Professional Documents

Culture Documents

Bag Palletizing Web PDF

Bag Palletizing Web PDF

Uploaded by

tintucinbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bag Palletizing Web PDF

Bag Palletizing Web PDF

Uploaded by

tintucinbCopyright:

Available Formats

Bag Palletizer

Bag Palletizer

Schneider offers Bag Palletizers for

single and multi-line systems. These economical and flexible solutions provide consistent, well packed pallet patterns that increase line throughput and reduce product damage associated with manual handling.

Multiple products per pick combined with up to 30 picks per minute enable high throughput.

Up to 30 Picks Per Minute Fast Pallet Exchange Customized End Of Arm Tooling (EOAT) specifically designed to handle products reliably Flexible Work Cells

Packing Solution

The optional over/under conveyor allows pallet exchange while operating for continuous production. End Of Arm Tooling (EOAT) Options include vacuum, mechanical, fork or a combination of these with or without pallet hooks and slip sheet handling A wide range of work cell configurations are available to handle single and multiple lines to accommodate your floor space, facility and ergonomic requirements.

2 In - 2 Out Example

An Approved

I n n o vat i v e E n d - o f - l i n e S o L U t i o n s

Operation Summary: Schneider bag palletizers utilize a robot with an end of arm tool (EOAT) to build a unit load. An empty pallet enters the cell. A pallet dispenser or magazine can be utilized. The pallet is then transferred onto the load station by the robot. Product is transported to the robotic cell by the case infeed conveyor(s). Once sufficient product and an empty pallet are available, the robot will pick product from the infeed and place it onto the appropriate pallet in the appropriate pallet pattern. Slip sheets are placed as required from the slip sheet magazine. Once a unit load is completed, it is discharged. In the meantime, another empty pallet has been transferred onto the load station and the robot can continue to palletize. The process repeats. Typical Equipment Layout 1 In / 1 Out Application

Bag Palletizer

Packing Solution

Integration Options Stretch Wrapper Product and Pallet Labeling Conveyors, Shuttle Cars and Automated Guided Carts Pallet & Slip Sheet Dispenser or Magazine

SPECIFICATIONS

Product Types: Paper, poly, or burlap style bags Pallet Type: GMA, CHEP, Metric End of Arm Tooling (EOAT): Fork, vacuum or gripper or a combination (determined by product) Visual Display: Standard: One (1) Allen Bradley 600 Color Touchscreen Control Voltage: 24 VDC Controller: PLC microprocessor Ambient Temperature: 40 to 85F (4.4 to 29.4C) Optional AC packages available Enclosures and Electrics: Standard: NEMA 12 Construction: Standard: Painted, carbon steel Power Requirements: 480 volt, 3 phase Safety: Meets ANSI/PMMI B155.1 safety standards

OTHER SCHNEIDER END-OF-LINE SOLUTIONS

Horizontal /Vertical Case Packers Robotic Case Packers Robotic Palletizers Multi-Line Systems Wrapping Equipment Bundling Equipment Ancillary Equipment

Bag Palletizer / 1005/003

P.O. Box 890 | 5370 Guy Young Rd. Brewerton, NY 13029

315.676.3035 ph 315.676.2875 fax

info@schneiderequip.com www.schneiderequip.com

You might also like

- Solutions Chapter14Document10 pagesSolutions Chapter14Ali Rehman100% (8)

- Vibrapac Maintenance ManualDocument211 pagesVibrapac Maintenance ManualMatthew PhillipsNo ratings yet

- CAT Hand Tools CatalogDocument354 pagesCAT Hand Tools CatalogArul Speleo100% (13)

- Instruction Manual: AH-250H Automatic Hitch Feed Metal Cutting Band Saw (415V) 280 X 250mm (W X H) RectangleDocument134 pagesInstruction Manual: AH-250H Automatic Hitch Feed Metal Cutting Band Saw (415V) 280 X 250mm (W X H) Rectanglemaicon sulivanNo ratings yet

- E-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaDocument6 pagesE-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaImpel IntralogisticsNo ratings yet

- Pan Conveyors PDFDocument24 pagesPan Conveyors PDFcachorrexNo ratings yet

- HSD PDFDocument3 pagesHSD PDFDavid AguilarNo ratings yet

- Use and Maintenance Manual Co. 20-6483 PDFDocument202 pagesUse and Maintenance Manual Co. 20-6483 PDFKing NileshNo ratings yet

- Technical Proposal Pbas Annular and Roof TankDocument13 pagesTechnical Proposal Pbas Annular and Roof TankVeva Santi DNo ratings yet

- UKHSE - Location and Design of Occupied Buildings at Chemical PlantsDocument17 pagesUKHSE - Location and Design of Occupied Buildings at Chemical Plantskhaiseah922567% (3)

- Paint IndustryDocument27 pagesPaint IndustryVishal VinitNo ratings yet

- 90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorDocument7 pages90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorImpel IntralogisticsNo ratings yet

- TDTG Bucket ElevatorDocument20 pagesTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- AUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaDocument14 pagesAUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaNicolas Recio Fdez-Tresguerres100% (1)

- Datasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignDocument10 pagesDatasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignImpel IntralogisticsNo ratings yet

- Lecture 8 9Document46 pagesLecture 8 9Mr. A.ENo ratings yet

- Expandable MandrelsDocument3 pagesExpandable Mandrelsali-masoodNo ratings yet

- Ventomatic Packing MachineDocument85 pagesVentomatic Packing MachineMudassir RafiqNo ratings yet

- Peak 209 Manual - RedDocument40 pagesPeak 209 Manual - RedbugseNo ratings yet

- 2015 MNCDocument33 pages2015 MNChiepNo ratings yet

- Longitudinal Seam Welders Brochure PDFDocument8 pagesLongitudinal Seam Welders Brochure PDFVijo JoseNo ratings yet

- Fixed Welding Automation: Where Precision, Quality and Speed ConvergeDocument8 pagesFixed Welding Automation: Where Precision, Quality and Speed ConvergeOscar JiménezNo ratings yet

- Verderflex: Industrial Peristaltic Hose PumpsDocument20 pagesVerderflex: Industrial Peristaltic Hose PumpsWilmerNo ratings yet

- Manual E11 Bucket Elevator Jema AgroDocument40 pagesManual E11 Bucket Elevator Jema AgroMuhammad Wasay KhalidNo ratings yet

- 13 1 2 Part Feeding DeviceDocument41 pages13 1 2 Part Feeding Devicedavid mierNo ratings yet

- Palletizer Stretch Wrapper Combo EOL BrochureDocument2 pagesPalletizer Stretch Wrapper Combo EOL Brochurered patriotNo ratings yet

- GSI Bucket Elevator AssemblyDocument38 pagesGSI Bucket Elevator AssemblyElias ArizaNo ratings yet

- Rotary ConditionerDocument7 pagesRotary ConditionerMiguel OrhlNo ratings yet

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 11 - 0.doc, Codeword: VedantaDocument17 pagesTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 11 - 0.doc, Codeword: VedantaSubhransu MohapatraNo ratings yet

- TR521 Tier 4i - 1112 - WebDocument6 pagesTR521 Tier 4i - 1112 - WebBrunoNo ratings yet

- Belt and Bucket Elevator - LBEB - Data Sheet - ENDocument2 pagesBelt and Bucket Elevator - LBEB - Data Sheet - ENsalih khattabNo ratings yet

- Screw Conveyor Engineering Guide - Horsepower CalculationDocument5 pagesScrew Conveyor Engineering Guide - Horsepower Calculationbrpnaidu2157No ratings yet

- MBL Volkmann Che Mag IsDocument47 pagesMBL Volkmann Che Mag IsarizakarolNo ratings yet

- Palletizer SelectionDocument4 pagesPalletizer Selectionred patriotNo ratings yet

- Dunlop Conveyor Belt Design Manual - P2Document15 pagesDunlop Conveyor Belt Design Manual - P2perdhana2000No ratings yet

- Chain ConveyorsDocument4 pagesChain Conveyorsarup11nvNo ratings yet

- Conveyor Chain CatalogueDocument51 pagesConveyor Chain CatalogueRay RojasNo ratings yet

- Bühler Chain CatalogDocument32 pagesBühler Chain CatalogenricoorNo ratings yet

- Combined PDFDocument22 pagesCombined PDFThafer MajeedNo ratings yet

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 13 - 0.doc, Codeword: VedantaDocument46 pagesTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 13 - 0.doc, Codeword: VedantaSubhransu MohapatraNo ratings yet

- Catalogo GehaDocument42 pagesCatalogo GehaSebastian Deossa RestrepoNo ratings yet

- Jetline Capabilities CatalogueDocument4 pagesJetline Capabilities CatalogueJuan RodriguezNo ratings yet

- 13 2 1 Non Vibratory Part FeederDocument45 pages13 2 1 Non Vibratory Part Feederdavid mierNo ratings yet

- HammerDocument20 pagesHammerdatnguyen789jNo ratings yet

- TS 5 Transfer SystemDocument246 pagesTS 5 Transfer SystemSantosh DengleNo ratings yet

- BVD 2462 GBDocument2 pagesBVD 2462 GBAnonymous P18XRitOPPNo ratings yet

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 pagesBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNo ratings yet

- Westrup BrochureDocument36 pagesWestrup BrochureADS ADSNo ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- Weighing SystemDocument41 pagesWeighing SystemmkpqNo ratings yet

- Model 7900Document73 pagesModel 7900Carlos MartínezNo ratings yet

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaNo ratings yet

- THIELE Catalog Bucket-Elevator-Chains E 2014 PDFDocument20 pagesTHIELE Catalog Bucket-Elevator-Chains E 2014 PDFNuzuliana EnuzNo ratings yet

- Sidewall Splicing MechanicalDocument11 pagesSidewall Splicing MechanicalTamer EmamNo ratings yet

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- Belt ScaleDocument9 pagesBelt ScaleMuhammad ChabibiNo ratings yet

- Synergy Shuttle ConveyorDocument5 pagesSynergy Shuttle ConveyorTamal Tanu RoyNo ratings yet

- VibrofeederDocument32 pagesVibrofeederNaveen LingamkuntaNo ratings yet

- VDL Weweler Corporate UK 2012 ScreenDocument48 pagesVDL Weweler Corporate UK 2012 ScreenGabriel Zardo100% (1)

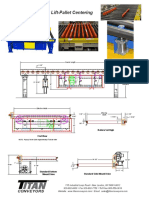

- Transfer-PalletLift-Centering StopDWGDocument1 pageTransfer-PalletLift-Centering StopDWGHelena Nadine Mendes FerreiraNo ratings yet

- Bag Palletizer: Schneider Offers Bag PalletizersDocument2 pagesBag Palletizer: Schneider Offers Bag PalletizersKien Nguyen TrungNo ratings yet

- OCME - Palletiser - enDocument40 pagesOCME - Palletiser - enRameeSahibaNo ratings yet

- Roller ConveyorDocument6 pagesRoller ConveyorzainonayraNo ratings yet

- OryxCP20-60Palletiser 05 09 12 Spreads PDFDocument3 pagesOryxCP20-60Palletiser 05 09 12 Spreads PDFtintucinbNo ratings yet

- Check Weigher: Revolutionizing Quality Control with Computer VisionFrom EverandCheck Weigher: Revolutionizing Quality Control with Computer VisionNo ratings yet

- Swivel Eye Bolts ProjectDocument1 pageSwivel Eye Bolts ProjecttintucinbNo ratings yet

- Msds Dog Glue X-66 - EngDocument4 pagesMsds Dog Glue X-66 - Engtintucinb67% (3)

- Msds Sikagrout 212-11 - EngDocument8 pagesMsds Sikagrout 212-11 - EngtintucinbNo ratings yet

- Msds Sikagrout 212-11 - EngDocument8 pagesMsds Sikagrout 212-11 - EngtintucinbNo ratings yet

- Survey Welding-Standards 14-10-2015Document1 pageSurvey Welding-Standards 14-10-2015givaliNo ratings yet

- Price List & Product Catalog: Stainless Steel Drainage Systems, Pipe & ChannelsDocument74 pagesPrice List & Product Catalog: Stainless Steel Drainage Systems, Pipe & ChannelstintucinbNo ratings yet

- MHD56209 Jib CranesDocument44 pagesMHD56209 Jib CranestintucinbNo ratings yet

- MSDS Dulux Weathershield Powerflexx Inggris - ENGDocument11 pagesMSDS Dulux Weathershield Powerflexx Inggris - ENGtintucinbNo ratings yet

- Abus Jib CranesDocument26 pagesAbus Jib CranestintucinbNo ratings yet

- Abus Products634763209606250000Document28 pagesAbus Products634763209606250000tintucinbNo ratings yet

- Forklifts, Warehouse Trucks, Stackers and Hand Pallet TrucksDocument26 pagesForklifts, Warehouse Trucks, Stackers and Hand Pallet Truckstintucinb100% (1)

- Ridgid - Drain Cleaning and Diagnostic PartsDocument135 pagesRidgid - Drain Cleaning and Diagnostic PartstintucinbNo ratings yet

- Sata CatalogDocument188 pagesSata CatalogtintucinbNo ratings yet

- Moore and Wright Catalog - 2011Document92 pagesMoore and Wright Catalog - 2011tintucinbNo ratings yet

- Stanley 2012 Catalog - Print VersionDocument24 pagesStanley 2012 Catalog - Print VersiontintucinbNo ratings yet

- 2012 Bosch Catalog - AllDocument338 pages2012 Bosch Catalog - AllirwanaliasNo ratings yet

- Mac Tool Catalog - 2013Document804 pagesMac Tool Catalog - 2013tintucinb100% (1)

- LOTO Policy and ProceduresDocument11 pagesLOTO Policy and ProcedurestintucinbNo ratings yet

- Sta - Cat 08 (LR)Document159 pagesSta - Cat 08 (LR)tintucinb100% (1)

- HT 296 803Document10 pagesHT 296 803tintucinbNo ratings yet

- WD - Accessories & Replacement PartsDocument1 pageWD - Accessories & Replacement PartstintucinbNo ratings yet

- Moore and Wright Catalog - 2011Document92 pagesMoore and Wright Catalog - 2011tintucinbNo ratings yet

- Of Chinaptpl: Power Industry Standard of P.R. ChinaDocument501 pagesOf Chinaptpl: Power Industry Standard of P.R. ChinaMuhammad Junaid KhanNo ratings yet

- Customer Relationship Management and Supply Chain ManagementDocument36 pagesCustomer Relationship Management and Supply Chain ManagementIrina MurgescuNo ratings yet

- 2.2.1 Kyrgyzstan Manas International AirportDocument8 pages2.2.1 Kyrgyzstan Manas International AirportutobuNo ratings yet

- 2017 Winter Model Answer Paper PDFDocument12 pages2017 Winter Model Answer Paper PDFabdul rehman syed parvezNo ratings yet

- Example Fax PDFDocument2 pagesExample Fax PDFJamesNo ratings yet

- Os 12699 16 - Igbt ConverterDocument4 pagesOs 12699 16 - Igbt ConverterkasiiiiiNo ratings yet

- PeopleSoft Campus Solutions CS 9.2 Release NotesDocument8 pagesPeopleSoft Campus Solutions CS 9.2 Release NotesAkash Kumar Shandilya100% (1)

- Capri 2014 BrochureDocument108 pagesCapri 2014 BrochurePGNo ratings yet

- Oracle Usion Middleware Upgrade Guide For Oracle WebLogic Server 12 C Release 1 (12.1.1)Document124 pagesOracle Usion Middleware Upgrade Guide For Oracle WebLogic Server 12 C Release 1 (12.1.1)mraza30No ratings yet

- BS en 12285-2 2005 Workshop Fabricated Steel Tanks-Part 2Document35 pagesBS en 12285-2 2005 Workshop Fabricated Steel Tanks-Part 2Andrea BarbieriNo ratings yet

- Supply Chain ManagementDocument12 pagesSupply Chain ManagementFaris KhetanNo ratings yet

- CMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)Document3 pagesCMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)souvik5000No ratings yet

- Annexure II UNOPS Health Safety PlanDocument8 pagesAnnexure II UNOPS Health Safety PlanBojan Bijelic100% (1)

- HyperWorks Desktop 14.0.120 ReleaseNotesDocument78 pagesHyperWorks Desktop 14.0.120 ReleaseNotesLucy RubenNo ratings yet

- c7200 White PaperDocument1 pagec7200 White PaperjaskrzyNo ratings yet

- EAI Architecture Vodafone IndiaDocument11 pagesEAI Architecture Vodafone IndiaacetaleleNo ratings yet

- Active DatabasesDocument22 pagesActive Databasesradhikakumaran3No ratings yet

- EOI - Feasibility Studies Detailed Design and Tender Document Preparation For Angololo Water Resources Development Project - NELSAPDocument2 pagesEOI - Feasibility Studies Detailed Design and Tender Document Preparation For Angololo Water Resources Development Project - NELSAPACIDNo ratings yet

- Logos and Punchlines of Famous OrgnisationsDocument16 pagesLogos and Punchlines of Famous OrgnisationsAyan MitraNo ratings yet

- Stages of Development of Operations ResearchDocument4 pagesStages of Development of Operations Researchswatiraj0550% (4)

- ATC Exemption Part3Document11 pagesATC Exemption Part3Anonymous z3uMNTJHnZNo ratings yet

- Qa LHB Bogie RepairDocument6 pagesQa LHB Bogie RepairSriram SubramanianNo ratings yet

- JzqoxdlgbdDocument348 pagesJzqoxdlgbdflorin_nite2750No ratings yet

- Mir Arge Company CatalogDocument128 pagesMir Arge Company CatalogVladimir VukovicNo ratings yet

- Previews 2000375 PreDocument11 pagesPreviews 2000375 PreAmgad Alwy BalabelNo ratings yet

- MINISTRY OF PUBLIC WORKS-Engineer IVDocument1 pageMINISTRY OF PUBLIC WORKS-Engineer IVEs HanNo ratings yet