Professional Documents

Culture Documents

ZG Chime/Buzzer Warning Systems 8U - 1

ZG Chime/Buzzer Warning Systems 8U - 1

Uploaded by

ensmartisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZG Chime/Buzzer Warning Systems 8U - 1

ZG Chime/Buzzer Warning Systems 8U - 1

Uploaded by

ensmartisCopyright:

Available Formats

ZG CHIME/BUZZER WARNING SYSTEMS 8U - 1

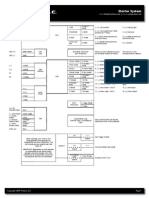

CHIME/BUZZER WARNING SYSTEMS

CONTENTS

page page

GENERAL INFORMATION DIAGNOSIS AND TESTING

INTRODUCTION . . . . . . . . . . . ............. 1 DRIVER DOOR AJAR SWITCH . . . . . . . . . . . . . 2

DESCRIPTION AND OPERATION DRIVER SEAT BELT SWITCH . . . . . . . . . . . . . . 3

BODY CONTROL MODULE . . . . . . . . . . . . . . . . 1 HEADLAMP SWITCH . . . . . . . . . . . . . . . . . . . . . 3

DRIVER DOOR AJAR SWITCH . . . . . . . . . . . . . 2 KEY-IN IGNITION SWITCH . . . . . . . . . . . . . . . . . 3

DRIVER SEAT BELT SWITCH . . . . . . . . . . . . . . 2 REMOVAL AND INSTALLATION

HEADLAMP SWITCH . . . . . . . . . . . . . . . . . . . . . 2 CHIME WARNING SYSTEM SWITCHES ...... 4

KEY-IN IGNITION SWITCH . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION versions of affected vehicle components have been

constructed as mirror-image of the LHD versions.

INTRODUCTION While most of the illustrations used in this group

This group covers the chime warning system, represent only the LHD version, the diagnostic and

which is standard factory-installed equipment on this service procedures outlined can generally be

model. The chime warning system provides an audi- applied to either version. Exceptions to this rule

ble warning to the driver under the following condi- have been clearly identified as LHD or RHD, if a

tions: special illustration or procedure is required.

• A door is ajar above a critical speed [about 16

kilometers-per-hour (10 miles-per-hour) for the driver

side front door, or about 5 kilometers-per-hour (3 DESCRIPTION AND OPERATION

miles-per-hour) for any other door]

• Check engine lamp illumination BODY CONTROL MODULE

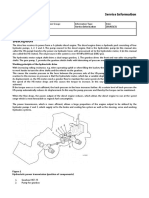

• Check gauges lamp illumination A Body Control Module (BCM) is used on this

• Driver side seat belt is not fastened (belt web- model to control and integrate many of the electronic

bing is on the retractor spool) with the ignition functions and features on the vehicle. The BCM con-

switch in the On position tains a central processing unit and interfaces with

• Head or park lamps are turned on with the igni- other modules in the vehicle on the Chrysler Colli-

tion switch Off and the driver side front door open sion Detection (CCD) data bus network.

• High speed warning - Gulf Coast Countries The CCD data bus network allows the sharing of

(export only) sensor information. This helps to reduce wire har-

• Key is in the ignition switch with the ignition ness complexity, reduce internal controller hardware,

switch Off and the driver side front door open and reduce component sensor current loads. At the

• Low fuel warning lamp illumination - less than same time, this system provides increased reliability,

about one-eighth tank of fuel remaining enhanced diagnostics, and allows the addition of

• Rear lamp failure many new feature capabilities.

• Transmission oil temperature is too high One of the functions and features that the BCM

• Turn signal remains on for about 1.6 kilometers supports is the chime warning system. The BCM con-

(one mile) with no decrease in speed or throttle open- tains a chime tone generator to perform the functions

ing of the chime warning module. The BCM uses hard-

• Washer level low lamp illumination. wired inputs, internal programming, and CCD data

Following are general descriptions of the major bus chime request message inputs to decide when a

components in the chime warning system. Refer to chime tone is required.

8W-44 - Interior Lighting or 8W-45 - Body Control The BCM is mounted under the driver side out-

Module in Group 8W - Wiring Diagrams for complete board end of the instrument panel, behind the instru-

circuit descriptions and diagrams. ment panel support armature and below the

outboard switch pod. Refer to Group 8E - Instrument

NOTE: This group covers both Left-Hand Drive

Panel Systems for the removal and installation pro-

(LHD) and Right-Hand Drive (RHD) versions of this

cedures.

model. Whenever required and feasible, the RHD

8U - 2 CHIME/BUZZER WARNING SYSTEMS ZG

DESCRIPTION AND OPERATION (Continued)

This group only covers the diagnosis and service of signal to the Body Control Module (BCM) park lamp

the hard-wired inputs used by the BCM to determine relay output circuit when the park or head lamps are

that a chime tone should be generated. For diagnosis turned on. The headlamp switch opens the park lamp

of the BCM, the CCD data bus, or the other elec- relay output circuit when the headlamp switch is

tronic modules on the CCD data bus that send chime turned off.

request messages to the BCM, refer to the proper The headlamp switch cannot be repaired and, if

Body Diagnostic Procedures manual. The BCM can faulty or damaged, the outboard switch pod unit

only be serviced by an authorized electronic repair must be replaced. Refer to Group 8E - Instrument

station. Refer to the latest Warranty Policies and Panel Systems for the service procedures.

Procedures manual for a current listing of authorized

repair stations.

DIAGNOSIS AND TESTING

DRIVER DOOR AJAR SWITCH

The driver door ajar switch is mounted to the DRIVER DOOR AJAR SWITCH

driver side front door latch pillar. The switch closes a For circuit descriptions and diagrams, refer to

path to ground for the Body Control Module (BCM) 8W-45 - Body Control Module in Group 8W - Wiring

driver front door ajar switch circuit when the driver Diagrams.

door is opened, and opens the ground path when the

WARNING: ON VEHICLES EQUIPPED WITH AIR-

driver door is closed.

BAGS, REFER TO GROUP 8M - PASSIVE

The driver door ajar switch cannot be repaired

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

and, if faulty or damaged, it must be replaced. Refer

STEERING WHEEL, STEERING COLUMN, OR

to Group 8Q - Vehicle Theft/Security Systems for the

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

service procedures.

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

DRIVER SEAT BELT SWITCH

BAG DEPLOYMENT AND POSSIBLE PERSONAL

The driver seat belt switch is integral to the driver

INJURY.

seat belt tip-half retractor assembly. The switch is

normally closed, providing a ground path to the Body (1) Open the driver side front door and note

Control Module (BCM) through the seat belt switch whether the interior lamps light. They should light.

sense circuit. The switch monitors the amount of seat If OK, see the diagnosis for the Key-In Ignition

belt webbing wound onto the seat belt retractor Switch or the Headlamp Switch in this group. If not

spool. When the seat belt tip-half webbing is pulled OK, go to Step 2.

out of the retractor far enough to engage the seat (2) Disconnect and isolate the battery negative

belt buckle-half, the switch opens the ground path. cable. Unplug the driver door ajar switch from its

The driver seat belt switch cannot be repaired and, wire harness connector. Check for continuity between

if faulty or damaged, the entire driver seat belt tip- the switch terminal and the switch body. There

half and retractor unit must be replaced. Refer to should be continuity with the switch plunger

Group 23 - Body for the service procedures. released, and no continuity with the switch plunger

depressed. If OK, go to Step 3. If not OK, replace the

KEY-IN IGNITION SWITCH faulty switch.

The key-in ignition switch is integral to the igni- (3) Unplug the black 14-way wire harness connec-

tion switch, which is mounted on the right side of the tor from the Body Control Module (BCM). Check for

steering column. It closes a path to ground for the continuity between the driver door ajar switch wire

Body Control Module (BCM) when the ignition key is harness connector and a good ground. There should

inserted in the ignition lock cylinder. The key-in igni- be no continuity. If OK, go to Step 4. If not OK,

tion switch opens the ground path when the key is repair the short circuit as required.

removed from the ignition lock cylinder. (4) Check for continuity between the driver side

The key-in ignition switch cannot be repaired and, front door ajar switch sense circuit cavities of the

if faulty or damaged, the entire ignition switch must driver door ajar switch wire harness connector and

be replaced. Refer to Group 8D - Ignition Systems for the black 14-way BCM wire harness connector. There

the service procedures. should be continuity. If OK, use a DRB scan tool and

the proper Diagnostic Procedures manual to test the

HEADLAMP SWITCH BCM. If not OK, repair the open circuit as required.

The headlamp switch is integral to the outboard

switch pod located in the instrument panel, outboard

of the steering column. It provides a battery voltage

ZG CHIME/BUZZER WARNING SYSTEMS 8U - 3

DIAGNOSIS AND TESTING (Continued)

DRIVER SEAT BELT SWITCH SERVICE. FAILURE TO TAKE THE PROPER PRE-

For circuit descriptions and diagrams, refer to CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

8W-45 - Body Control Module in Group 8W - Wiring BAG DEPLOYMENT AND POSSIBLE PERSONAL

Diagrams. INJURY.

WARNING: ON VEHICLES EQUIPPED WITH AIR- (1) Disconnect and isolate the battery negative

BAGS, REFER TO GROUP 8M - PASSIVE cable. Remove the steering column shrouds. Refer to

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY Group 8D - Ignition Systems for the procedures.

STEERING WHEEL, STEERING COLUMN, OR Unplug the key-in ignition switch wire harness con-

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR nector from the ignition switch.

SERVICE. FAILURE TO TAKE THE PROPER PRE- (2) Check for continuity between the key-in igni-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR- tion switch sense and ground terminals of the key-in

BAG DEPLOYMENT AND POSSIBLE PERSONAL ignition switch. There should be continuity with the

INJURY. key in the ignition lock cylinder, and no continuity

with the key removed from the ignition lock cylinder.

(1) Disconnect and isolate the battery negative If OK, go to Step 3. If not OK, replace the faulty igni-

cable. Unplug the driver seat belt switch wire har- tion switch assembly.

ness connector from the driver seat belt retractor (3) Check for continuity between the ground cir-

behind the B pillar trim. Check for continuity cuit cavity of the key-in ignition switch wire harness

between the seat belt switch sense circuit and the connector and a good ground. There should be conti-

ground circuit cavities of the seat belt retractor half nuity. If OK, go to Step 4. If not OK, repair the open

of the driver seat belt switch wire harness connector. circuit to ground as required.

There should be continuity with the seat belt web- (4) Unplug the black 24-way wire harness connec-

bing retracted, and no continuity with the seat belt tor from the Body Control Module (BCM). Refer to

webbing extracted far enough to buckle the seat belt. Group 8E - Instrument Panel Systems for the proce-

If OK, go to Step 2. If not OK, replace the faulty seat dures. Check for continuity between the key-in igni-

belt tip-half and retractor assembly. tion switch sense circuit cavity of the key-in ignition

(2) Check for continuity between the ground cir- switch wire harness connector and a good ground.

cuit cavity in the body half of the driver seat belt There should be no continuity. If OK, go to Step 5. If

switch wire harness connector and a good ground. not OK, repair the short circuit as required.

There should be continuity. If OK, go to Step 3. If not (5) Check for continuity between the key-in igni-

OK, repair the circuit to ground as required. tion switch sense circuit cavities of the key-in igni-

(3) Unplug the black 14-way wire harness connec- tion switch wire harness connector and the black

tor from the Body Control Module (BCM). Check for 24-way BCM wire harness connector. There should

continuity between the seat belt switch sense circuit be continuity. If OK, use a DRB scan tool and the

cavity in the body half of the driver seat belt switch proper Diagnostic Procedures manual to test the

wire harness connector and a good ground. There BCM. If not OK, repair the open circuit as required.

should be no continuity. If OK, go to Step 4. If not

OK, repair the short circuit as required. HEADLAMP SWITCH

(4) Check for continuity between the seat belt If the park lamps are inoperative, refer to Group

switch sense circuit cavities in the body half of the 8L - Lamps for diagnosis. If the park lamps operate,

driver seat belt switch wire harness connector and but there is no chime warning issued with the driver

the 14-way BCM wire harness connector. There side front door open, proceed as follows. For circuit

should be continuity. If OK, use a DRB scan tool and descriptions and diagrams, refer to 8W-40 - Instru-

the proper Diagnostic Procedures manual to test the ment Cluster or 8W-44 - Interior Lighting in Group

BCM. If not OK, repair the open circuit as required. 8W - Wiring Diagrams.

KEY-IN IGNITION SWITCH WARNING: ON VEHICLES EQUIPPED WITH AIR-

For circuit descriptions and diagrams, refer to BAGS, REFER TO GROUP 8M - PASSIVE

8W-40 - Instrument Cluster or 8W-44 - Interior RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

Lighting in Group 8W - Wiring Diagrams. STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

WARNING: ON VEHICLES EQUIPPED WITH AIR- SERVICE. FAILURE TO TAKE THE PROPER PRE-

BAGS, REFER TO GROUP 8M - PASSIVE CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY BAG DEPLOYMENT AND POSSIBLE PERSONAL

STEERING WHEEL, STEERING COLUMN, OR INJURY.

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

8U - 4 CHIME/BUZZER WARNING SYSTEMS ZG

DIAGNOSIS AND TESTING (Continued)

(1) Disconnect and isolate the battery negative REMOVAL AND INSTALLATION

cable. Remove the outboard switch pod from the

instrument panel. Refer to Group 8E - Instrument CHIME WARNING SYSTEM SWITCHES

Panel Systems for the procedures. Unplug the head- Service procedures for the various hard-wired

lamp switch wire harness connector. Unplug the switches used in the chime warning system can be

black 24-way wire harness connector from the Body found in the appropriate group as follows:

Control Module (BCM). Check for continuity between • Driver door ajar switch - refer to Group 8Q -

the park lamp relay output circuit cavity of the head- Vehicle Theft/Security Systems

lamp switch wire harness connector and a good • Driver seat belt switch - refer to Group 23 -

ground. There should be no continuity. If OK, go to Body

Step 2. If not OK, repair the short circuit as • Headlamp switch - refer to Group 8E - Instru-

required. ment Panel Systems

(2) Check for continuity between the park lamp • Key-in ignition switch - refer to Group 8D - Igni-

relay output circuit cavities of the headlamp switch tion Systems.

wire harness connector and the black 24-way BCM

wire harness connector. There should be continuity. If

OK, use a DRB scan tool and the proper Diagnostic

Procedures manual to test the BCM. If not OK,

repair the open circuit as required.

You might also like

- Fuse Box Diagram Chrysler Town & Country (2008-2016)Document49 pagesFuse Box Diagram Chrysler Town & Country (2008-2016)Fab SveNo ratings yet

- Volkswagen Audi Diagnostic Trouble Code DTC OverviewDocument27 pagesVolkswagen Audi Diagnostic Trouble Code DTC OverviewAnonymous UnVea6Tn100% (2)

- 1996 Chrysler Sebring Jxi 1996 Chrysler Sebring JxiDocument10 pages1996 Chrysler Sebring Jxi 1996 Chrysler Sebring JxiCarlos HurtadoNo ratings yet

- 745 Cat EtDocument6 pages745 Cat EtLucky advantureNo ratings yet

- 2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XDocument12 pages2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XJorge RaulNo ratings yet

- 2005 KJ PowertrainDocument520 pages2005 KJ PowertrainFrancisco De LimaNo ratings yet

- Sbec 3Document7 pagesSbec 3gatito1971No ratings yet

- 2001 Camaro 3800 PCM Pin OutsDocument5 pages2001 Camaro 3800 PCM Pin OutsRashid JuarezNo ratings yet

- Ford Ignition Tfi EditDocument5 pagesFord Ignition Tfi EditRafa Perez Hernandez100% (2)

- ICOP-6054VE: Embedded 386SX PC104 CPU ModuleDocument47 pagesICOP-6054VE: Embedded 386SX PC104 CPU ModuleCarlos Junior100% (1)

- Jtec PDFDocument9 pagesJtec PDFcesar Miranda100% (1)

- 02 RgebDocument1,168 pages02 Rgebprožnik100% (3)

- 02 RgepDocument332 pages02 RgepEngine Tuning UpNo ratings yet

- D75KS Manual Partes PDFDocument806 pagesD75KS Manual Partes PDFSara100% (3)

- 2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00Document2 pages2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00AlainbravopaezNo ratings yet

- CompuStar CM5200Document7 pagesCompuStar CM5200JamesParadisoNo ratings yet

- 08M Passive Restraint SystemsDocument12 pages08M Passive Restraint SystemsDane WallaceNo ratings yet

- ENGINE Starting - Service Information - Ram Pickup PDFDocument27 pagesENGINE Starting - Service Information - Ram Pickup PDFcharlesNo ratings yet

- Model Indentifiction For Cars TestsDocument454 pagesModel Indentifiction For Cars TestsRichard Thodé JrNo ratings yet

- 01 WgepDocument462 pages01 WgepKenneth PaulNo ratings yet

- Dodge Ram 2500 HEMI Magnum 5.7l V8 2004Document6 pagesDodge Ram 2500 HEMI Magnum 5.7l V8 2004Ana RoblesNo ratings yet

- Operational Manual - LITE 3Document52 pagesOperational Manual - LITE 3Navish Kumar Singh100% (1)

- 2005 KJ Transmission DSLDocument244 pages2005 KJ Transmission DSLmock_er100% (2)

- Antirrobo MonteroDocument136 pagesAntirrobo MonteroJorge RuzNo ratings yet

- ADS Manual 5310Document9 pagesADS Manual 5310extremesfire1571No ratings yet

- ENGINEDocument2,790 pagesENGINEAdan Flores CorreaNo ratings yet

- 02wgeb PDFDocument782 pages02wgeb PDFAlex BoxNo ratings yet

- GM OBD Trouble Code InfoDocument3 pagesGM OBD Trouble Code InfoJuicy69Mann0% (1)

- 2013 GMC Terrain OwnersDocument362 pages2013 GMC Terrain Ownerstechnowizard100% (2)

- Toro Super Recycler 3322-287Document24 pagesToro Super Recycler 3322-287skustarzNo ratings yet

- Reverse Camera Installation Guide: Tools and Supplies NeededDocument9 pagesReverse Camera Installation Guide: Tools and Supplies Neededaxell AxelzonNo ratings yet

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- 2008-08-09 105818 Alarm 96 Jeep CherokeeDocument9 pages2008-08-09 105818 Alarm 96 Jeep CherokeeAxel FernandezNo ratings yet

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- 338 Tachometer InstructionsDocument3 pages338 Tachometer InstructionsjuanNo ratings yet

- 084 - Hydraulic BrakesDocument180 pages084 - Hydraulic BrakesGedas GvildysNo ratings yet

- Shift InterlockDocument87 pagesShift InterlockAbelCastellanosCruzNo ratings yet

- Technical Service Information: Chrysler 45rfeDocument8 pagesTechnical Service Information: Chrysler 45rfeAlfredo PerezNo ratings yet

- Grand Cherokee Color Code 1999-2000Document1 pageGrand Cherokee Color Code 1999-2000NotengoNombre TampocoApellido100% (1)

- Eti 4M09 4 09 04 29 GM TacDocument8 pagesEti 4M09 4 09 04 29 GM TaclaurianNo ratings yet

- Manual Trans ServiceDocument3 pagesManual Trans ServiceGeraldo Pozos VazquezNo ratings yet

- Vwunlli 8 PP 2 S 69 Niim 8Document415 pagesVwunlli 8 PP 2 S 69 Niim 8viper_oneNo ratings yet

- How To Adjust Hand Brake On Volvo XC90Document1 pageHow To Adjust Hand Brake On Volvo XC90Johnny Sins100% (1)

- Accessories: Chrysler Town & CountryDocument8 pagesAccessories: Chrysler Town & CountryswiftNo ratings yet

- Hummer H2 2003-2005Document4 pagesHummer H2 2003-2005Yoga AriantNo ratings yet

- 86 Manual PDFDocument3 pages86 Manual PDFAdrian ReyesNo ratings yet

- 3 Series: The Ultimate Driving MachineDocument54 pages3 Series: The Ultimate Driving MachinekcornNo ratings yet

- 2005 Chevrolet Classic Owner's ManualDocument320 pages2005 Chevrolet Classic Owner's ManualDjango RodNo ratings yet

- Start No ClickDocument4 pagesStart No Clicklamping_apNo ratings yet

- M R S B E C (Sbec Iii) : Opar Emanufactured Ingle Oard Ngine OntrollerDocument7 pagesM R S B E C (Sbec Iii) : Opar Emanufactured Ingle Oard Ngine OntrollercristntNo ratings yet

- Vincard16 Car 08-23-16 r1.12Document29 pagesVincard16 Car 08-23-16 r1.12rahulNo ratings yet

- Fuse & Relay MalibuDocument21 pagesFuse & Relay MalibuBasim FakhryNo ratings yet

- Alarm Eaglemaster E8-LCD (ENG)Document44 pagesAlarm Eaglemaster E8-LCD (ENG)bdi_roNo ratings yet

- Ford FaultcodesDocument5 pagesFord FaultcodesJuan PabloNo ratings yet

- Solenoide lb7Document1 pageSolenoide lb7Anonymous 5tkF5bFwONo ratings yet

- Diesel PowertrainDocument284 pagesDiesel PowertrainCOSTIN NESTIANNo ratings yet

- 4 Instrument Cluster 10: 2006 05+ Mustang (197) Owners Guide (Post-2002-Fmt) USA (Fus)Document248 pages4 Instrument Cluster 10: 2006 05+ Mustang (197) Owners Guide (Post-2002-Fmt) USA (Fus)ricabreraNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- 93ZJ Secc 8D Ignition SystemsDocument40 pages93ZJ Secc 8D Ignition Systemshelgith74No ratings yet

- 08T - Power Mirror Systems - Jeep ZJ - 96 - Service ManualDocument6 pages08T - Power Mirror Systems - Jeep ZJ - 96 - Service ManualThiago CulauNo ratings yet

- ZG Power Window Systems 8S - 1Document8 pagesZG Power Window Systems 8S - 1ensmartisNo ratings yet

- General Information: Vehicle Identification Number Decoding ChartDocument10 pagesGeneral Information: Vehicle Identification Number Decoding ChartensmartisNo ratings yet

- ZG Exhaust System and Intake Manifold 11 - 1Document14 pagesZG Exhaust System and Intake Manifold 11 - 1ensmartisNo ratings yet

- Emission Control Systems: On-Board DiagnosticsDocument28 pagesEmission Control Systems: On-Board Diagnosticsensmartis100% (1)

- Ezg 22Document10 pagesEzg 22ensmartisNo ratings yet

- Ezg 19Document32 pagesEzg 19ensmartisNo ratings yet

- Ezg 13Document12 pagesEzg 13ensmartisNo ratings yet

- Fuel System: General InformationDocument108 pagesFuel System: General InformationensmartisNo ratings yet

- General Service InformationDocument48 pagesGeneral Service InformationensmartisNo ratings yet

- Ezg 8TDocument8 pagesEzg 8TensmartisNo ratings yet

- ZG Vehicle Theft/Security Systems 8Q - 1Document22 pagesZG Vehicle Theft/Security Systems 8Q - 1ensmartisNo ratings yet

- ZG Power Window Systems 8S - 1Document8 pagesZG Power Window Systems 8S - 1ensmartisNo ratings yet

- ZG Turn Signal and Hazard Warning Systems 8J - 1Document6 pagesZG Turn Signal and Hazard Warning Systems 8J - 1ensmartisNo ratings yet

- Electrically Heated Systems: Defogger SystemDocument10 pagesElectrically Heated Systems: Defogger SystemensmartisNo ratings yet

- ZG Horn Systems 8G - 1Document4 pagesZG Horn Systems 8G - 1ensmartisNo ratings yet

- 08K Wiper & Washer SystemsDocument14 pages08K Wiper & Washer SystemsDane WallaceNo ratings yet

- 08E Instrument Panel SystemsDocument70 pages08E Instrument Panel SystemsDane WallaceNo ratings yet

- ZG Audio Systems 8F - 1Document18 pagesZG Audio Systems 8F - 1ensmartisNo ratings yet

- ZG Charging System 8C - 1Document10 pagesZG Charging System 8C - 1ensmartisNo ratings yet

- 08D Ignition SystemDocument24 pages08D Ignition SystemDane WallaceNo ratings yet

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- ZG Battery 8A - 1Document18 pagesZG Battery 8A - 1ensmartisNo ratings yet

- ZG Cooling System 7 - 1Document72 pagesZG Cooling System 7 - 1ensmartisNo ratings yet

- Welcome To The 1997 Jeep Grand Cherokee (RHD & LHD) Interactive Electronic Service Manual!Document1 pageWelcome To The 1997 Jeep Grand Cherokee (RHD & LHD) Interactive Electronic Service Manual!ensmartisNo ratings yet

- 02 SuspensionDocument32 pages02 SuspensionDane WallaceNo ratings yet

- Lubrication and Maintenance: General InformationDocument14 pagesLubrication and Maintenance: General InformationensmartisNo ratings yet

- OBD2 CodesDocument35 pagesOBD2 CodesJubril AkinwandeNo ratings yet

- 403C-15G ElectropaK (PN1663 75th)Document2 pages403C-15G ElectropaK (PN1663 75th)OGNo ratings yet

- HONDA Marketing Strategies of Honda SIEL Cars India LTDDocument12 pagesHONDA Marketing Strategies of Honda SIEL Cars India LTDKunal Behrani0% (1)

- Edited - VCDS TutorialDocument153 pagesEdited - VCDS TutorialCherles Ponte100% (3)

- SSP 446 2.5L TDI Euro V Engines With SCR System in CrafterDocument36 pagesSSP 446 2.5L TDI Euro V Engines With SCR System in CrafterRobert SearleNo ratings yet

- Diesel Engine ComponentsDocument33 pagesDiesel Engine ComponentsRicky Thomas100% (1)

- ZF 5HP19HL PDFDocument4 pagesZF 5HP19HL PDFwilderNo ratings yet

- Prof. Dr. Ulrich Hackenberg Annual Press Conference 2014Document11 pagesProf. Dr. Ulrich Hackenberg Annual Press Conference 2014AUDI AGNo ratings yet

- SM - VOLVO L50D WHEEL LOADER Service Repair ManualDocument20 pagesSM - VOLVO L50D WHEEL LOADER Service Repair ManualJulio CesarNo ratings yet

- 936 Tapping Machine 0915 PDFDocument4 pages936 Tapping Machine 0915 PDFAndrés Vergara GonzálezNo ratings yet

- EWD 180 TR1pwrrw97Document6 pagesEWD 180 TR1pwrrw97Henry CanalesNo ratings yet

- Massey Ferguson: Parts CatalogueDocument523 pagesMassey Ferguson: Parts CatalogueAngel Bret SerranoNo ratings yet

- Cylinder Head and Valves/Special Tools: RG5100 - UN-23AUG88Document21 pagesCylinder Head and Valves/Special Tools: RG5100 - UN-23AUG88WSMengine WSMengineNo ratings yet

- ELFL004Document15 pagesELFL004Destry YoungNo ratings yet

- Research Paper SuspensionDocument7 pagesResearch Paper SuspensionAnirudh GuptaNo ratings yet

- Performance Curve V158TIH 2010-04-29Document1 pagePerformance Curve V158TIH 2010-04-29ramsi17No ratings yet

- Vehicle Mileage LogbookDocument21 pagesVehicle Mileage LogbookHemen Sharadkumar UpadhyayaNo ratings yet

- Chain LessDocument30 pagesChain LessAbhyudaya PrakashNo ratings yet

- Gross: 194 KW 260 HP / 1950 Min Net: 186 KW 250 HP / 1950 Min 19300 KG (With Ripper 22150 KG) 4.32 MDocument20 pagesGross: 194 KW 260 HP / 1950 Min Net: 186 KW 250 HP / 1950 Min 19300 KG (With Ripper 22150 KG) 4.32 MSabahNo ratings yet

- DYNAPAC CA5000、5500、6000、6500Document164 pagesDYNAPAC CA5000、5500、6000、6500Cui100% (2)

- Mitsubishi Forklift Fd25 Service ManualDocument24 pagesMitsubishi Forklift Fd25 Service Manualfrankgray081100mjz99% (135)

- Main EngineDocument10 pagesMain EngineFe CaprichoNo ratings yet

- D10R Hydraulic System Track-Type TractorDocument2 pagesD10R Hydraulic System Track-Type Tractorsarahrou100% (1)

- Case Cx210b Service Material EngineDocument8 pagesCase Cx210b Service Material Engineharriet100% (62)

- FMVSS 109 2022-10-01Document11 pagesFMVSS 109 2022-10-01skr_757No ratings yet

- Reciprocating Piston Engine Lubrication SystemDocument39 pagesReciprocating Piston Engine Lubrication SystemccoyureNo ratings yet

- FMVSS Time LineDocument3 pagesFMVSS Time LineMNo ratings yet