Professional Documents

Culture Documents

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Uploaded by

Adrián ZMCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5833)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PTCB Exam 1Document20 pagesPTCB Exam 1Amber Chen80% (5)

- EFST en PDFDocument16 pagesEFST en PDFMohamed ShabirNo ratings yet

- 200 Series: Insert Style Flow Sensors by Data Industrial Owner's ManualDocument16 pages200 Series: Insert Style Flow Sensors by Data Industrial Owner's Manualaries26marchNo ratings yet

- Phenolic FoamDocument20 pagesPhenolic FoamkenandyouNo ratings yet

- Chemistry Investigatory ProjectDocument20 pagesChemistry Investigatory ProjectFaith92% (13)

- Technical Data Epoxy Primer EP-R-30Document2 pagesTechnical Data Epoxy Primer EP-R-30Sheikh Shoaib100% (1)

- Uaspl InfoDocument2 pagesUaspl InfoDilipraja KolliNo ratings yet

- What Is NaphthaDocument4 pagesWhat Is NaphthaMaria Popa100% (1)

- Correct Procedure For Flange BoltingDocument7 pagesCorrect Procedure For Flange BoltingAkshay KalraNo ratings yet

- Dynamic Reviseed Sheets 01.04.2021 To Ason DateDocument19 pagesDynamic Reviseed Sheets 01.04.2021 To Ason DateArnav KaleNo ratings yet

- تحضير ثايودايزول 22Document1 pageتحضير ثايودايزول 22Usama AliNo ratings yet

- Electro Chemistry (E)Document29 pagesElectro Chemistry (E)Rahul Garg0% (1)

- Okaro Onoriode Jude ProjectDocument108 pagesOkaro Onoriode Jude ProjectOnoriode Jude OkaroNo ratings yet

- Pt. MMF 15 Juli 2022Document249 pagesPt. MMF 15 Juli 2022Agus Sudiana NurmansyahNo ratings yet

- Water, Density, Specific Enthalpy, Viscosity PDFDocument3 pagesWater, Density, Specific Enthalpy, Viscosity PDFmartinezdavid93No ratings yet

- Mecchsyll PDFDocument172 pagesMecchsyll PDFPavana KumaraNo ratings yet

- Fat Substitutes and Replacers in Food Product, PDFDocument31 pagesFat Substitutes and Replacers in Food Product, PDFYustinAyuNo ratings yet

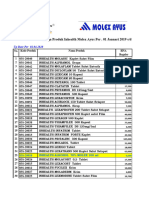

- Price List MOLEX AYUS Per 18.11.2020 (Cabang)Document24 pagesPrice List MOLEX AYUS Per 18.11.2020 (Cabang)Apotek Hilda AlnairaNo ratings yet

- Full Report-Oil Skimmer Cum Metal Chip CollectorDocument55 pagesFull Report-Oil Skimmer Cum Metal Chip Collectorrajkumar100% (1)

- SOLIDS AND THEIR Properties 1Document4 pagesSOLIDS AND THEIR Properties 1JohnnardBelenNo ratings yet

- b2.3 FoundationDocument34 pagesb2.3 FoundationJohura KhanamNo ratings yet

- Erosion CorrosionDocument26 pagesErosion CorrosionElma MhjNo ratings yet

- General Notes: Between Soldier PilesDocument1 pageGeneral Notes: Between Soldier PilesRaja SundaramNo ratings yet

- Magnesia Silicate MsdsDocument5 pagesMagnesia Silicate MsdsPaulo RobertoNo ratings yet

- Group ExperimentDocument9 pagesGroup ExperimentChelsie NicoleNo ratings yet

- GIKEN Aux PilerjetsystemDocument2 pagesGIKEN Aux PilerjetsystemPHÁT NGUYỄN THẾNo ratings yet

- Crouse-Hinds Catalog 2015 PDFDocument375 pagesCrouse-Hinds Catalog 2015 PDFwillian renee carrion aguileraNo ratings yet

- Price List: With Effect From 01 January, 2021Document12 pagesPrice List: With Effect From 01 January, 2021Dev KumarNo ratings yet

- Aerator/Mixer: Surumi UMPDocument7 pagesAerator/Mixer: Surumi UMPVILMA CAROLINA PORTILLO CHAVEZNo ratings yet

- DIY Etched Bullet Necklaces 5467Document14 pagesDIY Etched Bullet Necklaces 5467Santiago GdsNo ratings yet

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Uploaded by

Adrián ZMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Effect of Sulfate Ion On The y Al2O3 Surface Area Synthesized by

Uploaded by

Adrián ZMCopyright:

Available Formats

VOL. 3, NO.

5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

Effect of Sulfate Ion on the -Al2O3 Surface Area Synthesized by Homogeneous Precipitation

1, 2

Adrin Zamorategui, 2 Satoshi Sugita Department of Chemistry, University of Guanajuato, Guanajuato, Gto. Mxico. Col. Noria

ABSTRACT

Amorphous basic aluminum sulfate (BAS) was synthesized by homogeneous precipitation using an aluminum sulfate solution and ammonium bisulfate as the precipitating agent. A second neutralization in the solid/liquid phase of the BAS with ammonia solution eliminates the sulfate ions of the amorphous structure and obtains pseudoboehmite (PB) at pH 10.3 with fibrousnano-sized morphology. The structure of the PB is transformed to the amorphous structure of the gamma alumina phase (-Al2O3) by thermal dehydroxylation (400C). Thus, the eliminating water in the form of hydroxides, maintained the fibrous morphology with a high specific surface area 350 m2/g. The neutralization of the BAS the second time generates a slight reduction in specific surface area to 338 m2/g. The sample of BAS, PB and -Al2O3 was analyzed using the techniques TGA-DTA, XRD, FTIR, EDS, TEM and adsorption/desorption of N 2 gas (BET). Keywords: Homogeneous precipitation, basic aluminum sulfate, pseudoboehmita, -Al2O3.

1. INTRODUCTION

Alumina is a material of significant importance from the technological point of view, for its application in electronics, personal protective equipment, refractoriness, catalysts, catalyst support, oil refining, and control of pollutant emissions from cars. The fine powder of nanometer size and high purity is of great interesting the preparation of ceramics with high hardness and wear resistance in applications or membranes or catalytic materials [1,2]. Some methods have been developed to prepare mono disperse particulate oxides or their precursors, such as sol-gel [20], emulsion, homogeneous precipitation, etc. Among these techniques, homogeneous precipitation appears to be industrially advantageous because it does not require expensive alkoxides, organic solvents or, surface tents that can raise the cost of production [3-5]. Aluminum oxy hydroxide, amorphous spherical particles of Al(OH)3 and boehmite particles of different shapes, prepared by hydrolysis of aluminum ions in aqueous solution were prepared. Interestingly, for the formation of spherical particles of amorphous Al(OH)3, the sulfate ion was necessary as an intermediate[6]. Dense particles of basic aluminum sulfate (BAS) of sub micron size have been prepared by homogeneous precipitation of aluminum sulfate using urea as the precipitating agent. The urea rapidly dissolves in water to produce a uniform solution with pH during decomposition. The pH of the solution can be controlled via the thermal decomposition of the urea to ammonia and carbon dioxide in the temperature range of 70-100C.In addition, the formamide was used to precipitate the BAS to lower pH than that used with urea to obtain a BAS with the highest purity [7-10]. The physical properties, crystal structure, morphology, specific surface area, pore volume and size must be controlled to increase the catalytic activity and adsorption characteristics of pseudoboehmite (-AlOOH). Thus, these properties can be controlled by homogeneous

precipitation, depending on the relationship of H2O/Al2 (SO4)3, precipitating agent, pH, temperature and time of aging [11,12,13]. The objective of this study is to evaluate the effect of the remained sulfate ion concentration on the specific surface area of gamma alumina (-Al2O3) synthesized by homogeneous precipitation, using ammonium bisulfate (NH4HSO3) as precipitating agent.

2. EXPERIMENTAL PROCEDURE

Basic aluminum sulfate was synthesized by the homogeneous precipitation method, mixing solutions of aluminum sulfate and ammonium bisulfite 0.311M (1.3 g/cm3density). The ratio of ion sulfate to aluminum ([SO42 ]/[Al+3]) in the mixture was 2/3.This was heated to 90C and maintained at this temperature for 30 minutes. The heating rate up to 90C was 2C/minute and the agitation was maintained at 350 rpm. The pH during the precipitation was kept at 3.7 and controlled by the thermal decomposition of ammonium bisulfate at 75C, generating ammonium sulfite, sulfur dioxide and water, as shown in reaction 1 [6,14]. 2 NH4HSO3(ac)

(NH4)2SO3(ac) + H2O (l) + SO2(g) -- (1)

The Al2(SO4)3 reacts due to the high affinity between the sulfate and Al3+ ion. Thus, the formation of the polymeric species of the Al3+ion with the hydroxide ion (OH-) is strongly inhibited by the sulfate ion in the precipitation reaction at pH 3.7. Indeed, the precipitation occurs upon reaching temperature between 75 and 90C.The reaction (2) describes the precipitation process to obtain the BAS (Al(OH)x (SO4) (3-x)/2) using the aluminum salt and ammonium sulfite generated in the first reaction (1), where the value of x is approximately 2.6.The white precipitate of the BAS was filtered and washed with distilled water and subsequently dried for 12 hours in an oven at 110C to obtain a fine powder. Al2 (SO4)3(ac)+ x(NH4)2SO3(ac)+ xH2O (l)

2 Al (OH)x(SO4)(3-x)/2(s)+ (NH4)2SO4(ac)+ SO2 (g) ---(2)

485

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

The final pH of the neutralization of the BAS was determined by titration with constant agitation. Thus, a dispersion of BAS was prepared (0.08 wt. %) and titrated with 1M NH4OH at an addition rate of 0.02cm3 per minute. The pH was measured using a potentiometer 210 brand HANNA pH instrument. The titration curve is shown in Fig.1. On the other hand, the optimal time of the BAS neutralization with an ammonia solution to completely remove the sulfate ions generated in reaction (2) was determined. The BAS powder was dispersed in d is tilled water at a solid/liquid ratio of 1/8 to be neutralized at a temperature of 75C and constant agitation of 350 rpm. Table 1 show the times used in each neutralization test. The Al(OH)3 solid obtained was filtered and was heated with hot distilled water, then the solid was dried in an oven at 110C for 12 hours to give a white powder psedoboehmite (PB).Also, the PB was thermally treated at 450C and was transformed by thermal De hydroxylation to the -Al2O3 phase. Finally, the effect on the specific surface area of the sulfate ion remaining in the -Al2O3 structure was evaluated. The material crystallinity was analyzed by X-ray diffraction (XRD) using the Siemens D500 diffractometer in the range of 5 to 80, with monochromatic copper radiation (Cu) K; spectroscopy Fourier transform infrared (FTIR) was carried out using the Perkin Elmer (1600 series) in the range of 400cm-1 to 4000 cm-1 using KBr pellets; thermal analysis (TGA and DTA) was developed in the equipment model TA Instrument SDT2960 simultaneous TGA-DTA type in air flow. The morphology of the material was observed by transmission electron microscopy (TEM) with the field emission microscope PhilipsTecnai F-20, and textural properties of the powders were analyzed by adsorption/desorption of N2 gas using the BET method. Table 1: Neutralization time No.

Sample

corresponding to the high consumption of OH- in the nucleation stage without variation of pH. As is known, the ion Al3+ predominatesin acidic media and coexists with basic species (AlOH2+ and Al (OH)2+). In the presence of ions that exhibit high affinity for the aluminum ion, such as sulfate, the basic salt precipitation occurs rapidly after mixing with the counter ion. The affinity of the sulfate ion for the aluminum ion (Al3+) prevents or at least retards the polymerization of the Al-OH and its hydrolysis poly meriting in the crystalline structure of Al(OH)3[9]. Thus, the point B at pH 3.9 corresponds to the formation of basic salts of aluminum. The two well-defined regions bc and c dare very consistent with the regions BC and CD in the two cases. The region b corresponds to the functional groups present as weak acid in the system develops by the hydrolysis of the sulfate surface groups through Kolth off reaction [10].

11 10 9 8 7 6 5 4 3 2 0

D d c C

pH

----- Al2(SO4)3

b

B A

BAS

0.5

1.5

Vol. NH4OH (mL)

Fig. 1: Titration curves of BAS and Al2(SO4)3

The region cd represents the titration of the excess of base added to the system after the point of equivalence. This region corresponds to the saturation zone and occurs at a pH 10.3 corresponding to -AlOOH formation. Since the sulfate ion is an ion penetrated in the basic aluminum species, this can be easily exchanged with the hydroxyl ion favoring the formation of aluminates. This ion later becomes an aluminum hydroxide by the action of the addition of an ammonium action (weak acid) at high pH values[15, 16]. In both cases the end point of neutralization was at pH 10.3 as shown in Fig. 1. 3.2 Thermal Analysis of BAS and PB The thermal behavior of the BAS and PB obtained by homogeneous precipitation was analyzed as shown in Fig. 2a and b. In the thermal analysis of BAS (Fig. 2a), the TGA curve shows a weight loss between 50 and 850C.This corresponds to the loss of structural water and dehydroxylation temperature of the material. Furthermore, there is a second weight loss between 850 and 950C, resulting from the thermal decomposition of the sulfate ion in the sample, generating the gas, SO3. Finally, a third weight loss was observed at approximately 1200C attributable to the formation of the -Al2O3 phase.

Time (min)

First Neutralization Second Neutralization

Relation

BAS/H2O

pH 10 10 10 10 10 10 10 10

1 2 3 4 5 6 5 6 7

1 10 30 80 120 10 10 10

10 20 30

1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

3. RESULTS AND DISCUSSION

3.1 Titration of the BAS and Al2 (SO4)3 The BAS titration curve (Fig. 1) compared with the curve of Al2(SO4)3 lacks the segment AB

486

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

The DTA curve shows a short endothermic band between 100 and 250C with a maximum at 170C, and a broad band between 250 and 800C attributable to a process of structural water loss and progressive thermal dehydroxylation. A more intense and narrow band is observed between 850 and 950C, corresponding to the decomposition of the sulfate present in the material which is released as a gas, SO3.Additionally, there is a small exothermic peak at approximately 1200C, corresponding to the formation of the -Al2O3.

a

0.10

.00

between 26 and 132C attributable to desorption of water. The second is observed as a slight inflection between 200 and 270C because of the loss of residual NH3 in the PB superficially adsorbed during neutralization, the third corresponding to the temperature range between 300 and 460C,with a maximum at 390C,corresponding to the dehydroxylation and structural transformation of the PB towards -Al2O3 phase[18]. Likewise, the fourth loss inflection exists in the range of 800 to 1000C with a maximum at 910C corresponding to the removal of the residual sulfate ion, adsorbed on the surface of the PB. The fifth exothermic loss is between 1180 and 1200C corresponding to the formation of -Al2O3 phase. 3.3 XRD analysis Diffraction patterns were determined to determine the structure and the degree of structural order of the samples. The BAS obtained by homogeneous precipitation is an amorphous material as shown in Fig. 3. This BAS was neutralized in a solid/liquid reaction in order to obtain the PB. The diffraction angles correspond to the crystal planes of the PB (020), (120), (140), (031), (200), and agree very well with those reported in the JCPDS No. 211307. Thus, the diffraction peaks with little height indicate that the material has low crystallinity. Furthermore, the diffraction angles of the -Al2O3 corresponding to the planes 311, 400 and 440 are consistent with those reported in the JCPDS No. 10-0425. Additionally, the broad peaks with low intensity show that the -Al2O3 powder is very amorphous [19].

140 120

0.08

80

Weight (%)

0.06 60

Temp. Diff ( C/mg)

-.05

0.04

-.10

40 20 0 0 200 400 TG

0.02

-.15

0.00 -0.02

600 800 1000 1200 1400 Temperature ( C) DTG DTA

b

120

0.14

0.0

Weight (%)

80

0.12

0.10

Deriv. Weight (%/ C).

100 100

Deriv. weight (%/ C).

100

36.5 45.87

100

80

66.65 -Al2O3

9060

40

0.08 0.06

-0.1

13.30

u.a

28.1

38.3

48.9 64.85 71.4 PB

80

20

0.04 0.02

60

40

20

70 0

0 300 600 900 1200 Temperature ( C) TG DTG DTA

0.00

BAS

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 2 ()

Fig 2: Thermal analysis of: a) BAS and b) PB The chemical composition in weight percent of the BAS was determined with the results obtained by thermal analysis: 47.8% Al2O3, 22% SO3 and 30.2% H2O. Thus, the empirical formula of BAS agrees with other reported formulas [17]. Al2O30.6SO34.4H2O Al4(OH)10SO4 Fig. 2b shows the thermal analysis of the PB obtained by neutralizing the BAS for 30 minutes. The thermal gravimetric analysis curve shows five very significant weight losses. The first endothermic loss is

Fig 3: XRD analysis of the BAS, PB and -Al2O3 (450C) 3.4 Microanalysis EDS (Energy Dispersive Spectroscopy). To remove the remaining sulfate ion in the powder of the PB observed in the thermo gram (Fig. 2b), various BA Sneutralizations were performed at different times (Table 1). Thus, the PB obtained in each test was heat treated at 450C to obtain the -Al2O3 phase according to the thermal analysis of Fig. 2b and the diffractogram of Fig. 3. The EDS microanalysis results (Fig. 4) show that the sulfate ion is not removed completely with only first

487

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

neutralization regardless of the time duration thereof. However a second neutralization with times of 10 minutes each (10 +10) eliminates 100% of the sulfate ions. The same results are obtained with 20 +30, 30 +30 minutes each. To corroborate the results, detection of residual sulfate ions was performed with FTIR spectroscopy (Fig. 5b).

corresponding -Al2O3 sample obtained by double neutralization: 10 + 10, 10 + 20and10 + 30 minutes indicates that the absorption band attributable to sulfate ions does not appear.

a

1100 3445 610

3

O-H

100% 80%

SO3

100.0%

60% 40% 20% 0%

SBA 1 9.0%

Absorbance (u.a.)

990 1

1635

O-H

4.0% 2.6% 2.2% 2.5% 0.0% 0.0% 0.0% 10 30 80 120 10+1010+2010+30

3500 3000 2500 2000 1500 1000 500 Wave number [1/cm]

Neutralization time (min)

Fig 4: Sulfate ion (SO3) remaining in the -Al2O3 powder obtained by neutralization of the BAS.

Absorbance (u.a).

3.5 FTIR of the BAS and -Al2O3 (450C) Fig. 5a shows the FTIR spectrum of the BAS. Five absorption bands can be observed, the first at 3445cm1 corresponding to the vibration modes 1 and 3 of the water molecules and bond stretching H-O, the second band located at 1635 cm-1corresponding to the vibration mode 2 of the coordination water, the third, fourth and five absorptions appear at 1140 cm-1, 990 cm-1 and 610 cm1 corresponding to the vibrations 3, 1 and 4, respectively of the sulfate ion SO42-[20,21]. The spectrum of -Al2O3 (Fig. 5b), shows vibration frequencies below 1000 cm-1which represent fundamental interactions of the aluminum Al-O, coordinated in the structure -Al2O3. It has been established that the octahedral coordination AlO4 and tetrahedral AlO6 are characterized by vibrational frequencies in the range 500-700cm-1 and 700-900cm-1respectively. The spectrum also exhibits an OH stretching mode associated with water and the hydroxide species, and a scissor mode H-O-H associated with the water, found at 3464cm-1 and 1630 cm1 respectively[22]. Thus, the amplitude of the absorption bands can be due to the amorphous material. Additionally, the spectra corresponding to 1, 10 and 30 minutes of neutralization shows a band at 1100 cm1 corresponding to the remaining sulfate ion in the Al2O3 powder. The presence of the sulfate ion in the sample is a result of the sulfate ion affinity for aluminum, being difficult to remove with onetime neutralization. However, applying a second neutralization, totally removes any sulfate ion remaining. The FTIR spectrums (Fig.5b) of the

3464

-Al2O3 10+30 770 598 -Al2O3 10+20 -Al2O3 10+10 -Al2O3 30 -Al2O3 10 -Al2O3 1 1100

1630

0 . -0.1 1

3500 3000 2500 2000 1500 1000 500 Wave number [1/cm]

Fig 5: FTIR spectra of the BAS and -Al2O3 3.6 Morphology and particle size of the PB and -Al2O3 by TEM The transmission electron microscope (TEM) was used to evaluate the shape and particle size of the PB and the -Al2O3. As shown, the samples are formed by nano fibers, in arrangements of agglomerates and this is in agreement with the amorphous material observed by XRD analysis (Fig. 3). Fig. 6a shows nano fibers of the PB thinner than those corresponding to the -Al2O3 powder (Fig. 6b). As is known, the high surface area can be related to the geometry of the particle. Thus, according to the specific surface area (338 m2/g) an average length of 75 nm and a diameter of 3 nm (approx.) was calculated per fiber for the -Al2O3.

488

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

400

a

SBET (m2 /g)

350

100.0%

350

338

325

300

250

271 234

200

150

100

50

11

9.0%

4.0%

2.6%

0.0%

0.0%

BAS

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0%

1 10 30 10+10 10+30 Neutralization time (min)

Fig 7: Effect of sulfate ion and neutralization times on the specific surface area of the -Al2O3 Fig. 8 shows the adsorption-desorption isotherms of the BAS and -Al2O3 powder obtained from PB synthesized with different neutralization times of the BAS. The isotherms except for the BAS sample presents a type IV is other according to the IUPAC definition which is characteristic of a mesoporous material. The irregular shape isotherms, with the hysteresis loop indicating that the pores do not have uniform size have an inkwell-type shape. The BAS is other m is very horizontal due to its low surface area and negligible porosity.

600

Vol. Adsorbed (cm3 /g)

500 400

300 200 100 0 0.00

10 + 30 min. 30 min. 10 min. 1 min. 0 min.

Fig 6: TEM micrographs of: (a) PB and (b) -Al2O3. 3.7 Adsorption / desorption of N2, BET area analysis Fig. 7 shows the specific surface area of -Al2O3 and the sulfate ion remaining against the neutralization time. As can be seen the -Al2O3 powder with higher surface area (350m2/g) is obtained with a neutralization time of 30 minutes and the percentage of remaining sulfate ions in the -Al2O3 powder was 2.63%. Thus, for neutralizations with time under 30 minutes, the contents of sulfates present in the solid neutralized (AlOOH) drastically decreases the surface area of -Al2O3. In fact, sulfate ion shave not been exchanged for hydroxide ions during neutralization and they are occupying more space within the structure of the -Al2O3. Furthermore, with the double neutralization the sulfate ions are eliminated and even though slightly affect the specific surface area of the powder. This can be due to aging of the solid during the second neutralization. However, the specific surface area is kept high to 325 m2/g.

0.20

0.40 0.60 0.80 Relative Pressure (P/Po)

1.00

Fig 8: Adsorption-desorption isotherm of -Al2O3 obtained from different neutralization times

4. CONCLUSIONS

The ammonium bisulfate used as precipitating agent to synthesize the basic aluminum sulfate (BAS) maintains a pH of 3.7. The BAS with amorphous structure obtained by homogeneous precipitation was used as starting material for the synthesis of -Al2O3 with high specific surface area (350m2/g). The high surface area of the -Al2O3 is due to the febrile morphology of the pseudoboehmite (-AlOOH) which was used as a precursor material. The removal of sulfate ions from the structure of BAS by neutralization of the solid is accomplished by double neutralization each one for a short time (10 + 10 minutes). However, the double neutralization diminishes the specific surface area (350 m2/g) due to the aging effect.

489

SO3

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

REFERENCES

[1] M.M. Mart-Ruiz,L.A. Prez-Maqueda, T. Cordero, V. Balek, J. Subrt, N. Murafa, J. Pascual-Cosp, High surface area -alumina preparation by using urban waste, Ceramics International 35 (2009) 2111. Z. Li, X. Feng, H. YaoUltrafine alumina powders derived from ammonium aluminum carbonate hydroxide, Journal of Materials Science 39 (2004) 2267. [15] [3] S. Li, Z.H. Jiang, Q. Jiang Thermodynamic phase stability of three nano-oxides, Materials Research Bulletin 43 (2008) 3149. H. Unuma, S. Kato., T. Ota and M. TakahashiHomogeneous precipitation of alumina precursors via enzymatic decomposition of urea, Advanced Powder Technol 9 (1998) 181. S. Dhara,Synthesis of Nan crystalline Alumina Using Egg White,J. Am. Ceram. Soc.88 (2005) 2003. [17] [6] E. Matijevic,Preparation and Properties of Monodispersed Colloidal Metal Hydrous Oxides, Pure & Appl. Chem.50 (1978) 1193. H. H. Willard and N. K. Tang, Precipitation of Aluminum Basic Sulfate by Urea,J. Am. Chem. Soc.59 (1937) 1190. E. S. II Robert, C. Habeger, A. Rabinovich and James H. Adair, Enzyme-Catalyzed Inorganic Precipitation of Aluminum Basic Sulfate,J. Am. Ceram. Soc.81 (1998) 1377. J.T. Kloprogge, R.L. Frost The dehydroxylation of basic aluminum sulfate: An infrared emission spectroscopic study, Thermochemical Act. 320 (1998) 245. [20] [10] J.E. Rodrguez-Pez, C. Villaquirn, J. CoboEstudio de la Formacin de los Complejos Intermedios Durante la Sintes is de Alumina, Materials Research 4 (2001) 255. [21] [11] G. Paglia, Craig E. Buckley, Andrew L. Rohl, Robert D. Hart, Kartsen Winter, Andrew J. Studer,Brett A. Hunter, and John V. Hanna Boehmite Derived g-Alumina System. 1. Structural Evolution with Temperature, with the Identification and Structural Determination of a New Transition Phase, -Alumina, hem. Mater 16 (2004) 220. B. K. Park and J. M. Jeong Effect of the H2O/Al2(SO4)3 ratio on physical properties in the synthesis of porous AlO(OH) nano gel by homogeneous precipitation, Journal of Ceramic Processing Research 9 (2008) 204. [16] [13]

K. P. Prodromou and A. S. Pavlatou-VeFormation of Aluminum Hydroxides as Influenced by Aluminum Salts and Bases, Clays and Clay Minerals 43 (1995) 111. T. Sugimoto, H. Itoh, and H. Miyake Formation of Monodisperse Microcrystals of Basic Aluminum Sulfate by the GelSol Method, Journal of Colloid and Interface Science 188 (1997) 101. C. Feng,Q. Wei, S. Wang, B. Shi, H. Tang Speciation of hydroxyl-Al polymers formed through simultaneous hydrolysis of aluminum salts and urea, Colloids and Surfaces A: Physicochemical. Eng. Aspects 303 (2007) 241. J. Cobo, J. E. Rodrguez-Pez, R. C. Villaquirn& Albero ScianEfecto del Etanol y de la Concentracin inicial de Precursor de Aluminio en la Obtencin de -Al2O3 por el Mtodo de Precipitacin Controlada,Rev.Acad. Colomb. Cienc.29 (2005) 571. Y. Sarikaya,S.K. Ada, T. Alemdaroglu, I. Bozdogan, The effect of Al3+ concentration on the properties of alumina powders obtained by reaction between aluminiumsulphate and urea in boiling aqueous solution, Journal of the European Ceramic Society 22 (2002) 1905. J. Lu, L. Gao, J. GuoPreparation and phase transition of superfine boehmite powders with different crystallinity,Journal of Materials Science Letters 20 (2001) 1873. C. V. Coelho, G.A. Rocha, P. Souza Santos, H. Souza Santos, P.K.KiyoharaSpecific surface area and structures of aluminas from fibrillarPseudoboehmite, Revista Matria 13 (2008) 329. J. R.Sohnand W. C. Park Highly Active Catalyst of Nickel Sulfate Supported on Titania for Ethylene Demonization, Bull. Korean Chem. Soc. 22(2001) 1303. H. Rudolph, G. Irmer Raman and infrared spectroscopic investigation of contact ion pair formation in aqueous cadmium sulfate solutions, Journal of solution chemistry 23(1994) 663. A. Boumaza, L.Favaro, J.Ldion, G. Sattonnay, J.B. Brubach, P. Berthet, A.M.Huntz, P. Roy, R. Ttot Transition alumina phases induced by heat treatment of boehmite: An X-ray diffraction and infrared spectroscopy study, Journal of Solid State Chemistry 182 (2009) 1171.

[14] [2]

[4]

[5]

[7]

[18]

[8]

[19]

[9]

[22]

[12]

490

VOL. 3, NO. 5, May 2013

ISSN 2225-7217

ARPN Journal of Science and Technology

2011-2013. All rights reserved. http://www.ejournalofscience.org

[23]

H.X. Wu,T. J. Wang, J. L. Duan, and Y. Jin Effects of SO42- on the Heterogeneous Precipitation Coating of Hydrous Alumina on TiO2 Particles in an

Aqueous Process, Ind. Eng. Chem. Res. 46(2007) 3590.

491

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5833)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PTCB Exam 1Document20 pagesPTCB Exam 1Amber Chen80% (5)

- EFST en PDFDocument16 pagesEFST en PDFMohamed ShabirNo ratings yet

- 200 Series: Insert Style Flow Sensors by Data Industrial Owner's ManualDocument16 pages200 Series: Insert Style Flow Sensors by Data Industrial Owner's Manualaries26marchNo ratings yet

- Phenolic FoamDocument20 pagesPhenolic FoamkenandyouNo ratings yet

- Chemistry Investigatory ProjectDocument20 pagesChemistry Investigatory ProjectFaith92% (13)

- Technical Data Epoxy Primer EP-R-30Document2 pagesTechnical Data Epoxy Primer EP-R-30Sheikh Shoaib100% (1)

- Uaspl InfoDocument2 pagesUaspl InfoDilipraja KolliNo ratings yet

- What Is NaphthaDocument4 pagesWhat Is NaphthaMaria Popa100% (1)

- Correct Procedure For Flange BoltingDocument7 pagesCorrect Procedure For Flange BoltingAkshay KalraNo ratings yet

- Dynamic Reviseed Sheets 01.04.2021 To Ason DateDocument19 pagesDynamic Reviseed Sheets 01.04.2021 To Ason DateArnav KaleNo ratings yet

- تحضير ثايودايزول 22Document1 pageتحضير ثايودايزول 22Usama AliNo ratings yet

- Electro Chemistry (E)Document29 pagesElectro Chemistry (E)Rahul Garg0% (1)

- Okaro Onoriode Jude ProjectDocument108 pagesOkaro Onoriode Jude ProjectOnoriode Jude OkaroNo ratings yet

- Pt. MMF 15 Juli 2022Document249 pagesPt. MMF 15 Juli 2022Agus Sudiana NurmansyahNo ratings yet

- Water, Density, Specific Enthalpy, Viscosity PDFDocument3 pagesWater, Density, Specific Enthalpy, Viscosity PDFmartinezdavid93No ratings yet

- Mecchsyll PDFDocument172 pagesMecchsyll PDFPavana KumaraNo ratings yet

- Fat Substitutes and Replacers in Food Product, PDFDocument31 pagesFat Substitutes and Replacers in Food Product, PDFYustinAyuNo ratings yet

- Price List MOLEX AYUS Per 18.11.2020 (Cabang)Document24 pagesPrice List MOLEX AYUS Per 18.11.2020 (Cabang)Apotek Hilda AlnairaNo ratings yet

- Full Report-Oil Skimmer Cum Metal Chip CollectorDocument55 pagesFull Report-Oil Skimmer Cum Metal Chip Collectorrajkumar100% (1)

- SOLIDS AND THEIR Properties 1Document4 pagesSOLIDS AND THEIR Properties 1JohnnardBelenNo ratings yet

- b2.3 FoundationDocument34 pagesb2.3 FoundationJohura KhanamNo ratings yet

- Erosion CorrosionDocument26 pagesErosion CorrosionElma MhjNo ratings yet

- General Notes: Between Soldier PilesDocument1 pageGeneral Notes: Between Soldier PilesRaja SundaramNo ratings yet

- Magnesia Silicate MsdsDocument5 pagesMagnesia Silicate MsdsPaulo RobertoNo ratings yet

- Group ExperimentDocument9 pagesGroup ExperimentChelsie NicoleNo ratings yet

- GIKEN Aux PilerjetsystemDocument2 pagesGIKEN Aux PilerjetsystemPHÁT NGUYỄN THẾNo ratings yet

- Crouse-Hinds Catalog 2015 PDFDocument375 pagesCrouse-Hinds Catalog 2015 PDFwillian renee carrion aguileraNo ratings yet

- Price List: With Effect From 01 January, 2021Document12 pagesPrice List: With Effect From 01 January, 2021Dev KumarNo ratings yet

- Aerator/Mixer: Surumi UMPDocument7 pagesAerator/Mixer: Surumi UMPVILMA CAROLINA PORTILLO CHAVEZNo ratings yet

- DIY Etched Bullet Necklaces 5467Document14 pagesDIY Etched Bullet Necklaces 5467Santiago GdsNo ratings yet