Professional Documents

Culture Documents

OMA For Air Assessment 2009

OMA For Air Assessment 2009

Uploaded by

ServosteelCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (52)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ifix Migration GuideDocument44 pagesIfix Migration GuideMoses TanNo ratings yet

- Brodkorb Trucktrolley Luleaminingday HandoutDocument45 pagesBrodkorb Trucktrolley Luleaminingday HandoutArtur KanashNo ratings yet

- Hazardous Waste Registration 2015Document1 pageHazardous Waste Registration 2015ServosteelNo ratings yet

- Hazardous Waste Registration 2014Document1 pageHazardous Waste Registration 2014ServosteelNo ratings yet

- LRQA Focus Visit - January 2014Document18 pagesLRQA Focus Visit - January 2014Servosteel100% (1)

- MCERTs Self Monitoring of Effluent Flow Audit 2013Document6 pagesMCERTs Self Monitoring of Effluent Flow Audit 2013ServosteelNo ratings yet

- LRQA Management System Audit 2011Document18 pagesLRQA Management System Audit 2011ServosteelNo ratings yet

- Environment Agency EPR Compliance Assessment Report - May 2013Document4 pagesEnvironment Agency EPR Compliance Assessment Report - May 2013ServosteelNo ratings yet

- Environment Agency Audit 2009Document3 pagesEnvironment Agency Audit 2009ServosteelNo ratings yet

- Environment Agency Audit 2011Document3 pagesEnvironment Agency Audit 2011ServosteelNo ratings yet

- LRQA Management System Audit 2010Document10 pagesLRQA Management System Audit 2010ServosteelNo ratings yet

- SCS Briefing - Vol. 1 Issue 4Document2 pagesSCS Briefing - Vol. 1 Issue 4ServosteelNo ratings yet

- 2 - 3 Force Mass AccelerationDocument15 pages2 - 3 Force Mass Accelerationanton082117No ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- AC Hipots 15-200kVDocument4 pagesAC Hipots 15-200kVHung NguyenNo ratings yet

- FreeYouTubeToMP3Converter LogDocument25 pagesFreeYouTubeToMP3Converter LogYemina JaraNo ratings yet

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- 1Z0 062 Oracle Database 12cinstallation and Administration PDFDocument146 pages1Z0 062 Oracle Database 12cinstallation and Administration PDFankur singhNo ratings yet

- AIGA 012 - 04 - Cleaning of Equipment For Oxygen ServiceDocument60 pagesAIGA 012 - 04 - Cleaning of Equipment For Oxygen Serviceryanmakua100% (1)

- Steam Turbines.: The Energy Conversion ProcessDocument9 pagesSteam Turbines.: The Energy Conversion ProcessJaviStg1100% (1)

- LNG Plant1Document32 pagesLNG Plant1Shadi ZuraikatNo ratings yet

- Key Personnel - UG01 - 15112023Document1 pageKey Personnel - UG01 - 15112023Erfan KhanNo ratings yet

- TCM-4127 ZF 5HP19 (All)Document2 pagesTCM-4127 ZF 5HP19 (All)Valentin Ivanov100% (3)

- CS197 SyllabusDocument8 pagesCS197 SyllabusGrantham UniversityNo ratings yet

- Conclusion and Recommendation Heat ExchangersDocument2 pagesConclusion and Recommendation Heat ExchangersAzura Bahrudin0% (1)

- Lesson Plan: School For Aircraft Maintenance EngineeringDocument3 pagesLesson Plan: School For Aircraft Maintenance Engineeringarindam debnathNo ratings yet

- Product Selection Guide: Tube & Clamp ScaffoldDocument8 pagesProduct Selection Guide: Tube & Clamp ScaffoldMostafa RostomNo ratings yet

- Singapore SingTel SettingsDocument3 pagesSingapore SingTel SettingsPurwanda Nur HidayatNo ratings yet

- SP ThinDocument6 pagesSP ThinfarazakrimNo ratings yet

- ZXCTN 9000 MML Configuration Guide (Raliability) V2.08.32 enDocument194 pagesZXCTN 9000 MML Configuration Guide (Raliability) V2.08.32 entaipm100% (1)

- Itr Cat Repair Parts Complete CatalogDocument279 pagesItr Cat Repair Parts Complete CatalogLee Yoon YowNo ratings yet

- BGP QuestionsDocument3 pagesBGP QuestionsArvind KumarNo ratings yet

- PI - Valvoline Axle Oil 75W 90 LS - 257 02 PDFDocument2 pagesPI - Valvoline Axle Oil 75W 90 LS - 257 02 PDFAlicia Rodriguez de AmadoNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- Sri Rudram Namakam Oriya LargeDocument7 pagesSri Rudram Namakam Oriya LargeBibhudatta SahuNo ratings yet

- Wd12t754dbx-Co EvDocument21 pagesWd12t754dbx-Co EvHolman CastiblancoNo ratings yet

- In App Purchase Programming Guide: Networking & InternetDocument38 pagesIn App Purchase Programming Guide: Networking & InternetSuman GuhaNo ratings yet

- Struktur Organisasi R1 03122020 PDFDocument2 pagesStruktur Organisasi R1 03122020 PDFarief312No ratings yet

OMA For Air Assessment 2009

OMA For Air Assessment 2009

Uploaded by

ServosteelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OMA For Air Assessment 2009

OMA For Air Assessment 2009

Uploaded by

ServosteelCopyright:

Available Formats

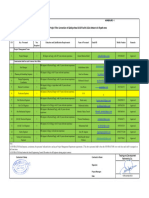

OMA CHECKSHEETS – Emissions to Air – IPPC

SUMMARY SHEET

Permit Number: KP3732PL PIR Officer: Steve Mearns

Operator: Oakside Solutions Auditor (if different): Richard Croll

Emission Point: A1 Others Present: Wayne Roden

OMA ATTRIBUTES SCORE

OMA 1 - Management, training and competency of personnel 97%

OMA 2 - Fitness for purpose of monitoring methods (CEMs, periodic monitoring and surrogate methods) 88%

OMA 3 - Maintenance of monitoring equipment 100%

OMA 4 - Calibration of monitoring equipment 100%

OMA 5 - Quality assurance/quality control of monitoring effort 80%

OVERALL SCORE 93%

Letter

OVERALL SITE ASSESSMENT COMMENTS Variation

Enforcement

The emissions monitoring is well managed and conforms to MCERTS.

Date of audit: 13th March 2009

Signed: R Croll

Date:

OMA CHECKSHEETS – Emissions to Air – IPPC

OMA 1: Management, training and competency of personnel

OMA ELEMENTS SCORE COMMENTS

A. Corporate commitment to monitoring. 5 The process operator has a 3rd party certified EMS.

The high level policy references MCERTS emissions

monitoring.

B. Appropriate management structure in 5 Wayne Roden (Environmental & Quality Assurance

relation to monitoring. Manager) is responsible for the emissions monitoring.

This was documented in detail.

Jenny Lee & Roy Field are nominated deputies. Their

training programme commencing 1st April 2009 was seen.

C. Production of monitoring schedules. 4 A full monitoring and reporting schedule was seen.

Roy and Jenny have access to the schedule.

D. Procedures for feedback of monitoring 5 Monitoring results are formally reviewed Quarterly.

results.

Results are tabulated.

It was demonstrated that results below the ELV are acted on

if required.

E. Knowledge and understanding of monitoring 5 Wayne demonstrated knowledge of Environment Agency

requirements. TGNs M1 & M2

MCERTS accreditations and certifications were explained.

Wayne also explained that the monitoring was carried out

iso-kinetically due to possible droplets.

F. Competency of contractors’ or operators’ 5

personnel carrying out monitoring to The contractors were seen to be appropriately MCERTS

MCERTS personnel competence standards. certified.

OMA 1 – SCORE 97%

SUMMARY COMMENTS FOR OMA 1

The permit states an hourly average HCl result.

As BS EN 1911 is based on wet chemistry the sample duration should be dependant on a number of sampling

parameters, determined by the MCERTS organisation.

The sampling had taken place over a duration of 2 hours. Whilst strictly not compliant with the permit, this

should produce more reliable results.

OMA CHECKSHEETS – Emissions to Air – IPPC

OMA 2: Fitness for purpose of monitoring methods (continuous monitors, periodic monitoring and

surrogate methods)

OMA ELEMENTS SCORE COMMENTS

A. Does the monitoring method or surrogate 4 BS EN 1911 has been used to measure HCl.

method measure what it should?

FUNDAMENTAL ELEMENT The test method is listed in Environment Agency TGN

M2 and was accredited.

Methods are not formally review to ensure they remain

current.

B. Are the monitoring methods or surrogate 5 BS EN 1911 has been used to measure HCl.

methods traceable to a relevant and validated

standard? The test method is listed in Environment Agency TGN

M2 and was accredited.

C. Does the monitoring method or equipment 5 BS EN 1911 has been used to measure HCl.

conform to the appropriate minimum design

and performance standard e.g. MCERTS? The test method is listed in Environment Agency TGN

M2 and was accredited.

D. Does the monitoring method or 5 BS EN 1911 has been used to measure HCl.

equipment have acceptable performance

characteristics e.g. range, limit of detection, The test method is listed in Environment Agency TGN

linearity, response speed, and uncertainty? M2 and was accredited.

E. Are the sampling positions spatially 3 The sample location does not meet the full requirements

representative with good access? for iso-kinetic monitoring.

FUNDAMENTAL ELEMENT

The location is in a horizontal duct and sampling only

takes place along 1 axis.

There is no other reasonable alternative sampling

location.

The report seen shows there is laminar flow in the duct.

It is deemed the results are representative of the

emission.

OMA 2 – SCORE 88%

SUMMARY COMMENTS FOR OMA 2

OMA CHECKSHEETS – Emissions to Air – IPPC

OMA 3: Maintenance of monitoring equipment

OMA ELEMENTS SCORE COMMENTS

A. Acceptability of the maintenance schedule and 5

the maintenance frequency.

B. Existence of maintenance records. 5

C. Acceptability of a documented maintenance 5

procedure.

D. Reliability of continuous emission N/A

monitors and percentage of data capture.

E. Spares held on site for continuous emission N/A

monitors and periodic monitors. General

availability of equipment. Competence of

persons servicing and/or undertaking repairs.

OMA 3 – SCORE 100%

SUMMARY COMMENTS FOR OMA 3

A maximum score has been awarded as the sampling is carried out by MCERTS accredited and certified contractors.

OMA CHECKSHEETS – Emissions to Air – IPPC

OMA 4: Calibration of monitoring equipment

OMA ELEMENTS SCORE COMMENTS

A. Existence of a calibration schedule. 5

B. Acceptability of calibration frequency. 5

C. Documentation of the calibration procedure. 5

D. Acceptability of calibration methods. 5

FUNDAMENTAL ELEMENT

E. Traceability of calibration. 5

OMA 4 – SCORE 100%

SUMMARY COMMENTS FOR OMA 4

A maximum score has been awarded as the sampling is carried out by MCERTS accredited and certified contractors.

OMA CHECKSHEETS – Emissions to Air – IPPC

OMA 5: Quality assurance/quality control of monitoring effort

OMA ELEMENTS SCORE COMMENTS

A. Use of documented procedures for monitoring 5 A Site Specific Protocol was available for the work that

(including sampling and analysis) by operators had been carried out.

and/or contractor carrying out monitoring.

B. Accreditation of monitoring organisation to 5 The monitoring organisation is MCERTS accredited for

MCERTS performance standards. BS EN 1911.

C. Internal and external auditing of the 1 The process operator has not formally audited the

monitoring work (including sampling and sampling organisation.

analysis)

D. Degree of compliance with monitoring N/A

procedures.

E. Reporting. 5 The returns meet the requirements of the permit.

OMA 5 – SCORE 80%

SUMMARY COMMENTS FOR OMA 5

To aid operators with auditing emissions testing contractors, the Source Testing Association (STA) have produced auditing

forms.

The process operators contractors are members of the STA and have access to these forms, if the process operator wishes.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (52)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ifix Migration GuideDocument44 pagesIfix Migration GuideMoses TanNo ratings yet

- Brodkorb Trucktrolley Luleaminingday HandoutDocument45 pagesBrodkorb Trucktrolley Luleaminingday HandoutArtur KanashNo ratings yet

- Hazardous Waste Registration 2015Document1 pageHazardous Waste Registration 2015ServosteelNo ratings yet

- Hazardous Waste Registration 2014Document1 pageHazardous Waste Registration 2014ServosteelNo ratings yet

- LRQA Focus Visit - January 2014Document18 pagesLRQA Focus Visit - January 2014Servosteel100% (1)

- MCERTs Self Monitoring of Effluent Flow Audit 2013Document6 pagesMCERTs Self Monitoring of Effluent Flow Audit 2013ServosteelNo ratings yet

- LRQA Management System Audit 2011Document18 pagesLRQA Management System Audit 2011ServosteelNo ratings yet

- Environment Agency EPR Compliance Assessment Report - May 2013Document4 pagesEnvironment Agency EPR Compliance Assessment Report - May 2013ServosteelNo ratings yet

- Environment Agency Audit 2009Document3 pagesEnvironment Agency Audit 2009ServosteelNo ratings yet

- Environment Agency Audit 2011Document3 pagesEnvironment Agency Audit 2011ServosteelNo ratings yet

- LRQA Management System Audit 2010Document10 pagesLRQA Management System Audit 2010ServosteelNo ratings yet

- SCS Briefing - Vol. 1 Issue 4Document2 pagesSCS Briefing - Vol. 1 Issue 4ServosteelNo ratings yet

- 2 - 3 Force Mass AccelerationDocument15 pages2 - 3 Force Mass Accelerationanton082117No ratings yet

- Tabel Konversi Nilai KekerasanDocument14 pagesTabel Konversi Nilai KekerasanSeptiana NugrahaNo ratings yet

- AC Hipots 15-200kVDocument4 pagesAC Hipots 15-200kVHung NguyenNo ratings yet

- FreeYouTubeToMP3Converter LogDocument25 pagesFreeYouTubeToMP3Converter LogYemina JaraNo ratings yet

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- 1Z0 062 Oracle Database 12cinstallation and Administration PDFDocument146 pages1Z0 062 Oracle Database 12cinstallation and Administration PDFankur singhNo ratings yet

- AIGA 012 - 04 - Cleaning of Equipment For Oxygen ServiceDocument60 pagesAIGA 012 - 04 - Cleaning of Equipment For Oxygen Serviceryanmakua100% (1)

- Steam Turbines.: The Energy Conversion ProcessDocument9 pagesSteam Turbines.: The Energy Conversion ProcessJaviStg1100% (1)

- LNG Plant1Document32 pagesLNG Plant1Shadi ZuraikatNo ratings yet

- Key Personnel - UG01 - 15112023Document1 pageKey Personnel - UG01 - 15112023Erfan KhanNo ratings yet

- TCM-4127 ZF 5HP19 (All)Document2 pagesTCM-4127 ZF 5HP19 (All)Valentin Ivanov100% (3)

- CS197 SyllabusDocument8 pagesCS197 SyllabusGrantham UniversityNo ratings yet

- Conclusion and Recommendation Heat ExchangersDocument2 pagesConclusion and Recommendation Heat ExchangersAzura Bahrudin0% (1)

- Lesson Plan: School For Aircraft Maintenance EngineeringDocument3 pagesLesson Plan: School For Aircraft Maintenance Engineeringarindam debnathNo ratings yet

- Product Selection Guide: Tube & Clamp ScaffoldDocument8 pagesProduct Selection Guide: Tube & Clamp ScaffoldMostafa RostomNo ratings yet

- Singapore SingTel SettingsDocument3 pagesSingapore SingTel SettingsPurwanda Nur HidayatNo ratings yet

- SP ThinDocument6 pagesSP ThinfarazakrimNo ratings yet

- ZXCTN 9000 MML Configuration Guide (Raliability) V2.08.32 enDocument194 pagesZXCTN 9000 MML Configuration Guide (Raliability) V2.08.32 entaipm100% (1)

- Itr Cat Repair Parts Complete CatalogDocument279 pagesItr Cat Repair Parts Complete CatalogLee Yoon YowNo ratings yet

- BGP QuestionsDocument3 pagesBGP QuestionsArvind KumarNo ratings yet

- PI - Valvoline Axle Oil 75W 90 LS - 257 02 PDFDocument2 pagesPI - Valvoline Axle Oil 75W 90 LS - 257 02 PDFAlicia Rodriguez de AmadoNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- Sri Rudram Namakam Oriya LargeDocument7 pagesSri Rudram Namakam Oriya LargeBibhudatta SahuNo ratings yet

- Wd12t754dbx-Co EvDocument21 pagesWd12t754dbx-Co EvHolman CastiblancoNo ratings yet

- In App Purchase Programming Guide: Networking & InternetDocument38 pagesIn App Purchase Programming Guide: Networking & InternetSuman GuhaNo ratings yet

- Struktur Organisasi R1 03122020 PDFDocument2 pagesStruktur Organisasi R1 03122020 PDFarief312No ratings yet