Professional Documents

Culture Documents

Combustion Science and Technology

Combustion Science and Technology

Uploaded by

Muhammad AwaisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combustion Science and Technology

Combustion Science and Technology

Uploaded by

Muhammad AwaisCopyright:

Available Formats

This article was downloaded by: [Bibliothek der TU Muenchen]

On: 21 May 2013, At: 13:46

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

Combustion Science and Technology

Publication details, including instructions for authors and subscription information:

http://www.tandfonline.com/loi/gcst20

A Method for Particle and Gas Temperature

Measurement in Laboratory-Scale, Pulverized-Coal

Flames

D. W. MACKOWSKI

a

, R. A. ALTENKIRCH

a

, R. E. PECK

a

& T. W. TONG

a

a

Department of Mechanical Engineering, University of Kentucky, Lexington, Kentucky, 40506

Published online: 29 Mar 2007.

To cite this article: D. W. MACKOWSKI , R. A. ALTENKIRCH , R. E. PECK & T. W. TONG (1983): A Method for Particle and Gas

Temperature Measurement in Laboratory-Scale, Pulverized-Coal Flames, Combustion Science and Technology, 31:3-4, 139-153

To link to this article: http://dx.doi.org/10.1080/00102208308923636

PLEASE SCROLL DOWN FOR ARTICLE

Full terms and conditions of use: http://www.tandfonline.com/page/terms-and-conditions

This article may be used for research, teaching, and private study purposes. Any substantial or systematic

reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any form to

anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representation that the contents

will be complete or accurate or up to date. The accuracy of any instructions, formulae, and drug doses should

be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims,

proceedings, demand, or costs or damages whatsoever or howsoever caused arising directly or indirectly in

connection with or arising out of the use of this material.

Combustion Science and Technology, 1983. Vol. 31, pp. 139-153

0010-2202/83/3104-0139518.30/0

1983 Gordon and Breach Science Publishers. Inc.

Printed in Great Britain

A Method for Particle and Gas Temperature Measurement

in Laboratory-Scale, Pulverized-Coal Flames

D. W. MACKOWSKI. R. A. ALTENKIRCH. R. E. PECK and T. W. TONG

Department of Mechanical Engineering. University of Kentucky. Lexington.

Kentucky 40506

(Received August 5, 1982; in final form October 5, 1982)

Abstract-A multiple-wavelength, infrared pyrometer suitable for making line-of-sight particle

and gas temperature measurements in pulverized-coal flames is 'described. The pyrometer uses

lead selenide detebors covered with narrow-band filters to measure emitted and transmitted

radiation. Scattering effects may be and are here incorporated into data reduction schemes for

calculating temperatures. Measurements were made on one-dimensional, coal-dustjoxygen{argon

flames stabilized on a flat-flame burner. Profiles of particle and gas temperatures and optical

depths as a function of distance from the burner are presented. In general, particle and gas

temperatures do not differ much close to the burner, but farther downstream the gas temperature

exceeds the particle temperature.

INTRODUCTION

Accurate measurement of temperatures in pulverized-coal flames is necessary if the

kinetics of the processes occurring in these flames is to be quantified. In general,

particle and gas temperatures differ (Cashdollar and Hertzberg, 1982; Smoot et al.,

1978), and because it is the particle temperature that determines the devolatilization

rate and the gas temperature that determines the rate of pyrolysis and oxidation of

gas-phase it is important to be able to distinguish between these two tempera-

tures.

Experimental investigations of laminar, premixed, pulverized-coal flames in which

flame temperatures were measured by thermocouples have been reported (Smoot

et al., 1978; Altenkirch et al., 1979; Milne and Beachey, 1977). Such measurements

are not accurate because deposition of solids upon the thermocouple bead augments

the bead's radiative heat loss, resulting in temperatures generally lower than expected

(Smoot et al., Also, thermocouples are obviously incapable of differentiating

between particleI and gas temperatures.

Multiple-wavelength pyrometry, which is inexpensive and relatively easy to apply,

has been used before for temperature measurement in two-phase flames. Cashdollar

and Hertzberg (11982) developed an infrared pyrometer that measures radiant intensity

at four wavelengths where only the particles radiate and two wavelengths that are

within C02 absorption bands. Particle and gas temperatures were calculated by

"fitting" the measured intensities to Planck's law assuming particle and gas emittances

independent of wavelength. Adams (1972) describes a spectroscopic technique for

temperature measurement in two-phase flames in which a monochromator is used to

measure condensed-phase and gas-wavelength emission. Additional light scattering

and extinction measurements are used to determine the radiative properties of the

flame.

In this paper we describe a four-wavelength pyrometer that we used to measure

particle and gas temperatures in pulverized-coal/oxidizer flames stabilized on a

139

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

140 D. W. MACKOWSKI et al.

specially designed, flat-flame burner (Altenkirch et al., 1979). The instrument is

similar in design to the one described by Cashdollar and Hertzberg (1982) with

modifications made to accommodate continuous operation and a smaller radiation

collection angle. Both emission and transmission measurements arc made, and the

effects of scattering on the data reduction are investigated.

EXPERIMENTAL

Temperature measurements were made as part of our investigation into the trans-

formation of fuel nitrogen and sulfur in pulverized-coal flames. The investigation

utilizes the flat-flame burner developed in our previous work (Altenkirch et al., 1979).

The 40 ern- Meker-type burner produces a laminar, free-burning, coal-dust flame of

approximately 6 em diameter at the base. A set of water-cooled, stainless-steel

screens serves to anchor the flame to the burner. The burner is contained within a

15.24 em diameter, 38 em tall aluminum chimney, and the flame is viewed through

open slits cut in the side of the chimney. Gas and solid sampling and optical measure-

ments were performed at various heights within the flame by adjusting the elevation

of the burner with respect to the instrumentation. The fuel used in this study was

Eastern Kentucky bituminous coal pulverized to a volume-surface mean diameter

(Dobbins and Jizmagian, 1966) of 16[Lm, which gives a mass mean diameter of

26 [Lm. The size distribution and composition of the coal is given in Table 1.

Flame particle and gas temperatures were measured using a four-wavelength,

infrared pyrometer that we developed in our laboratory and is described in detail by

TABLE I

Coal analysis and size distribution

Proximate analysis Weight Ultimate analysis Weight

(as received) percent (dry) percent

Moisture 1.6 C 68.58

Volatile matter 31.6 H 4.61

Fixed carbon 47.7 S 1.53

Ash 19.1 N 1.63

0 4.24

Ash 19.41

Total 100.0 Total 100.00

Heating value 26,540 kJ/kg

Size distribution by sieving

Range Weight percent Number percent

40-74 I'm

30-40 I'm

20-30 I'm

10-20 I'm

0-10 I'm

16.9

13.5

19.8

38.1

11.7

0.1

0.3

1.2

10.6

87.8

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-coAL FLAMES 141

Mackowski (1982). The pyrometer uses four lead selenide detectors, each covered

with one narrow-band optical filter, to measure the radiative emission and transmission

of the flame ati the four wavelengths. Band centers of the filters are located at 1.6,

2.3, 3.8 and 4.4 I'm, and the bandwidth of each filter is approximately 2.5 percent of

the band center The first three wavelengths mentioned above are free of gas absorp-

tion bands and can be used to determine the temperature and extinction coefficient

of the particle cloud. The 4.4 I'm wavelength is within the fundamental C02 vibration

band, and the detector sensitive to this wavelength is used to measure the combined

gas-particle c16ud emission and transmission. Knowledge of the particle-cloud

properties from: the particle-wavelength measurements allows us to calculate the gas

temperature from a measurement at 4.4 I'm.

The pyrometer was initially designed following the six-wavelength pyrometer

developed at Bureau of Mines (BOM) that was used to measure particle and gas

temperatures in! coal-dust explosions (Cashdollar and Hertzberg, 1982). Although

conceptually suited for our needs, the electronic design of the BOM pyrometer

required extensive modification in order to make its application to "steady-state",

burner-stabilized, pulverized-coal flames feasible.

5.1 k

v

10 k

5.6 k

FIGURE 1 Detector circuit diagram.

TI.

r,cord.r

A schematic diagram of the circuit for a single detector is shown in Figure I.

Because performance is sensitive to ambient temperature. the detectors are

biased in the constant current mode to stabilize their temperature and prevent thermal

runaway. In addition, a temperature control circuit was added to maintain the

detectors at a liked temperature of 35C. Detector signals are AC coupled to an

amplifier through a high-pass filter with a cutoff frequency of 1000 Hz. The high level

of filtering, in conjunction with a chopping frequency of 960 Hz, is necessary to sep-

arate the chopped signals from AC signals due to natural fluctuations within the flame.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

142 D. W. MACKOWSKI ef al,

In this way, only signals that are chopped are passed to the amplifier. Full-wave

rectification provides a DC voltage output that maintains output linearity with

incident intensity. The output is filtered through a 0.1 Hz, low-pass filter to reduce

output noise to an acceptable level.

A source of infrared radiation for flame transmittance measurements was usually

provided by a carbon-rod, black-body furnace. The carbon-rod-type source has been

used before in similar applications because it is effective in providing a high-tempera-

ture, near black-body source of radiation (Smith and Fridovich, 1978). The source

filament is a spectroscopically pure carbon rod, 17.8em long, with a 0.76 em diameter.

The rod was drilled through to an inner diameter of 0.50 em, and a 7.6 by 0.30 em

slit was centered along its length to create a black-body cavity and aperture. The rod

is mounted between two 2.54 em diameter copper electrodes and heated electrically

to a temperature, which is monitored continuously with a thermocouple, of approxi-

mately 1500 K. The entire assembly is contained within a water-cooled, argon-filled,

stainless-steel, cylindrical chamber. The rod is viewed through a 2.54 em diameter,

3 mm thick sapphire window, which has a 0.92 transmittance in the infrared wave-

lengths of interest.

Difficulties were encountered in maintaining the carbon rod at a constant tempera-

ture throughout the course of an experiment. Because of this, we used a commercially

available, black-body reference source (freon Model Be15) on several occasions.

Its peak temperature of 1100 K was just sufficient to allow accurate transmittance

measurements to be made.

source len 1

shutter

n

lens burner

lens stop

lenl

chopper

detectors

FIGURE 2 Optical setup.

The optical system, which is shown in Figure 2, consists of three, 5.08 em diameter,

calcium fluoride lenses. This lens material was chosen because it has a transmittance

above 0.9 from the visible to mid-infrared wavelengths, thus enabling visual align-

ment. A pair of fll lenses projects the image of the source to the chopper and then

from the .chopper to the burner centerline. A single 1/3 lens projects the source and

flame images upon the detectors. The lens stop serves to limit the detectors' collection

angle to approximately 0.022 rad vertically and 0.219 rad horizontally, centered

about the burner axis.

The lenses are arranged so that the image of the source upon the burner centerline

has unity magnification, and the source and flame images upon the detectors are

magnified by two. A detector's active area is 2 mrn-, so each detector can at best

resolve a I mm

2

area at the point at which it is focused. Because of the physical

distance between the detectors in their mounts and chromatic aberration of the

lenses, the points at which the detectors are focused are dispersed over an area

1.5 em parallel and 2 em normal to the line of sight. Thus, each detector does not

intercept exactly the same solid angle.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-COAL FLAMES 143

The //3 lens and the detectors are mounted on opposite ends of a 50.8 em long by

15.24 em diameter aluminum cylinder, which is mounted on a heavy-duty tripod.

The chopper, ,hich is located near the detectors, is attached so that it can be readily

removed, during flame transmission measurements, from the detectors' line of sight.

The two 111 lenses, source and source chopper are positioned on a modified optical

rail assembly. I

Alignment of the pyrometer is accomplished by removing the' back plate of the

aluminum tube containing the detectors and chopper and replacing it with an

alignment aperture, The pyrometer is sighted through the aperture and aligned with

a cross-hair target placed above the burner centerline. At the same time, the pyro-

meter is leveledin the directions parallel and normal to the line of sight. The source

is aligned by superimposing the image of the source, as seen through the alignment

aperture, on the cross-hair target.

Prior to making measurements, the pyrometer was calibrated with the standard

black-body reference source placed above the burner centerline. With this completed,

I

the black-body Ireference was removed, and the carbon-rod source was heated to a

constant temperature. The detector chopper was removed, and the source intensity

at the burner cehterline was measured. This determined the incident source intensity

H

A

FIGURE 3 Cylindrical flame model.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

144 D. W. MACKOWSKI et al.

for subsequent transmittance measurements. An initial burner position was estab-

lished by raising the burner to where it just began to cut off the source beam as seen

by the detectors.

With the flame lit and adjusted to the desired conditions, a measurement of the

transmitted source intensity was made, with the detector chopper removed. Because

the emitted flame radiation is not detected, the transmittance of the flame at a par-

ticular wavelength is the ratio of the source intensity with the flame present to the

incident source intensity. The intensity of the emitted flame radiation was measured

by closing the shutter in front of the III lens and replacing the detector chopper.

Once a transmittance and emission measurement were made, (he burner was lowered

(0 a new position, and the measurement sequence was repeated. Gas and particle

temperatures ean be calculated using the optieal measurements outlined above along

with solutions to the radiative transfer equation. The following section gives two

approximate solutions that we used to calculate temperatures.

DATA REDUCTION

Anisotropic Model

With the flame modeled as a cylinder (see Figure 3) of height H and diameter t, the

intensity distribution for the particles, 11', as a function of location, s, along the line

of sight at arbitrary distance A above the burner is governed by

(I)

where source radiation is' incident on the flame at s=O, and the pyrometer collects

radiation emerging at s=t. In Eq. (1), fJ is the extinction coefficient, i.e. {3=K+a

where K is the absorption coefficient and a is the scattering coefficient, subscript ,\

implies a particular wavelength, subscript b implies black-body, superscript p implies

particles and F is the phase function. Realize that [1'"b is fixed along the isothermal

line of sight. For arbitrary position s, as shown in Figure 3, (47T)-1(4>, 8) dQ is the

probability that radiation incident from the P direction within solid angle dQ is

scattered into the s direction. Because in what follows the intensity of this radiation

depends on 8 and 4>, the result is labeled anisotropic.

To get an expression for JP.(4). 8, s) in the phase-function integral term in Eq. (I),

we neglect scattering into the P direction so that from the radiative transfer equation

for [P" as a function of P we get for JP,(4), 8, s) at point s along the line of sight

I

[P

A

(4), 8,s) = exp(-{3p.,/) J(l-wp),)fJ

P),ex

P({3p),P)[P),b(P)dP

(2)

o

where the path along the P direction is I long, and fJ

P

" is taken to be constant along

that path, as is KP". In Eq. (2), w is the albedo, the ratio of the scattering to the

extinction coefficient.

Using Eq. (2) in Eq. (I) and solving the resulting differential equation subject to

["v=O at s=O, which corresponds to the emission measurement, we get for the

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZIi:D-COAL FLAMES

measured, emitted intensity of the particles at a height A in the flame

t

x (I - w

P

A

) exp( -f3P

A

I ) fexp(f3

P

As)

f F(q" 8) exp( -f3P

A

/ )

o 12.,.411

I

X fexp(f3P

A

P) [1'AD (1') dPdfJds

o

145

(3)

where KP

A

and aPA are constant along the line of sight. Equation (3) can be used to

get the particle temperature distribution as a function of height in the flame by

applying it at bach height and solving for 11>Ab, but the process is an iterative one

because IP

AD

~ ) depends on the temperature distribution.

We fit the emission data in a least-square-error sense, using the measured, wave-

length-dependent transmittances, and hence extinction coefficients, to Eq. (3) to

calculate the particle temperature and wavelength-independent albedo, w

p

Com-

putations that we have carried out, and those of Viskanta et al. (I 981), indicate that

the single-scatter albedo for coals for the range of the size parameter 7Td p/;" of interest

here, from over: 5 to over 12 based on the mean particle size, dfl' of 16 (Lm, ought to be

independent of I;., and equal about 13 to 31.

To carry out the iterative process, an initial guess for IPAD (1') was established

using the temperature distribution determined from the gray-isotropic model dis-

cussed below. Expressions for I, /P

AD

(1'), fJ and the extinction coefficient along the

p direction, f 3 P ~ (1'), as functions of s, A. 8 and q, were derived so that the integrals in

Eq. (3) could be performed. Recall that in obtaining Eq. (2), f3P

A

was taken to be

constant along the P direction. Tn applying Eq. (3) though we allowed f3P

A

to depend

on its P location. The inconsistency is unimportant because, as we will see later, f31>

does not vary much with distance from the burner. For the phase function we chose

the expression of Tong and Tien (1980), i.e., F=I-a cos 8', with a= 1.0 to imply

predominantly ,forward scattering.

The integrals in Eq. (3) were computed numerically. Values of the extinction

coefficient and temperature at P locations corresponding to heights at which measure-

ments were not' made were obtained from linear interpolation between existing data

points. The guessed temperature profile and measured values of f3P

A

and IP

A

(I) were

then used in Eq. (3) to calculate a distribution of IPAD with height and hence a new

temperature distribution. This new temperature distribution was used as a guess, and

the process repeated until the new and guessed profiles were within I K of each other

at each measurement height.

Measurements were only made up to a height of 6.35 cm above the burner. The

height of the model, H, was chosen to be 12 cm because at this height the temperature

was estimated to be nearly the ambient value. To specify temperatures for heights

between 6.35 and 12 cm, we used the three or four data points obtained at the highest

locations in the flame to establish a linearly decreasing temperature with height. The

extinction coefficient in this region was taken to be independent of height and set

equal to values ;"easured farthest from the burner.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

146 D. W. MACKOWSKI e al.

Employing the same assumptions as those used to get Eqs. (2) and (3), the measured,

emitted intensity at 4.4 fLm is

(3P

s

.

s

w

P

+ - e- Pt

471

t

JePs JF(,p, 0)

o U=41T

I

X e-

P1

re

PP

[Kg Igb(P) + KPIPb(P)]dPdfJds

0"

(4)

where superscript g implies gas. In Eq. (4), which is solved for /g4.4b to get the gas

temperature, the right-hand side is to be evaluated at 4.4 fLm, except as noted, and the

integrals were computed using the same procedures that were applied to Eq. (3). The

quantities KP

4.4,

set equal to KPS.S, and IP

4.4b

are known from measurements at the other

2500

2000

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-COAL FLAMES 147

three wavelengths, and KU

44

was calculated from the difference in the measured

extinction coefficients at 4.4 and 3.8 lim. The albedo used in Eq. (4) is the one deter-

mined from the anisotropic particle computations.

Isotropic Model

The problem may be simplified somewhat by taking IP;, (,p, e, s) to be IP;, (s) at the

s location of interest, which is equivalent to assuming that the particle radiation is

isotropic about any point along the line of sight. With this assumption, Eq. (3)

becomes

(5)

Physically, Eq. (5) implies that radiation scattered into the line of sight is balanced by

the out-scattering. Because the exact manner in which scattering is treated becomes

less important ~ s the optical depth becomes small (Ozisik, 1973), Eq. (5) is likely to be

applicable as long as the optical depth is not large, which, as we shall see later, is the

case here.

We applied Eq. (5) to the data in two ways. In the first, which we call the gray-

isotropic model, KP;, was taken to be independent of '\, and the emission data at the

three particle wavelengths were fit, in a least-square-error sense, to Eq. (5) to get the

2500

+ +

+

+

2000

+

+

00

+

'"

+

c

0

0

+

+

1500

0

<II

~

0

0 :J

0

0

0 0 0 <II

0

C>

E

1000 Q>

I-

285 mgll

+ T

9

23% 2-77% Ar

o T

p

500

14 ern Is

o r c

o

0.0 10 20 30 4.0 5.0 6.0

Distance from screen in em

FIG URE 5 Pyrometer- and thermocouple-measured temperature distributions in a 285 rng/I

coal-dust flame u ~ i n g the gray-isotropic model.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

148 D. W. MACKOWSKI et al.

+ T QI

0 Tp I

6-

TQz

X Tp2

4.0 5.0 60 30 20 10

470 mg/ 1

23% Oz-77%Ar

14 cm/s

OL------'-------'- .l...-__--'-__---'__----l

0.0

2000

t.

+

~

+ + +

1500

00 t

+

OQ

t

t

0 6-

6-

Q

Iil

X

X

500

2500

..

"

o

:;;

~ 1000

..

I-

Distance from screen in cm

FIGURE 6 Pyrometer- and thermocouple-measured temperature distributions in a 470 mgjl

coal-dust flame using the gray-isotropic model.

particle temperature T n- and KP. Transmission data are not needed in this treatment.

In the second, which we call the nongray-isotropic model, we used the measured

transmittances at the three particle wavelengths, which are equal to

exp[-KPAI/(I-w

P

A)],

along with Eq. (5) to fit the emission data to calculate the

particle temperature and a wavelength-independent albedo.

The measured intensity at 4.4 I,m, with the same assumptions that are contained

in Eq. (5), is given by

(6)

Kg /gb + KP /1'/,

/4.4(/) = {I - exp[ - (KP + Kg)l])

(Kg + KP)

where the right-hand side is to be evaluated at 4.4 pm. Again, in Eq. (6), we set

K

P,1.4

equal to KP

a.s

and Kg4.4 equal to the measured value of ({J4.4-fhs).

RESULTS AND DISCUSSION

As a test of our optical techniques, we made emission and transmission measurements,

at 4.4 I,m, on a CH4-02-Ar flame, stabilized on our coal-dust burner, at an equivalence

ratio, ,p, of 0.4 and a cold-gas speed through the burner of 1I ctn]. The black-body

intensity at 4.4 pm is, in this case, the measured intensity divided by one minus the

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-COAL FLAMES 149

2000

'"

~ to +

c: e + +

1500

00 +a

~

OQ

+

is. ::>

0 t

0

~

t:>.

t:>.

0000

fill

Q>

DO

X

C-

O 0

X

E 0

0

Q>

1000

f- 0

470 mg / I + T gl

23%Oz-77%Ar

0 T pi

500

14 cm/s t:>.

T gz

X T pz

oL

0 TC

I

0.0 10 20 30 4.0 50 60

Distance from screen In em

FIGURE 7 Pyrometer-measured temperature distributions from the anisotropic model in a

470 mg/I coal-dust flame.

transmittance. Jn Figure 4 we present the pyrometer-measured temperature, Tg ,

as a function of distance from the burner along with uncorrected thermocouple-

I

measured temperatures, TC. The thermocouples used were PtjPt-lO% Rh made from

0.127 mm diameter wire, butt welded, stretched diametrically across the burner and

coated to prevent catalysis (Kent, J970).

We estimate that the adiabatic flame temperature for the conditions of Figure 4

is about 1700 K for complete combustion. The pyrometer-measured temperatures

are somewhat lower than this due to heat loss to the burner. Thermocouple-measured

temperatures are lower again due to radiative heat loss from the bead. Correction

for radiative heat loss would, for our conditions, increase the thermocouple-measured

temperatures abolit 100to 300 K, depending on the values taken for the emittance and

diameter of thd bead, which would bring them in line with the pyrometer results.

Pyrometer Jnd thermocouple data for two different coal-dustjoxygenjargon

flames are presented in Figures 5 and 6 in which the pyrometer-measured temperatures

were calculated from the gray-isotropic model. The coal-dust concentration, the

volume percent oxygen in the oxidizer and the cold-gas speed of the oxidizer through

the burner are given on the figures. In Figure 5, pyrometer data between I and 2 em

from the screen, i.e., particle temperatures indicated by filled hexagons and the

corresponding ;gas temperatures directly above them, were obtained in a separate

experiment. Data were gathered between I and 2 em when the data associated with

the open hexagons were taken, but a malfunction of the coal-feed system caused the

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

150 n:W.'MACKOWSKI et al.

1.2

+

+ +

+ +

+

+ +

+

++

+

1.0

++

+

s:

0.8 +

a.

'"

"tJ

+

0

o

Ci

06

0

0

0.4

0

0

00 0 0

0

0 0

0

00

0

00 0

0.2

285 mgl 1 +

Kg,

23% Oz-77%Ar

0

f3 P ,

14 cmls

0.0

00 1.0 2.0 30 4.0 5.0 6.0

Distance from screen in em

FIGURE 8 Optical depth distribution in a 285 mgjl coal-dust flame.

actual experimental settings during the time period in which the data between 1 and

2 em were taken to be different than what is given in the figure, and so they were

discarded. Two sets of data are shown for the 470 mg(l flame to indicate the degree

of accuracy to which the data can be reproduced.

We calculated temperatures using the nongray-isotropic model too but did not find

substantial differences between the gray and nongray treatment due to the fact that

the measured extinction coefficients at the three particle wavelengths are usually all

within ten percent of one another, although at times two may differ by as much as

30 percent. The normalized rms error in fitting the data to the gray-isotropic model

is typically less than 2 percent.

The particle temperature peaks ahead of the gas temperature, and the peak tem-

peratures are higher and later for the leaner stoichiometry. Early in the flame the

particle and gas jemperatures do not differ appreciably, but after 2 em or so the gas

may be a few hundred K hotter than the particles. The initial heating rate is about

IOLlOo K(s.'

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-COAL FLAMES

1.2

10

+ + +

+

++ +

+

D. +

+ t>

0.8

s:

C.

X X X

Q>

X

0

0

X

"0

0

00000 0

"

06

o

c. X 09JXX

0

0.4

+

K

9

1 I

470 mg/I

0 {3 PI I

23% O

2-77

% Ar

t> K 91 2

O'l

14 cm/s

X {3P 1 2

I

1

0.0

00 10 2.0 3.0 4.0 5.0 6.0

Distance from screen in cm

FIGURE 9 Optical depth distribution in a 470 mgJI coal-dust flame.

151

Thermocouple-measured temperatures, as seen in Figures 5 and 6, are substantially

lower than the pyrometer-measured temperatures with the difference in the two

techniques being much greater than was the case for the methane flame. As mentioned

before, this behavior is to be expected because of the buildup of solid material on the

thermocouple bead. In addition, the thermocouple results reveal less structure to the

flame than apparently exists.

Figure 7 shows gas and particle temperatures, for the 470 rng/l flame, calculated

using the anisotropic model with the iteration scheme outlined above. Convergence

was obtained irt 3 iterations for the particle temperature and 4 for the gas temperature.

As can be seenlfrom comparing Figures 6 and 7, the anisotropic model and the gray-

isotropic model do not give temperatures that differ much. Similar results were

obtained for leaner concentration (Mackowski, 1982).

Particle and gas optical depths are shown in Figures 8 and 9 where {3P/ is an average

of the measured values at the three particle wavelengths, and Kg/ is the difference

between the measured optical depth at 4.4 I"m and the average {3P/. Apart from the

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

152 D. W. MACKOWSKI et af.

10

08 +

+

cP-6 + +

+

06

0&+

+

0

D D ~ ffi

6

A

+

'0

666

6

+

+

QI

+

0

~

D

c:r +

0

0

0.4 +

+ 285

285- 470 mg/I

0 470 I

0.2

23% Oz-77%At

6 4702

14 cm/s

50 4.0 30 2.0 1.0

0.0 '--__-L-__----' ...l-__---'- .J.-__--J

0.0 6.0

Distance from screen

FIGURE 10 Albedo distribution from the nongray-isotropic model for two coal-dust flames.

initial few millimeters of the flame, the optical depths remain fairly constant through-

out the flame.

Albedos for the two coal-dust flames are shown in Figure 10. These were calculated

by fitting the data to the nongray-isotropic model. Both concentrations show a

similar trend of the albedo peaking at about 0.9 near the bottom of flame and then

falling to about 0.5. The value of 0.9 is unreasonably high, but, as of yet, we have no

explanation as to why it occurs. Albedos of 0.5 agree with those calculated by

Viskanta et al. (1981).

To be sure, some caution must be exercised in the interpretation of temperature

data such 'as those we presented here. For example, the meaning of the particle

temperature is not completely clear. All particles may not be at the same temperature,

and soot particles formed during devolatilization (Seeker et al., 1981), whose con-

centration and optical properties are unknown, may contribute to the collected

radiation. Nonetheless, temperatures measured optically provide more information

than conventionally measured thermocouple temperatures.

CONCLUSIONS

The infrared pyrometer described here is an inexpensive and simple diagnostic tool

for measuring particle and gas temperatures in pulverized-coal flames. Results

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

PULVERIZED-COAL FLAMES 153

indicate that it is capable of providing detailed flame structure information. Soph-

isticated radiation modeling is not needed for the optical depth range I) that is

likely to be found in laboratory-scale, pulverized-coal flames because scattering is

unimportant. Data presented for one-dimensional, coal-dust flames show that the

gas temperature is substantially higher than the particle temperature beyond the

initial stages br the flame. Thermocouple-measured temperatures in coal-dust flames

are not indidtive of either the gas or particle temperatures and are well below both.

ACKNOWLEDGEMENTS

. ,

I

Support for this work from the National Science Foundation under Grant CPE-7926312 is

gratefully acknt/wledged. We thank RAC Mining Corporation for providing the coal. We also

thank K. L. Cashdollar of the Bureau of Mines for his willingness to share with us his experiences

in making optical measurements in coal flames,

REFERENCES

Adams, J. M. The spectral comparison method for temperature measurement in two-phase

flames. Temperature, Its Measurement in Science and Industry 4, 627.

Altenkirch, R. A., Peck, R. E., and Chen, S. L. (1979). The appearance of nitric oxide and cyanide

in one-dimensional coal-dust/oxidizer flames. Combustion Science and Technology 20, 49.

Cashdollar, K. L., and Hertzberg, M. (1982). Infrared pyrometers for measuring dust explosion

temperatures. Optical Engineering 21, 82.

Dobbins, R. A.,Iand Jizmagian, G. S. (1966). Optical scattering cross sections for polydispersions

of dielectric spheres. Journal of the Optical Society of America 56, 1345.

Kent, J. H. (1970). A noncatalytic coating for platinum-rhodium thermocouples. Combustion

ond Flame 14, 279.

Mackowski, D.W. (1982). Infrared pyrometer measurement of particle and gas temperatures in

pulverized-coal flames. MSME thesis in preparation, University of Kentucky, Lexington,

Kentucky. I

Milne, T. A., and Beachey, J. E. (1977). The microstructure of pulverized coal-air flames. II.

Gaseous species, particulate and temperature profiles. Combustion Science and Technology

16, 139.

Ozisik, M. N. (197J). Radiative Transfer. John Wiley, New York.

Seeker, W. R., Samuelsen, G. S., Heap, M. P., and Trolinger, J. D. (1981). The thermal decompo-

sition of pulverized coal particles. Eighteenth Symposium (International) on Combustion,

The Combustion 1nsitute, Pittsburgh, pp. 1213-1226.

Smith, G. R., and Fridovich, B. (1978). Carbon furnace infrared source-some practical con-

Review of Scientific Instruments 49, 1223.

Smoot, L. D., Horton, M. D., Nielsen, S. M., and Luke, D. E. (1978). The structure of laminar

pulverized toal dust flames. Presented at the Seventeenth Symposium (International) on

Combustion, Leeds, England, 1978.

Tong, T. W., and Tien, C. L. (1980). Resistance-network representation of radiative heat transfer

with particulate scattering. Journal of Quantitative Spectroscopy and Radiative Transfer

24,491.

Viskanta, R., Ungan, A., and Menguc, M. P. (1981). Predictions of radiative properties of

pulverized coal and fly-ash polydispersions. ASME Paper 8l-HT-24.

D

o

w

n

l

o

a

d

e

d

b

y

[

B

i

b

l

i

o

t

h

e

k

d

e

r

T

U

M

u

e

n

c

h

e

n

]

a

t

1

3

:

4

6

2

1

M

a

y

2

0

1

3

You might also like

- Cardinal 748Document47 pagesCardinal 748Juan MontufarNo ratings yet

- In Defense of The FalsiloquiumDocument13 pagesIn Defense of The FalsiloquiumScott Sullivan100% (1)

- CMP Final Draft FuelDocument33 pagesCMP Final Draft Fuelapi-594648232No ratings yet

- RP338 Flue Gas Flow EN-12952-15Document81 pagesRP338 Flue Gas Flow EN-12952-15Muhammad AwaisNo ratings yet

- PhET Plate Tectonics - 2013Document2 pagesPhET Plate Tectonics - 2013CloudKielGuiangNo ratings yet

- Holmes-Poirot DocumentDocument2 pagesHolmes-Poirot Documentapi-242851904No ratings yet

- Samuel Goroshin Et Al - Optical Pyrometry of Fireballs of Metalized ExplosivesDocument13 pagesSamuel Goroshin Et Al - Optical Pyrometry of Fireballs of Metalized ExplosivesGhoree23456No ratings yet

- 1.3.3 Carbon Particle CombustionDocument3 pages1.3.3 Carbon Particle Combustionhamed12077No ratings yet

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDocument8 pagesIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklNo ratings yet

- 09 Combustion (Burners, Combustion Systems)Document1 page09 Combustion (Burners, Combustion Systems)ahmed1581973No ratings yet

- Content ServerDocument7 pagesContent ServerajiemsNo ratings yet

- Spontaneous Combustion Coal Parameters For The Crossing-Point Temperature (CPT) Method in A Temperature-Programmed System (TPS)Document15 pagesSpontaneous Combustion Coal Parameters For The Crossing-Point Temperature (CPT) Method in A Temperature-Programmed System (TPS)lopohi2934No ratings yet

- Yi Lu, Zhenping Zhu and Zhenyu Liu - Catalytic Growth of Carbon Nanotubes Through CHNO Explosive DetonationDocument10 pagesYi Lu, Zhenping Zhu and Zhenyu Liu - Catalytic Growth of Carbon Nanotubes Through CHNO Explosive DetonationSteemWheelNo ratings yet

- 10 1 1 614 7186 PDFDocument13 pages10 1 1 614 7186 PDFKhobaib HayatNo ratings yet

- Two Dimensional Temperature and Carbon Dioxide ConcentrationDocument10 pagesTwo Dimensional Temperature and Carbon Dioxide ConcentrationdfcortesvNo ratings yet

- An Improved Two-Colour Pyrometer Based Method For Measuring Dynamic Temperature Mapping of Hydrogen-Air CombustionDocument6 pagesAn Improved Two-Colour Pyrometer Based Method For Measuring Dynamic Temperature Mapping of Hydrogen-Air CombustionSama AljohaniNo ratings yet

- Color Values and Spectra of The Principal Emitters in Colored FlamesDocument22 pagesColor Values and Spectra of The Principal Emitters in Colored FlamesAlexNo ratings yet

- Assessment of Mercury Emission at Norcems CementDocument20 pagesAssessment of Mercury Emission at Norcems CementtoriNo ratings yet

- The Growth Fission Gas Bubbles in Irradiated Uranium DioxideDocument16 pagesThe Growth Fission Gas Bubbles in Irradiated Uranium DioxideGwanyun JeongNo ratings yet

- f02045 PDFDocument10 pagesf02045 PDFbeqsNo ratings yet

- In CertezaDocument13 pagesIn CertezaEduardoNo ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- Case Studies in Thermal Engineering: Peiyong Wang, Faqing Fan, Qiong LiDocument8 pagesCase Studies in Thermal Engineering: Peiyong Wang, Faqing Fan, Qiong LiChandra SekharNo ratings yet

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)

- Lowtemp Didari2009Document8 pagesLowtemp Didari2009Zia Ru'ya HilalNo ratings yet

- The Modelling of Premixed Laminar Combustion in A Closed Vessel PDFDocument24 pagesThe Modelling of Premixed Laminar Combustion in A Closed Vessel PDFGourav PundirNo ratings yet

- Hydrogen Production From Natural Gas Thermal Cracking: Design and Test of A Pilot-Scale Solar Chemical ReactorDocument7 pagesHydrogen Production From Natural Gas Thermal Cracking: Design and Test of A Pilot-Scale Solar Chemical ReactorChandarshekar SwaminathanNo ratings yet

- 1Document7 pages1Ankit GargNo ratings yet

- Coal Inj PDFDocument9 pagesCoal Inj PDFhalder_kalyan9216No ratings yet

- 1 s2.0 S008207848980075X MainDocument8 pages1 s2.0 S008207848980075X MainYokoNo ratings yet

- Numerical Simulation and Measurements of Wall Heat Fluxes in A Single-Element GO2/GCH4 Rocket CombustorDocument11 pagesNumerical Simulation and Measurements of Wall Heat Fluxes in A Single-Element GO2/GCH4 Rocket CombustorDr-Ganesh DombeNo ratings yet

- Vamvuka1998 CoalDocument14 pagesVamvuka1998 CoalMahmud Arman KibriaNo ratings yet

- Flame Spray Synthesis of Tin Dioxide Nanoparticles For Gas SensingDocument6 pagesFlame Spray Synthesis of Tin Dioxide Nanoparticles For Gas SensingphallekNo ratings yet

- Simulation of Non-Premixed Natural Gas FlameDocument4 pagesSimulation of Non-Premixed Natural Gas FlameArul RizkiNo ratings yet

- CHNS oDocument7 pagesCHNS oAnonymous xcJJIqETwNo ratings yet

- CFD Analisys CoalDocument6 pagesCFD Analisys CoalOscar DorantesNo ratings yet

- Combustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion ConditionsDocument6 pagesCombustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion Conditionsphemt84No ratings yet

- NRC ch3-6Document131 pagesNRC ch3-6wsdupont2No ratings yet

- Sensors: Problems Encountered in Fluctuating Flame Temperature Measurements by ThermocoupleDocument12 pagesSensors: Problems Encountered in Fluctuating Flame Temperature Measurements by ThermocoupleShajil VazhakkalilNo ratings yet

- Methodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) CarbonatesDocument8 pagesMethodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) Carbonatesnomore891No ratings yet

- Measuring and Modeling Thermal Conductivity of Gas Hydrate-Bearing SandDocument10 pagesMeasuring and Modeling Thermal Conductivity of Gas Hydrate-Bearing SandMaiud Abdalate OtmanNo ratings yet

- 1 s2.0 S1540748912002702 Main - Cetane - NumberDocument7 pages1 s2.0 S1540748912002702 Main - Cetane - NumberEverton Luiz Dias da SilvaNo ratings yet

- Photoacoustic Detection of Dissolved Gases in Transformer OilDocument15 pagesPhotoacoustic Detection of Dissolved Gases in Transformer OilАртем КлимчукNo ratings yet

- CFD Analysis of A 210 MW Tangential Fired BoilerDocument6 pagesCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsNo ratings yet

- Computational Evaluation of Emissions For Non-Premixed Natural Gas CombustionDocument3 pagesComputational Evaluation of Emissions For Non-Premixed Natural Gas CombustionijsretNo ratings yet

- 1 s2.0 001793108490262X MainDocument18 pages1 s2.0 001793108490262X MainReza KH100% (1)

- Validation of Coal Combustion Model by Using Experimental Data of Utility BoilersDocument8 pagesValidation of Coal Combustion Model by Using Experimental Data of Utility BoilersKhadeeja NicyNo ratings yet

- 2004 - Smucker and Ellzey Computational and Experimental Study of A Two-SectDocument20 pages2004 - Smucker and Ellzey Computational and Experimental Study of A Two-Sectvivek joshiNo ratings yet

- General Characteristics of Thermally Cycled Tin Oxide Gas Sensors 1989Document10 pagesGeneral Characteristics of Thermally Cycled Tin Oxide Gas Sensors 1989Koit MauringNo ratings yet

- Brazilian Journal of Chemical EngineeringDocument50 pagesBrazilian Journal of Chemical EngineeringMarialison IriarteNo ratings yet

- Laser-Ignition of Methane-Air Mixtures at High Pressures and TemperaturesDocument6 pagesLaser-Ignition of Methane-Air Mixtures at High Pressures and Temperaturesseva0No ratings yet

- Burners, Combustion SystemsDocument1 pageBurners, Combustion Systemsmompou88No ratings yet

- Applied Thermal Engineering: Xing Li, Jing Zhang, Haolin Yang, Liqiao Jiang, Xiaohan Wang, Daiqing ZhaoDocument8 pagesApplied Thermal Engineering: Xing Li, Jing Zhang, Haolin Yang, Liqiao Jiang, Xiaohan Wang, Daiqing Zhaoherdi sutanto adigunaNo ratings yet

- 2 Natural Gas ProcessingDocument5 pages2 Natural Gas ProcessingJhon Charles UvadoNo ratings yet

- APS 2 ExperimentalDocument4 pagesAPS 2 Experimentaljuanjo_cvNo ratings yet

- Lkhamsuren Bayarjargal - Recent Developments of The Laser-Heating Facility in Frankfurt and at Petra-IIIDocument23 pagesLkhamsuren Bayarjargal - Recent Developments of The Laser-Heating Facility in Frankfurt and at Petra-IIIDrebuioNo ratings yet

- Temperature Dependence of Thermal Expansivity of Carbon Fullerene and 20-nm Nickel NanocrystalDocument8 pagesTemperature Dependence of Thermal Expansivity of Carbon Fullerene and 20-nm Nickel Nanocrystalnano_journalNo ratings yet

- Raouf ICSOBADocument12 pagesRaouf ICSOBAPedro Milton ChibulachoNo ratings yet

- Synthesis of Carbon Nanotubes by Chemical Vapor Deposition and Their Application For CO and CH DetectionDocument4 pagesSynthesis of Carbon Nanotubes by Chemical Vapor Deposition and Their Application For CO and CH DetectionaslkalksafNo ratings yet

- Mwcnts Synthesis From Butanol, Diethyl Ether, Ethyl Acetate and Hexane by Chemical Vapor Deposition With A Stainless Steel Core As CatalystDocument3 pagesMwcnts Synthesis From Butanol, Diethyl Ether, Ethyl Acetate and Hexane by Chemical Vapor Deposition With A Stainless Steel Core As CatalystCassie MinorNo ratings yet

- Final Laboratory Report: de La Salle UniversityDocument15 pagesFinal Laboratory Report: de La Salle UniversityGela EcalNo ratings yet

- Highly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SDocument18 pagesHighly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SSaptarshi SenguptaNo ratings yet

- Laminar Flame Speeds of Ethanol, N-Heptane, IsooctaneDocument8 pagesLaminar Flame Speeds of Ethanol, N-Heptane, IsooctaneanilkoleNo ratings yet

- Report NO. 79-4Document14 pagesReport NO. 79-4bmaychNo ratings yet

- P. Neuwald, H. Reichenbach and A. L. Kuhl - After-Burning of Nitropenta Products in A CalorimeterDocument4 pagesP. Neuwald, H. Reichenbach and A. L. Kuhl - After-Burning of Nitropenta Products in A CalorimeterTremannNo ratings yet

- Solar Water Heating Slope Roof and CoilDocument1 pageSolar Water Heating Slope Roof and CoilMuhammad AwaisNo ratings yet

- LLL LLL: Mazdon HP200 - 20 Tube Manifold Mazdon HP200 - 30 Tube ManifoldDocument5 pagesLLL LLL: Mazdon HP200 - 20 Tube Manifold Mazdon HP200 - 30 Tube ManifoldMuhammad AwaisNo ratings yet

- EXAMPLE 8.1-2: Conductance of A Cross-Flow Heat Exchanger (Revisited)Document1 pageEXAMPLE 8.1-2: Conductance of A Cross-Flow Heat Exchanger (Revisited)Muhammad AwaisNo ratings yet

- 1761 Performance Aspen SeriesDocument2 pages1761 Performance Aspen SeriesMuhammad AwaisNo ratings yet

- 1 s2.0 S0017931005003005 MainDocument9 pages1 s2.0 S0017931005003005 MainMuhammad AwaisNo ratings yet

- View A-A: Part No. Ordering InformationDocument2 pagesView A-A: Part No. Ordering InformationMuhammad AwaisNo ratings yet

- Transient Conduction and Lumped Capacitance MethodDocument15 pagesTransient Conduction and Lumped Capacitance MethodMuhammad Awais100% (1)

- In-Situ Gas AnalyzrDocument4 pagesIn-Situ Gas AnalyzrMuhammad AwaisNo ratings yet

- Emissions Incinerator Plants - Application Note (2006) ... FtirDocument3 pagesEmissions Incinerator Plants - Application Note (2006) ... FtirMuhammad AwaisNo ratings yet

- Portable Flue Gas Analyzer: Tempest 50Document7 pagesPortable Flue Gas Analyzer: Tempest 50Muhammad AwaisNo ratings yet

- Android Quiz App 22617 MADDocument19 pagesAndroid Quiz App 22617 MADSandip kotkarNo ratings yet

- Dsa PaperDocument24 pagesDsa Paperhimanshusharma15868No ratings yet

- Is.2042.2006 Insulating BricksDocument8 pagesIs.2042.2006 Insulating BricksGaneshNo ratings yet

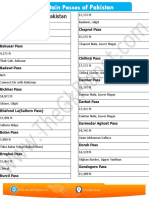

- Mountain Passes of PakistanDocument3 pagesMountain Passes of PakistanMohsin Raza Maitla0% (2)

- Term-Project-Ii-Bch3125 ADocument8 pagesTerm-Project-Ii-Bch3125 APure PureNo ratings yet

- Geology Notes For IFS (Statigraphy Concise)Document20 pagesGeology Notes For IFS (Statigraphy Concise)dun_aromatix50% (6)

- Purpose RediscoveredDocument102 pagesPurpose RediscoveredErnest NguboNo ratings yet

- Mendiola ScriptDocument25 pagesMendiola ScriptAila Obrero MendiolaNo ratings yet

- Email Boarding Pass (Web Check In) Goindigo - inDocument1 pageEmail Boarding Pass (Web Check In) Goindigo - inVyas Narayan DewanganNo ratings yet

- COMP90016 2023 08 Variant Calling IIDocument41 pagesCOMP90016 2023 08 Variant Calling IILynn CHENNo ratings yet

- Satellite Communication NotesDocument17 pagesSatellite Communication NotesAkhil RajuNo ratings yet

- Pemurnian EnzimDocument54 pagesPemurnian EnzimwulanNo ratings yet

- CEE Download Full Info - 07.15 PDFDocument29 pagesCEE Download Full Info - 07.15 PDFFaizal FezalNo ratings yet

- Ad620 PDFDocument16 pagesAd620 PDFRODRIGO TROCONISNo ratings yet

- By: Kellina LeachDocument6 pagesBy: Kellina Leachapi-280592348No ratings yet

- The Worlds Cities in 2018 Data Booklet PDFDocument34 pagesThe Worlds Cities in 2018 Data Booklet PDFdianaNo ratings yet

- Other Publications by CADCIM Technologies: Autodesk Revit Architecture TextbooksDocument2 pagesOther Publications by CADCIM Technologies: Autodesk Revit Architecture Textbooksankit suriNo ratings yet

- Practice Problems In, R and ChartsDocument2 pagesPractice Problems In, R and ChartsChand Patel100% (1)

- Chapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentDocument7 pagesChapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentAde Y SaputraNo ratings yet

- LPG Sensor TechnologyDocument20 pagesLPG Sensor Technologyeddie eddNo ratings yet

- 0610 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesDocument2 pages0610 BIOLOGY: MARK SCHEME For The October/November 2015 Seriesmath magicNo ratings yet

- Zohdy, Eaton & Mabey - Application of Surface Geophysics To Ground-Water Investigations - USGSDocument63 pagesZohdy, Eaton & Mabey - Application of Surface Geophysics To Ground-Water Investigations - USGSSalman AkbarNo ratings yet

- Filipino Values Month PROPOSAL 2022 NEWDocument3 pagesFilipino Values Month PROPOSAL 2022 NEWLavinia Mipaña Fortuna100% (1)

- 6.08 - Bacterial Transformation Live Lesson 1.19.21Document23 pages6.08 - Bacterial Transformation Live Lesson 1.19.21Elyzabeth BeauchampNo ratings yet

- Homework 2 - 202881 - 01 - SentDocument3 pagesHomework 2 - 202881 - 01 - SentDavid E. MuñozNo ratings yet