Professional Documents

Culture Documents

Water Management Business Division: Clariflocculators

Water Management Business Division: Clariflocculators

Uploaded by

ganeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Management Business Division: Clariflocculators

Water Management Business Division: Clariflocculators

Uploaded by

ganeshCopyright:

Available Formats

Water Management Business Division

CLARIFLOCCULATORS

Central slewing ring drive will have necessary extension for mounting independently driven flocculators. Paddle type flocculators (independently driven type) located on bridge with suitable gear drive and motor. Central slewing ring drive is provided with suitable electric motor which will have either mechanical shear pin arrangement or electronic shear pin arrangement for overload protection. Scrapers connected to central cage at the lower end with neoprene squeegees for scraping of sludge which will have adjustment facility to match with tank floor slope.

GENERAL

The Clariflocculators are provided in mild steel, epoxy painted construction and can also be provided in stainless steel FRP coated/galvanized construction as per client's requirement. Approach ladders/platform around tank along with handrailing and civil work to be arranged by client to suit equipment requirement or client's own requirement. Electrical, piping, automation etc., to be arranged by clients as per their requirement.

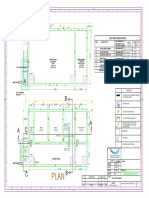

SECTIONAL VIEW OF CENTRAL DRIVEN TYPE CLARIFLOCCULATOR WITH TWO FLOCCULATORS

For more information contact:

Voltas Limited

Water Management Business Division Mumbai (HO) Voltas House B, T.B.Kadam Marg, Chinchpokli, Mumbai 400033. Tel: +91 22 66656589/571, Fax: +91 22 66656592, Email: sksen@voltas.com Kolkata Gillander House 8, Netaji Subhas Road, P.O.No.606, Kolkata 700001. Tel: +91 33 666266290, Email: relsan@voltas.com Delhi A-43, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110004. Tel: +91 11 66505576, Fax: +91 11 26950022/081, Email: chandankumar@voltas.com Chennai 624, AnnaSalai, Teynampet, Chennai 600018, Tel: +91 44 66760338, Fax: +91 44 24342178, Email:kannanl@emm.voltas.co

CLARIFLOCCULATOR MECHANISM: Clariflocculator mechanism is a combination of Flocculator and Clarifier, designed to achieve compact sizing, construction and cost competitiveness. Clariflocculator is used for industrial wastewater treatment and potable water treatment. It involves two concentric tanks wherein inner tank serves as a flocculation zone and the outer one as a clarifier. These can be constructed in RCC or mild steel depending upon size and client's requirement (normally large size units are preferred in RCC construction). Clariflocculators are manufactured in two configurations viz., Peripheral driven type and Central driven type from the range of 4M dia to a maximum upto 70M dia. I) Peripheral driven type Clariflocculator

Telescopic valve can be provided for the Clariflocculator depending on client's requirement. Slipring collector is provided on central RCC column for distribution of current to traction drive and flocculator drive/motors. Electric cables are laid through a conduit. II) Central driven type Clariflocculator (fixed bridge type) Central driven Clariflocculators are provided in two configurations viz. Bridge mounted Clariflocculator (for small diameter : upto 20-25M) and Central column mounted Clariflocculator with radial rotating bridge (usually preferred for larger diameter). 1) Bridge mounted Clariflocculator

Peripheral driven type Clariflocculator consists of the following: Bridge mounted Clariflocculator consists of: Radial half bridge with handrailing, chequered plates and gratings for walkway and extension to cover flocculation zone barrier and flocculators. The Flocculators are provided with the bridge spanning full diameter depending upon client's requirement. Bridge rests on centre pivot bearing on central RCC column and is provided with trailing & traction drive at the peripheral end. Traction drive is made up of suitable gearing arrangement with wheels in mild steel rubber-lined or mild steel with polyurethane bonding to move on an annular RCC wall top or with mild steel/CI wheels to move on rails to be laid on annular wall top. Bridge width varies from 0.75M to 1.5M depending on client's specific requirement. Structural bridge spanning the full diameter with chequered plates & handrailing and width of the bridge varies from 0.75M to 1.5M with extension for mounting independently driven flocculators. Scraper drive is located centrally on the bridge with shaft connected at the top end with the drive and guided at lower end in the guide bearing. Shaft will have scrapers for sludge scraping. Independently driven flocculators are located on the bridge, which vary from 1 to 4 Nos. depending upon process requirement. Flocculators are provided with gearing arrangement and electric motors of suitable size. Central drive is provided with mechanical shear pin/electronic shear pin arrangement for overload protection. Scrapers are connected to shaft at lower end and are provided with neoprene squeegees with adjustment facility to match with tank floor slope. Effluent/waste water is fed to flocculation zone which is hung from the bridge sideways or from the top for which required inlet piping and support to be provided by client as per requirement. 2) Central column mounted (with radial bridge) Clariflocculator Central column mounted Clariflocculator consists of : SECTIONAL VIEW OF PERIPHERAL DRIVEN TYPE CLARIFLOCCULATOR WITH FOUR FLOCCULATORS Slewing ring drive located on top of central column Cage (structurally fabricated) for rotation around central column with guide arrangement at the bottom end. Rotating bridge with handrailing and chequered plates (bridge width ranging from 0.75M to 1.5M) which provides approach to central slewing ring drive and supports floculators and flocculation zone barrier.

Traction drive is provided with suitable capacity electric motor with either mechanical shear pin or electronic shear pin arrangement for overload protection, Variable Frequency Drive (VFD) arrangement can also be provided with the traction drive motor for controlling the bridge speed depending on client's requirement. Centre pivot bearing is provided with trunion arrangement which facilitates smooth movement of the bridge traction wheels on the annular wheel top due to irregularities of traction wheels thus safeguarding the bearings as well as cushioning for the bridge rotation. Greasing arrangement for the centre pivot bearing can be accessed from the bridge. Independently driven paddle type flocculators are located on the bridge extension and are provided with gear drive and suitable capacity electric motor for desired flocculation. Number of flocculators vary between 1 to 4 depending on the size and process requirement. Flocculation zone barrier is usually provided in RCC construction for big size units or in mild steel construction depending on size. Scrapers are hung from rotating bridge and are provided with neoprene squeegees at the bottom end for sludge scraping on the tank floor slope.

You might also like

- o & M Instruction Manual (Rapid Gravity Filter)Document68 pageso & M Instruction Manual (Rapid Gravity Filter)ahmed salam100% (1)

- List SAP PP TcodesDocument6 pagesList SAP PP TcodesganeshNo ratings yet

- E2185 - Offer RENESCO - Rev0Document39 pagesE2185 - Offer RENESCO - Rev0Umut Sinan ÇetinbaşNo ratings yet

- Hyflux Standard Membrane Systems Brochure - Ver5.1 - ENDocument40 pagesHyflux Standard Membrane Systems Brochure - Ver5.1 - ENIGNyomanAnomWijayaNo ratings yet

- Uf Toray PresentationDocument54 pagesUf Toray PresentationPrateek VermaNo ratings yet

- Effective Screen Area CalculationsDocument6 pagesEffective Screen Area CalculationsAwtar SinghNo ratings yet

- Open Channel Head Loss: H L C Q HDocument51 pagesOpen Channel Head Loss: H L C Q HKolos Char YiuNo ratings yet

- Benenv Products CatalogueDocument40 pagesBenenv Products CataloguePham Nguyen Phuc100% (3)

- Vendor EvaluationDocument2 pagesVendor Evaluationganesh100% (1)

- Vendor EvaluationDocument2 pagesVendor Evaluationganesh100% (1)

- Air Conditioning System (Presentation 1)Document26 pagesAir Conditioning System (Presentation 1)dreamst4rNo ratings yet

- 04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35Document12 pages04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35kunal singhNo ratings yet

- Filtration Process DescriptionDocument4 pagesFiltration Process DescriptionJoy Das MahapatraNo ratings yet

- DM Plant DrawingDocument1 pageDM Plant DrawingMd SuruzzamanNo ratings yet

- DesignDocument3 pagesDesigntata_77No ratings yet

- 50 KLD Biological & Tertiary Treatment Plant - RLS FinalDocument19 pages50 KLD Biological & Tertiary Treatment Plant - RLS FinalkezaihrajNo ratings yet

- Air Reverse OsmosisDocument12 pagesAir Reverse Osmosisirdawan100% (2)

- Ate Huber-1Document47 pagesAte Huber-1Ravena RemaditaNo ratings yet

- Standard MBR Units PDFDocument9 pagesStandard MBR Units PDFWilmer Martelo Sarabia100% (1)

- MBBR DesignDocument5 pagesMBBR Designsaurabh kushwaha100% (1)

- 07 - Lime SofteningDocument4 pages07 - Lime SofteningRAJ_1978No ratings yet

- DM PlantDocument9 pagesDM Plantsohag97No ratings yet

- 02.12.21 90m3hr Euroclean-DHV MaithonDocument16 pages02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasNo ratings yet

- 50 KLD Biological & Tertiary Treatment Plant - RLS FinalDocument6 pages50 KLD Biological & Tertiary Treatment Plant - RLS FinalkezaihrajNo ratings yet

- Tube SettlerDocument7 pagesTube SettlerAlvin Setyo BudiNo ratings yet

- Techno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDocument11 pagesTechno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDogo ArgentinoNo ratings yet

- Flint WTP O-M Manual With SOPs 553219 7Document83 pagesFlint WTP O-M Manual With SOPs 553219 7Omkar BharankarNo ratings yet

- Anzir Zero DischargeDocument7 pagesAnzir Zero DischargeMohammad MahediNo ratings yet

- Handling Dairy Milk House WastewaterDocument31 pagesHandling Dairy Milk House WastewaterAndreea CalcanNo ratings yet

- Softener Plant-2Document2 pagesSoftener Plant-2Md. Suruz Zaman100% (1)

- Manual On The Causes and Contril of Activated SludgeDocument21 pagesManual On The Causes and Contril of Activated SludgeRiianti WidiiNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- Budgetary Offer: Sms Envocare Limited For Muzafarpur CetpDocument41 pagesBudgetary Offer: Sms Envocare Limited For Muzafarpur Cetpsreekanth reddy100% (1)

- Trehan STPDocument2 pagesTrehan STPsoma_sharadNo ratings yet

- Aquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvDocument5 pagesAquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvNitin GajmalNo ratings yet

- High Rate Solids Contact Clarifier HRSCCDocument4 pagesHigh Rate Solids Contact Clarifier HRSCCshambhurajesurywanshi1No ratings yet

- Chapter 4 - ExampleDocument11 pagesChapter 4 - ExampleAsegid Bezabih100% (2)

- Degasifier SpecificationsDocument1 pageDegasifier SpecificationsMuhammad Hamza NaveedNo ratings yet

- Presentation - MBBR-Fair Electronics (Samsung) by ShakibDocument32 pagesPresentation - MBBR-Fair Electronics (Samsung) by Shakibshakib nazmus0% (1)

- Biomod: Packaged Moving Bed Biofilm ReactorDocument4 pagesBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- The Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper MillsDocument3 pagesThe Kaldnes Moving Bed Process For Wastewater Treatment at Pulp and Paper Millsvinhphat90No ratings yet

- SWTP Operation ManualDocument131 pagesSWTP Operation ManualKASHIFNo ratings yet

- Ionexchange PDFDocument31 pagesIonexchange PDFAnonymous 6Nt20xKNo ratings yet

- Dual MediaDocument12 pagesDual MediaPraveen Kesavan NairNo ratings yet

- Reverse Osmosis Design GuidelinesDocument2 pagesReverse Osmosis Design Guidelineswacsii ccasullaNo ratings yet

- Efficiency Comparison of Various Sewage Treatment Plants in BangaloreDocument36 pagesEfficiency Comparison of Various Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- MBBR Pack - GB - 1.0 - 06-10-2015Document8 pagesMBBR Pack - GB - 1.0 - 06-10-2015SvetlanaNo ratings yet

- SBR Sewage Treatment Plant Clear WaterDocument12 pagesSBR Sewage Treatment Plant Clear WaterAndreea CalcanNo ratings yet

- Filter Design ParameterDocument3 pagesFilter Design ParameteruemaaplNo ratings yet

- TMF Lime SofteningDocument2 pagesTMF Lime SofteningRachel HechanovaNo ratings yet

- DesalinationDocument14 pagesDesalinationmarishankar1990No ratings yet

- Potassium Permanganate As Oxidant in The Cod Test For Saline Water SamplesDocument11 pagesPotassium Permanganate As Oxidant in The Cod Test For Saline Water SampleskomodobutaNo ratings yet

- 50 Cum/day Capacity Softener System Sl. No. Particulars Specification Feed Pump / Backwash Pump With MotorDocument8 pages50 Cum/day Capacity Softener System Sl. No. Particulars Specification Feed Pump / Backwash Pump With MotorkoppinenipraneethNo ratings yet

- 75 KLD Over Head MBBR TVDocument1 page75 KLD Over Head MBBR TVPrabal singhNo ratings yet

- Recommended Design Criteria For Sedimentation... : General Considerations..Document5 pagesRecommended Design Criteria For Sedimentation... : General Considerations..Ahmed WagihNo ratings yet

- Filter Ion ExchangeDocument10 pagesFilter Ion Exchangemanjunath hrNo ratings yet

- Hydromagx 1Document19 pagesHydromagx 1Jeya KumarNo ratings yet

- HYDRAcap MAX Presentation - Abril 2012Document32 pagesHYDRAcap MAX Presentation - Abril 2012PC VSNo ratings yet

- 2022.10.27B Dewatering Screw PressDocument16 pages2022.10.27B Dewatering Screw PressGeorgeNo ratings yet

- Plate and Tube SettlersDocument4 pagesPlate and Tube Settlerstrdakshayani100% (3)

- ATFD PiparDocument10 pagesATFD Piparrajesh kothariNo ratings yet

- Diligent Etp 1000m3Document18 pagesDiligent Etp 1000m3Prabhakar DhamaleNo ratings yet

- Metito - TSE RO Presentation KM DC WorkshopDocument24 pagesMetito - TSE RO Presentation KM DC WorkshopMohamed Tahoun100% (1)

- Business ProcessDocument12 pagesBusiness ProcessganeshNo ratings yet

- Business Partner in S4 HanaDocument16 pagesBusiness Partner in S4 Hanaganesh100% (1)

- 2B9 Financial Accounting Global SettingsDocument2 pages2B9 Financial Accounting Global SettingsganeshNo ratings yet

- PP Sap TableDocument4 pagesPP Sap Tableganesh100% (1)

- Steps For REM & DiscreteDocument7 pagesSteps For REM & DiscreteganeshNo ratings yet

- Long Term Planning Execution Step by StepDocument10 pagesLong Term Planning Execution Step by StepganeshNo ratings yet

- Source Inspection and Vendor EvaluationDocument3 pagesSource Inspection and Vendor EvaluationganeshNo ratings yet

- SPRO Quality Management Basic Settings Maintain Settings at Client LevelDocument3 pagesSPRO Quality Management Basic Settings Maintain Settings at Client LevelganeshNo ratings yet

- QM Certificate From SupplierDocument1 pageQM Certificate From SupplierganeshNo ratings yet

- List of SAP QM T-CodesDocument8 pagesList of SAP QM T-CodesganeshNo ratings yet

- Create Storage LocationDocument6 pagesCreate Storage LocationganeshNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- SAP PP Tables List PDFDocument3 pagesSAP PP Tables List PDFNadeemNo ratings yet

- BOM ConfigurationDocument21 pagesBOM ConfigurationganeshNo ratings yet

- SAP Navigation Notes by GKDocument5 pagesSAP Navigation Notes by GKganeshNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 pagesChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanNo ratings yet

- Design For Manufacturing PDFDocument29 pagesDesign For Manufacturing PDFcadcam01No ratings yet

- ApexDC Windows User GuideDocument16 pagesApexDC Windows User Guidenikubej100% (1)

- 60 (415) 65 (450) 70 (485) Grade: SA-515/SA-515MDocument1 page60 (415) 65 (450) 70 (485) Grade: SA-515/SA-515MganeshNo ratings yet

- Ganesh BoilerDocument16 pagesGanesh BoilerganeshNo ratings yet

- BASF - Sports Flooring 2020Document12 pagesBASF - Sports Flooring 2020Carlitos PrincipeNo ratings yet

- Transportation EngineeringDocument301 pagesTransportation EngineeringKapil Kushwah100% (1)

- Manual de Partes XAVS1800Cd WUXDocument191 pagesManual de Partes XAVS1800Cd WUXMantenimiento MACDESANo ratings yet

- ASTM A182 F22 Flange - Alloy Steel F22 Socket Weld - Threaded FittingsDocument5 pagesASTM A182 F22 Flange - Alloy Steel F22 Socket Weld - Threaded FittingsMohanasundaram KandasamyNo ratings yet

- Crystal DriveDocument158 pagesCrystal DriveAnonymous RMSMcXZQDeNo ratings yet

- Trickle Irrigation System Components and LayoutDocument8 pagesTrickle Irrigation System Components and LayoutSeble GetachewNo ratings yet

- Specification: Filter Regulator+LubricatorDocument2 pagesSpecification: Filter Regulator+LubricatorLuiggi Javier Juliano BarraNo ratings yet

- TDS - Protectosil CITDocument3 pagesTDS - Protectosil CITVenkata RaoNo ratings yet

- Costing Sheet - 1835 - Die CastingDocument3 pagesCosting Sheet - 1835 - Die CastingRakesh SharmaNo ratings yet

- Loss of Prestressed Due To ANCHORAGEDocument38 pagesLoss of Prestressed Due To ANCHORAGEKimberly Shawn Nicole SantosNo ratings yet

- KE02Document6 pagesKE02Radu StamatinNo ratings yet

- TDC 516 GR 70Document2 pagesTDC 516 GR 70I Kailash Rao100% (2)

- Maintenance Plan-VMCDocument40 pagesMaintenance Plan-VMCArjohn LascanoNo ratings yet

- Chapter 3 STR 3 Beams Shear BondDocument8 pagesChapter 3 STR 3 Beams Shear BonddaniNo ratings yet

- TSA Spec-2Document9 pagesTSA Spec-2Subodh KulkarniNo ratings yet

- Arch Guidelines FINAL 14OCT 2014Document225 pagesArch Guidelines FINAL 14OCT 2014Sogyel TobgyelNo ratings yet

- Polyflow Dec 2020Document16 pagesPolyflow Dec 2020Abdul Rahman HilmiNo ratings yet

- Determination of Flakiness and Elongation Index of Given Aggregate Sample - Seismic ConsolidationDocument8 pagesDetermination of Flakiness and Elongation Index of Given Aggregate Sample - Seismic ConsolidationSajjad HussainNo ratings yet

- Kaiyuan CatalogDocument6 pagesKaiyuan CatalogGogyNo ratings yet

- Lessons Learnt in Construction ProjectsDocument13 pagesLessons Learnt in Construction ProjectsMai Tuan AnhNo ratings yet

- Fire and Explosion Proof DoorsDocument15 pagesFire and Explosion Proof DoorspotatoteddyNo ratings yet

- Handout 1 Rig HyrdaulicsDocument13 pagesHandout 1 Rig HyrdaulicsMarco PlaysNo ratings yet

- Mechanical Atomizer Oil Gun RepairDocument4 pagesMechanical Atomizer Oil Gun RepairGautam GhoshalNo ratings yet

- Causes of Construction Project Failures in PakistanDocument4 pagesCauses of Construction Project Failures in PakistanANDLENATUNo ratings yet

- Analysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadDocument10 pagesAnalysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadmahakNo ratings yet

- A1-10 Curtain WallsDocument19 pagesA1-10 Curtain Wallslwin_oo2435No ratings yet

- GAS STATION v1Document1 pageGAS STATION v1ashier dave calulotNo ratings yet

- Quote AnalysisDocument4 pagesQuote AnalysisGokul NathNo ratings yet