Professional Documents

Culture Documents

Design of Draft Tube Top Slab: I. Due To U.D.L.

Design of Draft Tube Top Slab: I. Due To U.D.L.

Uploaded by

BADRI VENKATESHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Draft Tube Top Slab: I. Due To U.D.L.

Design of Draft Tube Top Slab: I. Due To U.D.L.

Uploaded by

BADRI VENKATESHCopyright:

Available Formats

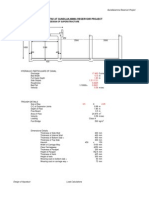

Design of Draft Tube Top Slab

Width of Draft tube

Height of Draft tube

Depth of beam

=

=

=

2.520 m

0.950 m

0.750 m

+ 217.90

Concrete

+ 217.15

0.950

D.T. opening

+ 216.20

2.520

Analysis :

Consider '1m' length of draft tube.

1. Calcualtion of loads :

i. Due to u.d.l.:

Weight of concrete above opening

=

Take '1m' width of concrete around the opening:

Effective span

0.750 x 2.50

1.875 t/m2 /m

=

=

2.520

+ 1.00

3.520 m

1.875

16

1.452

1.875

2

3.300

1.875 t/m

3.52

Max. Possitive B.M.

=

Max. Shear

=

x 3.52 ^2

t-m

x 3.52

t

ii. Due to point load :

Load from Spiral case

19.400 kN ( AS per KBL drawing)

19.400

3.52

Max. Possitive B.M.

=

=

19.400

x 3.52

8

8.536 t-m

19.400

2

9.700 t

Max. Shear

Total B.M. = i + ii

Total Shear = i + ii

=

=

=

=

1.452

+ 8.54

9.988 t-m

3.300

+ 9.70

t

13.000

Design :

cbc

7 N/mm2

st

m

k

j

Q

=

=

=

=

=

190 N/mm2

13.333

0.329

0.890

1.026

Overall depth

Provided Effective depth

Required Area of steel

Provide

Area of one bar

Sapcing

Provide

=

=

=

=

750.000 mm

750.000

- 50.00

- 10.00

690.000 mm

9.988

x 10 ^7

190 x 0.89

x 690.00

855.835 mm2

=

=

314.159 mm2

367 mm

150 mm c/c.

2094.395 mm2

=

=

3.300 t

3.300

x 10 ^4

1000.000

x 690.00

20 mm dia. Bars.

20

Provided Area of steel

2. Check for Shear:

S.F. ( V )

Nominal shear stress

bars of

0.048 N/mm2

% of steel

Ref : Table No.23 of IS 456.

Pt

0.50

0.75

Pemissible shear stress

100

1000.000

x 2094.40

x 690.00

0.304 %

0.261 N/mm2

c

0.30

0.35

Hence OK

Design of Draft Tube Top Slab

Width of Draft tube

Height of Draft tube

Depth of beam

=

=

=

2.520 m

0.950 m

3.550 m

+ 220.70

Concrete

+ 217.15

0.950

D.T. opening

+ 216.20

2.520

Analysis :

Consider '1m' length of draft tube.

1. Calcualtion of loads :

i. Due to u.d.l.:

Weight of concrete above opening

=

Consider '1m' width of concrete around the opening:

Effective span

3.550 x 2.50

8.875 t/m2 /m

=

=

2.520

+ 1.00

3.520 m

8.875

10

10.996

8.875

2

15.620

8.875 t/m

3.52

Max. Possitive B.M.

=

Max. Shear

=

x 3.52 ^2

t-m

x 3.52

t

ii. Due to point loads :

Load from Spiral case

19.400

1.178

0.582

19.400 kN ( AS per KBL drawing)

19.400

1.178

3.52

Ref : Roark's Formulas for Stress and Strain.

a . For Load 1 :

w=19.40

a=0.582

A

B

l=3.52

Reaction at 'A' =

w * ( l - a )2 * (l + 2a)

l3

Reaction at 'B' =

- w * a2 * (3 l - 2a )

l3

Max. Possitive B.M. =

2 * w * a 2 * ( l - a )2

l3

Max. Negative B.M. =

- w * a * ( l - a )2

l2

Reaction at "A"

Reaction at "B"

Max. Possitive B.M.

Max. Negative B.M.

=

=

=

=

17.984

-1.416

2.601

-7.866

t

t

t-m

t-m

b . For Load 2 :

w=19.40

a=2.94

A

B

l=3.52

Reaction at "A"

Reaction at "B"

Max. Possitive B.M.

=

=

=

1.416 t

-17.984 t

2.601 t-m

Max. Negative B.M.

-10.113 t-m

Reaction at "A"

Reaction at "B"

Max. Possitive B.M.

Max. Negative B.M.

=

=

=

=

19.400

-19.400

5.202

-17.979

Total B.M. = i + ii

=

=

=

=

Total :

Total Shear = i + ii

t

t

t-m

t-m

10.996 + 10.11

21.110 t-m

15.620 + 19.40

35.020 t

Design :

cbc

7 N/mm2

st

m

k

j

Q

=

=

=

=

=

190 N/mm2

13.333

0.329

0.890

1.026

Overall depth

Provided Effective depth

=

=

=

=

Required Area of steel

Provide

Area of one bar

Sapcing

Provide

3550.000 mm

3550.000

- 50.00

- 10.00

3490.000 mm

21.110

x 10 ^7

190 x 0.89

x 3490.00

357.620 mm2

=

=

314.159 mm2

878 mm

150 mm c/c.

2094.395 mm2

=

=

35.020 t

35.020

x 10 ^4

1000.000 x 3490.00

20 mm dia. Bars.

20

Provided Area of steel

2. Check for Shear:

S.F. ( V )

Nominal shear stress

bars of

0.100 N/mm2

% of steel

Ref : Table No.23 of IS 456.

Pt

0.15

0.25

Pemissible shear stress

100

1000.000

x 2094.40

x 3490.00

0.060 %

0.144 N/mm2

c

0.18

0.22

Hence OK

You might also like

- Hna tacFPS Aim Guide (Kovaaks and AimLabs)Document9 pagesHna tacFPS Aim Guide (Kovaaks and AimLabs)Kyrion6666100% (1)

- Design of Reinforced Concrete Water TanksDocument71 pagesDesign of Reinforced Concrete Water Tanksace1205100% (3)

- Presentation 8th SemDocument60 pagesPresentation 8th SemZayan Khan100% (1)

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- TCSP10403R0Document30 pagesTCSP10403R0BADRI VENKATESHNo ratings yet

- Act. 2Document8 pagesAct. 2olpotNo ratings yet

- Cost and Scale-Up FactorsDocument16 pagesCost and Scale-Up FactorsRicardo Hurtado HernándezNo ratings yet

- 1.0 Basic PDFDocument2 pages1.0 Basic PDFAnonymous wosn1lyNo ratings yet

- River Weirs - Good Practice Guide Guide - Section B2: Charles Rickard, Rodney Day, Jeremy PursegloveDocument35 pagesRiver Weirs - Good Practice Guide Guide - Section B2: Charles Rickard, Rodney Day, Jeremy Pursegloveeduardotorri100% (1)

- Slab Bridge Design ExampleDocument12 pagesSlab Bridge Design ExampleDaniel SolomonNo ratings yet

- Design of Vertical Drop: Design Data Units Description U/S Side D/S SideDocument10 pagesDesign of Vertical Drop: Design Data Units Description U/S Side D/S SideSudip ShresthaNo ratings yet

- List of ContentsDocument53 pagesList of ContentstiniNo ratings yet

- Probabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportDocument74 pagesProbabilistic Seismic Hazard Analysis Nepal (Solukhumbu) Complete ReportSabin AcharyaNo ratings yet

- GL-13 Irrigation Pump Facilities Study and Design FGLDocument166 pagesGL-13 Irrigation Pump Facilities Study and Design FGLEphremNo ratings yet

- Topology Optimization (Report)Document11 pagesTopology Optimization (Report)Mahmoud KassabNo ratings yet

- Circular Culvert Design Culvert Calculations - Software - EquationsDocument3 pagesCircular Culvert Design Culvert Calculations - Software - EquationsmustaffakadirNo ratings yet

- Designed For Class A LoadingDocument4 pagesDesigned For Class A Loadingdsananda100% (1)

- A Numerical Study of Bifurcation-A Case Study of Phukot Karnali HEPDocument12 pagesA Numerical Study of Bifurcation-A Case Study of Phukot Karnali HEPBardan DangiNo ratings yet

- NetafimDocument67 pagesNetafimxtianNo ratings yet

- DCHSDocument383 pagesDCHSMamoshara GucheNo ratings yet

- Bridge Girder Design of An EOT Crane Structure - A CAD ApproachDocument5 pagesBridge Girder Design of An EOT Crane Structure - A CAD ApproachChristian Oribe CastilloNo ratings yet

- Building Estimation: Quantity SheetDocument20 pagesBuilding Estimation: Quantity SheetAjay katkarNo ratings yet

- 4 - HE 731 - Example - Surge Tank and TurbinesDocument11 pages4 - HE 731 - Example - Surge Tank and TurbinesHa NaNo ratings yet

- Pipe Culvert Quantity Estimation and Schedule - Mozambique by PassDocument100 pagesPipe Culvert Quantity Estimation and Schedule - Mozambique by PassEskinderNo ratings yet

- Well FoundationDocument15 pagesWell FoundationNehaSinghNo ratings yet

- As Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjaDocument32 pagesAs Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjajaffnaNo ratings yet

- Part-E Design Examples of Bridges: Road Structures Manual For Single Lane BridgesDocument55 pagesPart-E Design Examples of Bridges: Road Structures Manual For Single Lane Bridgesbartlucena9505No ratings yet

- Hydraulic Design of Energy Tors For Culverts and ChannelsDocument15 pagesHydraulic Design of Energy Tors For Culverts and ChannelsCharles S. MeehanNo ratings yet

- Analisa Box Culvert Otiola 1Document12 pagesAnalisa Box Culvert Otiola 1agussalim lammaseNo ratings yet

- Aqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of SuperstructureDocument58 pagesAqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of Superstructurep_ignatiusNo ratings yet

- Design of The HVA Water TunnelDocument10 pagesDesign of The HVA Water TunnelSjoerd_BNo ratings yet

- Quiz 2 On Earthquake EngineeringDocument7 pagesQuiz 2 On Earthquake EngineeringKenny CantilaNo ratings yet

- Thrust BlocksDocument16 pagesThrust Blockshemantkle2uNo ratings yet

- Pier Design Example - US Units - Design Step 8Document50 pagesPier Design Example - US Units - Design Step 8amitdas19830131No ratings yet

- Tyrolean IntakeDocument9 pagesTyrolean Intakezulkifli1220No ratings yet

- Design of JoistDocument26 pagesDesign of Joistallen2912100% (1)

- Drip Design at SolDocument13 pagesDrip Design at SolVan BGNo ratings yet

- Planning and DesignDocument112 pagesPlanning and DesignkvsnlrNo ratings yet

- Part-3 Frequency AnalysisDocument32 pagesPart-3 Frequency AnalysisAbse TarikuNo ratings yet

- EN1994 4 HanswilleDocument73 pagesEN1994 4 Hanswilleoluomo1No ratings yet

- Transitions-Cross Drainage WorkDocument3 pagesTransitions-Cross Drainage WorkShibani PatelNo ratings yet

- Crack WidthDocument1 pageCrack WidthD SRINIVASNo ratings yet

- Sub Theme 2 - Full PaperDocument752 pagesSub Theme 2 - Full PaperDedi ApriadiNo ratings yet

- Design of SyphonDocument7 pagesDesign of SyphonraghurmiNo ratings yet

- Spillway DesignDocument6 pagesSpillway DesignguildkeyNo ratings yet

- Retaining Wall DesignDocument40 pagesRetaining Wall DesignAnonymous Clm40C1No ratings yet

- List of Files (AD2-CANALS) FinalDocument33 pagesList of Files (AD2-CANALS) FinalnidhisasidharanNo ratings yet

- 1000 Pipe Culvert Concrete QuantitiesDocument1 page1000 Pipe Culvert Concrete QuantitiesHegdeVenugopalNo ratings yet

- Lecture No.6 and 9 - BridgeAnalysisDesignDocument49 pagesLecture No.6 and 9 - BridgeAnalysisDesignRiffat SaidNo ratings yet

- Working Principle of Submersible PumpDocument5 pagesWorking Principle of Submersible PumpSatinder saini100% (1)

- Design Example 3 - Reinforced Strip Foundation-1Document8 pagesDesign Example 3 - Reinforced Strip Foundation-1seljak_veseljakNo ratings yet

- Wind and EQ Analysis For Overhead TanksDocument13 pagesWind and EQ Analysis For Overhead TanksMesfin Derbew50% (2)

- IE - LESSON 16. Design and Operation of Underground Pipeline SystemDocument5 pagesIE - LESSON 16. Design and Operation of Underground Pipeline SystemEfremWakjiraHodeNo ratings yet

- Permissible Velocities in Lined ChannelsDocument2 pagesPermissible Velocities in Lined ChannelsEknath TaleleNo ratings yet

- Nameof Work:-Design of Circular Water Tank: Narok ETPDocument27 pagesNameof Work:-Design of Circular Water Tank: Narok ETPAbhay Thakur100% (1)

- Asignment HPDocument6 pagesAsignment HPAbdirahman ali100% (1)

- Zentrament Super BVDocument2 pagesZentrament Super BVMohit JangidNo ratings yet

- Static and Dynamic Behaviour of Raft of A BarrageDocument8 pagesStatic and Dynamic Behaviour of Raft of A BarrageTadigotla SasidharNo ratings yet

- Canal FallsDocument45 pagesCanal FallsjkNo ratings yet

- Concrete Mix Design Report PDFDocument32 pagesConcrete Mix Design Report PDFMohamed AhmedNo ratings yet

- Circular Pier With Circular Footing.Document25 pagesCircular Pier With Circular Footing.Balaji Rao Ch100% (5)

- Design of Compound WallDocument4 pagesDesign of Compound WallMaku Rajkumar100% (3)

- Pipe Support Columns at Bridge CrossingDocument9 pagesPipe Support Columns at Bridge CrossingChamil Mahagamage100% (1)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- 84103128Document1 page84103128BADRI VENKATESHNo ratings yet

- DPS AmmendmentDocument26 pagesDPS AmmendmentBADRI VENKATESHNo ratings yet

- Fair Practices Code: ObjectiveDocument16 pagesFair Practices Code: ObjectiveBADRI VENKATESHNo ratings yet

- LED Lighting Solutions: Safer. Smarter. More Vibrant SpacesDocument14 pagesLED Lighting Solutions: Safer. Smarter. More Vibrant SpacesBADRI VENKATESHNo ratings yet

- 3-Annexure 3 Drawings Set - R2Document57 pages3-Annexure 3 Drawings Set - R2BADRI VENKATESHNo ratings yet

- Distribution Code 2015-YellowDocument111 pagesDistribution Code 2015-YellowBADRI VENKATESHNo ratings yet

- 001 RP en - 6Document97 pages001 RP en - 6BADRI VENKATESHNo ratings yet

- Battery Sizing: From Open ElectricalDocument11 pagesBattery Sizing: From Open ElectricalBADRI VENKATESH100% (1)

- SatconDocument18 pagesSatconBADRI VENKATESHNo ratings yet

- TESB10605R1Document11 pagesTESB10605R1BADRI VENKATESHNo ratings yet

- Presentation PDFDocument15 pagesPresentation PDFBADRI VENKATESH0% (1)

- Load Flow Study For The Year 2017-18 - 26052017 PDFDocument45 pagesLoad Flow Study For The Year 2017-18 - 26052017 PDFBADRI VENKATESHNo ratings yet

- TESB10606R1Document11 pagesTESB10606R1BADRI VENKATESHNo ratings yet

- Corrigendum I Part 2 of 2 PDFDocument391 pagesCorrigendum I Part 2 of 2 PDFBADRI VENKATESHNo ratings yet

- CSERC CONNECTIVITY AND INTRA-STATE OPEN ACCESS Regulation-2011 PDFDocument59 pagesCSERC CONNECTIVITY AND INTRA-STATE OPEN ACCESS Regulation-2011 PDFBADRI VENKATESHNo ratings yet

- English Exercise (For High School)Document14 pagesEnglish Exercise (For High School)AdhitantoNabilShobirinNo ratings yet

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNo ratings yet

- 7 Strategic Planning For PRDocument35 pages7 Strategic Planning For PRNsyazwani JUNo ratings yet

- Osullivan T 09071996 TranscriptDocument2 pagesOsullivan T 09071996 Transcriptapi-380159566No ratings yet

- Pitot TubesDocument16 pagesPitot TubesKishan PatelNo ratings yet

- Siemens SIMATIC Step 7 Programmer's HandbookDocument57 pagesSiemens SIMATIC Step 7 Programmer's HandbookEka Pramudia SantosoNo ratings yet

- On Plain Stress Analysis of A Composite BlockDocument11 pagesOn Plain Stress Analysis of A Composite BlockSrinivas NadellaNo ratings yet

- Tiếng Anh 6 Smart World - Unit 9 Test - Answer keyDocument5 pagesTiếng Anh 6 Smart World - Unit 9 Test - Answer keyHà Lê100% (1)

- Level of Customer Satisfaction On Benefits of Using Duralite SandalsDocument20 pagesLevel of Customer Satisfaction On Benefits of Using Duralite SandalsRobert DacusNo ratings yet

- Heavy Lifting: Parking Concerns Stymie New Classroom PlansDocument24 pagesHeavy Lifting: Parking Concerns Stymie New Classroom PlansAnonymous 2yVesLNo ratings yet

- Communication Basics PDFDocument84 pagesCommunication Basics PDFTatenda PaduzeNo ratings yet

- NGO - Jobs-Entry-Level-CVDocument1 pageNGO - Jobs-Entry-Level-CVAkay Ahmed AliyuNo ratings yet

- .Au Steel-GradesDocument5 pages.Au Steel-GradesClayton RobersonNo ratings yet

- Co d12Document2 pagesCo d12grrrrtomtomNo ratings yet

- Kollmorgen B With ServoStar S and CD TB CatalogDocument10 pagesKollmorgen B With ServoStar S and CD TB CatalogElectromateNo ratings yet

- Montessori MethodDocument4 pagesMontessori MethodRida ButtNo ratings yet

- Plato On Respect, and What "Belongs To" Oneself: Christopher J. RoweDocument16 pagesPlato On Respect, and What "Belongs To" Oneself: Christopher J. RoweOctavian DanNo ratings yet

- Article - Controlled Release Fertilizers and Nanotechnology TracesDocument11 pagesArticle - Controlled Release Fertilizers and Nanotechnology TracesIrvan Key Rizky100% (1)

- Sample Conclusion and GraphicDocument3 pagesSample Conclusion and Graphicapi-260339450No ratings yet

- Sap OverviewDocument82 pagesSap OverviewSrinivasa ReddyNo ratings yet

- LECTURE 07 Comprehensive Development PlanDocument30 pagesLECTURE 07 Comprehensive Development PlanTJ BungayNo ratings yet

- Yukiko NakamuraDocument2 pagesYukiko Nakamuraapi-478200172No ratings yet

- Quiz On Normal DistrributionDocument2 pagesQuiz On Normal Distrributiongulafshan100% (1)

- CPADocument13 pagesCPAAlwyn Pinto100% (2)

- Stakeholder AnalysisDocument5 pagesStakeholder Analysisapi-491761735No ratings yet

- Test Bank For Sociology For The 21st Century Census Update 5th Edition Tim CurryDocument36 pagesTest Bank For Sociology For The 21st Century Census Update 5th Edition Tim Curryzebrula.violatorzw1hf100% (44)

- Review Roulette Ae1 FinalDocument20 pagesReview Roulette Ae1 Finalapi-241222198No ratings yet