Professional Documents

Culture Documents

Sugar Mill Short Description

Sugar Mill Short Description

Uploaded by

Anindya Vikram SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sugar Mill Short Description

Sugar Mill Short Description

Uploaded by

Anindya Vikram SinghCopyright:

Available Formats

Sugar Mill.docx (Size: 5.

75 MB / Downloads: 705) Sugar Mill A cane sugar mill is a factory that processes sugar cane to produce raw or white sugar. Sugar Cane Sugarcane refers to any of 6 to 37 species (depending on which taxonomic system is used) of tall perennial grasses of the genus Saccharum (family Poaceae, tribe Andropogoneae). Native to warm temperate to tropical regions of Asia, they have stout, jointed, fibrous stalks that are rich in sugar, and measure two to six meters (six to nineteen feet) tall. All sugar cane species interbreed, and the major commercial cultivars are complex hybrids. Sugar cane products include table sugar, falernum, molasses, rum, cachaa (the national spirit of Brazil), bagasse and ethanol. Raw Sugar Manufacturing Process Extraction Cane Handling The cane will be dumped in the feeding carrier. The feeding carrier will carry the canes and transfer it to the cane carrier. In the feeding carrier there is an equalizer and kicker which are responsible for efficient feeding in the cane carrier. Then the canes will pass through a leveller, two cutters, another leveller and then a kicker. Then it will be shredded in the shredder.The shredded cane will be carried by the shredded cane elevator. It will be received by the two pusher rollers. Then, the canes will be pushed to the three rollers where the juice will be extracted. The bagasse will be carried by the intermediate carrier and then to the next mill. There are five mills in the station. There is a maceration box in the 2nd mill. The mixed juice extracted in 5th mill will be pumped to the 4th mill; the mixed juice in the 4th mill will be pumped to the 3rd mill; the one in the 3rd mill will pumped to the 2nd mill. There is no maceration in the 1st mill. The pure juice in the 1st mill will be mixed with the extracted juice in the 2nd mill and will be pumped to the rotary juice filter. Auxiliary Parts of the Cane Handling Station DUMPER The dumper will aid the trucks without built in dumpers in dumping their sugar canes on the feeding carrier. FEEDING CARRIER It transports the dumped cane to the equalizer, kicker and into the cane carrier. It is powered by a motor. Its speed is manually controlled by the operator. EQUALIZER It controls the level of the canes and it will make sure that the canes are evenly distributed. The rotation of the equalizer is against the direction of the feeding carrier. This is driven by a motor. FEEDING CARRIER KICKER It pushes the canes from the feeding carrier to the cane carrier. Its rotation is along with the direction of the feeding carrier. This is driven by a motor. CANE CARRIER

It carries and transports the cane coming from the feeding carrier into the shredder. CANE CUTTER It cuts the cane in the cane carrier. This is powered by a motor. CANE SHREDDER Its function is to pulverize the canes. It is composed of 88 swing type hammers properly arranged into 8 rows. Each row has 11 hammers. It is responsible in pulverizing the cane. Because of too high rpm, it can produce shredded canes. It is driven by a 800 KW turbine.

Process

OF SUGAR

Every year Bajaj Hindusthan Ltd. conducts a survey of its command area to bring on record the cane cultivated area of the farmers. This also takes care of the different varieties of sugarcane that are grown by farmers. Post this massive exercise, every farmer within the command area of the mill is provided with a calendar, which tells him when he can expect a Mill Supply Ticket (Purchy) against which he will supply the cane Every year Bajaj Hindusthan Ltd. conducts a survey of its command area to bring on record the cane cultivated area of the farmers. This also takes care of the different varieties of sugarcane that are grown by farmers. Post this massive exercise, every farmer within the command area of the mill is provided with a calendar, which tells him when he can expect a Mill Supply Ticket (Purchy) against which he will supply the cane sia's Number 1 and World's Number 4 integrated sugar company It has an aggregated sugarcane crushing capacity of 136,000 tonnes crushed per day (TCD), and alcohol distillation capacity of 800 kilo liters per day (KLD) across 14 locations in the north Indian State of Uttar Pradesh (UP). The company is a leader in the Asian and Indian sugar industry and is also one of the largest producer of green fuel ethanol in India. sia's Number 1 and World's Number 4 integrated sugar company It has an aggregated sugarcane crushing capacity of 136,000 tonnes crushed per day (TCD), and alcohol distillation capacity of 800 kilo liters per day (KLD) across 14 locations in the north Indian State of Uttar Pradesh (UP). The company is a leader in the Asian and Indian sugar industry and is also one of the largest producer of green fuel ethanol in India. Asia's Number 1 and World's Number 4 integrated sugar company It has an aggregated sugarcane crushing capacity of 136,000 tonnes crushed per day (TCD), and alcohol distillation capacity of 800 kilo liters per day (KLD) across 14 locations in the north Indian State of Uttar Pradesh (UP). The company is a leader in the Asian and Indian sugar industry and is also one of the largest producer of green fuel ethanol in India.

You might also like

- Training Report On Manufacturing of SugarDocument33 pagesTraining Report On Manufacturing of SugarShivam Mittal50% (6)

- Sugar Manufacturing ProcessDocument18 pagesSugar Manufacturing Processdeepu0787100% (12)

- Industrial Training Report On DSMDocument14 pagesIndustrial Training Report On DSMVipul Sharma0% (1)

- Sugar Mill Feasibility Report PDFDocument23 pagesSugar Mill Feasibility Report PDFBaba YagaNo ratings yet

- Project Report On Sugar IndustryDocument78 pagesProject Report On Sugar IndustryBahubali Khanapure62% (29)

- FINAL Sugar Industry ReportDocument17 pagesFINAL Sugar Industry ReportChetan Maski80% (10)

- Production: Santosh Kr. Paswan Roll No 138510 ME3 YearDocument21 pagesProduction: Santosh Kr. Paswan Roll No 138510 ME3 YearEricMargateNo ratings yet

- Industry Profile: K.S.S.K LTD, HaveriDocument42 pagesIndustry Profile: K.S.S.K LTD, HaveriManju PalegarNo ratings yet

- Sugar Mill HiDocument46 pagesSugar Mill HiSaravanapriya KarthikNo ratings yet

- Sugar Plant Project ReportDocument5 pagesSugar Plant Project ReportBryan TanNo ratings yet

- Angel Rajput 2 Sem - Sugar IndustryDocument29 pagesAngel Rajput 2 Sem - Sugar IndustryMayank jain100% (1)

- Sugar Process 2003Document7 pagesSugar Process 2003pacoto livingstoneNo ratings yet

- Fresh Refined Suger-Meghna Group of IndustriesDocument16 pagesFresh Refined Suger-Meghna Group of Industriesiphone nokiaNo ratings yet

- Sugar IndustriesDocument46 pagesSugar Industriesshine king100% (1)

- Sugarcane Manufacturing ProcessDocument3 pagesSugarcane Manufacturing Processdante224No ratings yet

- Ashraf Sugar MillDocument64 pagesAshraf Sugar MillIdrees Akbar Rajput100% (2)

- Sugar Manufacturing ProcessDocument20 pagesSugar Manufacturing ProcessYadav ShwetaNo ratings yet

- Renuka Sugar Tech PDFDocument44 pagesRenuka Sugar Tech PDFNanasaheb PatilNo ratings yet

- Term Paper: Master of Buisness ApplicationDocument28 pagesTerm Paper: Master of Buisness Applicationashishsuman50% (2)

- Operations at Daurala Sugar ComplexDocument2 pagesOperations at Daurala Sugar ComplexShubhamNo ratings yet

- FinalDocument18 pagesFinalUmar AbbasNo ratings yet

- Sugar Manufacturing Process PDFDocument55 pagesSugar Manufacturing Process PDFShivkumar SK67% (3)

- Sugar Factory DefinitionDocument8 pagesSugar Factory Definitiontsrinivasan5083100% (1)

- Case Study - Venkatesh Krupa SugarDocument3 pagesCase Study - Venkatesh Krupa Sugarvishal aggarwal100% (1)

- Internship ReportDocument59 pagesInternship ReportYasir Khosa0% (1)

- AirtechDocument75 pagesAirtechMonica ThakurNo ratings yet

- Sugar Industry ReportDocument69 pagesSugar Industry ReportNupur Agrawal100% (1)

- Sugar Factory ProjectDocument75 pagesSugar Factory Projectkalaivani100% (1)

- Sugarcane Processing Technologies: by Md. Akram HossainDocument16 pagesSugarcane Processing Technologies: by Md. Akram HossainDeva Mk100% (1)

- Overview of Raw Cane Sugar Process-SDocument30 pagesOverview of Raw Cane Sugar Process-SPranetr R.No ratings yet

- Sales & Distribution Channel TrivaniDocument100 pagesSales & Distribution Channel TrivaniAshok Kumar100% (1)

- Pan Automation Presentation PDFDocument30 pagesPan Automation Presentation PDFarcher178100% (1)

- 3530 Nellikuppam Clarifier SpecDocument62 pages3530 Nellikuppam Clarifier Specgopalakrishnannrm1202100% (1)

- Sugar INTERNSHIP - REPORTDocument26 pagesSugar INTERNSHIP - REPORTokoya marvinNo ratings yet

- Sugar Manufacturing Process - Brief Introduction SlidesDocument52 pagesSugar Manufacturing Process - Brief Introduction Slideskiller120No ratings yet

- Notes of Sugar Manufacturing ProcessDocument27 pagesNotes of Sugar Manufacturing ProcesskujagdishNo ratings yet

- SUGARDocument15 pagesSUGARtakshi80% (5)

- Diffusion Vs MillingDocument4 pagesDiffusion Vs MillingcbqucbquNo ratings yet

- Plant Design PDFDocument181 pagesPlant Design PDFChristine FernandezNo ratings yet

- Manju Final ReportDocument68 pagesManju Final ReportnaglikarNo ratings yet

- Sagar Final ProjectDocument74 pagesSagar Final Projectkeremanevi100% (1)

- Sugar MillDocument48 pagesSugar Millshani2770% (10)

- Sugar IndustryDocument50 pagesSugar Industryzohaib ul hassanNo ratings yet

- Sugar Production ProcessDocument2 pagesSugar Production ProcessedmarkNo ratings yet

- Project Fin44Document62 pagesProject Fin44SidNo ratings yet

- Baroda Dairy (Prom)Document22 pagesBaroda Dairy (Prom)Bhavini UnadkatNo ratings yet

- Sugar Cane Ethanol Plant Best ParcticeDocument23 pagesSugar Cane Ethanol Plant Best ParcticeThiha Myat LwinNo ratings yet

- Sugar Plant - Cost - 2 PDFDocument23 pagesSugar Plant - Cost - 2 PDFSanjay PatelNo ratings yet

- Juice Sulphitation Process - Methods of Sugar Cane Juice SulphitationDocument6 pagesJuice Sulphitation Process - Methods of Sugar Cane Juice SulphitationYounas Sardar0% (1)

- Production Process of JaggeryDocument22 pagesProduction Process of JaggerySTRAIGHT TALK BY SURYA PRAKASHNo ratings yet

- Clarke Performance IndicatorsDocument3 pagesClarke Performance IndicatorsJavier Manuel IbanezNo ratings yet

- Company Profile-PT - Somerfield INDONESIA 2019Document13 pagesCompany Profile-PT - Somerfield INDONESIA 2019Nugraha KusumahNo ratings yet

- Working Capital Management For Sugar IndustryDocument12 pagesWorking Capital Management For Sugar Industryselvamech2337100% (4)

- Internship ReportDocument36 pagesInternship ReportSukumar SNo ratings yet

- Manufacture of SugarDocument79 pagesManufacture of SugarAhmed Ali100% (2)

- URC Passi Sugar Milling PlantDocument5 pagesURC Passi Sugar Milling PlantEmmanuel PlazaNo ratings yet

- The Lifecycle of SugarcaneDocument5 pagesThe Lifecycle of SugarcaneCelest Koh0% (1)

- Sugar MillDocument99 pagesSugar MillSunny Kataria67% (6)

- DPR Sugar CaneDocument12 pagesDPR Sugar Caneaneeshkumarkol015No ratings yet

- Arihant Sugar FactoryDocument9 pagesArihant Sugar FactoryNikhil HallurNo ratings yet

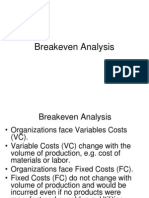

- 26 Break EvenDocument6 pages26 Break EvenAnindya Vikram SinghNo ratings yet

- LeadershipDocument100 pagesLeadershipAnindya Vikram SinghNo ratings yet

- Complex L-8Document64 pagesComplex L-8Anindya Vikram SinghNo ratings yet

- Chap 7 MEDocument56 pagesChap 7 MEAnindya Vikram SinghNo ratings yet

- Workshop Manual Demo PurposeDocument36 pagesWorkshop Manual Demo PurposeAnindya Vikram SinghNo ratings yet

- ARDUINO Based Automated Sprinkler Irrigation System With Soil Moisture Sensor and Notification System For Agricultural PurposesDocument18 pagesARDUINO Based Automated Sprinkler Irrigation System With Soil Moisture Sensor and Notification System For Agricultural PurposesMichael DarmstaedterNo ratings yet

- AvH22ProceedingsMauritius2015 StarzakDavisDocument22 pagesAvH22ProceedingsMauritius2015 StarzakDavisPratham AroraNo ratings yet

- 03-Colour Development and Removal, by Syed M.tariq & Sharif KhanDocument20 pages03-Colour Development and Removal, by Syed M.tariq & Sharif Khanranito zacariasNo ratings yet

- Geography March 2020 PaperDocument3 pagesGeography March 2020 PaperAryan SinghNo ratings yet

- Study Tour Report,: Willingdon College, SangliDocument6 pagesStudy Tour Report,: Willingdon College, SangliMaheshNo ratings yet

- Balrampur Chini AA ResearchDocument10 pagesBalrampur Chini AA ResearchadpradhanNo ratings yet

- Principles and Pressure Drop Calculation Across The Multiple Effect Evaporator Bodies - Sugar Industry TechnologiesDocument6 pagesPrinciples and Pressure Drop Calculation Across The Multiple Effect Evaporator Bodies - Sugar Industry TechnologiesYounas SardarNo ratings yet

- Importance of Crops in IndiaDocument4 pagesImportance of Crops in IndiaSaiTimmaraoNo ratings yet

- Biogas Fuel Agri WasteDocument5 pagesBiogas Fuel Agri WasteDinesh HindujaNo ratings yet

- Low Carb On Any BudgetDocument25 pagesLow Carb On Any BudgetRamkumar Sundaram100% (1)

- Agriculture Part-3Document14 pagesAgriculture Part-3FURYxAINTNo ratings yet

- Narrative of Accomp Jan Dec 2021Document7 pagesNarrative of Accomp Jan Dec 2021Erika Ahnne SantiagoNo ratings yet

- The Wealth of Sharad PawarDocument10 pagesThe Wealth of Sharad PawarrjagannathanNo ratings yet

- Farm Scheduler GunungMaduDocument5 pagesFarm Scheduler GunungMaduSetyo Pertiwi100% (1)

- OPTIMIZATION OF MilLING PERFORMANCE OF A SUGAR Mil PDFDocument7 pagesOPTIMIZATION OF MilLING PERFORMANCE OF A SUGAR Mil PDFSandeep YäðävNo ratings yet

- Sugar RefiningDocument64 pagesSugar RefiningVenus Abigail Gutierrez100% (1)

- Bagasse Based Co Generation 32Document5 pagesBagasse Based Co Generation 32gir_8No ratings yet

- Sugar Beets White Sugar FAO EBDocument9 pagesSugar Beets White Sugar FAO EBgombossandorNo ratings yet

- Sugar enDocument12 pagesSugar enakhmad zaenudinNo ratings yet

- Illustrative Guide To Sugarcane FarmingDocument82 pagesIllustrative Guide To Sugarcane FarmingNkanyisoNo ratings yet

- Research of Napier GrassDocument18 pagesResearch of Napier GrassheckybrizuelaNo ratings yet

- DesktopDocument56 pagesDesktoplucus12No ratings yet

- Fifty Shades of GreyDocument2 pagesFifty Shades of GreyKim BalotNo ratings yet

- John Rennie Short-Global Dimensions - Space, Place and The Contemporary World (2004)Document192 pagesJohn Rennie Short-Global Dimensions - Space, Place and The Contemporary World (2004)desain jalNo ratings yet

- Sugar Factory Internship ReportDocument54 pagesSugar Factory Internship Report15, Sweekar ChougaleNo ratings yet

- Annual Report Guysuco 2014Document55 pagesAnnual Report Guysuco 2014Guyana Sugar Corporation Inc.100% (1)

- Ba 2 PDFDocument12 pagesBa 2 PDFhakNo ratings yet

- 6 Glasses TimelineDocument3 pages6 Glasses TimelineDavid KimNo ratings yet

- Agricultural Problems in Pakistan and Their SolutionsDocument3 pagesAgricultural Problems in Pakistan and Their SolutionsAbdulhai Reki100% (3)

- Pakistan's Agro IndustriesDocument15 pagesPakistan's Agro Industrieshbadar76No ratings yet