Professional Documents

Culture Documents

Nonlinear Dynamic Analysis of Frames With Plastic Hinges

Nonlinear Dynamic Analysis of Frames With Plastic Hinges

Uploaded by

Caraiane CatalinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nonlinear Dynamic Analysis of Frames With Plastic Hinges

Nonlinear Dynamic Analysis of Frames With Plastic Hinges

Uploaded by

Caraiane CatalinCopyright:

Available Formats

THE STRUCTURAL DESIGN OF TALL AND SPECIAL BUILDINGS Struct. Design Tall Spec. Build.

19, 778801 (2010) Published online 2 April 2009 in Wiley Online Library (wileyonlinelibrary.com). DOI: 10.1002/tal.513

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES AT ARBITRARY LOCATIONS

Z. H. YAN AND F. T. K. AU*

Department of Civil Engineering, The University of Hong Kong, Hong Kong, PR China

SUMMARY This paper presents a method for nonlinear dynamic analysis of frames subjected to distributed loads, which is based on the semi-rigid technique and moving node strategy. The plastic hinge is modelled as a pseudo-semi-rigid connection with nonlinear hysteretic momentcurvature characteristics at element ends. The stiffness matrix with material and geometric nonlinearities is expressed as a sum of products of the standard and geometric stiffness matrices with their corresponding correction matrices based on the plasticity-factors developed from the section exural stiffness at the plastic hinge locations. Each beam member is modelled by two elements. The moving node strategy is applied to the intermediate node to track the exact location of any intermediate plastic hinge that may be formed. Equilibrium iterations and geometry updating are carried out in every time step. Stiffness degradation is adopted to describe the deterioration of plastic hinges, and the effects of various parameters in the degradation model are evaluated. Examples are used to illustrate the applicability and excellent performance of the proposed method. Copyright 2009 John Wiley & Sons, Ltd.

1.

INTRODUCTION

The inuence of material and geometric nonlinearities on the behaviour of frames is particularly signicant during extreme events such as earthquakes and typhoons. In static analysis when the external loading increases monotonically, one often focuses on the yielding of members as an important source of material nonlinearity. However, dynamic responses are often complicated by yielding, unloading, reloading, etc., especially around the plastic hinges, and the deterioration of members and joints. Furthermore, in frame members subjected to distributed loads, plastic hinges may be formed at intermediate locations in addition to those at the ends. On the other hand, modern structures also suffer from more signicant P- effects since they are often taller and more slender because of the use of stronger materials and more advanced construction techniques. To better understand their behaviour and to improve the design of modern buildings, it is necessary to develop methods for dynamic analysis, taking into account such effects and nonlinearities. The semi-rigid technique is a common method to analyse frames with semi-rigid connections (Monforton and Wu, 1963). Geometric nonlinearity (Xu, 1992) and the plastication concept (Hasan et al., 2002) were also introduced to the method, and a series of advanced analyses of steel frame structures were developed (Xu et al., 2005; Gong et al., 2005; Gong et al., 2006; Gong, 2006; Grierson et al., 2006). So far, the semi-rigid technique is mainly applied to static and pushover analyses. Although various researchers are trying to develop the pushover analysis as a means of

* Correspondence to: Francis T. K. Au, Department of Civil Engineering, The University of Hong Kong, Pokfulam Road, Hong Kong, PR China. E-mail: francis.au@hku.hk

Copyright 2009 John Wiley & Sons, Ltd.

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

779

practical design, nonlinear dynamic analysis is still essential, especially to those structures that are irregular and those of which the higher mode effects cannot be ignored. Besides, the strong-motion peculiarity is also a problem that the pushover analysis needs to overcome (Elnashai, 2002). Therefore, dynamic analysis is still important to frames with nonlinearities. Under lateral loading, the frame members subjected to distributed load may have plastic hinges formed at intermediate locations besides the member ends. To capture the behaviour of the intermediate plastic hinges, an efcient method for elasto-plastic large deection analysis of steel frames using an element with plastic hinges at mid-span and two ends was proposed (Chen and Chan, 1995). As the intermediate plastic hinges can only be formed at mid-span, the results obtained are subject to certain errors. Later, the moving node strategy was presented for the elasto-plastic analysis of frames subjected to loads including linearly varying distributed load (Wong, 1996). In addition, certain applications of the moving node method in the second-order inelastic analysis of two- and three-dimensional steel frames were reported (Kim et al., 2004; Kim and Choi, 2005). However, the above research on the intermediate plastic hinge was only for the static analysis of frames. Such plastic hinges are often formed when the frame is subjected to strong seismic excitations, and therefore, the corresponding dynamic problem warrants further study. The material and geometric nonlinearities in beamcolumn elements may be simulated by either the plastic hinge element or the bre element. Although the bre element model can handle the residual stresses and better simulate the yielding process, it is rather computation intensive. On the other hand, the plastic hinge element model can simulate nonlinearities well and it is computationally efcient. The two beamcolumn element models have been compared (Hall and Challa, 1995), and good agreement has been obtained for frame problems, including the level of ground motion at which collapses occur. Dynamic analysis of frames with nonlinear semi-rigid connections and geometric nonlinearity has been studied using RungeKutta integration and modied modal analysis (Lui and Lopes, 1997; Awkar and Lui, 1999). However, the nonlinear connections can only be located in the beams but not in the columns, since the stability functions to account for geometric nonlinearity are not compatible with the nonlinear connections. It is, therefore, not easy to extend the method to inelastic analysis because the bending moments in the columns of the lower oors are usually large enough to cause yielding. Another method to model the effect of connections is to adopt shape functions in the form of cubic Hermitian functions that account for end-springs to simulate the connection exibility and material nonlinearity (Chan and Chui, 2000). Although this method is capable of predicting the dynamic response of steel structures with geometric nonlinearities, hysteretic connection exibility and hysteretic material yielding, the element matrices are rather complicated and substantial modications are necessary to incorporate them into the existing linear dynamic analysis programmes. The force analogy method was extended to the dynamic analysis of frames with material and geometric nonlinearities in time domain (Zhao and Wong, 2006). The performance assessment and energy analysis for various structures were recently carried out based on the method (Wong and Zhao, 2007; Zhang et al., 2007; Wong, 2008). Recently, Au and Yan (2008) presented a method for nonlinear dynamic analysis of frames with material and geometric nonlinearities based on the semi-rigid technique. This paper describes further improvements, including the use of moving node strategy to track plastic hinges formed at arbitrary intermediate locations, as well as the degradation of members. The effects of distributed load on the formation of intermediate plastic hinges and the performance of degradation model will be examined. 2. DEVELOPMENT OF SEMI-RIGID TECHNIQUE

Semi-rigid behaviour often exists in frame connections, since there is no perfectly rigid or pinned connection in reality. Monforton and Wu (1963) modelled the semi-rigid connection as a zero-length

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

780

Z. H. YAN AND F. T. K. AU

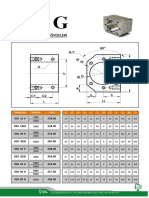

linear spring at each end of a member, as shown in Figure 1, and presented the xity factor li at end i of the member as

i =

ie ie 1 (i = 1, 2 ) = total = s + i i 1 + 3EI ri L

e i

(1)

s total where a e is the total endi is the elastic end-rotation at end i, a i is the spring rotation at end i, a i rotation at end i, ri is the rotational stiffness of the semi-rigid connection at end i, E is elastic modulus of the member, I is moment of inertia of the member and L is the length of the member. The xity factor is dened as the ratio of the rotational stiffness of the semi-rigid connection to the total stiffness comprising the connection and the member. It can also be interpreted as the ratio of the elastic endrotation of the member to the total end-rotation of the member. The xity factor li lies between 1 and 0, which corresponds to the rotational stiffness of the semi-rigid connection ri of innity and zero, respectively, namely the rigid connection and pinned connection. Monforton and Wu (1963) also presented a correction matrix Se as a function of the xity factors to develop a rst-order elastic analysis approach for semi-rigid frames. The stiffness matrix of an element with semi-rigid connections is taken as the product of the standard elastic stiffness matrix Ke and the correction matrix Se, i.e.

K semi rigid = K e Se

(2)

Much later, Xu (1992) presented another correction matrix Sg for geometric stiffness matrix as a function of the xity factors to develop a second-order elastic analysis for semi-rigid frames. To account for both rst-order and second-order effects, the stiffness matrix of a member with semi-rigid connection is written as the sum of product of the standard elastic stiffness matrix Ke with the correction matrix Se, and the product of the geometric stiffness matrix Kg with the correction matrix Sg, i.e. K semi rigid = K e Se + K g S g (3)

Hasan et al. (2002) later discovered that the model for post-elastic behaviour of a plastic hinge is similar to that for the elastic behaviour of a semi-rigid connection. Therefore, regarding the spring rotation a is at end i of the member as the plastic rotation a ip of the plastic hinge at the corresponding end of the member, and assuming that the rotational stiffness of the semi-rigid connection ri varies under the external bending moment according to certain nonlinear momentcurvature relation, then a potential plastic-hinge section can be regarded as a pseudo-semi-rigid connection. A plasticity factor can then be introduced based on the xity factor to describe the behaviour of a plastic hinge from the initial elastic state to the plastic state under monotonic loading. Let the rotational stiffness ri of the semi-rigid connection at end i be the section exural stiffness dMi /da ip at end i, namely

Figure 1. Concept of xity factor

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

781

ri =

dMi d ip

(4)

where a ip is the plastic end-rotation of the member at end i under the external bending moment. The plasticity factor (Hasan et al., 2002) can be dened as 1 1 + 3EI ( L dMi d ip )

pi =

(5)

The stiffness matrix with material and geometric nonlinearities can be expressed in the form of plasticity factors by replacing the xity factors li (i = 1, 2) with the plasticity factors pi (i = 1, 2) in Equation (3) as

p p K = K e Se + K g Sg

(6)

p p where Se and Sg are the corresponding correction matrices. The standard elastic stiffness matrix Ke and the geometric stiffness matrix Kg are, respectively

EA L Ke =

0 12 EI L3

0 6 EI L2 4 EI L

EA L 0 0

0 12 EI L3 6 EI 2 L 0 12 EI L3

EA L sym

6 EI L2 2 EI L 0 6 EI 2 L 4 EI L 0

(7)

0 0 6P 5L Kg = sym

0 P 10 2 PL 15

0 6P 0 5L P 0 10 0 0 6P 5L

0 P 10 PL 30 0 P 10 2 PL 5 15

(8)

p p and Sg are expressed, respectively, as functions of plasTheir corresponding correction matrices Se ticity factors as (Hasan et al., 2002)

Copyright 2009 John Wiley & Sons, Ltd.

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

782

Z. H. YAN AND F. T. K. AU

e11 0 0 e22 0 e32 1 p Se = 0 ( 4 p1 p2 ) 0 0 0 0 0

0 e23 e33 0 0 0

0 0 0 e44 0 0

0 0 0 0 e55 e65

0 0 0 0 e56 6 e66

(9a)

e11 = e44 = 4 p1 p2 e22 = 4 p2 2 p1 + p1 p2 e23 = 2 Lp1 (1 p2 ) e32 = e65 = 6 ( p1 p2 ) L e = 3 p ( 2 p ) 1 2 33 e55 = 4 p1 2 p2 + p1 p2 e56 = 2 Lp2 (1 p1 ) e66 = 3 p2 (2 p1 ) 0 0 0 1 0 g32 1 p = Sg 2 0 0 5 ( 4 p1 p2 ) 0 0 0 g62 0 0 g33 0 0 g63 0 0 0 0 0 g35 0 0 0 1 0 g65 0 0 g36 0 0 g66

(9b)

(10a)

2 2 2 2 g32 = g35 = 4 (8 p1 p2 13 p1 p2 32 p1 8 p2 + 25 p1 p2 + 20 ) L 2 2 g33 = p1 (16 p2 + 25 p1 p2 96 p1 p2 + 128 p1 28 p2 ) 2 2 5 p1 p2 + 9 p1 p2 28 p1 + 8 p2 ) g36 = 4 p2 (16 p1 2 2 2 2 g g 4 8 p p = = ( 62 65 1 2 13 p1 p2 32 p2 8 p1 + 25 p1 p2 + 20 ) L 2 2 g63 = 4 p1 (16 p2 5 p1 p2 + 9 p1 p2 + 8 p1 28 p2 ) 2 2 p2 96 p1 p2 28 p1 + 128 p2 ) + 25 p1 g66 = p2 (16 p1

(10b)

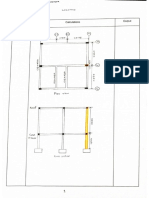

where P is the member axial force. 3. MOVING NODE STRATEGY IN DYNAMIC ANALYSIS When a member is under distributed loading, the location of intermediate plastic hinge varies according to the member forces and loading. Certain errors will be introduced if the intermediate plastic hinge is prescribed at mid-span, especially when the frame is under complicated load combination. To capture the location and behaviour of the intermediate plastic hinge, Wong (1996) rst presented a moving node strategy for the elasto-plastic analysis of frames subjected to loads, including linearly varying distributed load. In particular, the location of maximum bending moment with zero shear force is tracked by the moving node. Once the maximum bending moment reaches the yielding moment of the member, an intermediate plastic hinge is formed there. The moving node then continues to track the location of maximum bending moment until the next plastic hinge forms. Each beam member is, therefore, modelled by two elements and three nodes. Consider the portal frame in Figure 2 carrying distributed load and under earthquake excitation. At rst, the intermediate moving node is set at an arbitrary location such as mid-span of the beam member.

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

783

Figure 2. Illustration of the moving node strategy

In each time step, the location of the maximum total bending moment where the total shear force equals to 0 is obtained as x= T1total w (11)

where x is the distance from the left end of member to the location of maximum total bending moment, total w is the uniformly distributed load and T 1 is the total shear force at the left end of member. Then, the maximum total bending moment of the member can be calculated using

total M max =

wx 2 + T1total x M1total 2

(12)

tot al where M m ax is the maximum total bending moment including the effects from the inertial force, the damping force, the stiffness force, the earthquake excitation and the uniformly distributed load applied total on the beam member, and M1 is the total bending moment at the left end of member. Then, if the maximum total bending moment is larger than the yielding moment of the beam member, the moving node initially at location 3 is shifted to 3, where the total bending moment is the maximum and the plastic hinge is formed. Afterwards, the dynamic analysis of the whole structure can proceed assuming this new conguration, until another new intermediate plastic hinge forms at a different location 3. As seen from Figure 2, at any moment in time before the total collapse of structure, there is one and only one possible intermediate plastic hinge within each beam and therefore there are at most two plastic hinges formed in each beam. Using Figure 2 as an example, yielding can occur only in either locations 1 and 3 during loading in one direction, or locations 2 and 3 during loading in the opposite direction. The previous unloaded plastic hinge will become a damaged section if there is stiffness degradation. In view of the nite size of plastic hinge, the intermediate plastic hinge cannot be too close to a member end as well.

4.

STIFFNESS DEGRADATION MODEL

When the plastic hinge experiences yielding, unloading and reloading, its stiffness will deteriorate as a result of damage. Degradation models to describe the deterioration of members include those of Park and Ang (1985) and Rao et al. (1998) for concrete members, and models by Krawinkler and Zohrei

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

784

Z. H. YAN AND F. T. K. AU

(1983), Ballio and Castiglioni (1994), and Azevedo and Calado (1994) for steel members. As the plasticity factor in Equation (5) describes the plastic characteristics of a plastic hinge, the damage can be simulated by the gradual decrease in plasticity factor. The plastic hinge may also move into and out of the plastic region after the start of yielding. The idea of this stiffness degradation model comes from Shin and Oh (2007) and Yoshida (2001). The illustration of the change of plasticity factor and the corresponding change of plastic hinge stiffness ratio in the simplied stiffness degradation model are shown in Figure 3. The plastic hinge stiffness ratio can be solved from

( LdMi d ip )

EI =

3 pi 1 pi

(13)

Before a plastic hinge forms, the plasticity factor of the section is 1 and the corresponding stiffness is innite. The degradation of the stiffness starts when the section begins to yield, and nishes when the plasticity factor reaches a certain residual value or when the intermediate plastic hinge moves to another location. When the section yields, the plasticity factor becomes zero, and so does the stiffness of the section at the plastic hinge, as shown in Figure 3. Referring again to member 12 in Figure 2, when the previous plastic hinge 3 unloads and a new plastic hinge 3 is formed, member 12 will then be modelled by elements 13 and 32. In particular, element 32 has damage associated with the previous plastic hinge at 3 with stiffness degradation. The stiffness matrix Kd of an element with damage at an intermediate position can be expressed by the plasticity factor based on Equation (5) and the method adopted by Skrinar and Plibersek (2007) as h11 Kd = 0 h22 0 h23 h33 h14 0 0 h44 0 h25 h35 0 h55 0 h26 h36 0 h56 h66

(14a)

sym

Figure 3. Stiffness degradation model

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

785

h11 = EA L , h14 = h11 , h44 = h11 h22 = (12 EI ) (1 + 2 pd ) , h25 = h22 , h55 = h22 h23 = (6 EI )[3Lpd + 2 L1 (1 pd )], h35 = h23 h = (6 EI )[ L (2 + p ) 2 L (1 p )], h = h d 1 d 56 26 26 h = (12 EI )[ L2 (1 p ) + L2 p ] 1 d d 33 2 h36 = (6 EI )[2 L1 ( L L1 ) (1 pd ) + L pd ] h66 = (12 EI )[ L2 L1 (2 L L1 ) (1 pd )] = L [ L2 ( 4 pd ) 12 L1 ( L L1 ) (1 pd )]

(14b)

where L1 is the distance from the damage to the left element end and pd is the plasticity factor denoting the degree of degradation associated with the previous plastic hinge. Theoretically, there is no limit to the number of such previous damaged locations that can be introduced to the element. However, for practical cases of earthquake excitations, a beam member normally has an intermediate plastic hinge either at a single location or alternating between two different locations. Therefore, a member with an intermediate moving node to monitor the active plastic hinge is sufcient for most practical cases. 5. UPDATING OF GEOMETRY

To cope with the relatively large displacements, the geometry is updated according to the structural response at the end of each time step as follows

2 2 L = ( x1 x2 ) + ( y1 y2 )

(15) (16)

t = 0 +

where L is the length of the member at any time, (x1, y1) and (x2, y2) are the updated global coordinates at ends 1 and 2 of the member at the end of a time step, q0 is the anticlockwise angle of rotation so that the global X-axis becomes parallel to the initial element x-axis, qt is the anticlockwise angle of rotation so that the global X-axis becomes parallel to the updated element x-axis and q is the incremental rotation from q0 to qt. 6. PLASTIC ROTATION

The calculation of plastic rotation is only necessary when a potential plastic-hinge section becomes active by moving into the plastic region. The process is similar to that adopted by Au and Yan (2008), e should also be included. There are except that the effect of distributed load on the elastic rotation a i two ways to calculate the plastic rotation, depending on the nature of plastic hinge. If the plastic hinge has strain-hardening or strain-softening property after the onset of yielding, the section exural stiffness is non-zero. From Equation (4), the plastic rotation a ip can be calculated simply as the summation of plastic rotations in the previous time steps as

ip =

Mi ri

(17)

where Mi is the incremental external bending moment at end i of the element from time t to t + t, and ri is the rotational stiffness of the section that is chosen according to the moment-rotation curve

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

786

Z. H. YAN AND F. T. K. AU

of the plastic hinge. Where necessary, an iteration process is carried out to ensure global force equilibrium. If the plastic hinge is perfectly elastic-plastic, which means that the section exural stiffness after the onset of yielding is zero (dMi /da ip = 0), the plastic rotation can be solved indirectly. The deformation of a member under external bending moments and distributed load is shown in Figure 4. The variable atotal denotes the total rotation at end i of the member under external loading, a ie is the elastic rotation at the end and a ip is the plastic rotation there. The orientation of the member before load application is denoted by q0, which is the anticlockwise angle of rotation so that the global X-axis becomes parallel to the initial element x-axis. At the time considered, the member adopts a deformed conguration with an updated member x-axis pointing from End 1 to End 2. The orientation of the updated member x-axis is dened by qt, which is the anticlockwise angle of rotation so that the global X-axis becomes parallel to the updated element x-axis. The incremental rotation from q0 to qt is then denoted by q. The plastic rotation at the plastic hinge a ip can be calculated by reference to Figure 4 as

ip = itotal ie

(18)

where the elastic rotation a ie can be evaluated from the end moments Mi, Mj, and the effect of distrib e by ignoring the geometric nonlinearity of element without intermediate damage as uted load a i

ie =

Mi L M j L + ie 3EI 6 EI

for i = 1, j = 2 or i = 2, j = 1

(19a)

Figure 4. Deformation of member with plastic hinge

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

787

For uniformly distributed load w acting normally on the whole beam, the effect on the elastic rotation e can be evaluated as a i

ie = (1)i

wL3 24 EI

(i = 1, 2 )

(19b)

For a beam element with intermediate damage as in Section 4, the elastic rotation a ie and the effect e can be evaluated respectively as of uniformly distributed load a i e = 1 e 2 = M1h66 M 2 h36 e + 1 2 h33h66 (h36 ) M 2 h33 M1h36 e + 2 2 h33h66 (h36 )

(20a)

wL2 e = h66 + h36 1 2 h33h66 (h36 ) 12 h33 + h36 wL2 e 2 = 2 h33h66 (h36 ) 12

(20b)

where hij (i, j = 3,6) are obtained from Equation (14b). The total rotation a total can be solved from the i global equilibrium equation in each time step, while the incremental rotation q can be calculated from the updating of geometry in each time step. Note that Equations (17) or (18) applies only when a potential plastic-hinge section becomes active. In Equations (19a) and (20a), the effects of shear force and geometric nonlinearity on the local elastic rotation have been ignored for simplicity. These effects are actually minimal, as elaborated in the subsequent sections.

7. YIELD CRITERION The dynamic excitations mainly cause bending moments and shear forces in the frame members with relatively minor variations in axial forces. The yield criterion (Duan and Chen, 1990) involving both the bending moment M and the axial force P can be written as M P 1 p+ p P M

( ) 1

n

(21)

where the shape factor h depends on the type of cross section, Mp is the moment capacity in the absence of axial force, Pp is the axial force capacity in the absence of bending moment and the yield exponent n depends on the shape of cross section. As the transition from the fully elastic state to the fully plastic state is assumed to take place over an extremely small range of curvature, only the full yielding condition is used as the yield criterion, namely M P + p p M P

Copyright 2009 John Wiley & Sons, Ltd.

( ) 1

n

(22)

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

788

Z. H. YAN AND F. T. K. AU

8.

ELEMENT FORCE RECOVERY PROCEDURE

In the dynamic analysis of nonlinear structures, the element force should be known for calculation of the geometric stiffness matrix Kg and for determination of the unbalanced forces at nodal points. To calculate the element force that eliminates any erroneous additional straining due to rigid body motion, the external stiffness approach (Yang and Kuo, 1994) is adopted. The external stiffness matrix Ke g for a two-dimensional member is 0 = Ke g M1 + M 2 L2 P L 0 0 0 0 M1 + M 2 L2 0 0 sym M1 + M 2 L2 P L 0 M1 + M 2 L2 P L 0 0 0 0 0 0

(23)

where Mi is the bending moment at End i (i = 1,2) of the element, P is the axial force of the element and L is the length of the element, all of which are calculated for the last conguration. Since the effects of geometric nonlinearity and rigid body motion in the beam members are relatively small, the external stiffness approach is only applied to the column members in the present study. Unlike the standard and geometric stiffness matrices, incorporating the plastic hinges into the element e has no effect on the external stiffness matrix Kg . Therefore, by subtracting the external stiffness matrix e Kg from the tangent stiffness matrix, a matrix that accounts duly for the effect of element deformation can be obtained. The incremental element stiffness force f s t+t from time t to t + t caused by deformation increment of the element can be calculated in terms of the incremental displacement Xt+t from time t to t + t as

p p fts+ t = (K e Se + K g Sg Ke g )t + t X t + t

(24)

9.

PROCEDURES FOR DYNAMIC ANALYSIS

In the present study that involves material and geometric nonlinearities, the Newmark method of direct integration is adopted, together with an incremental iteration strategy. As usual, the inertial effect is modelled by lumped masses at the beamcolumn joints. The incremental equilibrium equation of motion of the whole structure can be written as MX t + t + CX t + t + KX t + t = Ft + t (25)

where M is the mass matrix, C is the damping matrix that may be formulated according to the damping t+t and X t+t model chosen, K is stiffness matrix that can be obtained from Equation (6), Xt+t, X are the incremental displacement, velocity and acceleration vectors relative to the ground, respectively, from time t to t + t, in which the dot denotes differentiation with respect to time t, and Ft+t is the incremental external excitation vector from time t to t + t. In the case of seismic loading, the incremental external excitation vector Ft+t can be expressed as

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

789

Ft + t = MHxg

(26)

where H is an index vector that assigns inertia forces to appropriate degrees of freedom, and x g is the incremental absolute ground acceleration from time t to t + t. In the present study, the stiffness matrix K changes in the process of dynamic analysis, and straightforward application of the Rayleigh damping model is not particularly rational. Therefore, for simplicity, mass proportional damping is assumed and the damping matrix C is written in terms of the mass matrix M as C = 2i i M (27)

where xi and wi are, respectively, the critical damping ratio and the circular frequency for mode i. In the subsequent simulations, the critical damping ratio and the circular frequency for the rst mode are chosen to calculate the damping matrix. An incremental iteration strategy is used in each time step to ensure equilibrium in the broad sense as elaborated below. (1) Specify the material and geometric properties, and the initial conditions for dynamic analysis. Set the moving nodes at arbitrary positions such as the middle of each member. Initialize various parameters and vectors, and evaluate the initial matrices M, C and K for analysis. (2) Form the effective tangent stiffness Keff and the effective incremental load Feff from time t to t + t as K eff = K + 1 M+ C t 2 t (28)

1 1 t t C X Feff = MHxg + M + C t Xt + M + t 2 2

(29)

where the stiffness matrix K is based on Equation (6), Xt is the displacement vector at time t, and the parameters for the Newmark method of direct integration are taken to be b = 025 and g = 05. (3) Solve for the incremental displacement Xt+t from time t to t + t from the equivalent equilibrium equation K eff X t + t = Feff (30)

t+t and acceleration X t+t from time t to t + t, respec(4) Solve for the incremental velocity X tively, from X t + t =

t X t + t X t t X 2 t t

1 1 1 X t + t Xt Xt 2 2 t t

(31)

X t + t =

(32)

t+t and acceleration X t+t at time t + t by Then, calculate the displacement Xt+t, velocity X X t + t = X t + X t + t , X t + t = X t + X t + t , X t + t = X t + X t + t

Copyright 2009 John Wiley & Sons, Ltd.

(33)

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

790

Z. H. YAN AND F. T. K. AU

(5) Update the geometry of the frame according to Equations (15), (16) and (33). (6) Calculate the incremental element stiffness forces of the elements f ts+t corresponding to the incremental displacements according to Equation (24), and then the element stiffness forces f ts+t at time t + t as fts+ t = fts + fts+ t

tal Then, calculate the total element dynamic force f tto +t at time t + t as

s fttotal + t = mx t + t + ft + t + M mx t + t + mx g (t + t )

(34)

(35)

(7) (8) (9) (10)

where m is the element mass matrix, aM is the mass coefcient taken as aM = 2xiwi, x t+t and x t+t are, respectively, the element velocity and acceleration vectors at time t + t with respect g(t + t) is the ground acceleration vector at time t + t with to the local element axes, and x respect to the local element axes. Actually, the four terms on the right-hand side of Equation (35) account for the element inertial force, element stiffness forces, element damping force and the element excitation force, respectively. Determine the force state of each element. Update the plasticity factors according to the state of elements, the stiffness degradation model and the simplied nonlinear hysteretic momentcurvature relation. Update the element and global stiffness matrices according to Equation (6). Calculate the incremental element stiffness forces corresponding to the incremental displacements and the total element stiffness forces in the frame using the updated element stiffness matrices, namely

(fts+ t )

updated

p p = (K e Se + K g Sg Ke g )t + t X t + t updated updated

(36) (37)

( fts+ t )

= fts + ( fts+ t )

updated

(11) Transform the total element stiffness forces to the nodal forces and assemble the internal nodal force vector Nt+t in the global coordinate system N t + t = Tk1 ( fts+ t )k

k =1 ne updated

(38)

where Tk is the transformation matrix from the global to the element axis system for element k, ne is the number of elements in the frame, and the summation here implies the assembly process. (12) Calculate the unbalance force vector t+t at time t + t by G t + t = MHxg (t + t ) ( MX t + t + N t + t + Ftd + t ) (39)

where Fd t+t is the damping force calculated according to the chosen damping model. (13) Check the convergence parameters 1 = G t + t MHxg and 2 = X t + t , where denotes the norm of a vector. If e1 > e1max and e2 > e2max, go to Step (14); otherwise, go to Step (17). (14) Solve for the incremental displacement X t+t for equilibrium iteration using unbalanced force t+t and effective tangent stiffness Keff evaluated with the updated stiffness matrices, namely

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

1 X t+ t = K eff G t + t

791

(40)

(15) Update the displacement, velocity and acceleration vectors at time t + t

( X t + t )

updated

= X t + t + X t+ t

(41) (42)

(X t + t ) (X t + t )

updated

= X t + t + = X t + t +

X t+ t t

1 X t+ t t 2

updated

(43)

(16) Go to Step (5) and repeat the analysis until the convergence criteria are satised. (17) If the maximum total bending moment within a beam element exceeds the yielding moment, the moving node strategy is invoked and the intermediate plastic hinge is formed there. Any previous intermediate plastic hinge unloaded will be recorded as damage if there is stiffness degradation. (18) If time t + t < T, where T is the total time of excitation, set t = t + t and go to Step (2b); otherwise, stop. 10. NUMERICAL EXAMPLES

After verication by a portal frame, a practical multi-storey frame is analysed to illustrate the applicability and performance of the proposed method. Unless otherwise stated, the Youngs modulus is 2 1011 N/m2, while the yield stress is 248 108 N/m2. Mass-proportional damping with a 5% critical damping ratio is assumed. For simplicity, the rotational inertial effect of the beam is ignored and the lumped mass matrix is adopted. A lumped mass is assigned to each beamcolumn joint to simulate the oor mass, and a joint load is applied to account for the gravity effect. 10.1 Seismic response of a portal frame

A portal frame made up of steel W-type I-beams, as shown in Figure 5, is used for verication. The accurate locations of intermediate plastic hinges are determined from trial calculations beforehand. Then, the results from the present method with moving node strategy are compared with those obtained by conning the intermediate plastic hinges to the above predetermined location, namely the xed node strategy. As the bending capacity of the beam is lower than that of the column, the top of column is unlikely to yield. The other properties of the steel W-type I-beams are given in Table 1. Each beamcolumn joint is assigned a lumped mass of 50 000 kg and an applied joint load P0 of 500 kN. To examine the basic performance, initially, the yield criterion adopted accounts for the bending moment only and no stiffness degradation is considered. The moving node is initially set at the middle of beam. The uniformly distributed load w on the beam is 50 kN/m. The assumed excitation is that of El Centro earthquake with magnied peak ground acceleration of 05 g, as shown in Figure 6, where g is the acceleration due to gravity. A regular time step of 0002 s is chosen. As the available El Centro earthquake excitation has been sampled at 50 Hz with time steps of 002 s, piecewise cubic Hermite interpolation is used to provide excitation data of time steps of 0002 s. The above data apply below unless otherwise stated. Through accurate trial calculations, the intermediate plastic hinge of the beam is formed sequentially as follows: 1435 m from the left column at 2210 s, and 5296 m from the left column at 4628 s.

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

792

Z. H. YAN AND F. T. K. AU

Figure 5. A portal frame for verication

Figure 6. Magnied El Centro earthquake time history Table 1. Properties of steel members in portal frame Member Column (W27 102) Beam (W12 58) Area (m2) 19355 102 10968 102 Moment of inertia (m4) 15068 103 19771 104 Yield moment (Nm) 12395 106 35113 105

Therefore, to obtain the reference solution, the beam is divided into three elements of lengths of 1435 m, 3861 m and 1404 m. With reference to Figure 5, the order of plastic hinge formations is as follows: PPHL4, PPHL3, PPHL1, PPHL2 and the intermediate beam plastic hinge at various locations. The horizontal beam displacement is shown in Figure 7, while the vertical displacement tracked by the moving node of the beam is presented in Figure 8. The result in Figure 8 up to 2210 s is actually that at mid-span before the formation of intermediate beam plastic hinge. It is followed by the vertical displacements of the rst and second positions of intermediate beam plastic hinge, respectively, in the periods 2212 s to 4628 s and beyond 4628 s. The results also show that the two intermediate beam plastic hinges are almost formed symmetrically, namely at 1435 m from the left joint and 1404 m

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

793

from the right joint. Figures 7 and 8 show that the moving node strategy can be used effectively in dynamic analyses. Various factors affecting the formation of intermediate plastic hinges are then examined. Analyses are repeated for uniformly distributed load w ranging from 0 to 50 kN/m at intervals of 10 kN/m while keeping the applied joint load P0 = 500 kN unchanged. Figure 9 shows that the uniformly distributed load has little effect on the horizontal displacements. When the uniformly distributed load is 30 kN/m or below, no intermediate plastic hinge is formed within the beam. Figure 10 further shows the variations of maximum span moment and its location in the beam with time when the uniformly distributed load is increased to 40 and 50 kN/m. When the uniformly distributed load is 40 kN/m,

Figure 7. Horizontal beam displacement of portal frame under magnied El Centro earthquake (t = 0002 s)

Figure 8. Vertical displacement of the moving node of beam in portal frame under magnied El Centro earthquake ((t = 0002 s)

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

794

Z. H. YAN AND F. T. K. AU

Figure 9. Horizontal beam displacements of portal frame under magnied El Centro earthquake and different uniformly distributed loads

Figure 10. Variations of maximum span moment and its location in the beam of portal frame under magnied El Centro earthquake

Figure 10(a) shows that an intermediate plastic hinge forms briey. When the uniformly distributed load reaches 50 kN/m, Figure 10(b) conrms that the rst intermediate plastic hinge forms briey at a location close to the left column, and the second intermediate plastic hinge forms twice at a location close to the right column. To study the effects of the plastic hinge deterioration on the response, the stiffness degradation model, as shown in Figure 3, is adopted in the subsequent analysis in order to examine the effects of residual value and rate of reduction of plasticity factor. In accordance with the model, when the plasticity factor decreases from 1 to the residual value, the plastic hinge stiffness ratio also decreases from positive innity to the corresponding residual stiffness. When a plastic hinge moves to another

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

795

location, there will be stiffness degradation associated with the previous location, and hence the stiffness matrix Kd of an element with intermediate damage, as shown in Equation (14), should be applied as appropriate. Analyses are repeated for uniformly distributed load of 50 kN/m, covering cases in which the plasticity factor begins to decrease from 1 upon yielding at a rate of 005/s until it reaches a residual value ranging from 1 (no degradation) to 08. The horizontal beam displacements shown in Figure 11 indicate that the response with stiffness degradation associated with plastic hinges obviously results in a lower frequency and larger amplitudes. For a residual plasticity factor of 095, the intermediate plastic hinge forms at two different locations of the beam. However, for a residual plasticity factor of 090 or below, the intermediate plastic hinge forms only at one single location of the beam. The variation

Figure 11. Horizontal beam displacements of portal frame under magnied El Centro earthquake and uniformly distributed load of 50 kN/m with rate of reduction of plasticity factor of 005/s

Figure 12. Variation of plasticity factor of active intermediate beam plastic hinge of portal frame under magnied El Centro earthquake and uniformly distributed load of 50 kN/m with rate of reduction of plasticity factor of 005/s

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

796

Z. H. YAN AND F. T. K. AU

of plasticity factor of the active intermediate beam plastic hinge shown in Figure 12(a) veries that the intermediate plastic hinge forms at two different locations, while that in Figure 12(b) indicates formation of intermediate plastic hinge at one single location. Analyses are repeated for uniformly distributed load of 50 kN/m, covering cases in which the plasticity factor begins to decrease from 1 upon yielding to 095 at a rate of reduction ranging from 005 to 02/s. Figure 13 shows that the horizontal beam displacements are not as sensitive to the rate of reduction of plasticity factor. The variations of plasticity factor of the active intermediate beam plastic hinge shown in Figures 12(a), 14(a) and 14(b) for the reduction rates of 005, 01 and 02/s, respectively, verify that the intermediate plastic hinge forms at two different locations in the rst case only, but at one single location in the last two cases. Generally, a higher rate of reduction causes the frame to degrade faster, so that the subsequent intermediate maximum moment becomes smaller. By proper

Figure 13. Horizontal beam displacements of portal frame under magnied El Centro earthquake and uniformly distributed load of 50 kN/m with residual plasticity factor of 095

Figure 14. Variation of plasticity factor of active intermediate beam plastic hinge of portal frame under magnied El Centro earthquake and uniformly distributed load of 50 kN/m with residual plasticity factor of 095

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

797

adjustment of the rate of reduction and residual value of plasticity factor of the stiffness degradation model, the deterioration characteristics of a plastic hinge can be simulated approximately. 10.2 Seismic response of a multi-storey frame

A more realistic three-storey frame made up of steel W-type I-beams, as shown in Figure 15, is then studied to illustrate the capability of the proposed method. The member used and their properties are shown in Table 2. At the roof level, the lumped masses on exterior and interior columns are 10 000 kg and 20 000 kg, respectively. On each oor below the roof, the lumped masses on exterior and interior columns are 20 000 kg and 40 000 kg, respectively. The applied joint loads to account for gravity effects are as follows: P1 = 500 kN, P1 = 1000 kN, P2 = 300 kN, P = 2 = 600 kN, P3 = 100 kN and P3 200 kN. The assumed excitation is that of the El Centro earthquake with magnied peak ground acceleration of 07 g. The multi-parameter yield criterion that takes into account bending moment M and axial force P is adopted with a yield exponent n = 13. The stiffness degradation model adopted has a residual plasticity factor of 09 and a rate of reduction of 01/s. Dynamic analysis is carried out with rather ne time steps of 0002 s. The horizontal displacements at various oors of the frame are shown in Figure 16, indicating that the response generally increases with height. The formation of intermediate beam plastic hinge differs from oor to oor. In each beam of the rst oor, the intermediate plastic hinge forms at two different locations, as observed in the plasticity factor of MN1 in Figure 17(a). However, Figure 17(b) shows that the intermediate plastic hinge (i.e., MN3) forms at one single location in each span of the second oor. Incidentally, no intermediate plastic hinge is formed in any span of the third oor. The locations of plastic hinges shown in Figure 18 indicate that,

Figure 15. A three-storey steel frame with moving nodes (MN) for tracking formation of intermediate plastic hinges in beams Table 2. Properties of steel members in three-storey frame Member Exterior column (W24 103) Interior column (W24 117) Beam (W10 77)

Copyright 2009 John Wiley & Sons, Ltd.

Area (m2) 19548 10 22194 102 14581 102

2

Moment of inertia (m4) 12487 10 14735 103 18939 104

3

Yield moment (Nm) 11379 106 13289 106 39665 105

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

798

Z. H. YAN AND F. T. K. AU

Figure 16. Horizontal oor displacements of three-storey frame under magnied El Centro earthquake with multi-parameter yield criterion

Figure 17. Variation of plasticity factor of active intermediate beam plastic hinge at moving nodes MN1 and MN3 of three-storey frame under magnied El Centro earthquake

besides the beam ends and column ends at ground level, intermediate beam plastic hinges can also be formed at various locations at certain instants. To evaluate the dynamic response of frames accurately, it is important that such phenomena are taken into account. The time histories of the plastic rotations at selected plastic hinges are further shown in Figure 19. The proposed method is also capable of efciently analysing complicated multi-storey frames commonly encountered in practice. 11. CONCLUSIONS

The paper describes a method for nonlinear dynamic analysis of frames carrying distributed loads, which is based on the semi-rigid technique and moving node strategy. The method uses

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

799

Figure 18. Locations of plastic hinges in three-storey frame under magnied El Centro earthquake with time shown in brackets (PH, plastic hinge; , end plastic hinge; , intermediate plastic hinge)

Figure 19. Plastic rotations at selected plastic hinges of three-storey frame under magnied El Centro earthquake with multi-parameter yield criterion

pseudo-semi-rigid connections to simulate the plastic hinges that may form in a frame. The moving node strategy is applied in the dynamic analysis to track the formation of intermediate plastic hinges accurately. Stiffness degradation is also included in the plastic hinge model to simulate its deterioration. With the increase of distributed loads, the intermediate beam plastic hinge may shift from one location to another. Once the frame starts yielding, the lower the residual plasticity factor is, the weaker the frame becomes. The apparent frequency of the frame after yielding normally drops. The rate of reduction of plasticity factor also affects the formation of intermediate beam plastic hinge. The numerical examples presented demonstrate that the method is efcient in dealing with multi-storey frames that may have intermediate plastic hinges.

Copyright 2009 John Wiley & Sons, Ltd. Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

800

Z. H. YAN AND F. T. K. AU

REFERENCES

Au FTK, Yan ZH. 2008. Dynamic analysis of frames with material and geometric nonlinearities based on semirigid technique. International Journal of Structural Stability and Dynamics 8(3): 415438. Awkar JC, Lui EM. 1999. Seismic analysis and response of multistory semirigid frames. Engineering Structures 21: 425441. Azevedo J, Calado L. 1994. Hysteretic behaviour of steel members: Analytical models and experimental tests. Journal of Constructional Steel Research 29: 7194. Ballio G, Castiglioni CA. 1994. Seismic behaviour of steel sections. Journal of Constructional Steel Research 29: 2154. Chan SL, Chui PPT. 2000. Non-Linear Static and Cyclic Analysis of Steel Frames with Semi-Rigid Connections. Elsevier: Kidlington. Chen WF, Chan SL. 1995. Second-order inelastic analysis of steel frames using element with midspan and end springs. Journal of Structural Engineering ASCE 121(3): 530541. Duan L, Chen WF. 1990. A yield surface equation for doubly symmetrical sections. Engineering Structures 12(2): 114119. Elnashai AS. 2002. Do we really need inelastic dynamic analysis? Journal of Earthquake Engineering 6(Special issue 1): 123130. Gong Y. 2006. Adaptive gradual plastic hinge model for nonlinear analysis of steel frameworks. Canadian Journal of Civil Engineering 33(9): 11251139. Gong Y, Xu L, Grierson DE. 2005. Performance-based design sensitivity analysis of steel moment frames under earthquake loading. International Journal for Numerical Method in Engineering 63: 1229 1249. Gong Y, Xu L, Grierson DE. 2006. Sensitivity analysis of steel moment frames accounting for geometric and material nonlinearity. Computers and Structures 84: 462475. Grierson DE, Gong Y, Xu L. 2006. Optimal performance-based seismic design using modal pushover analysis. Journal of Earthquake Engineering 10(1): 7396. Hall JF, Challa VRM. 1995. Beam-column modelling. Journal of Engineering Mechanics ASCE 121(12): 1284 1291. Hasan R, Xu L, Grierson DE. 2002. Push-over analysis for performance-based seismic design. Computers and Structures 80: 24832493. Kim SE, Lee JS, Choi SH, Kim CS. 2004. Practical second-order inelastic analysis for steel frames subjected to distributed load. Engineering Structures 26: 5161. Kim SE, Choi SH. 2005. Practical second-order inelastic analysis for three-dimensional steel frames subjected to distributed load. Thin-Wall Structures 43: 125160. Krawinkler H, Zohrei M. 1983. Cumulative damage in steel structures subjected to earthquake ground motions. Computers and Structures 16(14): 531541. Lui EM, Lopes A. 1997. Dynamic analysis and response of semirigid frames. Engineering Structures 19(8): 644654. Monforton GR, Wu TS. 1963. Matrix analysis of semi-rigidly connected frames. Journal of the Structural Division ASCE 89(6): 1342. Park YJ, Ang AHS. 1985. Mechanistic seismic damage model for reinforced concrete. Journal of Structural Engineering, ASCE 111(4): 722739. Rao PS, Sarma BS, Lakshmanan N, Stangenberg F. 1998. Damage model for reinforced concrete elements under cyclic loading. ACI Material Journal 95(6): 682690. Shin S, Oh SH. 2007. Damage assessment of shear buildings by synchronous estimation of stiffness and damping using measured acceleration. Smart Structures and Systems 3(3): 245261. Skrinar M, Plibersek T. 2007. New nite element for transversely cracked slender beams subjected to transverse loads. Computational Materials Science 39: 250260. Wong KKF. 2008. Seismic energy dissipation of inelastic structures with tuned mass dampers. Journal of Engineering Mechanics ASCE 134(2):163172. Wong KKF, Zhao D. 2007. Uncoupling of potential energy in nonlinear seismic analysis of framed structures. Journal of Engineering Mechanics ASCE 133(10):10611071. Wong MB. 1996. Effects of linearly varying distributed load on the collapse behaviour of frames. Computers and Structures 61(5): 909914. Xu L. 1992. Geometrical stiffness and sensitivity matrices for optimization of semi-rigid steel frameworks. Structural Optimization 5: 9599.

Copyright 2009 John Wiley & Sons, Ltd.

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

NONLINEAR DYNAMIC ANALYSIS OF FRAMES WITH PLASTIC HINGES

801

Xu L, Liu Y, Grierson DE. 2005. Nonlinear analysis of steel frameworks through direct modication of member stiffness properties. Advances in Engineering Software 36: 312324. Yang YB, Kuo SR. 1994. Theory and Analysis of Nonlinear Framed Structures. Prentice-Hall: Englewood Cliffs, NJ. Yoshida I. 2001. Damage detection using Monte Carlo lter based on non-Gaussian noise. Proceedings of Nonlinear System Identication and Structural Health Monitoring, DPRI, Kyoto University, 281292. Zhao DF, Wong KKF. 2006. New approach for seismic nonlinear analysis of inelastic framed structures. Journal of Engineering Mechanics ASCE 132(9): 959966. Zhang X, Wong KKF, Wang Y. 2007. Performance assessment of moment resisting frames during earthquakes based on the force analogy method. Engineering Structures 29(10): 27922802.

Copyright 2009 John Wiley & Sons, Ltd.

Struct. Design Tall Spec. Build. 19, 778801 (2010) DOI: 10.1002/tal

You might also like

- CIE5260 Slides 2019Document962 pagesCIE5260 Slides 2019language.ameyNo ratings yet

- The Maria Pia Bridge: A Major Work of Structural ArtDocument8 pagesThe Maria Pia Bridge: A Major Work of Structural ArtCaraiane CatalinNo ratings yet

- Contact Stress FatigueDocument31 pagesContact Stress Fatiguepkn_pnt9950No ratings yet

- Blachere IlluminationDocument14 pagesBlachere IlluminationCaraiane CatalinNo ratings yet

- Design of Steel Structures II, Prof. S.R.satish Kumar & Prof.a.R.santha KumarDocument553 pagesDesign of Steel Structures II, Prof. S.R.satish Kumar & Prof.a.R.santha Kumarmesecipres100% (1)

- Goldstein 18 21 13 14 20Document15 pagesGoldstein 18 21 13 14 20Abdul Shakoor ButtNo ratings yet

- CEE 541. Structural Dynamics: Fall 2014Document4 pagesCEE 541. Structural Dynamics: Fall 2014praveennagarajanNo ratings yet

- Nonlinear Steel Assignment TwoDocument2 pagesNonlinear Steel Assignment Twosami_bangash_1No ratings yet

- Coped Beam PDFDocument132 pagesCoped Beam PDFRestie TeanoNo ratings yet

- Seismic Retrofit of RC Structures - CSA 23.3-04 SaatciogluDocument83 pagesSeismic Retrofit of RC Structures - CSA 23.3-04 Saatcioglu700spymaster007No ratings yet

- CE 463.3 - Advanced Structural Analysis Lab 1 - Introduction To SAP2000Document8 pagesCE 463.3 - Advanced Structural Analysis Lab 1 - Introduction To SAP2000Ouafi Saha100% (1)

- SAP2000 Tutorial - CE463 Sap SummaryDocument1 pageSAP2000 Tutorial - CE463 Sap SummaryOuafi SahaNo ratings yet

- Note On: Second-Order Direct Analysis by NIDADocument29 pagesNote On: Second-Order Direct Analysis by NIDAPauloAndresSepulvedaNo ratings yet

- Buckling Analysis by AbaqusDocument37 pagesBuckling Analysis by AbaqusGurram VinayNo ratings yet

- Nonlinear Modeling With OpenSeesDocument71 pagesNonlinear Modeling With OpenSeesManu Vega100% (1)

- A New Codified Design Theory of Second-Order Direct Analysis For Steel A...Document7 pagesA New Codified Design Theory of Second-Order Direct Analysis For Steel A...Luis MartinsNo ratings yet

- CE220 Reader For 2009Document677 pagesCE220 Reader For 2009gabrielfc19100% (1)

- Structural Analysis - Ii: University of MumbaiDocument151 pagesStructural Analysis - Ii: University of MumbaiKanade's Engineering Classes PuneNo ratings yet

- A Study On Performance of Existing Building - Ordinary Moment Resisting FrameDocument184 pagesA Study On Performance of Existing Building - Ordinary Moment Resisting FrameThiha KyawNo ratings yet

- Connections 1 - Ch.2 Bolts Notes (48-93)Document18 pagesConnections 1 - Ch.2 Bolts Notes (48-93)travis8zimmermannNo ratings yet

- Connections 1 - Ch.4 Tension Members Notes (154-187)Document12 pagesConnections 1 - Ch.4 Tension Members Notes (154-187)travis8zimmermannNo ratings yet

- 2020 Notes 2-Behaviour of Structural ConcreteDocument34 pages2020 Notes 2-Behaviour of Structural ConcreteFourel LéoNo ratings yet

- TB Lecture10 Braced Frame StructuresDocument33 pagesTB Lecture10 Braced Frame StructuresSaeed Khawam100% (2)

- Theory of Elasticity: Exam Problems and Answers Lecture CT5141 (Previously B16)Document96 pagesTheory of Elasticity: Exam Problems and Answers Lecture CT5141 (Previously B16)Ashebir AsratNo ratings yet

- Example 3Document8 pagesExample 3AlexanderNCNo ratings yet

- Base Isolation of Structure SystemDocument33 pagesBase Isolation of Structure SystemHaris Alam100% (2)

- 10.1-Performance Based Plastic Design (SG) PDFDocument27 pages10.1-Performance Based Plastic Design (SG) PDFjulianNo ratings yet

- CE579 Half Course SummaryDocument192 pagesCE579 Half Course SummarySwarna RkNo ratings yet

- Interview Questions: 1. What Is Creep of A Concrete? and It's Effects of StructureDocument27 pagesInterview Questions: 1. What Is Creep of A Concrete? and It's Effects of StructureRupesh KhandekarNo ratings yet

- Experimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewDocument4 pagesExperimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewAsr FlowerNo ratings yet

- Collapse Load Analysis of Prestressed Concrete Structures - KW Wong & RF Warner, 1998Document26 pagesCollapse Load Analysis of Prestressed Concrete Structures - KW Wong & RF Warner, 1998Ben IndrawanNo ratings yet

- High Rise Structures (CVEN90024) - FEM LAB Exercise 2 - SolutionsDocument53 pagesHigh Rise Structures (CVEN90024) - FEM LAB Exercise 2 - SolutionsZuhair NadeemNo ratings yet

- Solution ManualDocument3 pagesSolution ManualhajasoftwareNo ratings yet

- 8 Approximate (Short) PDFDocument12 pages8 Approximate (Short) PDFRashedul IslamNo ratings yet

- About Pushover Analysis and SAP 2000 MethodDocument12 pagesAbout Pushover Analysis and SAP 2000 MethodHanush Anand100% (2)

- Buckling Analysis K Value CalculatorDocument3 pagesBuckling Analysis K Value Calculatorrodriguez.gaytanNo ratings yet

- Friction Pendulum System - A Parametric Study of Friction CoefficientDocument3 pagesFriction Pendulum System - A Parametric Study of Friction CoefficientIJSTENo ratings yet

- Lehigh U I: Finite Element Analysis of Elastic-Plastic PlatesDocument125 pagesLehigh U I: Finite Element Analysis of Elastic-Plastic PlatesRavindra MRNo ratings yet

- The Uniform Force MothodDocument4 pagesThe Uniform Force MothodJoaquin Ignacio Concha NúñezNo ratings yet

- Handout 5 13Document11 pagesHandout 5 13erikahuhuNo ratings yet

- ThesisDocument101 pagesThesisZaki Siddiqui100% (3)

- 2001 - Interaction Surfaces of Reinforced-Concrete Sections in Biaxial BendingDocument7 pages2001 - Interaction Surfaces of Reinforced-Concrete Sections in Biaxial Bendingryan rakhmatNo ratings yet

- Non-Linear Static (Pushover) AnalysisDocument3 pagesNon-Linear Static (Pushover) AnalysisAnonymous 4emDZITjoNo ratings yet

- Course On Structural StabilityDocument3 pagesCourse On Structural StabilityVenkatesh ReddyNo ratings yet

- Finite Difference Buckling Analysis of Non Uniform ColumnsDocument8 pagesFinite Difference Buckling Analysis of Non Uniform ColumnsJules NanaNo ratings yet

- How To Design A Transfer FloorDocument4 pagesHow To Design A Transfer Flooreplim60100% (1)

- Structural Systems in A High Rise Building.Document24 pagesStructural Systems in A High Rise Building.Tanya YadavNo ratings yet

- CEE 611 Earthquake Engineering Class 17Document8 pagesCEE 611 Earthquake Engineering Class 17John ShottkeyNo ratings yet

- Pushover AnalysisDocument20 pagesPushover AnalysisMarcelo Quisbert100% (2)

- Stability Chapter 01Document15 pagesStability Chapter 01Fabio IannoneNo ratings yet

- 15-Nguyen Van Thin-Bai Bao28!3!2007Document8 pages15-Nguyen Van Thin-Bai Bao28!3!2007Vo Dinh ThaoNo ratings yet

- Shear in One-Way Slabs Under Concentrate PDFDocument10 pagesShear in One-Way Slabs Under Concentrate PDFHesham MohamedNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingFrom EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingNo ratings yet

- Structural Health Monitoring of Large Civil Engineering StructuresFrom EverandStructural Health Monitoring of Large Civil Engineering StructuresNo ratings yet

- Inverter ManualDocument36 pagesInverter ManualCaraiane CatalinNo ratings yet

- DSG 20120401 111555Document2 pagesDSG 20120401 111555Caraiane CatalinNo ratings yet

- Vacon Frequency Converters: Small, Easy To Use But Still PowerfulDocument20 pagesVacon Frequency Converters: Small, Easy To Use But Still PowerfulCaraiane CatalinNo ratings yet

- KJN Manual Movement DimsDocument7 pagesKJN Manual Movement DimsCaraiane CatalinNo ratings yet

- NVCNC Nvumv2 enDocument41 pagesNVCNC Nvumv2 enCaraiane CatalinNo ratings yet

- DGI300 Manual 4.1Document154 pagesDGI300 Manual 4.1Caraiane Catalin100% (2)

- Electric Wiring Diagram: (Note: The Output Signal Must Be 5 V)Document1 pageElectric Wiring Diagram: (Note: The Output Signal Must Be 5 V)Caraiane CatalinNo ratings yet

- ST-V2 Mach3 Board PDFDocument12 pagesST-V2 Mach3 Board PDFCaraiane CatalinNo ratings yet

- Estimated Kerf-Width Compensation - Metric (MM) : 0.5 1 2 3 6 8 10 12 16 20 25 ProcessDocument6 pagesEstimated Kerf-Width Compensation - Metric (MM) : 0.5 1 2 3 6 8 10 12 16 20 25 ProcessCaraiane CatalinNo ratings yet

- Metalworking News November 2013Document108 pagesMetalworking News November 2013Caraiane CatalinNo ratings yet

- Euromodul Containers System Constructions enDocument6 pagesEuromodul Containers System Constructions enCaraiane CatalinNo ratings yet

- Manul009r2v2 - Xmp2-32 User ManualDocument37 pagesManul009r2v2 - Xmp2-32 User ManualCaraiane CatalinNo ratings yet

- 00 GB List of ContentsDocument2 pages00 GB List of ContentsCaraiane CatalinNo ratings yet

- Seismic Response of Stone Masonry Spires: Analytical ModelingDocument10 pagesSeismic Response of Stone Masonry Spires: Analytical ModelingCaraiane CatalinNo ratings yet

- Project Collaboration 181 EnuDocument29 pagesProject Collaboration 181 EnuCaraiane CatalinNo ratings yet

- Acknowledgement: Mr. Hemant ShuklaDocument19 pagesAcknowledgement: Mr. Hemant ShuklaPraveen KumarNo ratings yet

- Padeye Design: Input Sling Angle (From X-Z Plane)Document7 pagesPadeye Design: Input Sling Angle (From X-Z Plane)Alexandre FreitasNo ratings yet

- Physical Production Relationships (Chapter 2) : Principles of Agricultural and Resource Economics AE - 201Document17 pagesPhysical Production Relationships (Chapter 2) : Principles of Agricultural and Resource Economics AE - 201Ibtisam AliNo ratings yet

- Object Oriented Programming With C++Document2 pagesObject Oriented Programming With C++Azhar JamilNo ratings yet

- Determining Fake Statements Made by Public Figures by Means of Artificial IntelligenceDocument8 pagesDetermining Fake Statements Made by Public Figures by Means of Artificial Intelligenceyarrabandi Sk yogesh reddyNo ratings yet

- Current PolarizingDocument18 pagesCurrent PolarizingShafqat HussnainNo ratings yet

- LogarithmsDocument5 pagesLogarithmsAkshay KakaniNo ratings yet

- Meaning of DispersionDocument24 pagesMeaning of DispersionDhairyaa BhardwajNo ratings yet

- (1997 Primavera Et. Al) Tensile Behavior of Cast-In-Place and Undercut Anchors in High-Strength ConcreteDocument10 pages(1997 Primavera Et. Al) Tensile Behavior of Cast-In-Place and Undercut Anchors in High-Strength Concretep.c19.22100% (1)

- Pipe Flow ReviewDocument12 pagesPipe Flow ReviewsamadonyNo ratings yet

- Empowering Progress Education Innovations and Financi - 2023 - Journal of CleaDocument14 pagesEmpowering Progress Education Innovations and Financi - 2023 - Journal of CleaAna MartinsNo ratings yet

- FUNDAMENTALS OF FLUID MECHANICS, Cengel Cimbala Solutions Chap01 PDFDocument11 pagesFUNDAMENTALS OF FLUID MECHANICS, Cengel Cimbala Solutions Chap01 PDFLuis Varela50% (2)

- Quantum V4 N5Document68 pagesQuantum V4 N5Edney MeloNo ratings yet

- Page No.197 PDFDocument468 pagesPage No.197 PDFdhruvi kapadiaNo ratings yet

- Inverted Pendulum MATLAB ManualDocument37 pagesInverted Pendulum MATLAB ManualnutanayaNo ratings yet

- Simulation of An Adaptive Digital Beamformer Using MatlabDocument9 pagesSimulation of An Adaptive Digital Beamformer Using MatlabIJARBESTNo ratings yet

- MC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Document24 pagesMC33078 Dual High-Speed Low-Noise Operational Amplifier: D (Soic), DGK (Msop), or P (Pdip) Package (Top View)Ravi JagtianiNo ratings yet

- Finite Element Method Simulation of Drilling Process On Metal-Matrix CompositesDocument5 pagesFinite Element Method Simulation of Drilling Process On Metal-Matrix Compositesumesh vishwakarmaNo ratings yet

- Electromagnetics in CFXDocument53 pagesElectromagnetics in CFXVignesh WaranNo ratings yet

- CH 01Document22 pagesCH 01Fauzan AlfiNo ratings yet

- Section 1: Introducing The Binomial DistributionDocument6 pagesSection 1: Introducing The Binomial DistributionVarul SinhaNo ratings yet

- Fluid Mechanics: Key Concepts Exercise-I Exercise-Ii Exercise-Iii Answer KeyDocument16 pagesFluid Mechanics: Key Concepts Exercise-I Exercise-Ii Exercise-Iii Answer Keyrebel rocksNo ratings yet

- Column DesignDocument26 pagesColumn DesignZakwan ZakariaNo ratings yet

- Thorndike 1957Document62 pagesThorndike 1957drwussNo ratings yet

- Low Velocity Impact With NastranDocument8 pagesLow Velocity Impact With NastranD.c. PhamNo ratings yet

- CIB19076Document12 pagesCIB19076Gudeta JifaraNo ratings yet

- Assignment 1Document2 pagesAssignment 1Zobia KainatNo ratings yet

- Jntu Citd M.tech Mechatronics SyllabusDocument24 pagesJntu Citd M.tech Mechatronics SyllabusSai KiranNo ratings yet

- Winter 2022Document18 pagesWinter 2022GAMING PLUS TECHNo ratings yet