Professional Documents

Culture Documents

Guidelines For PRD Sizing

Guidelines For PRD Sizing

Uploaded by

nirmal_subudhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines For PRD Sizing

Guidelines For PRD Sizing

Uploaded by

nirmal_subudhiCopyright:

Available Formats

Guidelines for PRD Sizing

If a pressure relief device needs to relieve 2-phase flow, it may require a relief area several times larger than the area required for just the vapor portion of the flow. Many older relief system devices and their inlet/outlet piping have been found to be undersized for this reason. API STD 521, Sect. 5.15.3.3 and 3.4, indicate that, in most cases, even fire scenarios beginning with liquid-full vessels do not normally need to be sized for 2-phase flow. The main fire scenario exceptions that do require 2-phase analysis are highly foamy systems and runaway chemical reactions. Other, less frequent 2-phase scenarios are venting below the liquid surface and venting from vessels with narrow-flow passages (such as vessel jackets) where liquid disengagement does not occur. If the relief valves inlet piping begins below the liquid surface (for example, at the base of a distillation column after its trays dump), liquid is forced out the relief valve at a volumetric rate equal to the vapor generation rate, and the saturated liquid then flashes as it passes through the relief valve and its outlet piping. Equity engineers have extensive experience both in determining whether or not 2-phase relief is likely to occur and in sizing PRDs and their inlet/outlet piping for 2-phase flow. AIChEs DIERS guidelines can be used to determine whether the liquid level inside a vessel may be high enough to expect 2-phase relief, as well as the 2-phase flow regime (e.g., bubbly, churn turbulent, homogeneous). Many Owner/Operators have guidelines that require 2-phase analysis for a fire scenario if the vessels contents have high toxicity and/or a high fire hazard, or the vessel contains a large volume. If your company does not have such guidelines, we can help you establish them. If PRD sizing for 2-phase relief is required, we have used both the methods of Appendix D in API RP 520 (the Omega methods), as well as the more precise direct integration methods. All these methods are based on the Homogeneous Equilibrium Model (HEM), which assumes thermodynamic and mechanical equilibrium between phases. The correct 2-phase value for the relief valve discharge coefficient, KD, must also be selected. The direct integration method using the HEM may also be used to conservatively determine pressure drops in inlet/outlet piping. A wide variety of other 2-phase flow models not based on the HEM may also be used to calculate piping pressure drops, depending on the flow regime and the relieving fluids physical properties.

You might also like

- Reading Y3 Summer 1Document6 pagesReading Y3 Summer 1Surfyourlife UntilyoudieNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Chemical Engineering - Size Safety-Relief Valves For Any ConditionsDocument9 pagesChemical Engineering - Size Safety-Relief Valves For Any Conditionshajar_athirah75% (4)

- What You Should Know About Liquid Thermal ExpansionDocument3 pagesWhat You Should Know About Liquid Thermal ExpansionBacelis100% (3)

- Firewater System DesignDocument8 pagesFirewater System Designkenoly123No ratings yet

- BWT Septron Line 31-61 Rev01!08!05-18 Opm enDocument56 pagesBWT Septron Line 31-61 Rev01!08!05-18 Opm enDavide Grioni100% (1)

- Size SRV For Any ConditionsDocument9 pagesSize SRV For Any ConditionsBaba JohnehNo ratings yet

- API-521 Flare KOD Design and Even More - Part 1Document6 pagesAPI-521 Flare KOD Design and Even More - Part 1Said Ahmed Salem100% (1)

- Relief Systems Vent SystemsDocument10 pagesRelief Systems Vent Systemsaugur886No ratings yet

- Reliefandblowdown SudyDocument35 pagesReliefandblowdown Sudysivainduri100% (1)

- What You Should Know About Liquid Thermal - ExpansionDocument4 pagesWhat You Should Know About Liquid Thermal - ExpansionOthman Mat YamanNo ratings yet

- Properly Employ Overhead Condensers For Vacuum ColumnsDocument8 pagesProperly Employ Overhead Condensers For Vacuum ColumnsmrtiemannNo ratings yet

- Doc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10Document10 pagesDoc. No.: PDG-MUM-XXX Rev. 0 Relief Valve Sizing Philosophy Page 1 of 10kishna009No ratings yet

- Condenser - Valuable Book PDFDocument6 pagesCondenser - Valuable Book PDFRajesh OwaiyarNo ratings yet

- Pipeline Sizing: Learning ObjectivesDocument7 pagesPipeline Sizing: Learning Objectivesbikas_sahaNo ratings yet

- Calculation For Vacuum CondenserDocument0 pagesCalculation For Vacuum Condenserraden_aditiya39No ratings yet

- Oil& Gas SeparationDocument9 pagesOil& Gas SeparationHomam MohammadNo ratings yet

- Guidelines For Pressure Relief and Effluent Handling SystemsDocument1 pageGuidelines For Pressure Relief and Effluent Handling SystemsGhasem BashiriNo ratings yet

- Column PSV SizingDocument10 pagesColumn PSV SizingbalajikrishnanNo ratings yet

- Introduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDocument3 pagesIntroduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDheeraj Shukla100% (1)

- Pipeline Sizing: Learning ObjectivesDocument7 pagesPipeline Sizing: Learning ObjectivesRajasekar MeghanadhNo ratings yet

- Strategies For Inspecting HRSGs in Two-Shift and Low-Load ServiceDocument9 pagesStrategies For Inspecting HRSGs in Two-Shift and Low-Load Serviceokoro matthewNo ratings yet

- Flare For DesignDocument4 pagesFlare For DesignChem.EnggNo ratings yet

- Examine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)Document16 pagesExamine Inlet Separation Technologies For Increased Reliability (Nexo Solutions)DWNLD USRMLNo ratings yet

- Separator Design GuideDocument3 pagesSeparator Design Guidelaleye_olumideNo ratings yet

- CCCCC C: C À C × C Î C C !C C!C #C $!C %&"C "C#%!Document11 pagesCCCCC C: C À C × C Î C C !C C!C #C $!C %&"C "C#%!bejoise100% (2)

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocument4 pagesUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1No ratings yet

- Process Transients AnalysisDocument25 pagesProcess Transients AnalysisOtis ArmsNo ratings yet

- API 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsDocument14 pagesAPI 521 7 Edition Ballot Item 6.1 New Work Item - Potential ASME Code ViolationsAyadi_AymanNo ratings yet

- Vapor-Liquid Separator - WikipediaDocument3 pagesVapor-Liquid Separator - Wikipediaramthecharm_46098467No ratings yet

- The Design and Operation of Offshore Relief - Venting SystemsDocument24 pagesThe Design and Operation of Offshore Relief - Venting SystemsMichael HaiseNo ratings yet

- Coal Chemical PropertiesDocument6 pagesCoal Chemical PropertiesYan LaksanaNo ratings yet

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallDocument10 pagesPrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehNo ratings yet

- Solution Manual For Chemical Engineering Design Principles, Practice and Economics of Plant and Process Design Towler Sinnott 2nd EditionDocument27 pagesSolution Manual For Chemical Engineering Design Principles, Practice and Economics of Plant and Process Design Towler Sinnott 2nd Editionharold.morrison944100% (9)

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgNo ratings yet

- XX Paper 18 PDFDocument21 pagesXX Paper 18 PDFFauzi SaputraNo ratings yet

- Using DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesDocument8 pagesUsing DIERS Two-Phase Equations To Estimate Tube Rupture FlowratesAugusto Jorge Lozada100% (1)

- Fundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalDocument4 pagesFundamentals of Gas Pipeline Metering Stations - Pipeline & Gas JournalMehedi HasanNo ratings yet

- Real Separator GuideDocument23 pagesReal Separator GuideMuhammad Athar100% (6)

- Vacuum Condenser Drainage - Proper Design & Installation GuideDocument3 pagesVacuum Condenser Drainage - Proper Design & Installation Guidenirmal_subudhiNo ratings yet

- Oto 01061Document254 pagesOto 01061Yolanda Marcela Enríquez MéndezNo ratings yet

- Does Your Deaerator Really Work?: Altair Equipment Co. Inc. Warminster, PaDocument6 pagesDoes Your Deaerator Really Work?: Altair Equipment Co. Inc. Warminster, PaVinh Do ThanhNo ratings yet

- Steam Generator Tube Rupture Analysis Using Dynamic SimulationDocument5 pagesSteam Generator Tube Rupture Analysis Using Dynamic SimulationvasuNo ratings yet

- 1-XI GBDocument20 pages1-XI GBdd6077No ratings yet

- Fundamentals of Gas Pipeline Metering StationsDocument5 pagesFundamentals of Gas Pipeline Metering StationsSarah DeanNo ratings yet

- 2012-07 Overpressure Protection + Working With The CSB After An Accident - Selected PapersDocument8 pages2012-07 Overpressure Protection + Working With The CSB After An Accident - Selected PaperssourcemenuNo ratings yet

- HPHT Drill & Well ControlDocument40 pagesHPHT Drill & Well ControlanilkumarNo ratings yet

- Bypass Systems in Combined-Cycle Power PlantsDocument8 pagesBypass Systems in Combined-Cycle Power PlantsAnirban Banerjee100% (2)

- Using DIERS Two Phase Equations To Estimate Tube Rupture FlowratesDocument8 pagesUsing DIERS Two Phase Equations To Estimate Tube Rupture FlowratesNoirchevalNo ratings yet

- Biogas SystemsDocument8 pagesBiogas SystemsvedpathakNo ratings yet

- Vessel Sizing and Level InstrumentationDocument5 pagesVessel Sizing and Level InstrumentationAlexanderNo ratings yet

- Design PitfallsDocument4 pagesDesign PitfallsShailesh LohareNo ratings yet

- 1-XI - GB Steam Conditioning ManualDocument20 pages1-XI - GB Steam Conditioning ManualtxagusNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Class 6-1Document1 pageClass 6-1nirmal_subudhiNo ratings yet

- Hydrocarbon Processing: Deep Water FLNGDocument1 pageHydrocarbon Processing: Deep Water FLNGnirmal_subudhiNo ratings yet

- Compressor Dynamics 4Document1 pageCompressor Dynamics 4nirmal_subudhiNo ratings yet

- Compressor Dynamics 3Document1 pageCompressor Dynamics 3nirmal_subudhiNo ratings yet

- Compressor Dynamics 2Document1 pageCompressor Dynamics 2nirmal_subudhiNo ratings yet

- Compressor Dynamics 1Document1 pageCompressor Dynamics 1nirmal_subudhiNo ratings yet

- Msds DodecaneDocument6 pagesMsds Dodecanenirmal_subudhiNo ratings yet

- Process View VBA Tutorial: User'S ManualDocument1 pageProcess View VBA Tutorial: User'S Manualnirmal_subudhiNo ratings yet

- Dispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology MalaysiaDocument44 pagesDispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology Malaysianirmal_subudhi100% (1)

- M MercaptanDocument7 pagesM Mercaptannirmal_subudhiNo ratings yet

- Msds HexadecaneDocument5 pagesMsds Hexadecanenirmal_subudhiNo ratings yet

- Msds HeptadecaneDocument5 pagesMsds Heptadecanenirmal_subudhiNo ratings yet

- Msds PentadecaneDocument5 pagesMsds Pentadecanenirmal_subudhiNo ratings yet

- MSDS N EicosaneDocument3 pagesMSDS N Eicosanenirmal_subudhiNo ratings yet

- Msds TolueneDocument6 pagesMsds Toluenenirmal_subudhi100% (1)

- Msds NonaneDocument5 pagesMsds Nonanenirmal_subudhiNo ratings yet

- Msds UndecaneDocument5 pagesMsds Undecanenirmal_subudhiNo ratings yet

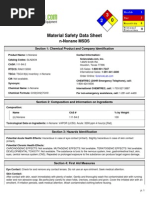

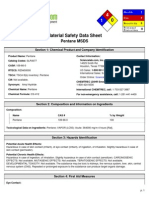

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationnirmal_subudhiNo ratings yet

- Msds OctaneDocument5 pagesMsds Octanenirmal_subudhiNo ratings yet

- Msds TetradecaneDocument5 pagesMsds Tetradecanenirmal_subudhiNo ratings yet

- Msds HeptaneDocument6 pagesMsds Heptanenirmal_subudhiNo ratings yet

- Msds N PentaneDocument6 pagesMsds N Pentanenirmal_subudhiNo ratings yet

- Msds N ButaneDocument6 pagesMsds N Butanenirmal_subudhiNo ratings yet

- Msds IsobutaneDocument6 pagesMsds Isobutanenirmal_subudhiNo ratings yet

- Msds EthaneDocument7 pagesMsds Ethanenirmal_subudhiNo ratings yet

- The Untouchables and The Pax Britannica Dr. B.R.ambedkarDocument61 pagesThe Untouchables and The Pax Britannica Dr. B.R.ambedkarVeeramani ManiNo ratings yet

- Fariha (MGT 212)Document11 pagesFariha (MGT 212)Rabib AhmedNo ratings yet

- Group 112-111 My Daily RoutineDocument9 pagesGroup 112-111 My Daily Routineapi-306090241No ratings yet

- New Vehicle Data - 25.03 - ENDocument3 pagesNew Vehicle Data - 25.03 - ENcllsjanusNo ratings yet

- Arduino iOS Blueprints - Sample ChapterDocument15 pagesArduino iOS Blueprints - Sample ChapterPackt PublishingNo ratings yet

- Epson EPL-5800 Service ManualDocument116 pagesEpson EPL-5800 Service ManualHarris FNo ratings yet

- Fortran CF DDocument160 pagesFortran CF DLahcen AkerkouchNo ratings yet

- Tutorial 1 Intro To PhotonicsDocument4 pagesTutorial 1 Intro To Photonicsamitgh88No ratings yet

- Thesis On Mughal ArchitectureDocument5 pagesThesis On Mughal Architecturecarlajardinebellevue100% (2)

- Physics 2018 Prelims NYJC Paper 2Document19 pagesPhysics 2018 Prelims NYJC Paper 2NG KAI EE EMMANUELLE NG KAI EE EMMANUELLENo ratings yet

- Gopi EnglishDocument31 pagesGopi EnglishGopi ShankarNo ratings yet

- MQ Series: Do Not Have To Be Executing at The Same TimeDocument10 pagesMQ Series: Do Not Have To Be Executing at The Same TimeSanjay DasNo ratings yet

- Hemorragic CystDocument14 pagesHemorragic CystNyoman TapayanaNo ratings yet

- Getting-Started nrf8001 Bluefruit-Le-BreakoutDocument38 pagesGetting-Started nrf8001 Bluefruit-Le-BreakoutnescafefrNo ratings yet

- 2009 Contexts Annual Report (Volume 36)Document12 pages2009 Contexts Annual Report (Volume 36)Haffenreffer Museum of AnthropologyNo ratings yet

- Bag Specification 3LDocument1 pageBag Specification 3LBookWayNo ratings yet

- Result Awaited FormDocument1 pageResult Awaited FormRoshan kumar sahu100% (1)

- Michael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)Document23 pagesMichael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)JustinWagnerNo ratings yet

- Punjab BotanyDocument9 pagesPunjab BotanyAYUSHNEWTONNo ratings yet

- NEW Curriculum Vitae Marking Scheme (Jan 2022)Document2 pagesNEW Curriculum Vitae Marking Scheme (Jan 2022)TONo ratings yet

- DLL - Mathematics 6 - Q4 - W2Document8 pagesDLL - Mathematics 6 - Q4 - W2RirinNo ratings yet

- DJ Lemon (Official Profile 2013)Document6 pagesDJ Lemon (Official Profile 2013)Monica Kshirsagar100% (1)

- Chaff CutterDocument23 pagesChaff CutterFekadie TesfaNo ratings yet

- 07. ĐỀ THI VÀO LỚP 10-CẦN THƠ (2020-2021)Document8 pages07. ĐỀ THI VÀO LỚP 10-CẦN THƠ (2020-2021)Vương ThànhNo ratings yet

- The Twilight ZoneDocument2 pagesThe Twilight ZonegatochaletNo ratings yet

- Form Jurnal JesikomDocument9 pagesForm Jurnal JesikomAhmad Hafiizh kudrawiNo ratings yet

- NIR Item PLM Change MGT FinalDocument245 pagesNIR Item PLM Change MGT FinalSiva KumaranNo ratings yet

- Impaired Skin IntegrityDocument7 pagesImpaired Skin Integrityprickybiik100% (8)