Professional Documents

Culture Documents

Camille Ri 99

Camille Ri 99

Uploaded by

tip31Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Camille Ri 99

Camille Ri 99

Uploaded by

tip31Copyright:

Available Formats

DEVELOPMENT OF A SILENT BRUSHLESS DC MOTOR DRIVE S. Camilleri, D. Patterson & H.

Pullen NT Centre for Energy Research, Australian CRC for Renewable Energy Northern Territory University Darwin, N.T. 0909 Email : Steven.Camilleri@darwin.ntu.edu.au

Abstract Brushless DC motors are known for their versatility and efficiency. Unfortunately the cheap and common method of using trapezoidal current control is not suitable for all applications because of the distracting acoustic noise made during commutation, known as 'ticking'. This paper outlines some methods of controlling the brushless motor to produce much less acoustic noise, including using a DSP for producing commutation period current wave-shaping and a sinusoidal Voltage/Frequency amplitude control. 1. INTRODUCTION & BACKGROUND The target application for this system is a high efficiency ceiling fan. This fan uses an unconventional blade design with extremely high pitch that produces standard levels of airflow at only half the rotational speed, compared to a conventional flat blade design. The result of this is an extremely low 'wind' noise, due to the improved aerodynamics. A picture of the fan blades is shown in Figure 1.

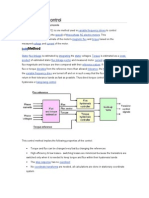

the low noise blade design. In addition, the motor controller design would have to be as cheap as possible to make the final product cost comparable with existing technology. In addition to this application, another motor was developed to drive a standard steel bladed ceiling fan. The control methodology would be the same for this application, but the speed would be twice as much as the low speed research fan. Again, low acoustic noise operation is required. When the fan was first tested with a standard trapezoidal current brushless motor controller, it produced noise in a wide spectrum. The loudest part of the noise was naturally at the frequency of commutation at around 100 Hz in a 16 pole machine, running at 125 RPM. To reduce the noise, a simple circuit was devised that would anticipate an impending commutation period (via mechanically shifted hall effect sensors) and control the motor current to zero, reverting it to the original value once that period was over. In effect, this circuit would act as a 'soft commutation' or 'deticking' circuit. Some waveshaping was required to reduce and increase the current in a manner that would not produce extra acoustic noise, for which the accurate control of a TMS320C30 DSP was required. A block diagram of the system is shown in Figure 2.

Figure 1 : Reseach Fan blades

To further improve the fan system, it was decided to use a high efficiency brushless DC motor with a power electronic drive instead of the standard split phase induction motor. This would improve the system efficiency significantly, provided the brushless motor could be driven to produce a low noise output to match

Figure 2 : Block Diagram of Deticking Circuit

In practice, the soft commutation circuit did reduce the noise but not to the level required. Spectral analysis was performed using a quality microphone and Hewlett-Packard 3561A signal analyser, in a standard audible range (20 Hz to 20 kHz). As can be seen from Figure 3, the deticking circuit was only effective on two areas, 250 Hz and the range 900 Hz to 1300 Hz. The largest part of the noise, below 150Hz, was nearly unaffected. Overall, the deticking circuit did not reduce the noise produced by the fan to an acceptable level in fact at the high frequency range above 1300 Hz, the noise was increased.

0 -10

manner appears to be a straightforward way to reduce the rapid di/dt's in the motor and correspondingly the acoustic noise produced. Sinusoidal control is difficult and complex to do using a closed loop current control system (usually involving the use of expensive position encoders) and since the system was designed to be cheap, an open loop strategy was decided upon, namely Voltage/Frequency (V/F) control. This method is most common in induction machines due to the simplicity of the control system and since it allows variable speed control of the machine. In basic terms, V/F control uses a microcontroller or similar digital control device to generate a sinusoidal Pulse Width Modulated (PWM) drive for which the fundamental amplitude varies proportionally to the fundamental frequency. For an induction machine, this means that the microcontroller starts with marginally above zero frequency and low sinewave amplitude, increasing both at a rate that the mechanical system can handle to accelerate them. The amplitude of the sinewave is directly proportional to the current through the windings of the machine at any one frequency, otherwise the current is inversely proportional to the frequency for a fixed amplitude. The main difference between this drive developed for a brushless machine and the one used for an induction machine is the use of 'slip'. An induction machine provides torque in proportion to the slip factor, which is related to the ratio between the rotating magnetic field on the stator and the mechanical speed of the rotor. As the rotor slows, slip increases and more torque is provided. With a brushless machine, the rotor has permanent magnets attached and hence if a pole slip occurs, negative torque will be generated. This causes the machine to stall, and after a stall has occured the machine will not restart using open loop control but simply stop and 'vibrate' as the rotating magnetic field repeatedly passes over the permanent magnets, generating no useful torque. It is therefore essential to ensure that the permanent magnet rotor stays completely synchronous with the rotating magnetic field on the stator. Fortunately for a ceiling fan system the load & speed profile is known and can be stored in a digital control device, so stalls under normal operation can be easily prevented.

-20

-30

-40

-50

Ticking Deticked

-60

-70

-80

-90

-100 0 500 1000 1500 2000 2500

Frequency(Hz)

Figure 3 : Fan Motor Noise Spectrum Deticking Circuit

Various wave shapes were used for increasing and decreasing the current at the commutation period, all accurately controlled using the DSP. Figure 3 shows the noise reduction results for the best shape (among many tested) which was in essence an extract of a sinusoidal curve between 90o and 270o. Of all the wave shapes tried, this shape produced the best results. 2. THEORY OF VOLTAGE/FREQUENCY CONTROL After abandoning the previous control method, a totally new approach was desired. The trapezoidal method of current control requires rapid changes in current in the machine, which in turn produces the acoustic noise. Control of the current in a sinusoidal

It is still neccesary to include a very basic form of closed loop control for situations that are unexpected (i.e. something comes into physical contact with the rotating fan, causing it to stall) due to the fact that in a stall condition, if a high ampltiude sinewave is applied to the fan motor then the currents through the motor may be extremely high and may damage the motor or controller. To this end, a single hall effect sensor can be used for a speed reference signal. Once the speed has been measured by the digital controlling device, it can be used to look up the appropriate section in the V/F table, guaranteeing that the currents will never be high for very long. In addition, using this methodology allows stall recovery. 3. VOLTAGE/FREQUENCY CONTROLLER DESIGN Listed below are the specifications of the motors used in the development of this control system. RESEARCH FAN Motor (1) : Three Phase Permanent Magnet Brushless 16 Pole - Prototype Application speed 140 RPM ( 18 Hz electrical frequency) 16.5 phase resistance average 53 mH phase inductance average STANDARD BLADE FAN Motor (2) : Three Phase Permanent Magnet Brushless 16 Pole - Prototype Application speed 280 RPM ( 36 Hz electrical frequency) 3.7 phase resistance average 12.8 mH phase inductance average

an isolated power stage for driving the motor from a 50V DC bus. The power section constructed for development of the prototype uses a standard six switch bridge comprised of SGS-Thomson STN3E06L MOSFETs, which are small (supplied in an SOT-223 surface mountable packages), efficient and cheap. A simple diagram of the bridge is shown in Figure 4.

Figure 4 : Basic diagram of Power Stage

Design of the power stage requires a working knowledge of the power range of the system, in this case the prototype system characteristics are : RESEARCH FAN Full speed : Current at full speed : Voltage at full speed : Power at full speed : 135 RPM 520 mA from DC supply 490 mARMS/ 52 V from DC supply (equates to 18.4 VRMS / ) 27 W

STANDARD BLADE FAN Full speed : Current at full speed : Voltage at full speed : Power at full speed : 260 RPM 550 mA from DC supply 520 mARMS/ 42 V from DC supply (equates to 14.85VRMS / ) 23 W

Note that both of these motors are still in the development stage, hence their parameters are still subject to future improvement. Both motors will use the same control system, running with a different V/F characteristic and maximum speed. Electronic requirements for a V/F converter of this nature can be divided into two modules - A digital control device to generate the PWM waveforms and

The MOSFET was selected on the basis of cost and size, rather than efficiency. Since either motor will not draw much more than 0.5 A, the resistive loss in the MOSFET will be negligible. Using an equation for MOSFET conduction loss PC: PC = IDS2RDS ON (1)

Where IDS is the Drain-Source current, and RDS is the Drain-Source resistance. Therefore, for this calculation we need to determine MOSFET current IDS(RMS), which will work out to half the RMS motor phase current (by basic KCL). This works out to 0.26 ARMS through each MOSFET on average. For the 100 m STN3E06L, using equation (1), this comes out at 6.8 mW of conduction loss in each MOSFET, a total of 40.8 mW through each leg in the bridge. Switching and gate losses are found to be about equal for this device, switching at a rate of 23.4 kHz. The total loss in the power section is therefore negligible and can be assumed to be a maximum of about 100 mW, giving a system efficiency above 99.6% at full output. During testing, the external case temperature of the MOSFETs could not be measured above ambient, thus they did not require heatsinking. The digital control section is more complex. There are many devices on the market that are ideally suited to the task of motor control, but in this case there are the heavy restrictions of cost and physical size that reduce the options significantly. The choice is between a cheap DSP and a cheap microcontroller - and the microcontroller wins due to it's simplicity and reduced size. In any case, there are currently no DSP systems available on the market that are as cheap and easy to use as a well chosen microcontroller. The prototype system was initially based on a microcontroller that was readily available, the Siemens 80C537. This microcontroller itself is not ideally suited to the task, but shares a common language with many other more suitable Siemens microcontrollers such as the SAB-C504 Motor Controller. Programs have been developed with the 80C537 that perform all of the requirements mentioned previously and there have been no major problems with the system. A block diagram of the prototype drive is shown in Figure 5.

Figure 5 : Block Diagram of Prototype V/F Controller

4. CONCLUSION While some of the initial methods tried such as deticking circuits with DSP control did not work to the standard required, the prototype V/F controller developed for the Brushless DC machine used in both the research and conventional ceiling fans has been tested to the levels required by the respective systems and found to work very well. Construction of a standard six switch block was simplified by the known parameters of the system and the low motor currents, also allowing a very efficient power stage. Selection of a digital control device for attaching to this power stage is not a simple procedure as the market for small and cheap motor control chips is extremely limited, however there are several that suit the task adequately. The Siemens range of microcontrollers has been tested using this control scheme and performs well. 5. REFERENCES [1] John G. Kassakian, Martin F. Schlecht & George C. Verghese, Principles of Power Electronics, Addison-Wesley Reading, Massachusetts 1992. [2]Werner Leonhard, Control of Electrical Drives, 2nd Ed. Springer-Verlag Berlin Heidelberg 1996. [3]T. Kenjo & S. Nagamori, Permanent Magnet and Brushless DC Motors, Clarendon Press, Oxford 1985. [4]M.F. Rahman, L. Zhong and K.W. Lim, A Comparison of Two High Performance, Wide Speed Range Drive Techniques for Interior Magnet Motors, 1998 International Conference on Power Electronics Drives and Energy Systems for Industrial Growth, Volume I, pp. 276-281, December 1998.

[5]K. Schmidt & D. J. Patterson, Performance Results for a High Efficiency Ceiling Fan and Comparisons with Conventional internet at Fans, 1999 World Renewable Energy Congress. Available at : http://ee.ntu.edu.au/ntcer/pdf_docs/

You might also like

- NUM Flexium PLUS Catalog en High ResDocument296 pagesNUM Flexium PLUS Catalog en High ResPalaniappan SolaiyanNo ratings yet

- DC Motor ControlDocument91 pagesDC Motor ControlElvins AguilarNo ratings yet

- DC MotorDocument91 pagesDC MotorSatadal DashNo ratings yet

- SPWM V/HZ InverterDocument51 pagesSPWM V/HZ InverterLabi BajracharyaNo ratings yet

- Variable Frequency DriveDocument4 pagesVariable Frequency Drivearavind_k104No ratings yet

- Research To Study Variable Frequency Drive and Its Energy SavingsDocument4 pagesResearch To Study Variable Frequency Drive and Its Energy SavingsIjsrnet EditorialNo ratings yet

- Direct Torque Control (DTC) Is One Method Used inDocument7 pagesDirect Torque Control (DTC) Is One Method Used inAnjana SudarsananNo ratings yet

- Audio NoiseDocument4 pagesAudio NoiseNguyễn Minh TríNo ratings yet

- ID 610C Carver Intro To Motor ControlDocument46 pagesID 610C Carver Intro To Motor Control조용규No ratings yet

- Single Phase Induction Motor Speed ControlDocument35 pagesSingle Phase Induction Motor Speed ControlHarshit Sengar100% (2)

- Paper - 5 Noise MinimizationDocument5 pagesPaper - 5 Noise MinimizationLTE002No ratings yet

- An-9019 Motor Drive System Using SPM InverterDocument25 pagesAn-9019 Motor Drive System Using SPM InverterasokanenNo ratings yet

- Direct Torque ControlDocument4 pagesDirect Torque Controlsanthurupesh0% (1)

- Pulse Width ModulationDocument5 pagesPulse Width ModulationMunira ZulkefliNo ratings yet

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionManzoor A. ShaikhNo ratings yet

- Technical Feedback On EHCDocument8 pagesTechnical Feedback On EHCvesridhar100% (1)

- Cascode Amp DesignDocument5 pagesCascode Amp DesignTamás BenyácsNo ratings yet

- A 10-mW Two-Channel Fully Integrated System-on-Chip For Eddy-Current Position SensingDocument10 pagesA 10-mW Two-Channel Fully Integrated System-on-Chip For Eddy-Current Position SensingkurabyqldNo ratings yet

- Field Oriented Control Reduces Motor Size, Cost and Power Consumption in Industrial ApplicationsDocument6 pagesField Oriented Control Reduces Motor Size, Cost and Power Consumption in Industrial ApplicationsnikanikolinaNo ratings yet

- U-93 Application NOTE A New Integrated Circuit For Current Mode ControlDocument9 pagesU-93 Application NOTE A New Integrated Circuit For Current Mode ControlpramodNo ratings yet

- Design of Sinusoidal Pulse Width Modulation 3 Phase Bridge InverterDocument4 pagesDesign of Sinusoidal Pulse Width Modulation 3 Phase Bridge InverterLawson SangoNo ratings yet

- Possible Problems and Solutions When Introducing Variable Speed DrivesDocument6 pagesPossible Problems and Solutions When Introducing Variable Speed DrivesIoan ŢileaNo ratings yet

- 05 - Electro - Hydraulic ControllerDocument7 pages05 - Electro - Hydraulic Controllerwildhoney1979No ratings yet

- EHTC Functional DescriptionDocument8 pagesEHTC Functional Descriptionveer_s100% (2)

- Input and Output: Power Electronic Direct Current Alternating Current Voltage PowerDocument4 pagesInput and Output: Power Electronic Direct Current Alternating Current Voltage PowerMohamed AbubackerNo ratings yet

- Speed Control of DC MotorDocument19 pagesSpeed Control of DC MotorVijaya LakshmiNo ratings yet

- VVVF - Working Principle & Its OperationDocument18 pagesVVVF - Working Principle & Its Operationdownload4sumitNo ratings yet

- Technical Feedback EhtcDocument9 pagesTechnical Feedback EhtcPrashant Kumar ChoudharyNo ratings yet

- Ginart 1999Document7 pagesGinart 1999Maximo La Vida ContinuaNo ratings yet

- Implementation of Ac Induction Motor Control Using Constant V/HZ Principle and Sine Wave PWM Technique WITH TMS320F28027Document7 pagesImplementation of Ac Induction Motor Control Using Constant V/HZ Principle and Sine Wave PWM Technique WITH TMS320F28027edi ediNo ratings yet

- What Is Frequency Inverter?Document3 pagesWhat Is Frequency Inverter?Dražen ĐukićNo ratings yet

- Design and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452Document4 pagesDesign and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452lajosmol100% (1)

- Direct Torque ControlDocument4 pagesDirect Torque Controlsf111No ratings yet

- Direct Torque Control (DTC) in Induction Motor: M.G.MorshadDocument12 pagesDirect Torque Control (DTC) in Induction Motor: M.G.MorshadAdil FarzandNo ratings yet

- Design and Analysis of PMSG Based Wind Power Generation: Ee Department, SRMGPC, Lucknow 1Document10 pagesDesign and Analysis of PMSG Based Wind Power Generation: Ee Department, SRMGPC, Lucknow 1AMANNo ratings yet

- Full Paper P-031Document9 pagesFull Paper P-031SUBRATA BISWASNo ratings yet

- Sensorless Control of Induction Motors Using Multi-Level ConvertersDocument11 pagesSensorless Control of Induction Motors Using Multi-Level ConvertersmssmsNo ratings yet

- A Low Cost High Efficiency Inverter For Photovoltaic ApplicationsDocument6 pagesA Low Cost High Efficiency Inverter For Photovoltaic ApplicationsbpchimeraNo ratings yet

- 3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800eDocument36 pages3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800ePrabhu RajNo ratings yet

- Speed Controllers & SwitchesDocument3 pagesSpeed Controllers & SwitchesKenneth MikeNo ratings yet

- WECS CSI HV Synch GenDocument23 pagesWECS CSI HV Synch GenPrasann KatiyarNo ratings yet

- TO Eliminate Common Mode Leakage Current IN Photovoltaic Grid Connected Power SystemDocument11 pagesTO Eliminate Common Mode Leakage Current IN Photovoltaic Grid Connected Power SystemLava KumarNo ratings yet

- Fabrication of Unconventional Compressor For Heavy Truck (Demo Model)Document8 pagesFabrication of Unconventional Compressor For Heavy Truck (Demo Model)vijayant gautamNo ratings yet

- PWM and DC Motor ControlDocument9 pagesPWM and DC Motor ControlYimy GarciaNo ratings yet

- Cascada SubsincronaDocument7 pagesCascada Subsincronafrsantos123No ratings yet

- DarshitDocument28 pagesDarshitdarkfire28304No ratings yet

- Sinko: Love Our EarthDocument13 pagesSinko: Love Our Earthmanchau717No ratings yet

- Power Quality Paper Aug 03Document6 pagesPower Quality Paper Aug 03leardpanNo ratings yet

- Fuzzy - Microsoft Word - IJEST11-03-10-070Document8 pagesFuzzy - Microsoft Word - IJEST11-03-10-0702K18/EE/244 VIPESH DUNKWALNo ratings yet

- Vsi Fed 3ph ImDocument13 pagesVsi Fed 3ph ImWisemin LinsNo ratings yet

- AC Into DC MotorDocument9 pagesAC Into DC MotorIvan RisticNo ratings yet

- Inching 1Document6 pagesInching 1Sridhar MakkapatiNo ratings yet

- Avr Newage mx321 PDFDocument4 pagesAvr Newage mx321 PDFLiya MahagamaNo ratings yet

- VFD Types: Igbts ThyristorsDocument8 pagesVFD Types: Igbts ThyristorsAshok MoreNo ratings yet

- Componding Excitation System - SeimensDocument12 pagesComponding Excitation System - SeimensBalu M100% (3)

- Amplifier ServoDocument3 pagesAmplifier ServoinputzNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- 9AKK106417 E Servo Motors - 1215 - WEBDocument100 pages9AKK106417 E Servo Motors - 1215 - WEBRoberto CNo ratings yet

- HYTORC Lithium Series TwoDocument4 pagesHYTORC Lithium Series TwoFederico Velázquez CasadosNo ratings yet

- MDS-EJ EJH Series Specifications Manual IB-1501232 CDocument256 pagesMDS-EJ EJH Series Specifications Manual IB-1501232 CLeszekNo ratings yet

- AC Induction Motors vs. Permanent Magnet Synchronous MotorsDocument5 pagesAC Induction Motors vs. Permanent Magnet Synchronous MotorsAhmed GhreebNo ratings yet

- SMMA Motor GlossaryDocument11 pagesSMMA Motor GlossaryNurulHardyNo ratings yet

- Giri 1Document18 pagesGiri 1GiridharNo ratings yet

- Comparison of BLDC and AC Motors in Electric VehiclesDocument26 pagesComparison of BLDC and AC Motors in Electric VehiclesJohnny Edward KingsleyNo ratings yet

- Simplified Sensorless Control For BLDC Motor, Using DSP TechnologyDocument12 pagesSimplified Sensorless Control For BLDC Motor, Using DSP Technologymichael.schuhNo ratings yet

- The Example Numbers Provided With The Spreadsheet Are For A 'Propdrive 5060 380Kv' BLDC Motor Geared 2.5:1 Spinning A 420mm X 75mm X 24mm Steel BarDocument4 pagesThe Example Numbers Provided With The Spreadsheet Are For A 'Propdrive 5060 380Kv' BLDC Motor Geared 2.5:1 Spinning A 420mm X 75mm X 24mm Steel BarWinden DarkNo ratings yet

- Automatic Solar Tracker With Dust Wiper Using PID ControllerDocument6 pagesAutomatic Solar Tracker With Dust Wiper Using PID ControllerEditor IJTSRD100% (1)

- Design of An Integrated Electronic Speed Controller For Compact Robotic VehiclesDocument8 pagesDesign of An Integrated Electronic Speed Controller For Compact Robotic Vehiclesadum turnipNo ratings yet

- Ti MotorDocument25 pagesTi MotorBruno SilvaNo ratings yet

- IV report-KERALA ELECTRICAL & ALLIED ENGINEERING CO. LTD, KOLLAMDocument15 pagesIV report-KERALA ELECTRICAL & ALLIED ENGINEERING CO. LTD, KOLLAMAmmu ChathukulamNo ratings yet

- Design of Electric Auto RikshawDocument20 pagesDesign of Electric Auto RikshawChakradhar YadavNo ratings yet

- Uav Introduction 3Document10 pagesUav Introduction 3Vijayanandh RNo ratings yet

- Power Electr CoDocument2 pagesPower Electr CoAmos KormeNo ratings yet

- MTU 12V4000 DS1750: DieselDocument4 pagesMTU 12V4000 DS1750: DieselDaniel Muratalla100% (1)

- Week 3 B 2 Electric MotorsDocument59 pagesWeek 3 B 2 Electric MotorsCharlton S.InaoNo ratings yet

- Lorentz Ps2 200Document8 pagesLorentz Ps2 200SINES FranceNo ratings yet

- Payload Manipulation For Seed Sowing UnmannedAerial Vehicle Through Interface With PixhawkFlight ControllerDocument4 pagesPayload Manipulation For Seed Sowing UnmannedAerial Vehicle Through Interface With PixhawkFlight ControlleradalbertotjrNo ratings yet

- ES-DH2306d - V1.2 Manual PDFDocument13 pagesES-DH2306d - V1.2 Manual PDFinder aroraNo ratings yet

- DC Speed Control Using 8051Document25 pagesDC Speed Control Using 8051musmankhanNo ratings yet

- Lec # 26 Brushless DC MotorDocument12 pagesLec # 26 Brushless DC MotorBuriro HayatNo ratings yet

- I-NEXT DX Technical BulletinDocument80 pagesI-NEXT DX Technical BulletinAh MedNo ratings yet

- BLDCDocument53 pagesBLDCstarboyNo ratings yet

- Endeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationDocument8 pagesEndeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationJNarigonNo ratings yet

- Speed Control of DC Motor Using Pid Controller ThesisDocument7 pagesSpeed Control of DC Motor Using Pid Controller ThesisWriteMyPaperForMeTucson100% (2)

- Argon User ManualDocument41 pagesArgon User ManualJuan Francisco Sanchez MassadiNo ratings yet

- DeWalt+India+Catalogue+2022 Final ScreenDocument100 pagesDeWalt+India+Catalogue+2022 Final ScreenDavid ZhangNo ratings yet