Professional Documents

Culture Documents

It465 Syllabus

It465 Syllabus

Uploaded by

sigmasundarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

It465 Syllabus

It465 Syllabus

Uploaded by

sigmasundarCopyright:

Available Formats

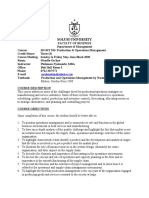

Southern Illinois University Carbondale Department of Technology IT 465 Lean Manufacturing Summer 2013

Catalog Description: 465-3 Lean Manufacturing. This course will cover the principles and techniques of lean manufacturing. Major topics covered include lean principles, 5S, value stream mapping, total productive maintenance, manufacturing/office cells, setup reduction/quick changeover, pull system/Kanbans, continuous improvement/ Kaizen, lean six sigma, lean simulation, and other modern lean manufacturing techniques and issues. Course Objectives: Explain the importance of implementing lean manufacturing. Describe the five key principles that guide lean thinking. Describe the eight general types of waste. Describe customer satisfaction and how higher customer satisfaction leads to lower cost. Describe 5S and its implementation steps. Describe 5 Whys. Explain the differences between value-added and non-value-added work. Describe VSM and demonstrate how to carryout this process. Describe and compute Takt time. Describe Poka-Yoke. Describe Total Productive Maintenance and its implementation steps. Compute Equipment Availability, Equipment Quality Performance, and Equipment Efficiency Performance. Describe various maintenance strategies. Describe the benefits of manufacturing cells. Describe setup reduction and its implementation steps. Explain how setup reduction reduces inventory and improves quality. Explain the differences between internal setup and external setup. Describe inventory kanbans and the implementation steps. Explain the kanban systems and how they reduce waste. Describe kaizen and its implementation steps. Explain the differences between kaikaku and kaizen. Describe implementation of lean manufacturing and six sigma. Describe lean simulation and its benefits. Important Dates/Times: Class meets Saturday and Sunday 6/22-23, 7/6-7, and 7/20-21 from 8:00am-4:30pm Test 1 6/23 Test 2 7/7 Test 3 7/21

As of April 23, 2013

Assessment Methods: Grade scale 90/80/70/60 1. 3 Exams (100 points each, all comprehensive) 2. 3 Homeworks (10 points each) 3. Lean paper (70 points) 4. No late work accepted 5. Class participation (attendance) Total Points = 400 points Note: College policy on cheating and plagiarism will be adhered to. Topical Outline: Chapters Intro,1 through 4 Chapters 5 through 7 Chapters 8 through 10

Test 1 Test 2 Test 3

Text and Supplies: Required: Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Revised and Updated, Second Edition, by James P. Womack and Daniel T. Jones, Free Press, 2003. ISBN 0-7432-4927-5 Implementing World Class Manufacturing (Includes Lean Enterprise), Second Edition, by Larry Rubrich and Madelyn Watson, Wcm Associates, 2004. ISBN 0-9662906-1-5 The Lean Pocket Guide, by Donald M. Tapping, MCS Media, Inc., 2003. ISBN 0-9725728-0-5 Scientific calculator (must have average, standard deviation, etc) Recommended: Microsoft Office or other similar programs Class Layout: Homework assignment Q/A Lecture Exercise/Exam Instructor: Jim Akers

Home: 815-877-1636 jnakers@hotmail.com (6-10pm M-F, 9am-10pm S-Su) Work: 815-639-6454 jakers@woodward.com (8am-5pm M-F) Website: http://jimakers.com

Disclaimer: Circumstances may require some changes to this syllabus.

As of April 23, 2013

You might also like

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- Completed AssignmentDocument13 pagesCompleted AssignmentAdrian Tay100% (1)

- An Introduction To Operations ManagementDocument3 pagesAn Introduction To Operations Managementjpgutierrez110% (1)

- Delta Signal Corporation: BSC StrategyDocument19 pagesDelta Signal Corporation: BSC StrategySandip ChhettriNo ratings yet

- SYLLABUSDocument13 pagesSYLLABUSGanesanDurairajNo ratings yet

- Lean Manufacturing QuizDocument6 pagesLean Manufacturing QuizsigmasundarNo ratings yet

- OM-IIPGP 1 (Problem Set - Interventions) (B B) PGP 1 (Problem Set - Interventions) (B B)Document5 pagesOM-IIPGP 1 (Problem Set - Interventions) (B B) PGP 1 (Problem Set - Interventions) (B B)Ashutosh KumarNo ratings yet

- CourseOutline (SML745)Document4 pagesCourseOutline (SML745)Pratyush GoelNo ratings yet

- BA9203 TQM Lesson PlanDocument12 pagesBA9203 TQM Lesson PlanvasanthasenanNo ratings yet

- Lecture 1Document24 pagesLecture 1Ayana ZholdasbekNo ratings yet

- DMCDocument5 pagesDMCAmarpal YadavNo ratings yet

- Vulcano OM-GB.2314 Summer13Document11 pagesVulcano OM-GB.2314 Summer13richmiddleNo ratings yet

- 6 1standard WorkDocument15 pages6 1standard WorkXiang Liu100% (1)

- MITx Syllabus 2.8301x V5Document4 pagesMITx Syllabus 2.8301x V5Lenin Franchescoleth Núñez PintadoNo ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration) WarningDocument12 pagesAllama Iqbal Open University Islamabad (Department of Business Administration) WarningAR KhanNo ratings yet

- Agile Lean PrinciplesDocument18 pagesAgile Lean Principlesajit.alweNo ratings yet

- BSBMGT516 Assessment 1 - Written QuestionsDocument5 pagesBSBMGT516 Assessment 1 - Written QuestionsIvson SilvaNo ratings yet

- Solved, MB0044 - Production Operations ManagementDocument5 pagesSolved, MB0044 - Production Operations ManagementArvind KNo ratings yet

- Schedule of SessionsDocument3 pagesSchedule of SessionsJoe KpozoiNo ratings yet

- Om +Section+GDocument10 pagesOm +Section+GAbhishek ShardaNo ratings yet

- Northwestern University Executive Management For Design and ConstructionDocument3 pagesNorthwestern University Executive Management For Design and ConstructionazamgabirNo ratings yet

- Quality: Q P / E P Performance E ExpectationsDocument39 pagesQuality: Q P / E P Performance E ExpectationsBHUSHAN PATILNo ratings yet

- 8509Document7 pages8509Danyal ChaudharyNo ratings yet

- Bulat-Ag, Lauren Mae S. Cbmec 2 Week 10-12Document9 pagesBulat-Ag, Lauren Mae S. Cbmec 2 Week 10-12Lauren Mae Bulat-agNo ratings yet

- POR Module 1Document36 pagesPOR Module 1Suresh NarayananNo ratings yet

- Chapter 06Document50 pagesChapter 06Richard DaouNo ratings yet

- TQM Implementation Project Report - SCDLDocument50 pagesTQM Implementation Project Report - SCDLSantosh Kumar MahtoNo ratings yet

- GE2022 TQM Question BankDocument21 pagesGE2022 TQM Question BankVadivel AeroNo ratings yet

- Systematic Problem Solving Approach - Brochure.Document4 pagesSystematic Problem Solving Approach - Brochure.RamavallabhanNo ratings yet

- Production and Total Quality ManagementDocument17 pagesProduction and Total Quality ManagementFalguni MathewsNo ratings yet

- 7BUIS021W - SimulationModelling - CW1 - Group PresentationDocument8 pages7BUIS021W - SimulationModelling - CW1 - Group Presentation20pwind0646No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Solution AnalysisDocument95 pagesSolution AnalysisRaluca UngureanuNo ratings yet

- CI Overview PresentationDocument36 pagesCI Overview Presentationyudiansyah27No ratings yet

- Course Syllabus of ISOM 2700 Operations Management: Fall 2018 Class ScheduleDocument5 pagesCourse Syllabus of ISOM 2700 Operations Management: Fall 2018 Class ScheduleSanjana ManikandanNo ratings yet

- CSS-Lesson01.2-Assess Own WorkDocument25 pagesCSS-Lesson01.2-Assess Own WorkavinmanzanoNo ratings yet

- Opermgt 408 Lean Manufacturing Systems Fall Semester, 2005: Course ObjectivesDocument5 pagesOpermgt 408 Lean Manufacturing Systems Fall Semester, 2005: Course ObjectivesMuhammad RedzuanNo ratings yet

- Chapter5 Six SigmaDocument38 pagesChapter5 Six SigmaSanjay AdhikariNo ratings yet

- Total Quality ManagementDocument5 pagesTotal Quality Managementshweta15marNo ratings yet

- Activity Based Costing (ABC) : 7 QC ToolsDocument16 pagesActivity Based Costing (ABC) : 7 QC ToolsManas DasguptaNo ratings yet

- International Academy of Management and EconomicsDocument6 pagesInternational Academy of Management and EconomicsPed SalvadorNo ratings yet

- Operations Management 2023Document8 pagesOperations Management 2023Mouphtaou YarouNo ratings yet

- PPIC Outline Fall 2016Document8 pagesPPIC Outline Fall 2016mianwaseemNo ratings yet

- TQM Brochure All6modDocument5 pagesTQM Brochure All6modAabraham Samraj PonmaniNo ratings yet

- CH 1 LEAN SS IntroductionDocument39 pagesCH 1 LEAN SS IntroductionandullaNo ratings yet

- 5564 Quantitative Techniques SaDocument8 pages5564 Quantitative Techniques SaziabuttNo ratings yet

- Module Information Module Title Quality Management and Six Sigma Module Code EMM502Document5 pagesModule Information Module Title Quality Management and Six Sigma Module Code EMM502sigmasundarNo ratings yet

- MGT 368: Operations Management: Course DescriptionDocument4 pagesMGT 368: Operations Management: Course DescriptionMehrin RahmanNo ratings yet

- Imt 15Document4 pagesImt 15Abhishek322No ratings yet

- MGMT 296 Production Operations Management Syllabus-Regular 1st Semester 2020Document5 pagesMGMT 296 Production Operations Management Syllabus-Regular 1st Semester 2020Nele GravesNo ratings yet

- Ptdoem Flyer Oct2012Document3 pagesPtdoem Flyer Oct2012simonyeo888No ratings yet

- Semester Final Syllabus - MGT 417 - 2020Document3 pagesSemester Final Syllabus - MGT 417 - 2020Abdulsamad BabbaNo ratings yet

- Capacity Planing?: Importance of Capacity DecisionsDocument5 pagesCapacity Planing?: Importance of Capacity DecisionsNur CaatoNo ratings yet

- Course Outline Operations ManagementDocument4 pagesCourse Outline Operations ManagementUmair GurmaniNo ratings yet

- UT Dallas Syllabus For Opre6302.501.11s Taught by Ganesh Janakiraman (gxj091000)Document8 pagesUT Dallas Syllabus For Opre6302.501.11s Taught by Ganesh Janakiraman (gxj091000)UT Dallas Provost's Technology GroupNo ratings yet

- IEE 6300: Advanced Simulation Modeling and AnalysisDocument7 pagesIEE 6300: Advanced Simulation Modeling and AnalysisTsega GetnetNo ratings yet

- Imt 15Document5 pagesImt 15pratiksha1091No ratings yet

- 8509Document8 pages8509Mudassar SaqiNo ratings yet

- Guidelines to make your own SOP (Standard Operating Procedure)): 1, #1From EverandGuidelines to make your own SOP (Standard Operating Procedure)): 1, #1No ratings yet

- Industrial Statistics: Practical Methods and Guidance for Improved PerformanceFrom EverandIndustrial Statistics: Practical Methods and Guidance for Improved PerformanceNo ratings yet

- Introduction To WeldingDocument8 pagesIntroduction To WeldingsigmasundarNo ratings yet

- MMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014Document48 pagesMMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014sigmasundarNo ratings yet

- Developing Delivering: Locally. GloballyDocument21 pagesDeveloping Delivering: Locally. GloballysigmasundarNo ratings yet

- TPM Score Criteria WorksheetDocument2 pagesTPM Score Criteria WorksheetsigmasundarNo ratings yet

- Downtime Analysis: SER 076 Issue2Document3 pagesDowntime Analysis: SER 076 Issue2sigmasundarNo ratings yet

- Industrial Statistics (2Ws02) : TeachersDocument3 pagesIndustrial Statistics (2Ws02) : TeacherssigmasundarNo ratings yet

- Section 1: Make Allowances For ItDocument28 pagesSection 1: Make Allowances For ItsigmasundarNo ratings yet

- Regcorr 5Document20 pagesRegcorr 5sigmasundarNo ratings yet

- Graduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodsDocument4 pagesGraduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodssigmasundarNo ratings yet

- Quantitative Quality Management Through Defect Prediction and Statistical Process ControlDocument6 pagesQuantitative Quality Management Through Defect Prediction and Statistical Process ControlsigmasundarNo ratings yet

- Process Capability Overview-TamilDocument2 pagesProcess Capability Overview-TamilsigmasundarNo ratings yet

- ISE 542 Production Planning and Control: Due Date: March 2, SundayDocument2 pagesISE 542 Production Planning and Control: Due Date: March 2, SundaysigmasundarNo ratings yet

- Hoshin Kanri Basics-Nested Experiments, X-Matrix, and Chartering TeamsDocument20 pagesHoshin Kanri Basics-Nested Experiments, X-Matrix, and Chartering Teamsrns116No ratings yet

- Erik - 2010Document10 pagesErik - 2010hafiz asadNo ratings yet

- Perancangan Relayout Tata Letak Fasilitas Guna Mengurangi Biaya Material Handling Pada UKM Tahu "SRT" KediriDocument10 pagesPerancangan Relayout Tata Letak Fasilitas Guna Mengurangi Biaya Material Handling Pada UKM Tahu "SRT" KedirianahNo ratings yet

- Quincy Apparel Frameworks & OthersDocument31 pagesQuincy Apparel Frameworks & Others0101191642No ratings yet

- 2018 Monthly OVERALL OEE SummaryDocument36 pages2018 Monthly OVERALL OEE SummaryCva RajNo ratings yet

- TPMDocument32 pagesTPMvignesh_sundaresan_1No ratings yet

- Lean Six Sigma HistoryDocument29 pagesLean Six Sigma HistoryRifki Rizal100% (1)

- BOK350 OPERATION MANAGEMENT INTRODUCTION 2020 CopieDocument11 pagesBOK350 OPERATION MANAGEMENT INTRODUCTION 2020 CopieJM DunandNo ratings yet

- HR's New Role Becoming A Strategic Business Partner: November 2005Document32 pagesHR's New Role Becoming A Strategic Business Partner: November 2005Divyam14No ratings yet

- Exploring The Impact of Higher Management S Leadership Styles On Lean ManagementDocument31 pagesExploring The Impact of Higher Management S Leadership Styles On Lean ManagementBankoleNo ratings yet

- New Logistics and Production TrendsDocument12 pagesNew Logistics and Production TrendsBohdan YarychNo ratings yet

- Innovation Management Chapter 2Document99 pagesInnovation Management Chapter 2bss4t6kdcvNo ratings yet

- Lean Lot Size OptimizationDocument105 pagesLean Lot Size OptimizationCarlos Delgado NietoNo ratings yet

- Presentation On TPS - JIT KanbanDocument93 pagesPresentation On TPS - JIT KanbanManish RajdevNo ratings yet

- R2 en COSIMA Process Optimization MethodsDocument45 pagesR2 en COSIMA Process Optimization MethodsRahul PatelNo ratings yet

- CH 1 Intro To LeanDocument26 pagesCH 1 Intro To LeanIslam FouadNo ratings yet

- Inventory ManagementDocument17 pagesInventory ManagementMunyaradzi MhlangaNo ratings yet

- Management of Operations: OM 711 - Winter 2007 Course InformationDocument3 pagesManagement of Operations: OM 711 - Winter 2007 Course InformationhyanandNo ratings yet

- Productivity Improvement With Kaizen Tool in Garment IndustryDocument6 pagesProductivity Improvement With Kaizen Tool in Garment IndustrySUHRIT BISWASNo ratings yet

- Technova 2010 PDFDocument30 pagesTechnova 2010 PDFraiyanduNo ratings yet

- IE 460 564 SyllabusDocument2 pagesIE 460 564 SyllabusLívia RodriguesNo ratings yet

- Chief Operating Officer in Southern CA Resume William ArsenaultDocument2 pagesChief Operating Officer in Southern CA Resume William ArsenaultWilliamArsenaultNo ratings yet

- A Road Map For The Implementation of Integrated JIT Lean Practices in Indian Manufacturing Industries Using The Best Worst Method ApproachDocument18 pagesA Road Map For The Implementation of Integrated JIT Lean Practices in Indian Manufacturing Industries Using The Best Worst Method ApproachfaizanNo ratings yet

- Lean Management PracticesDocument5 pagesLean Management PracticesMOHAN RAMNo ratings yet

- Transferring The Toyota Lean Cultural Paradigm Into India Implications For Human Resource Management PDFDocument19 pagesTransferring The Toyota Lean Cultural Paradigm Into India Implications For Human Resource Management PDFAdeel AkmalNo ratings yet

- Lean Construction and BIMDocument11 pagesLean Construction and BIMHeber Rubio Otiniano100% (1)

- Implementation of Lean Six Sigma PDFDocument8 pagesImplementation of Lean Six Sigma PDFRenato MayorgaNo ratings yet