Professional Documents

Culture Documents

Well Control Worksheet For A Surface Bop Stack: CANNON 1-21

Well Control Worksheet For A Surface Bop Stack: CANNON 1-21

Uploaded by

scrbdgharaviOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Control Worksheet For A Surface Bop Stack: CANNON 1-21

Well Control Worksheet For A Surface Bop Stack: CANNON 1-21

Uploaded by

scrbdgharaviCopyright:

Available Formats

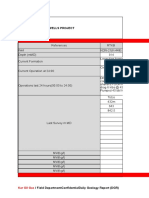

CANNON 1-21 BECKHAM COUNTY OK.

WELL GEOMETRY SEC 1 SEC 2

WELL CONTROL WORKSHEET FOR A SURFACE BOP STACK

SEC 3 SEC 4 SEC 5 SEC 6

Length, ft? = Hole Size, in? = Pipe OD, in? = Pipe ID, in? =

PRE-KICK DATA

927 8.75 7 3 8.9 5,400 12.0 0 0 0 9,721 0 0 0 8.90 1,000 1,000 1,798 6,891

8,794 8.75 5 4.276

MUD PUMP

Original Mud Weight, ppg? = TVD Last Casing Shoe, ft? = EMW of Last Shoe Test, ppg? = Slow Pump Pressure, psi? = Slow Pump Rate, spm? = Volume Active Mud Pits, bbls? =

KICK DATA

Liner Size, in? = Stroke Length, in? = Rod Size, in? = Pump Efficiency, %? =

TRIPLEX, bbl/stk

USER NOTES . . . . A. Enter Well Geometry starting from bottom of hole in SEC 1. B. The pump output defaults to a TRIPLEX, if Rod Size equals zero. C. Result in cell J24 is the TVD to spot a mud weight equivalent to last shoe test to generate a BHP equal to the hole being full of Kill Mud. D. Standard industry equations used for all calculations and solutions. CALCULATIONS

TVD of Well, ft? = SIDPP, psi? = SICP, psi? = Pit Gain, bbls? = Kill Mud Weight Initial Circulating Drill Pipe PSI Final Circulating Drill Pipe PSI Kill Mud - Surface to Bit, stks Kill Mud - Surface to Surface, stks

DRILL PIPE SCHEDULE

STROKES PRESSURE MINUTES

Mud Weight For a 100 psi Trip Margin, ppg Estimated Length of Kick Material Estimated Density of Kick Material, ppg Max Allowable Casing Pressure, psi Min Depth to Run Drill Pipe For a Kill Off-Bottom

DRILL PIPE SUMMARY

Sacks Needed to Weight-Up 100 Barrels of Mud Total Sacks For System Volume Increase in System, bbl Density of kick material < 2 ppg = POSS GAS Mixing Rate, sxs/min

DRILL PIPE SECTIONS SEC 1 SEC 2 SEC 3 SEC 4 SEC 5 SEC 6

0 180 360 540 719 899 1079 1259 1439 1619 1798

1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Capacity, bbls Displacement, bbls Surface to Bit, strokes Measured Depth or Length of Drill String, ft

ANNULUS SUMMARY

Capacity, bbls Bit to Surface, strokes Bit to surface, minutes

BARITE REQUIREMENTS

Barrels Strokes Displacement, bbl

ANNULUS SECTIONS

8.1 89 36.0

SEC 1

156.2 1710 57.4

SEC 2

0.0 0 0.0

SEC 3

0.0 0 0.0

SEC 4

0.0 0 0.0

SEC 5

0.0 0 0.0

SEC 6

Barrels Strokes Annular Velocity, fpm

UPDATE APRIL 1995

24.8 272 0

440.5 4821 0

0.0 0 0

0.0 0 0

0.0 0 0

0.0 0 0

APPLICATION CREATED 1993

THE END

A GENERAL WELL KILL PROCEDURE FOR "WAIT & WEIGHT METHOD" USING SURFACE BOP STACK 1. Increase mud weight in active pits to KILL WEIGHT. 2. Zero stroke counters. Start pump and simultaneously open choke. Pressure on the choke initially should be the shut-in casing pressure and this pressure should be maintained while the pump rate is brought up to the kill rate. 3. HOLD PUMP RATE CONSTANT and adjust choke so that the drill pipe pressure follows the above schedule. If drill pipe pressure is too high, open the choke slightly; if it is too low, close choke slightly. 4. After the Kill Mud has filled the drill pipe, MAINTAIN CONSTANT PUMP RATE and CONSTANT DRILL PIPE PRESSURE until the annulus is filled with the kill mud. 5. When kill weight mud reaches surface, stop pump and shut well in. At this time, the casing pressure and drill pipe pressure should be zero. If some pressure still exist on casing, open choke slightly and bleed a small amount or volume of mud. If the well is dead, pressure should fall to zero and the flow should stop.

Reference: LSU Blowout Control School Manual, LSU

WELL CONTROL WORKSHEET FOR A SURFACE BOP STACK

SEC 7

0 0 0 0

MUD PUMP

6 11 0 95 0.0914

of hole in SEC 1. . The pump output defaults to a TRIPLEX, if Rod Size equals zero. . Result in cell J24 is the TVD to spot a mud weight equivalent to last shoe test to generate a BHP equal to the hole being full of Kill Mud. . Standard industry equations used for all calculations and solutions. CALCULATIONS

9.10 0 #DIV/0! 2 0

DRILL PIPE SUMMARY

164 93 1,798 9,721

ANNULUS SUMMARY

465 5,093 0

BARITE REQUIREMENTS

0 0 0 0.00

SEC 7

0.0 0

SEC 7

0 0

APPLICATION CREATED 1993

Reference: LSU Blowout Control School Manual, LSU Baton Rouge, LA.

You might also like

- Bosch p7100 Injection Pump Service Manual PDFDocument2 pagesBosch p7100 Injection Pump Service Manual PDFAdam Johnson7% (14)

- Husqvarna Workshop ManualDocument71 pagesHusqvarna Workshop Manualsablejon67% (3)

- MACP and Well Control RecordDocument6 pagesMACP and Well Control RecordSudish BhatNo ratings yet

- (Training Documents) Strokes Bit To SurfaceDocument2 pages(Training Documents) Strokes Bit To SurfaceHeris SitompulNo ratings yet

- 22 - IWCF Review Questions 2014 - MSA PDFDocument9 pages22 - IWCF Review Questions 2014 - MSA PDFFoued NasriNo ratings yet

- ISX12 CM2350 X102 Wiring Diagram: Positive NegativeDocument1 pageISX12 CM2350 X102 Wiring Diagram: Positive Negativejorge67% (6)

- 1 A 16Document34 pages1 A 16Elmer VillegasNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- MACP and Well Control RecordDocument6 pagesMACP and Well Control RecordSudish BhatNo ratings yet

- 23 - Well Control Worksheet-Surface BOPDocument2 pages23 - Well Control Worksheet-Surface BOPAseem PandeyNo ratings yet

- Stimulation 4Document27 pagesStimulation 4DVScherbakovNo ratings yet

- Comp Tally W.P#14Document3 pagesComp Tally W.P#14nabiNo ratings yet

- EM CCS C - 4 PropuestoDocument1 pageEM CCS C - 4 PropuestoLenis CeronNo ratings yet

- MIS - XLSX S.E 2Document390 pagesMIS - XLSX S.E 2GPCNo ratings yet

- Balanced Cement Plug - Metres: Class "A" 5.2 Gal/sk Yields 1.18Document1 pageBalanced Cement Plug - Metres: Class "A" 5.2 Gal/sk Yields 1.18Dian SikumbangNo ratings yet

- Nitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGDocument29 pagesNitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGNaveen GuptaNo ratings yet

- BHA - 66 Opción 2 SlimpulseDocument1 pageBHA - 66 Opción 2 SlimpulseDiego Fabian Ruiz VacaflorNo ratings yet

- 2008 Workover and Completion Practice TestDocument14 pages2008 Workover and Completion Practice TestWaOne PrabowoNo ratings yet

- Hoja de Cálculo Sin TítuloDocument44 pagesHoja de Cálculo Sin TítuloJose GarciaNo ratings yet

- DP FatigDocument1 pageDP FatigscrbdgharaviNo ratings yet

- Agl TempDocument3 pagesAgl TempArun KumarNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- Production String: QTY Description Length Over All LengthDocument3 pagesProduction String: QTY Description Length Over All Lengthlupe.reyesNo ratings yet

- CDS 5.500 20.00lb L80+13Cr VAM+TOP+®+Casing SD+4.700 87.5Document1 pageCDS 5.500 20.00lb L80+13Cr VAM+TOP+®+Casing SD+4.700 87.5ZAMFERLENONo ratings yet

- TBG CSG Liner Liner Top KBDocument11 pagesTBG CSG Liner Liner Top KBbrunobozNo ratings yet

- HF2D06Document69 pagesHF2D06juangar1992No ratings yet

- Well DataDocument5 pagesWell Datamohamed elshemyNo ratings yet

- HH 83-1B DDR#3Document1 pageHH 83-1B DDR#3Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- PIPE Tally Sheet 7'' Liner kB2Document10 pagesPIPE Tally Sheet 7'' Liner kB2nabiNo ratings yet

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294No ratings yet

- Well Testing Calculation Using AGA 3Document22 pagesWell Testing Calculation Using AGA 3Yusuf OktoviyantoNo ratings yet

- Agl DSNDocument4 pagesAgl DSNR NilandNo ratings yet

- Step-1: Well Dataset Depth LOT PoDocument8 pagesStep-1: Well Dataset Depth LOT Ponikhil_barshettiwatNo ratings yet

- Running Procedure 5Document2 pagesRunning Procedure 5Pesireron RoberthNo ratings yet

- Day One Key AnswerDocument17 pagesDay One Key AnswerMostafa ElghifaryNo ratings yet

- Iwcf 2007 Halliburton 11 08Document338 pagesIwcf 2007 Halliburton 11 08daniel abiaNo ratings yet

- Horizontal Well Completion and Stimulation Techniques: A Project Report OnDocument48 pagesHorizontal Well Completion and Stimulation Techniques: A Project Report OnTripoli ManoNo ratings yet

- Kicktolerance Berekeningen: Kick Zone ParametersDocument1 pageKicktolerance Berekeningen: Kick Zone ParametersHerbertLansinkNo ratings yet

- Daily Drilling Progress Report: Mud PropertiesDocument1 pageDaily Drilling Progress Report: Mud PropertiesMarcoNo ratings yet

- 1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDDocument1 page1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDAntonio Hdez JmnzNo ratings yet

- P & P - QuestionsDocument125 pagesP & P - QuestionsShariq RaoNo ratings yet

- Henriksen, VibekeDocument150 pagesHenriksen, VibekeHamed SadeghiNo ratings yet

- Kick Tolerance FactorDocument1 pageKick Tolerance FactorAhmedNo ratings yet

- Schlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsDocument16 pagesSchlumberger: PIPESIM Open Link - Gas Lift Design & DiagnosticsnvnvNo ratings yet

- Derrick Loading Derrick Loading Worst Case: Pipe Weight in Derrick 223,242 LbsDocument2 pagesDerrick Loading Derrick Loading Worst Case: Pipe Weight in Derrick 223,242 LbsDian SikumbangNo ratings yet

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Document1 pageAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Cement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Document7 pagesCement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Emad JamshidiNo ratings yet

- Iwcf Certification Test Surface Bop Kill Sheet: Sicp SidppDocument15 pagesIwcf Certification Test Surface Bop Kill Sheet: Sicp SidppPAOLA ALEJANDRA CHINCHERO QUISPENo ratings yet

- DDR 27-10Document1 pageDDR 27-10GPCNo ratings yet

- Well Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)Document2 pagesWell Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)scrbdgharaviNo ratings yet

- Pre Recorded Imformation: Davis Family 1-42Document10 pagesPre Recorded Imformation: Davis Family 1-42scrbdgharaviNo ratings yet

- Well Kick Data: Sheet No. 2Document2 pagesWell Kick Data: Sheet No. 2Raul Dolo QuinonesNo ratings yet

- Kick ToleranceDocument1 pageKick ToleranceWasif KarimNo ratings yet

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Document1 pageDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNo ratings yet

- Enerplus Resources Inc - Drilling Diagram OurwellDocument4 pagesEnerplus Resources Inc - Drilling Diagram OurwellHeris SitompulNo ratings yet

- Casing ModuleDocument12 pagesCasing ModuleFarahKhanJamaliNo ratings yet

- Well Control FormulasDocument11 pagesWell Control FormulasLENDNo ratings yet

- Pump Fit/Lot Weight Up Equivalent Circulating DensityDocument100 pagesPump Fit/Lot Weight Up Equivalent Circulating DensityGustavo Javier FloresNo ratings yet

- DDR N°40 Omf-50 TP202 Du 05092021Document3 pagesDDR N°40 Omf-50 TP202 Du 05092021Mohamed SouidiNo ratings yet

- Cement Plug CalculationDocument7 pagesCement Plug CalculationEmad JamshidiNo ratings yet

- Choke ManifoldDocument5 pagesChoke ManifoldTarun AshokNo ratings yet

- Volumetric MethodDocument1 pageVolumetric MethodscrbdgharaviNo ratings yet

- Performing A Leak-Off TestDocument1 pagePerforming A Leak-Off TestemiljuchiacNo ratings yet

- Ref 4Document1 pageRef 4scrbdgharaviNo ratings yet

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Video Training Courses in Offshore Structures DesignDocument102 pagesVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- 0973r04 OKIOC Marine ManualDocument79 pages0973r04 OKIOC Marine ManualscrbdgharaviNo ratings yet

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Ref 17Document1 pageRef 17scrbdgharaviNo ratings yet

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferDocument8 pagesAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviNo ratings yet

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinDocument4 pagesInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviNo ratings yet

- Pigging Multi-Diameter Lines and Other Specialist TechniquesDocument6 pagesPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviNo ratings yet

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDocument6 pagesU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviNo ratings yet

- HSE Management - Guidelines For Working Together in A Contract EnvironmentDocument72 pagesHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviNo ratings yet

- Cleaning and Geometry Inspection Prior To Corrosion InspectionDocument4 pagesCleaning and Geometry Inspection Prior To Corrosion InspectionscrbdgharaviNo ratings yet

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonDocument6 pagesSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviNo ratings yet

- A Comparison of CP Survey Techniques and Intelligent Pig InspectionDocument6 pagesA Comparison of CP Survey Techniques and Intelligent Pig InspectionscrbdgharaviNo ratings yet

- Pre On-Line Inspection Pigging: by C KershawDocument6 pagesPre On-Line Inspection Pigging: by C KershawscrbdgharaviNo ratings yet

- New Developments in The Inspection of Gas Distribution MainsDocument6 pagesNew Developments in The Inspection of Gas Distribution MainsscrbdgharaviNo ratings yet

- Engineering Technical ServicesDocument11 pagesEngineering Technical ServicesscrbdgharaviNo ratings yet

- Horizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsDocument1 pageHorizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsscrbdgharaviNo ratings yet

- Mud MixDocument2 pagesMud MixscrbdgharaviNo ratings yet

- Hor PlanDocument1 pageHor PlanscrbdgharaviNo ratings yet

- Eficienta EnergeticaDocument4 pagesEficienta EnergeticaAneta HaziNo ratings yet

- GT PresentaionDocument98 pagesGT Presentaionmujeebtalib100% (6)

- EGS240-6 EGS240B-6 EGS240BS-6: Diesel Generator SetDocument3 pagesEGS240-6 EGS240B-6 EGS240BS-6: Diesel Generator SetAlifiona Nur AnisyahNo ratings yet

- U.S. Department of Energy Steam System Assessment ToolDocument43 pagesU.S. Department of Energy Steam System Assessment ToolDiana SoareNo ratings yet

- Electric Submersible Pumps (ESP) PDFDocument31 pagesElectric Submersible Pumps (ESP) PDFFernandoEnriqueCalveteGonzález100% (2)

- Anna University of Technology Chennai: Affiliated InstitutionsDocument42 pagesAnna University of Technology Chennai: Affiliated InstitutionsSAGUNTHVELNo ratings yet

- ATEX HandoutDocument7 pagesATEX Handoutanon_666816666No ratings yet

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDocument14 pagesLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiNo ratings yet

- Stefan Bachu PresentationDocument32 pagesStefan Bachu Presentationrecsco2No ratings yet

- Pneumatic and Hydraulic SystemsDocument7 pagesPneumatic and Hydraulic SystemsSergioEstevezNo ratings yet

- @@ER650EEFEUDocument123 pages@@ER650EEFEUpablocalle5No ratings yet

- Marpol Annex ViDocument5 pagesMarpol Annex ViThomas JoseNo ratings yet

- 15-3 Pistion & Connecting Rods PDFDocument9 pages15-3 Pistion & Connecting Rods PDFmefisto06cNo ratings yet

- Installation and Operating Manual: Air OnlyDocument11 pagesInstallation and Operating Manual: Air OnlyMauricio Ariel H. OrellanaNo ratings yet

- Mid128 Psid96 fm1Document31 pagesMid128 Psid96 fm1Vali Shopart100% (2)

- Natural Resources: and Their ConservationDocument18 pagesNatural Resources: and Their Conservationnihal_sawyerNo ratings yet

- EroriDocument3 pagesEroriCodewalkersNo ratings yet

- Fault Code 125Document3 pagesFault Code 125John MichaelNo ratings yet

- 53 Bowl MillDocument13 pages53 Bowl MillShashank PrasadNo ratings yet

- Coal Trading - Part 1 Information For Sourcing Coal.Document4 pagesCoal Trading - Part 1 Information For Sourcing Coal.DayalNo ratings yet

- 4012tag1a - Tag2aDocument12 pages4012tag1a - Tag2aBudi SNo ratings yet

- TPC Member ListDocument8 pagesTPC Member ListaliNo ratings yet

- Rab, Spek Dan IdentitasDocument2 pagesRab, Spek Dan IdentitasaritmNo ratings yet

- Website For CSa StandardsDocument2 pagesWebsite For CSa StandardsbuzbydfjNo ratings yet

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- Fail Codes T2Document2 pagesFail Codes T2Fastcross HondaNo ratings yet