Professional Documents

Culture Documents

Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Products

Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Products

Uploaded by

ashuna249396Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Products

Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Products

Uploaded by

ashuna249396Copyright:

Available Formats

Global Advanced Research Journal of Microbiology (ISSN: 2315-5116) Vol. 2(3) pp.

054-064, March, 2013 Available online http://garj.org/garjm/index.htm Copyright 2013 Global Advanced Research Journals

Full Length Research Paper

Microbial production of polyhydroxybutyrate, a biodegradable plastic using agro-industrial waste products.

Alyaa Hamieh*, Zakia Olama and Hanafi Holail

BAU, Debbiye, Lebanon

Accepted 24 February, 2013

Plastics produced from petrochemical sources and known as polypropylene are now accumulating in our environment at rates of millions of tons per year creating severe problems. The present study aims to the production and isolation of PHB (polyhydroxy-buty rate ), a biodegradable plastic, from agro-industrial waste products (whey and date molasses) due to its high economic and industrial importance , taking into consideration many points that lead to produce PHB on large scale. The methodology of this study includes screening study for the isolation of a promising microbial producer of PHB , and optimization experiments to evaluate the best environmental and physiological factors that lead to maximum PHB production. Under the optimized conditions, Lactobacillus acidophilus has shown maximum production when grown for 4 days on date molasses supplemented with NB yielding 0.412g/50ml of PHB, followed by Bacillus thuringiensis (0.367g/50ml) grown for 4 days on the same medium, and Bacillus subtilis (0.337g/50ml) grown for 6 days on whey supplemented with glucose, yeast extract, and peptone. Eleven nutritional factors were examined for their significance on PHB production using a statistical design known as Plackette-Burman. Maximum PHB output of 43.1 g/l produced by Lactobacillus acidophilus was revealed by the statistical design, which represents about 7.04 fold increase in PHB production. Fedbatch fermentation was carried out using the optimized fermentation medium and PHB production has been increased to 27.5% as compared with batch closed process. PHB was detected by transmission electron microscopy and monitoring UV spectra of the sample by scanning the samples between 220 and 300nm compared with standard PHB. Lactobacillus acidophilus can be used for PHB production on large industrial scale, solving by this one of the problems of solid waste management that results from the accumulation of plastics and saving the environment from additional air pollution caused by its recycling. Keywords: Microbial production, polyhydroxybutyrate, agro-industrial waste products. INTRODUCTION Plastics known as polypropylene are the essential ingredients that enhance the quality of our life. Its manufacturing has increased significantly since the 1940s and has successfully replaced wood, mud, metals, glass and other materials.

*Corresponding Authors E-mail: zakia.olama@bau.edu.lb

Hamieh et al. 055 The low cost, stability, durability, good mechanical and thermal properties of plastic make it the best choice for widespread applications (Amara, 2008). However, the extensive use of materials made from plastics causes a worldwide problem because they are non-degradable (Muller et al., 2001). Another problem is that traditional plastics are produced from petrochemical sources that may be depleted and takes millions of years to be renewed. Recently issues concerning the global environment and solid waste management have created much interest in the development of biodegredable plastics that should be produced on an industrial scale to be commonly used (Anderson & Dawes, 1990). Polyhydroxy-butyrate (PHB) is a linear polyester of D(-)-3- hydroxyl-butyrate , and the best known of the polymers of related polyhydroxyalkanoates, that is produced by several microorganisms as an energy source(Page, 1995 and Lee, 1996). It is a biodegradable plastic that can be degraded aerobically and anaerobically by soil microorganisms. It has similar physical properties as polypropylene so it can be used as an alternative source of plastics (Bryom, 1987). Eventhough there are more than 250 different microorganisms synthesizing PHAs, only several of these, such as Alcaligenes eutrophus (Kim et al., 1994), Alcaligenes latus (Yamane et al., 1996), Azotobacter vinelandii (Page & Knosb, 1989), methylotrophs (Kim et al., 1996), Pseudomonas oleovorans (Brandl et al., 1988) and recombinant Escherichia coli (Lee & Chang, 1994 and Lee et al., 1997) are suitable for the production of PHAs to a high concentration with high productivity. Various researchers have explained that soil bacteria generally produce PHB (Hanzlikova et al., 1985). A large proportion (80%) of the tested soil streptomyces was able to produce PHB. However the actual amounts of PHB accumulation were generally lower for industrial application than for other bacterial groups which are known to produce PHB (UGUR et al., 2002). Biodegradable plastics are seeing some use and they have been available for many years on the market. However, their high cost has meant they have not replaced the traditional non-degradable plastics. The present study aims to the optimization of PHB production by microorganisms through evaluating the physical and environmental factors that lead to the maximization of PHB production using agro-industrial waste products as cheap carbon sources, and trials for scaling up the product as a step to be used in large scale industry for its high economic and commercial value and its value as a product that is safe for the environment. MATERIALS AND METHODS Microorganisms Five different bacterial isolates were used throughout the screening experiments namely: Bacillus subtilis and Bacillus thuringiensis were isolated from the garden soil of the faculty of science, Alexandria University, the former was identified by IMI (International Mycological Institute, UK); Bacillus thuringiensis was identified using 16S rDNA; Lactobacillus acidophilus was isolated from whey and identified using 16S rDNA; Escherichia coli and Staphylococcus aureus were kindly provided by the Microbiology Research lab, Faculty of Science, Beirut Arab University, they were isolated from urine samples and identified using phenotypic characterizations. Fermentation media Unless otherwise indicated, media were prepared with distilled water, sterilized by autoclaving for 20 min at pressure 15 lb/inch2 to raise the temperature to 121C. Fermentation medium (I) containing (g/l): whey supplemented with peptone, 3 and yeast extract, 3. Fermentation medium( II) containing (g/l): whey supplemented with peptone, 3; yeast extract, 3 and sucrose,5. Fermentation medium (III) containing (g/l): whey supplemented with peptone, 3; yeast extract, 3 and glucose, 5. Fermentation medium (IV) containing (g/l): treated date molasses, 50 dissolved in 1L nutrient broth . Fermentation medium (V) containing (g/l): treated date molasses, 50 dissolved in 1L nutrient broth, supplemented with glucose,5. Maintenance of the microorganisms Bacterial strains were maintained on nutrient agar slants and culture is renewed at monthly intervals. For long preservation, the bacteria were folded with 25% glycerol. Preparation of seed culture Transfers from single slant bacterial cultures (24 hours old) into 250 Erlenmeyer flasks containing 50 ml seed culture medium were incubated to initiate growth for 18 hrs at 37C to reach an OD1 at 600 nm. Aliquotes of 3 ml were taken from the latter liquid culture as a standard inoculum unless otherwise indicated. Fermentation Techniques Using Free Cells Submerged Fermentation Technique Cultivation was achieved in 250ml Erlenmeyer flasks each containing 50ml aliquots of the specified fermentation medium. The media were sterilized by autoclaving for 20 min at 121C. Each flask received 3 ml of seed culture as a standard inoculum and was incubated at 37C for 4 days under shaken conditions (160 rpm). Each treatment was carried out in triplicates and the results obtained

056. Glo. Adv. Res. J. Microbiol. Throughout this work were the mean of at least two experiments. Fed-batch Fermentation Technique In a trial to test the effect of the fermentation technique on PHB production as a step for scaling up the product a continuous open system using fermentor (Biotron Liflus GR Fermentor, 3L) was evaluated. The fermentor was fortified with 2.5 L optimized fermentation medium. The aeration was 2 L/min; the pH of the medium was 5.5. The cultivation time of each batch was 4 days at 37C on 160 rpm. At the end of each batch, 500ml fermentation medium was taken out and 500ml fresh fermentation medium was added into the fermentor. Screening experiments for microbial production of PHB The five bacterial isolates used throughout the screening experiment were screened for their potentiality for PHB production under shaken conditions using five different fermentation media for different time intervals (2-8 days) at 37C. Physiological and environmental factors affecting PHB production by the bacterial isolates under test Different environmental factors such as pH, inoculum size, culure volume and incubation temperature were tested and screened for maximium PHB production. Optimization of nutritional factors affecting PHB production using multifactorial statistical design (Plackett-Burman). Application of a complete factorial design would require 2n experiments if n factor have to be investigated. In the present case, eleven variables would lead to 1024 trials, which is a very large number. Using a fraction of the factorial design without losing information about the main effects of variables (Ooijkas et al., 1998) can reduce the number of experiments. The Plackett-Burman experimental design, a fractional design, (Plackett & Burman, 1946 and Yu et al., 1997) was used in this research to reflect the relative importance of various environmental factors on PHB production by the promising bacterial strain. The design is recommended when more than five factors are under investigation (Lavilla et al., 1998 and Abdel-Fattah et al., 2002). Eleven independent variables were screened in twelve combinations organized according to the PlackettBurman design matrix described in the results section (table 1). For each variable, a high (+) and low (-) level was tested. All trials were performed in duplicates and the averages of obtained PHB was treated as the response for each trial. The main effect of each variable was determined with the following equation: Exi= (Mi+ - Mi-) / N Where; Exi is the variable main effect, Mi+ and Mi- are PHB amounts in trials where the independent variable (xi) was present in high and low levels, respectively, and N is the number of trials divided by 2. A main effect figure (figure 6) with positive sign indicates that the high level of this variable is nearer to optimum and a negative sign indicates that the low level of this variable is nearer to optimum. Using Microsoft Excel, statistical t-values for equal unpaired samples were calculated for determination of variable significance. Extraction of PHB PHB was extracted following the method adapted by (UGUR et al., 2002) after some modifications, and includes extraction of the product from the cells after they are harvested by centrifugation, washed by distilled water and then lysed in 30 ml of sodium hypochlorite for 24 hours. The solution was subjected to double extraction by chloroform in which PHB is highly dissolved , preceded with extraction with ethanol acetone solution (1:1 v/v) to remove cell lipids. Chloroform extract was evaporated to dryness at 70C in a water bath, then dry PHB crystals were weighed. Detection of PHB PHB granules were detected using TEM microscopy, and by monitoring UV spectra of PHB samples (after treatment with concentrated sulfuric acid) by scanning between 220 and 300nm, and compared with standard PHB which has highest absorbance at 235nm. Statistical analyses The values were subjected to linear regression analysis for the determination of R (regression coefficient) using SPSS16 (statistical package software) (Kutner et al., 2004). RESULTS AND DISCUSSION Screening Experiments for Microbial Production of PHB Data revealed that the highest PHB output (0.412g/50ml) was achieved with Lactobacillus acidophilus when grown on medium IV for 4 days under shaken conditions, followed by Bacillus thuringiensis (0.367g/50ml) when grown under the same conditions, and Bacillus subtilis (0.337g/50ml)

Hamieh et al. 057

Figure 1. PHB production by different bacterial isolates grown on different media at different time intervals.

when grown on medium III for 6 days under shaken conditions (figure 1). Physiological and Environmental Factors Affecting PHB Production For maximum PHB production, it is important to evaluate the physiological and environmental factors of the bacterial

isolates under investigation for the PHB production process. Medium IV was selected as the fermentation medium for further experimentation to evaluate the effect of environmental and physiological factors affecting the PHB production by the selected bacteria.

058. Glo. Adv. Res. J. Microbiol.

Table 1. Randomized Plackett-Burman experimental design for evaluating factors influencing PHB production by Lactobacillus acidophilus.

Variable s Trials 1 2 3 4 5 6 7 8 9 10 11 12 13

Date molasse s

+

(NH4)2S O4

Na2HP O4

KH2PO

4

Oliv e oil

NH4C l

MgSO 4. 7H2O + + + + + + 0

Malt Extrac t

+ +

FeSO4.7H2 O

Cystein e

Glycin e

PHB output (g/50m l) 0.25 0.399 2.188 0.786 1.381 0.451 0.489 0.614 1.235 0.212 0.27 0.141 0.306

+ + + + + 0

+ + + + + + 0

+ + + + + + 0

+ + + + + + 0

+ + + + + + 0

+ + + + + + 0

+ + + + 0

+ + + + + + 0

+ + + + + + 0

+ + + + + + 0

pH Relations Maximum PHB output (0.412 and 0.367g/50ml) was achieved by Lactobacillus acidophilus and Bacillus thuringiensis respectively at pH 5.5 (figure 2). Therefore pH 5.5 was selected for further experimentation. Higher or lower pH values showed inferior results. Metabolic processes are highly susceptible to even slight changes in pH (Wei et al., 2011), and drastic changes in PHB production seems to be due to the effect of initial pH on the bioavailability of trace elements (Ramadas et al., 2009). Flora et al. (2010) revealed that the maximum PHB

production (25%) by Bacillus sphaericus was at pH range from 6.5-7.5, and the reduction of polymer accumulation at higher pH values is due to the effect on the degradative enzymes of polymer breakdown, so that PHB is utilized at a rate almost equal to the rate of its synthesis. Effect of Inoculum Size Results revealed that maximum PHB output (0.412 and 0.367g/50ml) were achieved by Lactobacillus acidophilus and Bacillus thuringiensis respectively, with 3ml inoculum level/flask; however, minimal PHB contents (0.064 and

Hamieh et al. 059

0.139g/50ml) were achieved by Lactobacillus acidophilus and Bacillus thuringiensis respectively, with 7ml inoculum level/flask (figure 3). Accordingly, 3ml/50ml inoculum level was selected to carry out the next part of the research. Low inoculum size required longer time for cells to multiply and produce the desired product (Jiff et al., 1998). A small amount of inoculum can lead to insufficient number of microbial cells and a reduced amount of the secreted enzymes while a much higher inoculum could lead to or cause a lack of oxygen and depletion of nutrients in the culture media (Abusham et al., 2009). Effect of Culture Volume Both Lactobacillus acidophilus and Bacillus thurnigiensis has attained maximum PHB production (0.412 and 0.367g) respectively with 50 ml culture volume (figure 4) that was

utilized as the optimum culture volume in the next experiments. The finite volume of the culture medium means the limitation of the nutrients for the microorganism. The consumption of the nutrients is largely dependent on the bacterial population. To ensure a high PHB output in limited culture volume, the inoculum size should therefore be controlled (Abusham et al., 2009). Effect of Incubation Temperature Results indicated that maximum PHB production was achieved at 37C incubation temperature. Higher or lower temperatures showed inferior results (figure5). This result coincides with that represented by Aslim et al. (2002), who reported that optimum incubation temperature for PHB production by Bacillus thuringiensis, Bacillus

060. Glo. Adv. Res. J. Microbiol.

Figure 6. Main effect of variables on PHB production by Lactobacillus acidophilus.

subtilis, and Bacillus pumilis was at 37C. Tamodgan & Sidal (2011) reported that higher and lower temperatures than 30C lead to decrease in PHB synthesis by Bacillus subtilis ATCC 6633, as well as cell mass, probably due to the low enzymes activity. Optimization of the best nutritional factors affecting Lactobacillus acidophilus PHB production using multifactorial experiments (Plackett- Burman Design) Sequential optimization approaches were applied in the present part of the study. The first approach dealt with screening for the environmental factors affecting PHB production by the bacteria under investigation. The second approach was to optimize the nutritional factors that control PHB production process. The best culture conditions such as, incubation time for 4 days; initial pH at 5.5; 3 ml inoculum level; 50ml culture volume and 37C incubation temperature were used for the optimization of the

nutritional factors using the Plackett-Burman statistical design. Evaluation of the Factors Affecting PHB Production In screening and optimizing the factors affecting PHB production, it is very important to test as much factors as possible and to identify the significance of each of them. Plackett-Burman design offers good and fast screening procedure and mathematically computes the significance of large number of factors in one experiment, which is time saving and maintain convincing information on each component (Srinivas et al., 1994). The design is recommended when more than five factors are under investigation (Abdel-Fattah et al., 2002). The influence of eleven factors including carbon, nitrogen, amino acids and metal ions on PHB production were tested. A wide variation was shown in Lactobacillus acidophilus that was chosen rather than Bacillus

Hamieh et al. 061

Figure 7. Effect of initial glycine and olive oil amounts on PHB production by Lactobacillus acidophilus

thuringiensis as the promising microbial producer of PHB (that is safe to be used on large industrial scale) throughout the different trials. The variation in PHB production was ranging from 0.141 2.188g/50ml. This revealed that these factors have a strong influence on PHB production. It was shown that glycine and olive oil had a significant effect on PHB production (figure 7), whereas the other factors affected slightly the PHB production process. The main effect that was estimated as a difference between both average of measurements made at the high level (+1) and at the low level (-1) of the factor) of the examined factors affecting PHB production was calculated and presented graphically (figure 6). On the analysis of the regression coefficients of the eleven variables, (NH4)2SO4, Na2HPO4, olive oil, KH2PO4 , FeSO4.7H2O, glycine, and cysteine showed a positive effect, whereas date molasses, malt extract, NH4Cl,and MgSO4.7H2O showed a negative effect. Data in the present investigation showed that PHB production increased with high levels of glycine (0.05g/50ml), and olive oil (1g/50ml). PHB production was best achieved at high concentration of glycine, it was a positively significant factor. Maximum PHB output (7.6% PHB of cell dry weight) was produced by Streptomyces MU 117 when glycine was used as nitrogen source. Similarly high amount of PHB was accumulated (61.43%) when glycine was used as nitrogen source by Rhizobium sp. 2426 (Mercan et al., 2002), and by Bacillus subtilis ATCC 6633 (7.683%) (Tamdogan & Sidal, 2011). Olive oil used as a carbon source was also a positively significant factor, it affects PHB production in its high level (1g/50ml). Fukui & Doi (1998) reported that plant oils such as olive, corn, and palm oils were good carbon substrates for PHB production by A. eutrophus. Kahar et al. (2004).

Thakor et al. (2005) used the vegetable oils for PHB production by Ralstonia eutropha and Commomonas testosterone respectively. Oleic acid was good for the growth of Pseudomonas putida and it was used as carbon source instead of alkanes for production of PHAs since it exhibits less toxicity (Lee et al., 2000). Schizosaccharomyces pombe, achieved high PHB content on using oleic acid and glucose as carbon sources (Abdulhamid et al., 2007). Malt extract and date molasses used as carbon sources had negative effect on PHB production when used in high levels. Maximum Bacillus sp JMA5 growth and PHB production were noticed with 10% (w/v) molasses and higher concentrations lead to negative effect on both growth and PHB output (Younes et al., 2010). Data of the present study revealed that (NH4)2SO4 in its higher level had a positive effect on PHB production, whereas NH4Cl had a negative effect on PHB production in its higher level and it must be maintained with lower levels. It was reported that (NH4)2SO4 was the optimal nitrogen source for PHA production compared to NH4Cl as well as urea used by: Alcaligenes eutrophus (Grothe et al., 1999 & Koutinas et al., 2007), Methylobacterium sp. (Kim et al., 2006), Sinorhizobium fredii (Liangqi et al., 2006), and Rhodobacter sphaeroides (Sangkharak & Prasertan 2007). Forty times lower amount of (NH4)2SO4 (from 0.8 to 0.02g/l) in the optimum medium could tremendously reduce the medium cost, hence, gave higher potential for large scale production of PHB by Rhodobacter sphaeroides (Sangkharak & Prasertan 2007). In the present study both KH2PO4, Na2HPO4 supplied as phosphorus sources seemed to have positive effect on PHB production in their high levels at 0.15g/50ml and 0.05g/50ml respectively. Phosphorous limiting condition in

062. Glo. Adv. Res. J. Microbiol.

Figure 8. Fed batch fermentation for PHB production by Lactobacillus acidophilus.

the presence of KH2PO4 and K2HPO4 was important factor for PHB production (Sangkharak & Prasertan, 2007). However, addition of phosphate was also required for cell growth, and loss of buffer capacity led to high pH of approximately 10-11 which might be growth inhibiting level. On the contrary KH2PO4 was used with higher concentration of 2g/l with Na2HPO4 for PHB production (0.6g/l) by Bacillus sphaericus 5149 (Ramadas et al., 2009), and 3.75g/l of Na2HPO4 was used for PHB production by Hydrogenophaga pseudoflava (Mahmoudi et al., 2010). On the other hand Fe2+ ions induced PHB production by Lactobacillus acidophilus whereas Mg2+ ions negatively affected PHB production in its higher level, and it must be maintained in its lower level. PHB production (7g/l) by C. taiwanensis 184 was noticed with limited not lacking 2+ magnesium ions (Wei et al., 2011). Mg ions were used in higher amounts (0.6g/l) for PHB production by Bacillus sphearicus (Ramadas et al., 2009); 2g/l with Hydrogenophaga pseudoflava (Mahmoudi et al., 2010); 1.14g/l with Glycogen accumulating organisms (Dai et al., 2007) and 0.2g/l with Rhizobia spp. (Mercan et al., 2002). Fe2+ ions were used in trace amounts for PHB production by Azotobacter vinelandii (Yan et al., 2000), and by R. eutropha (Khanna & Srivastava, 2006). However, it was used in larger amounts by Mahmoudi et al. (2010) for PHB production by Hydrogenophaga pseudoflava. By the end of the present study, the conditions achieved nearer to optimum one for PHB production by Lactobacillus acidophilus were (g/l): date molasses, 50 ; (NH4)2SO4, 0.8 ; Na2HPO4, 1 ; olive oil, 20 (with few drops of tween 80) ; KH2PO4, 3 ; NH4Cl, 1 ; MgSO4.7H2O, 1 ; malt extract,2 ; glycine,1 ; cysteine,1 ; and 40 ml/l of 1 mm/l FeSO4.7H2O solution. Flasks with 50 ml culture volume were inoculated

with 3ml of 18 hrs seed culture and incubated for 4 days at 37C. Verification of Plackett-Burman A verification experiment was applied to examine model validation and to evaluate the basal versus the optimized conditions. Verification result revealed 98.4% validity and showed 43.1 g/l which represents about 7.04 fold increase in PHB production when compared to the control medium. Fed-batch fermentation technique Five batches of fermentation are done within 20 days with a 4 day time interval between every single batch. The amount of PHB at the end of each of the five batches was as following: 2.18, 2.3, 2.45, 2.54, 2.78g/50ml respectively. The PHB production of the 5 batches are shown in figure 8. During the five batches of the continuous fermentation, PHB production has been increased to 27.5% as compared with batch closed process. The greater cost of PHB production on large industrial scale is largely due to low productivity. Therefore, improvement of fermentation efficiency is a key factor in making a microbial PHB process viable (Khanna & Srivastava, 2005). Fedbatch cultivation is often employed to achieve high product concentrations (Sun et al., 2007). PHB detection PHB granules were detected using TEM microscopy (figure 9) and by monitoring UV spectra of PHB samples (after

Hamieh et al. 063

Figure 9. Transmission electron micrograph of Lactobacillus acidophilus grown on nutrient broth supplemented with date molasses showing PHB granules inside the cell.

Figure 10. UV spectra of PHB extracted from Lactobacillus acidophilus.

treatment with concentrated sulfuric acid) by scanning between 220 and 300nm. Maximum absorbance was at 235nm (figure 10). PHB was detected by transmission electron microscopy (Luengo et al., 2003 and Sangkharak & Prasertan, 2007). Ugur et al. (2002) and Abdulhamid et al. (2007) analyzed PHB after conversion into crotonic acid and absorbance spectra were determined by scanning the samples between 220 and 300 nm according to standard PHB that has maximum absorbance at 235nm. The number and size of granules vary depending on the producer microorganism (Anderson & Dawes, 1990 and Murray et al., 1994). CONCLUSION The results of the present investigation provides basis for assessing a potential for using Lactobacillus acidophilus for PHB (a biodegradable plastic) production, which is an economically and environmentally important product, on

large industrial scale, solving by this one of the problems of solid waste management that results from the accumulation of plastics and saving the environment from additional air pollution caused by its recycling.

REFERENCES Abdel-Fattah Y, Soliman N, Gaballa A, Sabry S, El-Diwany A (2002). Lipase production from novel thermophilic Bacillus sp.: Application of placket-Burman design for evaluating culture conditions affecting enzyme formation. Acta. Microbial. Polonica, 51: 33-36. Abdulhamid A, Abdelhaleem D, Zaki S, Amara A, Abolreesh G (2007). Genetic engineering of Schizosaccharomyces pombe to produce bacterial polhydroxyalkanoates. J. Appl. Sci. Environ. Manage., 11: 8390. Abusham R, Raja N, Rahman R, Abu B, Mahiran B (2009). Optimization of physical factors affecting the production of thermo-stable organic solvent-tolerant protease from a newly isolated halo tolerant Bacillus subtilis strain Rand. Microb. Cell Fact., 8: 20-28. Amara A (2008). Polyhydroxyalkanoates: From Basic Research and Molecular Biology To Application. IUM Eng. J., 9: 37-73.

064. Glo. Adv. Res. J. Microbiol.

Anderson A, Dawes A (1990). Occurrence, Metabolism, Metabolic Role, and Industrial Uses of Bacterial Polyhydroxyalkanoates. American society For Microbiology, Microbiol. Rev., 54:450-472. Aslim B, Yuksekdag Z, Beyatli Y (2002). Determination of PHB Growth Quantities of Certain Bacillus Species Isolated From Soil. Turk. Electronic J. Biotechnol., special issue, 24-30. Brandl H, Gross R, Lenz R, Fuller R (1988). Pseudomonas oleovorans as a source of poly( hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl. Environ. Microbiol., 54:1977-1982 Byrom D (1987). Polymer synthesis by micro-organisms: technology and economics. Trends Biotechnol., 5: 246250. Dai Y, Yuan Z, Jack K (2007). Production of targeted poly(3hydroxyalkanoates) copolymers by glycogen accumulating organisms using acetate as sole carbon source. J. Biotechnol., 129: 489-497. Environ. Sci., 7: 31-37. Environ. Sci., 7: 31-37. Flora G, Bhatt K, Tuteja U (2010). Optimization Of Culture Conditions For Poly -Hydroxybutyrate Production From isolated Bacillus Species. J. Cell Tissue Res., 10: 2235-2242. Fukui T, Doi Y (1998). Efficient production of polyhydroxyalkanoates from plant oils by Alcaligenes eutrophus and its recombinant strain. Appl. Microbiol. Biotechnol., 49: 333-336. Grothe E, Young M, Chistie Y (1999). Fermentation optimization for the production of poly( hydroxybutyric acid) microbial thermoplastic. Enzyme Microb. Technol., 25: 132-141. Hanzlikova A, Jandera A, Kunc F (1985). Formation of poly-3hydroxybutyrates by a soil microbial community in the soil. Folia Microbiologica., 30:58-64. Jiff B, Van leeuwen J, Patel B, Yu Q (1998). Utilization of starch processing waste water for production of biomass protein and fungal aamylase by Aspergillus oryzae. Biores. Technol., 66: 201-206. July 2008. Khanna S, Srivastava A (2005). Recent Advances in Microbial Polyhydroxyalkanoates. Process Biochem., 40: 607-619. Khanna S, Srivastava A (2006). Optimization of nutrient feed concentration and addition time for production of poly(hydroxybutyrate). Enzyme Microbiol. Technol., 39: 11451151. Kim B, Lee S, Chang H, Chang Y, Woo S (1994). Production of poly(3hydroxybutyric acid), by fed-batch culture of of Alcaligenes eutrophus with glucose concentration control. Biotechnol. Bioeng., 43:892-898. Kim M, Baek J, Lee J (2006). Comparison of H2 accumulation by Rhodobacter sphaeroides KD 131 and its uptake hydrogenase and PHB synthase deficient mutant. Int. J. Hydrogen Energ., 31: 121-127. Kim S, Kim P, Lee H, Kim J (1996). High production of poly-hydroxybutyrate (PHB) from Methylobacterium organophilum under potassium limitation. Biotechnol. Lett., 18: 25-30. Koutinas A, Xu Y, Wang R, Webb C (2007). Polyhydroxybutyrate production from a novel feedstock derived from a wheat based biorefinary. Enzyme Microb. Technol., 40: 1035-1044. Kutner MH, Nachtsheim CJ, Neter J (2004). Regression. In: Correlation and regression. Applied linear regression models, 4th edition, McGrawHill, Boston, p. 296-232. Lavilla I, Perez-Cid B, Bendicho C (1998). Optimization of digestion methods for sewage sludge using placket-Burman saturated designs. Anal. Chem., 361: 164-167. Lee S (1996). Bacterial polyhydroxyalkanoates. Biotechnol. Bioeng. 49:114. Lee S, Chang H (1994). Effect of complex nitrogen source on the synthesis and accumulation of poly(3-hydroxybutyric acid) by recombinant E.coli in flask and fed-batch cultures. J. Environ. Polymer degrad., 2: 169-176. Lee S, Middelberg A, Lee Y (1997). Poly (3-hydroxybutyrate) production from whey using recombinant Escherichia coli. Biotechnol. Lett., 19: 10331035. Lee S, Wong H, Choi J, Lee S, Han S (2000). Production of mediumchain-length polyhydroxyalkanoates by high-cell-density cultivation of Pseudomonas putida under phosphorus limitation. Biotechnol. Bioeng., 68: 466-470.

Liangqi Z, Jingfan X, Tao F, Haibin W (2006). Synthesis of poly(3hydroxybutyrate co-3 hydroxyoctanoate) by a Sinorhizobium fredii strain. Lett. Appl. Microbiol., 4: 344-349. Luengo J, Garcia B, Sandoval A, Naharro G, Oliver E (2003). Bioplastics from microorganisms. Current Opin. Biotechnol., 6: 251-260. Mahmoudi M, Sharifzadeh M, Nagafpour G, Tabandeh F, Eisazadeh H (2010). Kinetic model for polyhydroxybutyrate (PHB) production by Hydrogenophaga pseudoflava and verification of growth conditions. Afr. J. Biotechnol., 9: 3151-3157. Mercan N, Aslim B, Yuksekdag Z, Beyatli Y (2002). Production of Poly-hydroxybutyrate (PHB) by some Rhizobium Bacteria. Turk J. Biol., 26: 215-219. Muller R, Kleeberg I, Deckwer W (2001). Biodegradation of polyesters containing aromatic constituents. J. Biotechnol., 86: 87-95. Murray R, Doetsch R, Robinow C (1994). Determinative and cytological light microscopy. Manual of Methods for General Bacteriol., 10: 21-41. Ooijkas L, Wilkinson E, Tramper J, Buitelaar R (1998). Medium optimization for spore production of Conithyrium minitans using statistically-based experimental design. Biotechnol. Bioeng., 64: 92-100. Page W (1995). Bacterial polyhydroxyalkanoates, natural biodegradable plastics with a great future. Canadian J. Microbiol., 141:1-3. Page W, Knosp O (1989). Hyper production of poly- -hydroxybutyrate during exponential growth of Azotobacter vinelandii UWD. Appl. Environ. Microbiol., 55: 1334-1339. Plackett R, Burman J (1946). The design of optimum multifactorial experiments. Biometrika., 33: 305-325. Ramadas N, Singh S, Soccol C, Pandev A (2009). Polyhydroxybutyrate Production using Agro-industrial Residue as Substrate by Bacillus sphaericus NCIM 5149. Braz. Arch. Biol. Techno., 52: 17-23. Sangkharak K, Prasertsan P (2007). Nutrient optimization for production of polyhydroxybutyrate from halotolerant photosynthetic bacteria cultivated under aerobic-dark condition. Microb. Biotechnol., 11: issue of 15 Srinivas M, Chand N, Lonsane B (1994). Use of Plackett-Burman design for screening the several nitrogen sources, growth/product promoters, mineral and enzyme inducers for the production of alpha-galactosidase by Aspergillus niger MRSS 234 in solid state fermentation system. Bioproc. Eng., 10:139-144. Sun Z, Ramsay J, Guay M (2007). Fermentation process development for the production of medium-chain-length poly-3-hydroxyalkanoates. Appl. Microbiol. Biotechnol., 75: 475-485. Tamdogan N, Sidal U (2011). Investigation of Poly--Hydroxybutyrate (PHB) Production by Bacillus subtilis ATCC 6633 under different conditions. Kafkas Univ. Vet Fak Derg., 17:173-176. Ugur A, Sahin N, Beyatly Y (2002). Accumulation of Poly-Hydroxybutyrate in Streptomyces Species During Growth with Different Nitrogen Sources .Turk J. Biol 26:171-174. Wei Y, Chen W, Huang C, Wu H, Sun Y, Lo C, Janarthanan O (2011). Screening and Evaluation of Polyhydroxybutyrate- Producing Strains from Indigenous Isolate Cupriavidus taiwanensis Strains. Int. J. Mol. Sci., 12: 252-265. Yamane T, Fukunaga M, Lee Y (1996). Increased PHB productivity by high-cell- density-fed- batch culture ofAlcaligenes latus, a growthassociated PHB producer. Biotechnol. Bioeng., 50: 197-202. Yan Y, Wu Q, Zhang R (2000). Dynamic accumulation and degradation of poly(3-hydroxyalkanoate)s in living cells of Azotobacter vinelandii UWD characterized by 13C NMR. FEMS Microbiol. Lett., 193: 269-273. Younes M, Hezayen F, Nour-Eldein M, Shabeb M (2010). Optimization of cultivation medium and growth conditions for Bacillus subtilis KO strain isolated from sugar cane molasses. American-Eurasian J. Agric. and Yu X, Hallett S, Sheppard J, Watson AK (1997). Application of the Plackett-Burman experimental design to evaluate nutritional requirements for the production of Colletrichum coccodesspores. Appl. Microbiol. Biotechnol., 47:301-305.

You might also like

- Hitech Horticulture PDFDocument7 pagesHitech Horticulture PDFSofi MehrajNo ratings yet

- PHB Production in Azomonas, Acinteobacter and Bacillus Species: Isolation, Screening and IdentificationDocument8 pagesPHB Production in Azomonas, Acinteobacter and Bacillus Species: Isolation, Screening and IdentificationInternational Medical PublisherNo ratings yet

- Contrera Et Al 2013 NMRDocument10 pagesContrera Et Al 2013 NMRSurajit BhattacharjeeNo ratings yet

- Biotech Roject 1Document30 pagesBiotech Roject 1bhaskar VermaNo ratings yet

- Biodegradable Plastic A Potential Substi PDFDocument8 pagesBiodegradable Plastic A Potential Substi PDFBrynt Yuan Lord PlacidesNo ratings yet

- Brazilian Journal of MicrobiologyDocument7 pagesBrazilian Journal of MicrobiologyHimaniNo ratings yet

- Optimization of Cellulase Enzyme From Vegetable Waste by Using Trichoderma Atroviride in Solid State FermentationDocument6 pagesOptimization of Cellulase Enzyme From Vegetable Waste by Using Trichoderma Atroviride in Solid State FermentationIOSRjournalNo ratings yet

- Production and Optimization of Bioplastic From Bacillus Isolated From Environmental SampleDocument13 pagesProduction and Optimization of Bioplastic From Bacillus Isolated From Environmental SampleIJAR JOURNALNo ratings yet

- Bioconversion of Cassava Starch By-Product Into Bacillus and Related Bacteria PolyhydroxyalkanoatesDocument13 pagesBioconversion of Cassava Starch By-Product Into Bacillus and Related Bacteria PolyhydroxyalkanoatesMarelin Pereda SifuentesNo ratings yet

- Valorization of Ibombax CeibDocument23 pagesValorization of Ibombax CeibAbdullah Nur HakamiNo ratings yet

- Optimization of Bio-Mosquitocidal Production Using Local Bacterial Strains of Bacillus SphaericusDocument11 pagesOptimization of Bio-Mosquitocidal Production Using Local Bacterial Strains of Bacillus SphaericusTejas DoshiNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument18 pagesAccepted Manuscript: Bioresource TechnologyRuxandra BadiuNo ratings yet

- Rodrguez Contreras 2013Document10 pagesRodrguez Contreras 2013fernandoNo ratings yet

- Freitas2018 PDFDocument11 pagesFreitas2018 PDFVanesa CaroNo ratings yet

- The Study of Shelf Life For Liquid Biofertilizer From Vegetable WasteDocument6 pagesThe Study of Shelf Life For Liquid Biofertilizer From Vegetable WasteFadhilah SurotoNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Dubrovskis 2007 Biogas ZapalloDocument10 pagesDubrovskis 2007 Biogas ZapalloJulio ReyesNo ratings yet

- Bioplastics RRLDocument16 pagesBioplastics RRLAbegail Olivar100% (1)

- Bacterias - B.megateriumDocument7 pagesBacterias - B.megateriumCatalinaManjarresNo ratings yet

- FPD679.pdf Version 1Document6 pagesFPD679.pdf Version 1Ali IrtazaNo ratings yet

- 5580976Document7 pages5580976Sura C. JirNo ratings yet

- Ashah 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012105Document9 pagesAshah 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012105HarshNo ratings yet

- Bioresource Technology: Ho Myeong Kim, Chi Hoon Oh, Hyeun-Jong BaeDocument7 pagesBioresource Technology: Ho Myeong Kim, Chi Hoon Oh, Hyeun-Jong BaeLaura Ximena Vargas GutiérrezNo ratings yet

- Appl. Environ. Microbiol. 2009 Ibrahim 6222 31Document10 pagesAppl. Environ. Microbiol. 2009 Ibrahim 6222 31ashuna249396No ratings yet

- PHB Paper IJMRT March 2015 Copy1Document11 pagesPHB Paper IJMRT March 2015 Copy1Arjun JayakumarNo ratings yet

- 1 PBDocument6 pages1 PBjaka djNo ratings yet

- Aljuboori Et Al.. 2014. Production of A Bioflocculant From Aspergillus Niger Using Palm Oil Mill Effluent As Carbon SourceDocument5 pagesAljuboori Et Al.. 2014. Production of A Bioflocculant From Aspergillus Niger Using Palm Oil Mill Effluent As Carbon SourceAzb 711No ratings yet

- 1 s2.0 S2214785316303583 MainDocument6 pages1 s2.0 S2214785316303583 MainMaría Camila GonzalezNo ratings yet

- Bajaj, Singhal. 2011. Flocculation Properties of Poly (γ-Glutamic Acid) Produced from Bacillus subtilis IsolateDocument8 pagesBajaj, Singhal. 2011. Flocculation Properties of Poly (γ-Glutamic Acid) Produced from Bacillus subtilis IsolateAzb 711No ratings yet

- Microbiological and Physico-Chemical Dynamics During The Fermentation of The Millet-Based and The Sorghum-Based in The Republic of BeninDocument9 pagesMicrobiological and Physico-Chemical Dynamics During The Fermentation of The Millet-Based and The Sorghum-Based in The Republic of BeninOpenaccess Research paperNo ratings yet

- 1 s2.0 S0956053X18305063 MainDocument7 pages1 s2.0 S0956053X18305063 MainRick Anthony Rosal JaramilloNo ratings yet

- Article Abou Shanab2011Document7 pagesArticle Abou Shanab2011Benelux ModeNo ratings yet

- International Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticDocument10 pagesInternational Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticFalcon ChauNo ratings yet

- Fabrication and Characterization of Poly Lactic Acid (PLA) - Starch Based Bioplastic CompositesDocument11 pagesFabrication and Characterization of Poly Lactic Acid (PLA) - Starch Based Bioplastic CompositesAndrea VONo ratings yet

- Fei 2016Document8 pagesFei 2016Davide Di ZioNo ratings yet

- FTB 54 489Document8 pagesFTB 54 489Nurjihan FaNo ratings yet

- Application of Green ChemistryDocument19 pagesApplication of Green ChemistryKumaran RNo ratings yet

- DownloadDocument12 pagesDownloadjhoanna grace nideaNo ratings yet

- Isolation of Poly-β-hydroxybutyrate (PHB) Producing Bacteria from Sago and Sugarcane Solid WasteDocument10 pagesIsolation of Poly-β-hydroxybutyrate (PHB) Producing Bacteria from Sago and Sugarcane Solid WasteFiqriansyahwahabNo ratings yet

- Biological Diversity in Aerated Facultative LagoonDocument17 pagesBiological Diversity in Aerated Facultative LagoonJaderson CarvalhoNo ratings yet

- Bioresource Technology: Contents Lists Available atDocument7 pagesBioresource Technology: Contents Lists Available atAtchaya அட்சயாNo ratings yet

- Kanjan A Chump Ol 2013Document12 pagesKanjan A Chump Ol 2013Kaomi CarbajalNo ratings yet

- Rayhane Et Al., 2018. From Flasks To Single Used Bioreactor Scale-Up of Solid State FermentationDocument9 pagesRayhane Et Al., 2018. From Flasks To Single Used Bioreactor Scale-Up of Solid State FermentationArely PradoNo ratings yet

- 10 1002@app 50412Document10 pages10 1002@app 50412Tuyul SatuNo ratings yet

- Production of Poly (3-Hydroxybutyrate) From A Dairy Industry Wastewater Using Bacillus Subtilis EPAH18: Bioprocess Development and SimulationDocument9 pagesProduction of Poly (3-Hydroxybutyrate) From A Dairy Industry Wastewater Using Bacillus Subtilis EPAH18: Bioprocess Development and Simulationroseta0218No ratings yet

- 1 s2.0 S0926669023002674 MainDocument11 pages1 s2.0 S0926669023002674 MainOmar KHELILNo ratings yet

- Bioresource Technology: Malik S.Y. Haddadin, Jamal Haddadin, Omar I. Arabiyat, Butros HattarDocument10 pagesBioresource Technology: Malik S.Y. Haddadin, Jamal Haddadin, Omar I. Arabiyat, Butros HattarRodrigo TorresNo ratings yet

- Bhuwal 2013Document10 pagesBhuwal 2013keysofiNo ratings yet

- Production of The Lactic Acid From Mango Peel Waste - Factorial ExperimentDocument7 pagesProduction of The Lactic Acid From Mango Peel Waste - Factorial ExperimentVj ReddyNo ratings yet

- International Journal of Engineering and Science Invention (IJESI)Document5 pagesInternational Journal of Engineering and Science Invention (IJESI)inventionjournalsNo ratings yet

- Development of Biomass-Based Plastic Resins From Natural Algal PolysaccharidesDocument72 pagesDevelopment of Biomass-Based Plastic Resins From Natural Algal Polysaccharidesjustin_domingo_2100% (2)

- Chemrj 2016 01 04 01 10Document10 pagesChemrj 2016 01 04 01 10editor chemrjNo ratings yet

- 14.Applied-BioPlastic A Better-Mukti GilDocument6 pages14.Applied-BioPlastic A Better-Mukti GilImpact JournalsNo ratings yet

- Biogas Production From Food Waste ThesisDocument5 pagesBiogas Production From Food Waste Thesiskualxkiig100% (1)

- Research Article Bacillus SubtilisDocument10 pagesResearch Article Bacillus SubtilisDương Nguyễn Thùy DungNo ratings yet

- 2018) Finding of Novel Lactate Utilizing Bacillus Sp. YHY22 and Its Evaluation For Polyhydroxybutyrate (PHB) ProductionDocument9 pages2018) Finding of Novel Lactate Utilizing Bacillus Sp. YHY22 and Its Evaluation For Polyhydroxybutyrate (PHB) Productionadmos0319No ratings yet

- 10 11648 J Ajpst 20200602 12Document7 pages10 11648 J Ajpst 20200602 12data.caindog.swuNo ratings yet

- Jurnal 5-Bio Waste KitosanDocument12 pagesJurnal 5-Bio Waste KitosanNurhaliza YanuartiNo ratings yet

- Production of Ethanol by Fermentation Process by Using YeastDocument9 pagesProduction of Ethanol by Fermentation Process by Using Yeastdeepu kumarNo ratings yet

- Bioethanols 2Document39 pagesBioethanols 2ahmad buysyNo ratings yet

- Fungi and Lignocellulosic BiomassFrom EverandFungi and Lignocellulosic BiomassChristian P KubicekNo ratings yet

- ZMQ 9 H 2 CM5 I0 CDocument666 pagesZMQ 9 H 2 CM5 I0 Cashuna249396No ratings yet

- Review of Xanthan Gum Production From Unmodified Starches-2006Document11 pagesReview of Xanthan Gum Production From Unmodified Starches-2006ashuna249396No ratings yet

- Xanthan Gum ScifinderDocument15 pagesXanthan Gum Scifinderashuna249396No ratings yet

- BT 0306Document3 pagesBT 0306ashuna249396No ratings yet

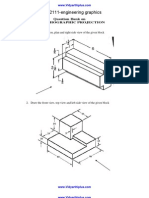

- GE2111-engineering Graphics: 1. Draw The Elevation, Plan and Right Side View of The Given BlockDocument4 pagesGE2111-engineering Graphics: 1. Draw The Elevation, Plan and Right Side View of The Given Blockashuna249396No ratings yet

- Production of Poly (3-Hydroxybutyrate) and Poly (3-Hydroxybutyrate-Co-4-Hydroxybutyrate) by Ralstonia Eutropha From Soybean OilDocument6 pagesProduction of Poly (3-Hydroxybutyrate) and Poly (3-Hydroxybutyrate-Co-4-Hydroxybutyrate) by Ralstonia Eutropha From Soybean Oilashuna249396No ratings yet

- Model-Based Fed-Batch Cultivation of R. Eutropha For Enhanced Biopolymer ProductionDocument8 pagesModel-Based Fed-Batch Cultivation of R. Eutropha For Enhanced Biopolymer Productionashuna249396No ratings yet

- Appl. Environ. Microbiol. 2009 Ibrahim 6222 31Document10 pagesAppl. Environ. Microbiol. 2009 Ibrahim 6222 31ashuna249396No ratings yet

- Cobas 4800 For HPV Detection and GenotypingDocument2 pagesCobas 4800 For HPV Detection and GenotypingMolecular_Diagnostics_KKUH0% (1)

- The Sauropods Evolution and Paleobiology - Kristina Curry Rogers Amp Amp Jeffrey Wilson PDFDocument360 pagesThe Sauropods Evolution and Paleobiology - Kristina Curry Rogers Amp Amp Jeffrey Wilson PDFManu Adri100% (4)

- Immunosero Notes 2Document20 pagesImmunosero Notes 2Rakim MikarNo ratings yet

- Ecas Clima Report 2018Document24 pagesEcas Clima Report 2018Aishwarya MathurNo ratings yet

- General Biology - Cell TheoryDocument4 pagesGeneral Biology - Cell TheorySage Of WholesomenessNo ratings yet

- Lesson 2 Upper ExtremitiesDocument23 pagesLesson 2 Upper ExtremitiesMARY JANE ANGELICA SEVANo ratings yet

- Bacteria ClassificationDocument395 pagesBacteria ClassificationJitendra MishraNo ratings yet

- SGBAU B.Pharm 1 SEM Human-Anatomy-n-Physiology-I 2018Document2 pagesSGBAU B.Pharm 1 SEM Human-Anatomy-n-Physiology-I 2018Abhay DeulkarNo ratings yet

- STS Project 2Document27 pagesSTS Project 2Diana CalderonNo ratings yet

- 12 White Blood Cell Counting Techniques in BirdsDocument5 pages12 White Blood Cell Counting Techniques in BirdsPablo LópezNo ratings yet

- Personal StatementDocument2 pagesPersonal StatementDaniela PerezNo ratings yet

- NSB Bulletin Feb. 2014Document153 pagesNSB Bulletin Feb. 2014nrpindiaNo ratings yet

- DuPont Distillase SSF Web enDocument2 pagesDuPont Distillase SSF Web ensushantNo ratings yet

- Soal Bahasa InggrisDocument5 pagesSoal Bahasa InggrisBintang MareetaNo ratings yet

- Jipmer DissertationsDocument8 pagesJipmer DissertationsPayToDoMyPaperUK100% (1)

- Pathologic Basis of Lumbar Radicular Pain: BackgroundDocument8 pagesPathologic Basis of Lumbar Radicular Pain: BackgroundVizaNo ratings yet

- Detection of Feline Panleukopenia With Antigen Test KitDocument2 pagesDetection of Feline Panleukopenia With Antigen Test KitMuhammad ihwanul usliminNo ratings yet

- Georges Cuvier's Theory of Correlation of PartsDocument5 pagesGeorges Cuvier's Theory of Correlation of PartsSoc SaballaNo ratings yet

- SUBHADIPA MAJUMDER2022-07-22Cell PotencyDocument2 pagesSUBHADIPA MAJUMDER2022-07-22Cell PotencySuvNo ratings yet

- Jacqueline Badgery Resume 2Document1 pageJacqueline Badgery Resume 2api-445750548No ratings yet

- Type 3 - Summary CompletionDocument7 pagesType 3 - Summary CompletionAnh ThuNo ratings yet

- 2021 Expt 7 Pre Lab - Diversity of BacteriacDocument2 pages2021 Expt 7 Pre Lab - Diversity of BacteriacjijiqNo ratings yet

- FlowerChart PDFDocument7 pagesFlowerChart PDFarthyNo ratings yet

- Orientation To The Human Body SlidesDocument24 pagesOrientation To The Human Body SlidesSamantha Kaye ReclaNo ratings yet

- Root Apex and It's SignificanceDocument33 pagesRoot Apex and It's Significancecitidotnet95% (20)

- 4life Transfer Factor TrifactorDocument2 pages4life Transfer Factor TrifactorYemsar AlhadarNo ratings yet

- Ether Lipids in Biomembranes: Fritz PaltaufDocument39 pagesEther Lipids in Biomembranes: Fritz PaltaufdnatechNo ratings yet

- Oig Method Validation Procedure 01 PDFDocument10 pagesOig Method Validation Procedure 01 PDFMargaretaSianneNo ratings yet

- Fascia and Primo Vascular SystemDocument7 pagesFascia and Primo Vascular SystemVladimir Rodrigues de LimaNo ratings yet