor value and modeled value (increased pulsation may occure when dump valve is for jammed in closed position) number of times engine coolant temperature intake air temperature > 0,352 > 0,352 pressure in front of throttle valve supervision phase is active > > 50.3 -10.5 C C > 50.3 C > -10.5 C 0.48 sec continuous 0.2 sec 2 dcy

> true

60

kPa

> 60 kPa true

>

counts

> 4 counts

conditions for an active supervision phase are - negative load gradient detected - ratio of pressure in front of throttle valve to minimum pressure after air filter - dump valve is active

true >

1.05 to 3.12

true > 1.05 to 3.12 true

true

Barometric Pressure Sensor ( ambient air pressure sensor )

P2227

rationality signal discontinuity

difference between barometric pressure signal pressure and pressure in front of throttle

3 sec > 15 kPa >15kPa plausible pressure signal pressure sensor in front of throttle and throttle angle and engine speed enabled by scheduler for time TRUE TRUE

0.1 sec

0.4 sec continuous

two driving cycles each

or 4 sec cumulative < < > 5 1000 3 % rpm sec <5% <1000rpm >3sec

with: 0.4 sec continuous or 4 sec cumulative

or

barometric pressure signal pressure jump from previous key off

>

10

kPa

>10kPa

Baro from previous drive difference: Baro substitute

valid >

15

kPa

valid->15kPa

and difference between barometric pressure signal pressure and pressure in front of throttle > 10 kPa >10kPa

model versus sensor engine speed lower and throttle angle

<

621

rpm

< 621 rpm

<

< 5%

both for time P2228 range check low sensor signal sensor voltage < < 45 0.45 kPa V <45kPa < 0,45V enabled by scheduler for time

> >

3 1

sec sec

>3sec >1sec 2 sec 0.5 sec

P2229

range check high

sensor signal sensor voltage

> >

115 4.8

kPa V

>115kPa >4,8V

enabled by scheduler for time

>

sec

>1sec

2 sec 0.5 sec

Idle Speed System (disabled during cold start)

P0506

functional check

desired rpm - actual rpm

>

100

rpm

>100rpm

load (for underspeed only) coolant temp.

< >

39.75 64.5

% C

<39.75% >64.5 C

10 sec

0.1 sec continuous

0.4 sec continuous

two driving cycles each

Page 21 of 32

08 GRP04 All Engines

Component/ System Fault Code P0507 Monitor Strategy Description Primary Malfunction Signal and Criteria desired rpm - actual rpm or fuel cut off due to overspeed during this idle Threshold Logic < Threshold Value -200 Threshold Units rpm Threshold Conditions <-200rpm Secondary Parameters intake air temp vehicle altitude factor ( sea level = 1.0 ) time after engine start cold start idle speed control intrusive evap test Idle Speed System (enabled during cold start) Enable Logic > at idle > > FALSE not active Enable Value -10.5 Enable Units C Threshold Conditions >-10.5 C at idle >0.703factor >0sec FALSE not active Time Required Frequency of Checks Criteria for Code or 4 sec cumulative MIL Illum. with: 0.4 sec continuous or 4 sec cumulative

>

count

>3count

0.703 0

factor sec

P0506

functional check

desired rpm - actual rpm

>

100

rpm

>100rpm

load (for underspeed only) Engine coolant start temp.

< > > at idle > > TRUE not active

39.75 -10 . +40 40

% C C

<39.75% > -10 . +40 C >40 C at idle

5 sec

0.1 sec continuous

0.4 sec continuous or 4 sec cumulative

two driving cycles each with: 0.4 sec continuous or 4 sec cumulative

P0507

during catalyst heating on desired rpm - actual rpm

<

-200

rpm

<-200rpm

intake air temp vehicle

during catalyst heating on altitude factor ( sea level = 1.0 ) time after engine start idle speed control catalyst heating intrusive evap test Vehicle speed sensor P0500 rationality (high range check) rationality (stuck check) CAN wheel speed message check vehicle speed vehicle speed minus previous vehicle speed CAN wheel speed message corrupt or missing no engine signal but phase signals available rationality check reference gap missing ( sensor signal but no reference ) unexpected resynchronization ( loss of reference mark ) > 6 gaps >6gaps > = 171.875 0 mph mph >171.875mph =0mph vehicle speed vehicle speed time > < > 0 319.375 10 mph mph sec -->0mph <319.375mph >10sec 2 sec 0.1 sec continuous 0.4 sec continuous or 4 sec cumulative two driving with: 0.4 sec continuous or 4 sec cumulative 0.703 0 factor sec >0.703factor >0sec TRUE not active

= = =

corrupt missing 0 rpm

=corrupt =missing =0rpm camshaft revolutions detected > 12 counts >12counts approx. 5 sec 0.01 sec continuous 0.4 sec continuous two driving cycles each

Crankshaft Position Sensor

P0335

circuit continuity

or 4 sec cumulative

with: 0.4 sec continuous or 4 sec cumulative

P0336

rationality check

>

count

>6count

rationality check P0338 rationality check

intermittent loss of engine speed signal difference in counted teeth between reference gap position events

> >

14 8

count teeth

>14count >8teeth approx. 2 sec 1 per rev continuous

Camshaft Position Sensor Bank 1 Intake

P0341 P0342 P0343

plausibility check circuit low circuit continuity or high

no cam position sensor signal

> > >

count

>5count > >

engine in synchronized mode

TRUE

TRUE--

10 revolutions

1 per rev continuous

0.4 sec continuous or 4 sec cumulative cumulative

two driving cycles each with: 0.4 sec continuous continuous or 4 sec cumulative

Bank 2 Intake

P0345 P0347 P0348

plausibility check circuit low circuit continuity or high

no cam position sensor signal

> > >

5 5 5

count count count

>5count >5count >5count

Page 22 of 32

08 GRP04 All Engines

Component/ System fuel tank pressure sensor P0453 circuit continuity - high fuel tank pressure or open > 3781 Pa > 3781 Pa Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters barometric pressure vehicle speed fuel level fuel level engine start finished enabled by diagnostic scheduler Enable Logic >= = > < true true 68 0 6,2 87 kPa mph % % Enable Value Enable Units Threshold Conditions >= 68 kPa = 0 mph > 6,2 % < 87 % true true 25.5 sec canister vent valve open for time vehicle speed enabled by diagnostic scheduler vehicle speed true > <= true 3 18.64 sec mph true > 3 sec <= 18.64 mph true 6.22 mph >= 6.22 mph true 0.477 68 kPa <= 0.477 >= 68 kPa true 6,2 87 % % > 6,2 % < 87 % true true 45 30 C % > 45 C > 30 % 0,3 sec continuous 2.6 sec no MIL 25 sec continous 0.4 sec 2 dcy continous 0.4 sec 2 dcy Time Required 14 sec Frequency of Checks continous Criteria for Code 0.4 sec MIL Illum. 2 dcy

P0452

circuit continuity - low

fuel tank pressure

<

-4000

Pa

< -4000 Pa

P0451

rationality sensor signal change within time (oscillation check)

fuel tank pressure difference within for integrated time

>= = >=

813 1 25.5

Pa sec sec

>= 813 Pa = 1 sec >= 25.5 sec

P0451

rationality - sensor signal stuck (incremental check)

max-min difference of canister purge valve duty cycle and max-min difference of fuel tank pressure signal for number of checks

>=

39.84

>= 39.84 % canister purge is active ratio of intake manifold pressure to atmospheric pressure atmospheric pressure incremental check without result yet fuel level fuel level enabled by diagnostic scheduler - Knock control is active. - engine coolant tempetature - load

>= true <= >= true > < true

< 80 Pa < >= 80 2 Pa counts >= 2 counts

P0327

P0328

Monitoring via knocksensor- and cylinder-based basic reference noise signal (voltage).

Cylinder individual signal value (depends on engine speed) Cylinder individual signal value (depends on engine speed)

<

0.7422 ... 6.8164

< 0.7422 ... 6.8164 V

true > >

>

57.8908 ... 72.7541

> 57.8908 ... 72.7541 V

- Engine speed for strong signals. - Engine speed for weak signals. - No phase sensor faults during engine start. - Engine speed dynamics for knock detection exist. - Load dynamics for knock detection exist. - No ECM knock-control ciruit error. - Engine stpeed limp home function is active.

> > true

2520 2520

rpm rpm

> 2520 rpm > 2520 rpm true

false

false

false

false

true

true

false

false

P0332

P0333

Monitoring via knocksensor- and cylinder-based basic reference noise signal (voltage).

Cylinder individual signal value (depends on engine speed) Cylinder individual signal value (depends on engine speed)

<

0.7422 ... 6.8164

< 0.7422 ... 6.8164 V

- Knock control is active. - engine coolant tempetature - load

true > > 45 30 C %

true > 45 C > 30 %

0,3 sec

continuous

2.6 sec

no MIL

>

57.8908 ... 72.7541

> 57.8908 ... 72.7541 V

- Engine speed for strong signals. - Engine speed for weak signals - No phase sensor faults during engine start.

> > true

2520 2520

rpm rpm

> 2520 rpm > 2520 rpm true

Page 23 of 32

08 GRP04 All Engines

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters - Engine speed dynamics for knock detection exist. - Load dynamics for knock detection exist. - No ECM knock-control ciruit error. - Engine speed limp home function is active. Knock control sensor's evaluation IC Response to Zero Pulse monitor IC's integrator integrator's value offset 715mV 250 working cylces > 0.215 V > 0.215 V knock control active no dynamic condition on engine speed no dynamic condition on engine load no fault assumption from knock control test pulse. the engine speed is within a calibrated range same as for IC integrator's offset monitoring true true true true - true - true - Zero and Test pulse alternate every 250 working cycles. 2.6 s 2 dcy Enable Logic false Enable Value Enable Units Threshold Conditions false Time Required Frequency of Checks Criteria for Code MIL Illum.

false

false

true

true

false

false

P0324

true

true - -

true

true - -

P0324

monitor IC's integrator integrator gradient gradient

>

measuring window length dependent

V/s

P0324

Response to Test Pulse integrator value check integrator value of test pulse

<

3.691

< 3.691 V

the engine coolant temperature > calibration no dynamic condition on engine speed no dynamic condition on engine load no fault assumption from the knock control zero test. -

true true true

true true true

true -

true --0.01 sec 0.01 sec continuous immediate immediate

Transmission Control Module MIL Illumination Request

P0700

OBD emission fault detected by the TCM

signal input

TCM MIL

FAULT

=TCM MILFAULT

(Specific TCM DTC shown in freeze frame) fuel injector cylinder #1

P0201 P0261 P0262

circuit continuity - open Voltage circuit continuity ground circuit continuity voltage circuit continuity - open circuit continuity ground circuit continuity voltage circuit continuity - open circuit continuity ground

IC internal

IC internal

engine speed battery voltage battery voltage output activated and deactivated for complete checking

> > <

80 9,99 17,99

rpm V V

> 80 rpm > 9,99 V < 17,99 V

immediatel y

continuous

0.2 sec

2 dcy

cylinder #2

P0202 P0264 P0265

true

true

cylinder #3

P0203 P0267

Page 24 of 32

08 GRP04 All Engines

Component/ System Fault Code P0268 cylinder #4 P0204 P0270 P0271 cylinder #5 P0205 P0273 P0274 cylinder #6 P0206 P0276 P0277 Monitor Strategy Description circuit continuity voltage circuit continuity - open circuit continuity ground circuit continuity voltage circuit continuity - open circuit continuity ground circuit continuity voltage circuit continuity - open circuit continuity ground circuit continuity voltage Primary Malfunction Signal and Criteria Threshold Logic Threshold Value Threshold Units Threshold Conditions Secondary Parameters Enable Logic Enable Value Enable Units Threshold Conditions Time Required Frequency of Checks Criteria for Code MIL Illum.

canister ventilation valve

P0449 P0498 P0499

circuit continuity - open Voltage circuit continuity ground circuit continuity voltage

IC internal

IC internal

engine speed battery voltage battery voltage output activated and deactivated for complete checking

> > <

80 9,99 17,99

rpm V V

> 80 rpm > 9,99 V < 17,99 V

immediatel y

continuous

0.2 sec

2 dcy

true

true

canister purge valve

P0443 P0458 P0459

circuit continuity - open Voltage circuit continuity ground circuit continuity voltage

IC internal

IC internal

engine speed battery voltage battery voltage output activated and deactivated for complete checking

> > <

80 9,99 17,99

rpm V V

> 80 rpm > 9,99 V < 17,99 V

immediatel y

continuous

0.2 sec

2 dcy

true

true

downstream oxygen sensor heater Bank #1

P0036 P0037 P0038

circuit continuity - open Voltage circuit continuity ground circuit continuity voltage

IC internal

IC internal

engine speed battery voltage battery voltage output activated and deactivated for complete checking

> > <

80 9,99 17,99

rpm V V

> 80 rpm > 9,99 V < 17,99 V

immediatel y

continuous

0.2 sec

2 dcy

true

true

secondary air pump

P0418 P2445 P2444

circuit continuity - open Voltage circuit continuity ground circuit continuity voltage

IC internal

IC internal

engine speed battery voltage battery voltage output activated and deactivated for complete checking

> > <

80 9,99 17,99

rpm V V

> 80 rpm > 9,99 V < 17,99 V

immediatel y

continuous

0.2 sec

2 dcy

true

true

Page 25 of 32

08 GRP04 All Engines