Professional Documents

Culture Documents

Personal Computer (Pentium - IV) : Ntroduction Arket Otential

Personal Computer (Pentium - IV) : Ntroduction Arket Otential

Uploaded by

anilshaw27Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Personal Computer (Pentium - IV) : Ntroduction Arket Otential

Personal Computer (Pentium - IV) : Ntroduction Arket Otential

Uploaded by

anilshaw27Copyright:

Available Formats

18

Personal Computer (Pentium IV)

PRODUCT CODE (ASICC) QUALITY AND STANDARDS PRODUCTION CAPACITY YEAR OF PREPARATION PREPARED AND UPDATED BY : 78304 : N.A. : Qty. Value : 360 Nos. (per annum) : Rs. 1,44,00,000

: 20022003 : Small Industries Service Institute Kurla Andheri Road, Sakinaka, Mumbai And Office of the Development Commissioner (Small Scale Industries), Electronics and Electrical Division, 7th Floor, Nirman Bhavan, New Delhi-110011.

INTRODUCTION

Personal Computers are widely used these days in office automation in Business/trade, Industries, Banks, Insurance Establishments, Hospitals, Hotels, Railway, Air-lines and Transport services etc. Personal Computer hardware consists of CPU, Memory, Direct memory access, Peripheral controllers and interfaces, Floppy disk drives and hard disk drives. The peripherals consists of Keyboard, CRT Monitor, Printer, Modem and Mouse etc. and connected to the main PC through cables and interfaces. Switched Mode Power Supply (SMPS) are used to power the personal computer for different dc voltage: +5V, -5V, +12V and -12V. The SMPS is housed in the PC cabinet . The CRT Monitor and Printer have their own power supply units.

MARKET POTENTIAL

The market for personal computer is expanding day by day due to rapid computerisation of offices for accounts, inventory, sales, correspondence and communication etc., in business/trade, industry, banks, insurance establishments, hotels, tourism sector, hospitals etc., and also due to rapid computerisation of reservations in railways, air-lines and other transport services. The demand for personal computer (PCs) continues to grow and will continue to account for a large share of the total computer and peripherals spending in India. According to the Manufacturers Association of Information Technology (MAIT), during 2000-01, more than 1.88 million desktops were sold in India, registering

P ERSONAL COMPUTER ( PENTIUM-IV)

131

a 34 per cent increase over the previous year. Over 135 small, medium and large firms manufacture computer in India. Many multinational companies such as HP, IBM, Compaq and ACER have a strong presence and manufacturing facilities in India. Dell has a marketing, sales and service operation in the country, providing PCs to the market from its facilities in Malaysia. Toether, the MNC brands have garnered a 27 per cent market share. Local Indian brands have a market share of 20 per cent, with the 53 per cent balance dominated by PCs assembled by Small Indian firms. The small manufacturers have to face tough competion from multinationals in terms of price, quality supply schedules and after sales services.

B ASIS AND PRESUMPTIONS

i) The basis for calculation of production capacity has been taken on single shift basis on 75% efficiency. ii) The maximum capacity utilization on single shift basis for 300 days a year. During first year and second year of operations the capacity utilization is 60% and 80% respectively. The unit is expected to achieve full capacity utilization from the third year onwards. iii) The salaries and wages, cost of raw materials, utilities, rents, etc. are based on the prevailing rates in and around Mumbai. These cost factors are likely to vary with time and location. iv) Interest on term loan and working capital loan has been taken at the rate of 16% on an average. This rate may vary depending upon

the policy of the financial institutions/agencies from time to time. v) The cost of machinery and equipments refer to a particular make/model and prices are approximate. vi) The break-even point percentage indicated is of full capacity utilization. vii) The project preparation cost etc. whenever required could be considered under pre-operative expenses. viii) The essential production machinery and test equipment required for the project have been indicated. The unit may also utilize common test facilities available at Electronics Test and Development Centres (ETDCs) and Electronic Regional Test Laboratories (ERTLs) set up by the State Governments and STQC Directorate of the Department of Information Technology, Ministry of Communication and Infor mation Technology, to manufacture products conforming to Bureau of Indian Standards.

IMPLEMENTATION SCHEDULE

The major activities in the implementation of the project has been listed and the average time for implementation of the project is estimated at 12 months:

Sl. Name of Activity No. Period in Months (Estimated)

1 1 3

1. Preparation of project report 2. Registration and other formalities 3. Sanction of loan by financial institutions

132

P ERSONAL COMPUTER ( PENTIUM-IV)

Sl. Name of Activity No.

4. Plant and Machinery (a) Placement of orders (b) Procurement (c) Power connection/ Electrification d) Installation/Erection of machinery/Test Equipment 5. Procurement of raw materials 6. Recruitment of Technical Personnel etc. 7. Trial production 8. Commercial production 1 2 2 2 2 2 11 12

Period in Months (Estimated)

cabinet and the interconnection done. The completed assembly i.e. compact unit is tested for various performance parameters by the help of dedicated software. The tested units are then packed well in cardboard packing cases to withstand shock and vibration during transportation and handling. Quality Control and Standards Intel pentium IV processor (1.9 GHZ) 128 MB-RAM AGP-8MB (VGA memory on board) Hard Disk Drive 40 GB Key Board (111 Key) 36 cm (14) colour monitor (Digital) Modem Inbuilt 56 Kbps Scroll Mouse Window 2000 XP Home edition 48/52x CD ROM Production Capacity (per annum)

Quantity 360 Nos. Value (Rs.) 1,44,00,000

Notes 1. Many of the above activities shall be initiated concurrently. 2. Procurement of raw materials commences from the 8th month onwards. 3. When imported plant and machinery are required, the implementation period of project may vary from 12 months to 15 months.

TECHNICAL ASPECTS

Process of Manufacture The manufacture of personal computer involves the assembly of Electronics and Electromechanical subassemblies, peripherals and integrating them into a compact unit. As per the design the motherboard, VGA card (Display card) are procured/assembled depending upon the volume of production. The other sub-assemblies Hard disk drives, floppy disk drive, cabinet with SMPS are procured from out side alongwith the peripherals i.e. Monitor (colour) Computer Keyboard, mouse etc. The mother-board alongwith other subassemblies are mounted in the

Motive Power Pollution Control

5KVA (Approx.)

The Govt. accords utmost importance to control environmental pollution. The small-scale entrepreneurs should have an environmental friendly attitude and adopt pollution control measures by process modification and technology substitution. India having acceded to the Montreal Protocol in Sept. 1992, the production and use of Ozone Depleting Substances (ODS) like Chlorofluoro Carbon (CFC), Carbon Tetrachloride, Halons and Methyl Chloroform etc. need to be phased out

P ERSONAL COMPUTER ( PENTIUM-IV)

133

immediately with alternative chemicals/ solvents. A notification for detailed Rules to regulate ODS phase out under the Environment Protection Act, 1986 have been put in place with effect from 19th July 2000. The following steps are suggested which may help to control pollution in electronics industry wherever applicable: i) In electronic industry fumes and gases are released during hand soldering/wave soldering/Dip soldering, which are harmful to people as well as environment and the end products. Alternate technologies may be used to phase out the existing polluting technologies. Numerous new fluxes have been developed containing 2-10% solids as opposed to the traditional 15-35% solids. ii) Electronic industry uses CFC, Carbon Tetrachloride and Methyl Chloroform for cleaning of printed circuit boards after assembly to remove flux residues left after soldering, and various kinds of foams for packaging. Many alternative solvents could replace CFC-113 and Methyl Chloroform in electronics cleaning. Other Chlorinated solvents such as Trichloroethylene, Perchloroethylene and Methylene Chloride have been used an effective cleaners in electronics industry for many years. Other organic solvents such as Ketones and Alcohols are effective in removing both solder fluxes and many polar contaminants. Energy Conservation With the growing energy needs and shortage coupled with rising energy

cost, a greater thrust in energy efficiency in industrial sector has been given by the Govt. of India since 1980s. The Energy Conservation Act, 2001 has been enacted on 18th August 2001, which provides for efficient use of energy, its conservation and capacity building of Bureau of Energy Efficiency created under the Act. The following steps may help for conservation of electrical energy: i) Adoption of energy conserving technologies, production aids and testing facilities. ii) Efficient management of process/ manufacturing machineries and systems, QC and testing equipments for yielding maximum Energy Conservation. iii) Optimum use of electrical energy for heating during soldering process can be obtained by using efficient temperature controlled soldering and desoldering stations. iv) Periodical maintenance of motors, compressors etc. v) Use of power factor correction capacitors. Proper selection and layout of lighting system; timely switching on-off of the lights; use of compact fluorescent lamps wherever possible etc.

FINANCIAL ASPECTS

A. Fixed Capital

(i) Land and Building Built up area Office, Stores Assembly and Testing Rent Payble/month 200 Sq. Mtrs. 50 Sq. mtrs. 150 Sq. mtrs. Rs. 20,000

134

P ERSONAL COMPUTER ( PENTIUM-IV)

(ii) Plant and Machinery, Testing Equipments Description 1. Oscilloscope (0-100 MHZ) (dual trace storage type) Ind./ Imp Ind. Qty. Amount Nos. (Rs.) 1 80,000 Sl. Designation No. 6. Peon 7. Watchman 8. Skilled Workers 2 1,00,000 3 9. Unskilled workers 2 No. 1 Salary/ month(Rs.) 1,000 1,000 2,500 2,000 Total Total (Rs.) 1,000 1,000 7,500 4,000 28,500 4,275 32,775 33,000

2. Computer testing system Ind. (consisting of CPU, Monitor, Keyboard, FDD, HDD, Communication Driver, Modem, Mouse, Printer and dedicated test software) 3. LCR-Q Meter (Digital) 4. D.C. Power Supply 30V, 2A 6. Analog Multimeter (iii) Other Fixed Assets 7. Office equipment, 8. Furniture and Working tables 9. Tools, Jigs, Fixtures, Soldering Iron/Stations, IC Insertor, extractor etc. 10. Electrification charges @ 10% of the cost of plant and machinery 11. Pre-operative Expenses Total G. Total or Say Ind. Ind.

Add Perquisites @ 15% of salary

Total or Say 1 3 2 5 15,000 10,000 17000 5000 2,27,000 27,000 40,000 30,000

(ii) Raw Material Requirement (per month) Particulars 1. Intel Pentium IV Processors 1.9 GHz/Chipset/845 GL with Mother Board 2. Monitor Colour (14) SVGA 3. Key Board (111 Keys) 4. 40 GB Hard Disk Drive 5. 52 CD ROM 6. Modem Internet Card 7. 10/100 Ether Net Card 8. 1.44 MB Floppy Disk Drive Ind/ Cost/ Imp. Unit (Rs.) Imp. 15,000

5. 4 digit digital Multimeter Ind. Ind. Total

Ind. Ind. Imp. Imp. Ind. Ind. Ind. Ind. Ind. LS LS Ind.

5,500 700 4,500 1,500 500 700 500 500 1,500 300 100 1000 32,300

22,700

9. Scroll Mouse 3 button 10. SMPS with Cabinet and other accessories

20,000 1,39,700 366700 3,67,000

11. Cables and Power Cords 12. Consumables (Solders and Packing Materials) 13. Multimedia Speakers Total Cost of Raw Materials for 30 Units (per month)

B. Working Capital (per month)

(i) Staff and Labour Sl. Designation No. 1. Manager 2. Sales and Service Engineer 3. Supervisor 4. Accountant 5. Clerk/Typist No. 1 1 1 1 1 Salary (Rs.) 6,000 3,000 2,500 2,000 1,500 Total (Rs.) 6,000 3,000 2,500 2,000 1,500

Rs. 9,69,000

Note: The quantity and quality of raw materials varies with the design requirement and features of Personal Computer.

(iii) Utilities (per month) Power Water Total (Rs.) 6,000 500 6,500

P ERSONAL COMPUTER ( PENTIUM-IV)

(iv) Other Contingent Expenses (per month) (Rs.) 1. Rent 2. Postage and stationery 3. Telephone/Telex/Fax charges 4. Repair and maintenance 5. Transport and conveyance charges 6. Advt. and publicity 7. Insurance and taxes 8. Miscellaneous expenditure Total 20,000 2,000 2,000 2,000 5,000 7,000 1,000 5,000 44,000 (5) Rate of Return Profit per annum 100 Total capital investment 11,62,500 100 35,24,500 32.98%

135

= = =

(6) Break-even Point Fixed Cost (per annum) Rent Depreciation on machinery and equipment @ 10 % Depreciation on tools, jigs and fixtures @ 25% Depreciation on office equipment, furniture @ 20% Interest on total capital investment @ 16% Insurance and Taxes 40% of Salaries and wages 40% of other contingent expenses and utilities (excluding rent and insurance) (Rs.) 2,40,000 22,700 7,500 13,400 5,63,920 12,000 1,58,400 1,41,600 11,59,520 11,59,500

(v) Total Recurring Expenditure (per month) (i + ii + iii + iv) Rs. 10,52,500

C. Total Capital Investment

Fixed Capital Total Rs. 3,67,000 Rs. 35,24,500 Working Capital on 3 months basis Rs. 31,57,500

FINANCIAL ANALYSIS

(1) Cost of Production (per annum) Total recurring expenditure Depreciation on machinery and equipment @ 10 % Depreciation on tools, jigs and fixtures @ 25% Depreciation on office equipment, furniture @ 20% Interest on total capital investment @ 16% Total or Say (2) Turnover (per annum) Item Qty. Rate/ (Nos.) Unit (Rs.) Total (Rs.) (Rs.) 22,700 7,500 13,400 5,63,920 1,32,37,520 1,32,37,500 1,26,30,000

Total or Say B.E.P. = = Fixed cost 100 Fixed cost + Profit 11,59,500 100 11,59,500 + 11,62,500

= 49.93%

Additional Information (a) The Project Profile may be modified/tailored to suit the individual entrepreneurship qualities/capacity, production programme and also to suit the locational characteristics, wherever applicable. (b) The Electronics Technology is undergoing rapid strides of change and there is need for regular monitoring of the national and international technology scenario. The unit may, therefore, keep abreast with the new

Personal Computer 360 Pentium IV (1.9 GHz)

40,000 1,44,00,000

(3) Profit (per annum) (Before Taxes) Rs. 11,62,500 (4) Net Profit Ratio = = = Profit (per annum) 100 Sales (per annum) 11,62,500 100 1,44,00,000 8.07%

136

P ERSONAL COMPUTER ( PENTIUM-IV)

technologies in order to keep them in pace with the developments for global competition. (c) Quality today is not only confined to the product or service alone. It also extends to the process and environment in which they are generated. The ISO 9000 defines standards for Quality Management Systems and ISO 14001 defines standards for Environmental Management System for acceptability at international level. The unit may therefore adopt these standards for global competition. (d) The margin money recommended is 25% of the working capital requirement at an average. However, the percentage of margin money may vary as per banks discretion. Addresses of Machinery, Computer Peripheral and Raw Material/ Component Suppliers

5. M/s. Systronics 89-92, Indl. Area, Naroda-382330 6. M/s. Electronics Trade and Technology Dev. Corpn. Ltd. 15/48, Malcha Marg, New Delhi-21 7. M/s. Noble Electronics 354, Lajpat Rai Market, Delhi-6

Soldering Equipment and Circuit Aids

1. M/s. Sysco Associates 30/106, (New No. 234), 11th Main, Malleswaram, Bangalore-3 2. M/s. Navanidhi Electronics (P) Ltd. 1-60/1, Snehapuri, Nacharam, Hyderabad-7 3. M/s. India Associates 16, Rest House Crescent, 27-B, Chandigarh-19 4. M/s. Bergen Associates Pvt. Ltd. 1082, Sector-27-B, Chandigarh-19

Testing Equipments

1. M/s. Applied Electronics Ltd. A-5, Wagle Indl. Estate, Thane, Mumbai - 4 2. M/s. Peico Electronics and Electrical Ltd. Shivasagar Estate, Block-A, Dr. Annie Besant Road, Mumbai-12 3. M/s. BPL (India) 84, M. G. Road, Bangalore-1 4. M/s. Agronic Instruments Pvt. Ltd. 201, Shiva-Shakti Industrial Estate, Mumbai-86

Raw Material and Component Suppliers

1. M/s. Electronics Trade and Technology Dev. Corp. Ltd. 15/8, Malcha Marg, Chanakyapuri, New Delhi-21 2. M/s. OEN Connectors Ltd. Vyattila, P.B. No.2, Cochin-19 3. M/s. Micropack Ltd. Plot No. 16, Jagani Indl. Area, Anekal T. J. Bangalore-562106 4. M/s. Amar Radio Corpn., 11/1, Thiglar Periyanna Lane, SJP Road, Bangalore-2.

P ERSONAL COMPUTER ( PENTIUM-IV)

137

5. M/s. Tomson Electronics Pulickkal Buildings, Pallimukku, M. G. Road, Cochin-68216 6. M/s. Saini Electronics, Pushpadant Nivas, 3, Chuman Lane, Dr. D. Bhadkamkar Marg, Mumbai-7 7. M/s. Bangalore Electronics No. 124, Sadarpatrappa Road, Bangalore-2 8. M/s. Southern Electronics No. 113, Sadarpatrappa Road, Bangalore-2.

4. M/s. Namtech Systems Pvt. Ltd. 35, Decosta Square, St. Thomas Town, Bangalore-84. 5. M/s. Jairamdas and Sons Pvt. Ltd. Mittal Towers, M. G. Road, Bangalore. 6. M/s. MCL Peripherals 158, Arcot Road, Vadapalani, Chennai-2 7. M/s. Wipro Peripherals Division 40/1, Levelle Road, Bangalore-1 8. M/s. Hewlett Packard India Ltd. Embassy Point, 150, Infantry Road, Bangalore-1. 9. M/s. VXL Instruments Pvt. Ltd. 159, 7th Main, I-Block, Koramangala, Bangalore-34. 10. M/s. TVS Electronics Tumkar, Karnataka 11. M/s. Microtek International Ltd. B-603, Emerald Appts. Parcy Panchayat Road, Andheri (E), Mumbai-69.

Imported Components and Computer Peripherals

1. M/s. General Electronics 19, 5th Floor, Tardeo Air Conditioned Market, Mumbai-34 2. M/s. Bakumbhai Ambalal (Electronics Dept.) Kaiser-I, Hind Building, Ballard Estate, Mumbai-38 3. M/s. Shilpa International 107, Park Lane, Secunderabad-3

You might also like

- Programming With Node Red EbookDocument325 pagesProgramming With Node Red EbookgfromageatNo ratings yet

- CH 17Document7 pagesCH 17anilshaw27No ratings yet

- P P O C C: Roject Rofile N Omputer Entre For Website Design and DevelopmentDocument10 pagesP P O C C: Roject Rofile N Omputer Entre For Website Design and DevelopmentSatish KumarNo ratings yet

- Electronic Weighing ScalesDocument12 pagesElectronic Weighing Scalestanpreet_makkadNo ratings yet

- Project Profile On LED Based Lighting SystemDocument8 pagesProject Profile On LED Based Lighting SystemAshish RanjanNo ratings yet

- P P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumDocument10 pagesP P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumNiju K ANo ratings yet

- CH 19Document7 pagesCH 19vijeyezNo ratings yet

- Project Profile On DVR: CCTV CameraDocument11 pagesProject Profile On DVR: CCTV CameraBest BetterNo ratings yet

- Mobile Phone Repairing and ServicingDocument9 pagesMobile Phone Repairing and Servicingsvkatkar0% (1)

- P P O M T: Roject Rofile N Edical RanscriptionDocument9 pagesP P O M T: Roject Rofile N Edical RanscriptionGanesh BabuNo ratings yet

- Electronics CCTV CameraDocument10 pagesElectronics CCTV CameraShanza ManzoorNo ratings yet

- Electronic Weighing ScaleDocument17 pagesElectronic Weighing ScaleVicky KaloniaNo ratings yet

- Top Examples and Applications of IIoT ManufacturingDocument4 pagesTop Examples and Applications of IIoT ManufacturingjackNo ratings yet

- Medical Transcription: NtroductionDocument6 pagesMedical Transcription: NtroductionSiraj Ahmed JafferiNo ratings yet

- Electronic Mus Le StimulatorDocument13 pagesElectronic Mus Le StimulatorsambhudharmadevanNo ratings yet

- Project Profile On LED Based Lighting System PDFDocument8 pagesProject Profile On LED Based Lighting System PDFsambhudharmadevanNo ratings yet

- Public Address AmplifiersDocument7 pagesPublic Address Amplifiersjayantsoni0211No ratings yet

- 2018 Manufacturing DigitalizationDocument66 pages2018 Manufacturing Digitalizationrohit ranjanNo ratings yet

- CH 14Document6 pagesCH 14Vishu5227No ratings yet

- ITI DocumentsDocument64 pagesITI DocumentsAtul Suryavanshi100% (1)

- Automaticvoltagestablizer 2Document14 pagesAutomaticvoltagestablizer 2ikhenemue.omohNo ratings yet

- IRJET Development of A Multipurpose IoTDocument12 pagesIRJET Development of A Multipurpose IoTJosseNo ratings yet

- Electrical Project1Document12 pagesElectrical Project1Lokanath ChoudhuryNo ratings yet

- P P O R & S E A: Product Code (Asicc)Document11 pagesP P O R & S E A: Product Code (Asicc)MathewsNo ratings yet

- Project Profile On Hybrid Solar InverterDocument11 pagesProject Profile On Hybrid Solar InvertersuryanathNo ratings yet

- Lead Acid Storage BatteriesDocument14 pagesLead Acid Storage BatteriesSivaramakrishna NeelamNo ratings yet

- Completed ProjectDocument111 pagesCompleted ProjectBasant SinghNo ratings yet

- IoT Solution For Energy Optimization in Industry 4.0Document6 pagesIoT Solution For Energy Optimization in Industry 4.0nguyenlesuhuyNo ratings yet

- Project Profile On Desk Top Publishing Centre: 1. ProductDocument9 pagesProject Profile On Desk Top Publishing Centre: 1. ProductvishuNo ratings yet

- Ajay Patel Project Part 2Document97 pagesAjay Patel Project Part 2saurabh1xNo ratings yet

- Employees SatisfactionDocument17 pagesEmployees Satisfactionvipul tandonNo ratings yet

- PLC and Scada ReportDocument39 pagesPLC and Scada ReportchandramaulsenNo ratings yet

- Digital Video Recorder (DVR) CCTV CamerasDocument9 pagesDigital Video Recorder (DVR) CCTV Camerasvivek raj pandeyNo ratings yet

- Web Controlled Industrial Actuators: Vrushab Bagul. Sudarshan NikaljeDocument22 pagesWeb Controlled Industrial Actuators: Vrushab Bagul. Sudarshan NikaljeMayur RaneNo ratings yet

- Computer CentreDocument52 pagesComputer Centresreddy_937709No ratings yet

- Agile IoT Transforming Production and Service PDFDocument3 pagesAgile IoT Transforming Production and Service PDFnorbyNo ratings yet

- Project Report Battery Manufacturing PlantDocument14 pagesProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Unit-3 Industry 4.0Document39 pagesUnit-3 Industry 4.0BALRAM SINGHNo ratings yet

- IJCRT1892198Document2 pagesIJCRT1892198FaisalNo ratings yet

- Report On InternshipDocument26 pagesReport On Internship4AI20EC078 Safa AliNo ratings yet

- 1624106057@g.usDocument15 pages1624106057@g.usNidhi MallyaNo ratings yet

- PDFDocument15 pagesPDFNorfazeli JaafarNo ratings yet

- Computers & Industrial EngineeringDocument22 pagesComputers & Industrial EngineeringJohn AngelopoulosNo ratings yet

- Cost Effective Digitalization Solution For Sinumerik CNC System To Increase The Transparency and Utilization of The Machine Pg. 6-13, July 2019Document8 pagesCost Effective Digitalization Solution For Sinumerik CNC System To Increase The Transparency and Utilization of The Machine Pg. 6-13, July 2019Eswaran PNo ratings yet

- ch23 PDFDocument6 pagesch23 PDFSambhu Dharmadevan VU3KQFNo ratings yet

- Tipos de ManufacturaDocument3 pagesTipos de Manufacturaluis gerardoNo ratings yet

- 500va Inverter: Small Industries Service Institute, AgartalaDocument10 pages500va Inverter: Small Industries Service Institute, AgartalaAvishek DuttaNo ratings yet

- Profiting From The IIoT White Paper 998-19887854 US SDocument10 pagesProfiting From The IIoT White Paper 998-19887854 US SjamujamuNo ratings yet

- Institute of Civil and Rural Engineering (Aided) : Basic of PLC Data Sheet of Various ManufacturersDocument13 pagesInstitute of Civil and Rural Engineering (Aided) : Basic of PLC Data Sheet of Various ManufacturersPranil KambleNo ratings yet

- Industrial Internet of Things (Iiot) and Its Impact On The Design of Automation SystemsDocument6 pagesIndustrial Internet of Things (Iiot) and Its Impact On The Design of Automation SystemsSHIVANI NANDANo ratings yet

- Peter G. Martin - Profiting From The IIoT (White Paper) - Schneider Electric (2016)Document10 pagesPeter G. Martin - Profiting From The IIoT (White Paper) - Schneider Electric (2016)AKRAMNo ratings yet

- 3 Technology and Operations ManagementDocument8 pages3 Technology and Operations ManagementJohn Julius MarquezNo ratings yet

- Electrical - Modern Solar LanternDocument10 pagesElectrical - Modern Solar Lanternsaritha nairNo ratings yet

- ISS Report (1) - 1Document11 pagesISS Report (1) - 1Nikhil ThosarNo ratings yet

- Embedded System and Design ReportDocument86 pagesEmbedded System and Design ReportGulati Rohit100% (1)

- Industrie 4.0 and The Latest Trends in Monozukuri Innovation in The Auto IndustryDocument6 pagesIndustrie 4.0 and The Latest Trends in Monozukuri Innovation in The Auto IndustryAnh VuNo ratings yet

- 36 - Battery Eliminator by Rakesh KumarDocument15 pages36 - Battery Eliminator by Rakesh KumarAbdu SamadNo ratings yet

- Computer-Integrated Manufacturing (CIM)Document46 pagesComputer-Integrated Manufacturing (CIM)Sukanth KannanNo ratings yet

- Understanding the Industrial Internet the $$$ Trillion Opportunities for Your EnterprisesFrom EverandUnderstanding the Industrial Internet the $$$ Trillion Opportunities for Your EnterprisesNo ratings yet

- 1031 - Application FormDocument3 pages1031 - Application Formanilshaw27No ratings yet

- Visitor's VisaDocument2 pagesVisitor's Visaanilshaw27No ratings yet

- Flower PotDocument4 pagesFlower Potanilshaw27No ratings yet

- 24 Sept 2012 ScheduleDocument5 pages24 Sept 2012 Scheduleanilshaw27No ratings yet

- CH 17Document7 pagesCH 17anilshaw27No ratings yet

- Result WebDocument2 pagesResult Webanilshaw27No ratings yet

- Ready To Send Revised Sci Comm ProgDocument4 pagesReady To Send Revised Sci Comm Proganilshaw27No ratings yet

- Cycle Rickshow Two Wheeler Rep ServicingDocument3 pagesCycle Rickshow Two Wheeler Rep Servicinganilshaw27No ratings yet

- 20 Posts Non Technical SpecificationDocument4 pages20 Posts Non Technical Specificationanilshaw27No ratings yet

- FlowerDocument1 pageFloweranilshaw27No ratings yet

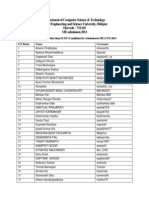

- Department of Computer Science and TechnologyDocument3 pagesDepartment of Computer Science and Technologyanilshaw27No ratings yet

- Secure Configuration ManagementPolicy Template For CIS Control 4Document19 pagesSecure Configuration ManagementPolicy Template For CIS Control 4Ivan NinanNo ratings yet

- GW 1000 User ManualDocument463 pagesGW 1000 User ManualRuddy Kurniawan GymkhanaNo ratings yet

- Recuruters and Telefone NumbersDocument5 pagesRecuruters and Telefone NumbersWaseem AhmadNo ratings yet

- JENA-ARQ TutorialDocument49 pagesJENA-ARQ Tutorialapi-19981384100% (2)

- (Selected) LVS Is That Simple (Digital Backend Physical Verification) - Lvs Verification-CSDN BlogDocument9 pages(Selected) LVS Is That Simple (Digital Backend Physical Verification) - Lvs Verification-CSDN BlogAgnathavasiNo ratings yet

- Desktop Engineering HPCHandbookDocument21 pagesDesktop Engineering HPCHandbooksamisdr3946No ratings yet

- CVIC II User Manual English 6159932190 En-08-EnDocument70 pagesCVIC II User Manual English 6159932190 En-08-EnAlvaro HorcajoNo ratings yet

- IEEE 802.4 Token Ring: - CSMA/CD - ProbabilitiesDocument8 pagesIEEE 802.4 Token Ring: - CSMA/CD - Probabilities23wingsNo ratings yet

- Hisense h65 Series Android TV Manual 50h6570g OptimizedDocument2 pagesHisense h65 Series Android TV Manual 50h6570g Optimizedgana dinero escuchando musicaNo ratings yet

- Slides PDFDocument268 pagesSlides PDFAmit PuriNo ratings yet

- Bill GatesDocument15 pagesBill GatesKomal KomNo ratings yet

- Models & Credits Pro + Sprint ModulesDocument12 pagesModels & Credits Pro + Sprint ModulesHeriberto Hernandez RodriguezNo ratings yet

- Management Information SystemDocument3 pagesManagement Information SystemIra DulgherNo ratings yet

- Teal Grey Blue Trendy Retro Digitalism Creative PresentationDocument19 pagesTeal Grey Blue Trendy Retro Digitalism Creative PresentationJustineSabandalNo ratings yet

- Mesin Digital Printing DeprintzDocument6 pagesMesin Digital Printing Deprintzsgg holikNo ratings yet

- Srikanth NodeDocument6 pagesSrikanth NodeShiva Kumar Kalakonda100% (1)

- SMB Controller DatasheetDocument3 pagesSMB Controller Datasheetikponmwosa olotuNo ratings yet

- CISCO MDS Eport IsolationDocument8 pagesCISCO MDS Eport IsolationShashi KanthNo ratings yet

- 0 0 Filtertrie IntermediateDocument52 pages0 0 Filtertrie IntermediateakunkelasdNo ratings yet

- Compal La 6901p r01 SchematicsDocument60 pagesCompal La 6901p r01 Schematicsscobie_21No ratings yet

- Modicon M580 System Planning Guide For Complex TopologiesDocument160 pagesModicon M580 System Planning Guide For Complex Topologiesjose david Galviz MNo ratings yet

- Transform Your Business With The Power of AzureDocument19 pagesTransform Your Business With The Power of AzureirfansakarkarNo ratings yet

- Setting Up Your Lab - VenkatDocument19 pagesSetting Up Your Lab - Venkatjust4 palsNo ratings yet

- IT FundamentalsDocument3 pagesIT FundamentalsCharles Ryan MontecinaNo ratings yet

- LSIS VFD Firmware Flash Procedure: PurposeDocument5 pagesLSIS VFD Firmware Flash Procedure: PurposeEngr.Zahedul HoqueNo ratings yet

- Mitsubishi MELSEC - A Series PlatformDocument73 pagesMitsubishi MELSEC - A Series Platformsunhuynh100% (1)

- The Difference Between RAM Speed and CAS LatencyDocument1 pageThe Difference Between RAM Speed and CAS LatencyVlad VahnovanuNo ratings yet

- Nikola Tesla Moji Izumi PDFDocument4 pagesNikola Tesla Moji Izumi PDFZodiac ShopNo ratings yet

- Oisplags News: Thatcher Backs MMIDocument1 pageOisplags News: Thatcher Backs MMIpoint_far_artNo ratings yet