Professional Documents

Culture Documents

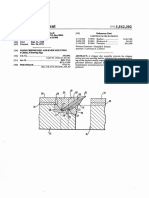

United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991

United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991

Uploaded by

James LindonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991

United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991

Uploaded by

James LindonCopyright:

Available Formats

United States Patent [191

Dirksen

[54] COMBINATION LEAF CADDY AND PICKUP

1111 Patent Number:

[45] Date of Patent:

3,264,809

4,991,386

Feb. 12, 1991

56/400.12

56/400.l7

. . . .. 56/40017

8/1966 Jackson .......................... .. 56/400.12

Mares ........................... .. 294/506

T001,

_

3,350,866 11/1967 Spencer

3,617,084 11/1971

[76]

[21]

Inventor:

Ole A. Dirksen, 1104 Pleasant La,

Spencer, Iowa 51301

3,654,754 4/1972 Scoggin, Jr. et a1.

3,688,484

3,724,188

9/1972

4/1973

COX ....... ................... .. 56/40012

Eads .........

APPI- N~= 45,309

4,037,397 7/1977 FlOl'ClltlllO' ...................... .. 56/400.l2

[22] Filed

[52] U5. C105 c1.

May 4 1987

............. 6 ~ | - 6 u o 6 - I 6 I v .. - a - I s 6. I66I66I666-6-56/400.12; -36666---n4-u 56/400.11

FOREIGN PATENT DOCUMENTS

Um I e d K _mg d ' ~ l I . l ' . . I l I I.

[58]

[56]

Field Of Search ......... .. 56/400.12, 400.04, 400.16,

Primary Examiner-Paul J- Husch

56/4()()_19y 400,11, 4001, 4()0_()1

References Cited

Attorney, Agent, or Firm-Zarley, McKee, Thomte,

v 11 &s Cor ees ease

U.S. PATENT DOCUMENTS

[57]

56/400.11

ABSTRACI

A pair of rakes are pivotally interconnected to gather

and transport leaf material. Blades are provided on the lower ends of the rakes which are identical in shape but

757,123 994,796 1,588,927 1,761,503 1,895,214 1,927,873 2,065,830 2,644,455 2,735,712 2,908,131 3,095,682

4/1904 Kampfe .......................... .. 56/400.05 6/1911 .. 56/400.12 6/1926 Willis ......... .. 294/508 6/1930 Tonhardt .. 294/508 l/l933 Stork ..... .. 56/400.16 9/1933 Lantz ..... .. 56/400.l1 12/1936 Sherman . 7/1953 294/ 50.5 2/1956 Hart ...... .. .. 56/400.12 10/1959 Ross .......... .. 7/1963 Pasquine ........................ .. 56/400.12

Stout . . ... . . . . . ..

Benoit . .. .. .. .. . . . .. 128/321

facing in opposite directions. Sleeves for the handles are offset from the vertical centerline of the blades allowing for the adjacent blade ends to be coplanar. The teeth may abut against each other at their lower ends in the closed position or intermesh in registering relationship.

4 Claims, 3 Drawing Sheets

40

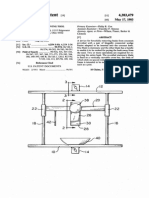

US. Patent

Feb. 12, 1991

Sheet 1 of 3

4,991,386

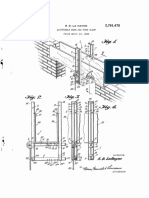

US. Patent

Feb. 12, 1991

Sheet 2 of 3

4,991,386

iii-51?;

111121111

" _""T *'

W'

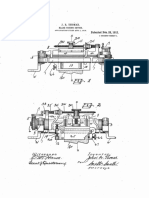

US. Patent

Feb. 12, 1991

Sheet 3 of 3

4,991,386

4,991,386

COMBINATION LEAF CADDY AND PICKUP TOOL

FIG. 9 is a view showing the rake in position for emptying leaves into a collection container. FIG. 10 is a view taken along line 10-10 in FIG. 9.

5

BACKGROUND OF THE INVENTION

Lawn rakes of the spring teeth type are shown in U.S. Pat. No. 4,037,397 and 3,688,484 wherein a pair of rakes are pivotally interconnected. The rake heads are curved

DESCRIPTION OF THE PREFERRED

EMBODIMENT

The combination leaf caddy and pickup tool of this invention is shown in FIG. 1 and referred to generally by the reference numeral 10. It includes a pair of rakes

12 and 14. Each rake has an elongated handle 16 and a blade head 20. Each of the blade heads 20 are of plastic sheet mate

along- their lower edges such that leaves carried be

tween the rakes cannot fall easily from either opposite end as they will catch on the right angle teeth end por tions. The spring teeth are easily deformed out of the plane of the rake head and thus interfere with removal of raked material. 15

In the 397 patent the handle of one rake extends through the center of the handle of the other rake to

rial molded identically in shape such that a single mold is required to produce each rake head. As seen in FIG.

3, sleeves 22 are provided on the back surfaces of the

rake heads and are offset from a vertical centerline. The

maintain the heads in alignment. In the 484 patent the handles have ?attened surfaces where they are pivotally interconnected to help position the heads as closely as

rake heads 20 are in alignment with each other such that the individual teeth 24 engage each other at their tip

ends 26, as seen in FIG. 2, when the rake heads are in

their closed position, as shown by the dash lines.

The teeth 24 have a smooth continuous curve along

possible in alignment.

A leaf caddy and pickup tool is needed that is easily manufactured by molding from plastic utilizing a com

their length which de?ne a cylindrical-like chute pas sageway therebetween through which leaf material 28

mon head for each rake but allowing for the rake heads flows when being emptied into a container 30, as seen in to be aligned. 25 FIG. 10, when the rake heads are positioned with their transverse axes in a vertical plane. The teeth remain SUMMARY OF THE INVENTION coplanar throughout use since they are formed from the Each rake head blade of this invention is produced sheet material rather than being individually con from the same mold. The handle sleeves on the back of structed as in a spring tooth type rake head. The rake the blade are offset from the vertical centerline such 30 heads are also seen to be rectangular in shape with a that when the blades are facing each other the interface straight top edge 32 and opposite end edges 34. The between the sleeves is on the centerline. The handles teeth all terminate in a straight line parallel to the top received in the sleeves may be pivotally interconnected edge 32. without ?attening abutting surfaces for the purpose of The handles 16 are cylindrical in cross section and aligning the rake heads since this is accounted for in the 35 have smooth abutting surfaces where they are pivotally offset sleeves of the rake heads. interconnected by a bolt 36. In FIGS. 5-8 a second embodiment is shown which The molded plastic sheet material has a smooth sur differs only in that the teeth 26A, rather than being in face from top to bottom and end to end along the trans direct opposing aligned relationship, are interrneshed in verse axis such that leaf material will slide smoothly registering relationship as seen in FIGS. 6 and 8. The from between the rake heads when the heads are posi sleeves 22 are offset from the centerline in a similar tioned for emptying the leaves therefrom. A chute-like fashion allowing for a single mold to produce both rake passageway is provided therebetween which offers no heads thereby minimizing costs of production and in resistance through the teeth which are maintained co planar at all times due to their being formed from a ?at ventory. Thus it is seen in operation that leaves may be gath sheet of material rather than individually formed as in a 45

spring-type rake.

The rake heads are rectangular in shape with straight

ered together by spreading the rake heads apart and

then closing them about the leaves. The leaves may then be carried to a collection container 30 with the rake

top and bottom edges and opposite end edges thereby

de?ning a cylindrical like chute passageway therebe

gather and hold leaf material but not to interfere with its

heads being turned on end and spread apart allowing

tween. There is enough curve in the rake head blades to 50 the leaves 28 to smoothly fall from between the rake

smooth flow transversely through the passageway formed by the opposing rake heads.

DESCRIPTION OF THE DRAWINGS

FIG. 1 is a perspective view of the combination leaf

55

heads along the smooth chute-like surfaces. I claim: 1. A combination leaf caddy and pickup tool, com

prising,

oppositely disposed pivotably interconnected ?rst

and second rakes each having a handle with a jaw of sheet material connected at one end, said jaws

caddy and pickup tool.

FIG. 2 is an enlarged end elevational view thereof

showing the tool in its closed and opened positions.

FIG. 3 is a side elevational view thereof. FIG. 4 is a bottom end view taken along line 44 in FIG. 2. FIG. 5 is a view similar to FIG. 1 but showing an alternate embodiment wherein the teeth are inter

being of plastic material and identical in shape but positioned in opposing relationship to each other, each of said jaws having upper and lower sections having a substantially uniform thickness through

out the area of each, said upper section being sub

stantially ?at and solid and merging smoothly into

said lower section, said lower section including a

65

meshed in registering relationship.

FIG. 6 is a fragmentary side elevational view thereof. FIG. 7 is a fragmentary end elevational view thereof.

FIG. 8 is a bottom view thereof.

plurality of curved teeth extending towards the

teeth of the other rake, said ?rst and second rakes

being pivotal between open and closed positions

with the teeth of each rake being in engagement

4,991,386

face on said jaws for gathered material to freely flow from said passageway when in said vertical

with the teeth of the other rake when in said closed

position,

said jaws having a rectangular shape including

position.

2. The structure of claim 1 wherein said teeth on straight end and top and bottom edges and when in said closed position de?ning a cylindrical-like 5 opposing jaws are coplanar and abut each other without overlapping at their lower tip ends when in said closed transverse passageway between said jaws which position. allows for emptying leaf material from either end

when the transverse axis of said passageway is

3. The structure of claim 1 wherein said teeth on

vertically positioned, said teeth having a width throughout their length greater than' their thick

ness, and

opposing jaws are offset from each other and intermesh

in registering relationship when in said closed position.

4. The structure of claim 1 wherein said mounting means on said jaws are sleeves integral with said jaws and are of molded plastic material.

1! >3 * * =4

a handle mounting means on entirely the back side of

each of said jaws at the upper edge of the top sec tion to provide an uninterrupted smooth front sur

20

25

30

35

40

45

55

60

65

You might also like

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Us 3688484Document4 pagesUs 3688484James LindonNo ratings yet

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Document2 pagesUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- O/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231Document5 pagesO/ie/7 Covaz: Nov. 4, 1941. O. H. Cottingham 2,261,231VyacheslavNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Sept. 4, 1956 R. D. La Hayne: Adjustable Beam and Form ClampDocument3 pagesSept. 4, 1956 R. D. La Hayne: Adjustable Beam and Form Clampkkd108No ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- June 23, 1925.: F . I: ZacherDocument3 pagesJune 23, 1925.: F . I: ZachershamsNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- 3 Way Finger JointDocument5 pages3 Way Finger JointspaceskipperNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Aug. 24, 1923. ? M 1,465,230: A. Ni KanderDocument3 pagesAug. 24, 1923. ? M 1,465,230: A. Ni KanderTechnical Staff/IPR Coordinator Wenceslao GavinaNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- US2236969Document7 pagesUS2236969José Ricardo ProchnowNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- US2125697Document3 pagesUS2125697davarniyaalirezasepehrelectricNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Document3 pagesQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNo ratings yet

- Us 5176330Document7 pagesUs 5176330ManivannanMudhaliarNo ratings yet

- Multiple Section Paper Tube and Method of Making Same Filed Dec.v 21, 1.956Document3 pagesMultiple Section Paper Tube and Method of Making Same Filed Dec.v 21, 1.956rodrigo_aguilar_4No ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- United States PatentDocument8 pagesUnited States PatentBarmak CheraghiNo ratings yet

- I Set: II. F TaxaDocument6 pagesI Set: II. F Taxafrank saruhanNo ratings yet

- US3377702Document3 pagesUS3377702j8fnnkhzpdNo ratings yet

- United States PatentDocument6 pagesUnited States Patent155No ratings yet

- US2439768Document3 pagesUS2439768William Rolando Miranda ZamoraNo ratings yet

- Filed July 16, 1943: Feb. 5, 1946. A. E. Rawald 2,394,404Document3 pagesFiled July 16, 1943: Feb. 5, 1946. A. E. Rawald 2,394,404Technical Staff/IPR Coordinator Wenceslao GavinaNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Us 2855252Document4 pagesUs 2855252Rohan KulkarniNo ratings yet

- Hwa M: March 16, 1911 - J, T. Del'Vecchm 3,570,129Document8 pagesHwa M: March 16, 1911 - J, T. Del'Vecchm 3,570,129diordesasNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- July 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting FabricDocument4 pagesJuly 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting Fabricdavid19775891No ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Us 20120148372Document28 pagesUs 20120148372phillosisNo ratings yet

- April 12, 1966: Filed July 10, 1962Document6 pagesApril 12, 1966: Filed July 10, 1962Freddy OrtegaNo ratings yet

- Dénventor - L: 971,733. Patented Oct. 4,, MMDocument4 pagesDénventor - L: 971,733. Patented Oct. 4,, MMpouyaNo ratings yet

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Document3 pagesPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesNo ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- Us2218783 PDFDocument4 pagesUs2218783 PDFlandagoNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- Zyzews/35.5% Az6.: Dec. 23, 1941. W.E. Corduan Etal 2,267,444Document4 pagesZyzews/35.5% Az6.: Dec. 23, 1941. W.E. Corduan Etal 2,267,444MURALIPRAKASH.S 18BIT131No ratings yet

- Jan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTDocument5 pagesJan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTRodrigoPomaNo ratings yet

- Examen de Auditor InternoDocument4 pagesExamen de Auditor InternoJavier CastañedaNo ratings yet

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Document6 pagesJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Fig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Document6 pagesFig. Ib: Oct.8,1968 M - ,. - A. - KER - 3,404,545Thiru MuruganNo ratings yet

- H. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867Document3 pagesH. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867asdfasfNo ratings yet

- 1,385,855, Patented July 26, 1921.: E, BalodDocument3 pages1,385,855, Patented July 26, 1921.: E, BalodChoo Wei shengNo ratings yet

- Us 2543888Document5 pagesUs 2543888Juan Sebastian PrietoNo ratings yet

- July 24, 1962 W. S. WILLIS: Fir Tree Blade Mount Filed Dec. 10, 1959Document3 pagesJuly 24, 1962 W. S. WILLIS: Fir Tree Blade Mount Filed Dec. 10, 1959Digvijay YadavNo ratings yet

- N Patented Dec. 25, 1900.: G. C. Ains WorthDocument5 pagesN Patented Dec. 25, 1900.: G. C. Ains Worthsorin robertNo ratings yet

- Patented May 27, 1919.: S. H. GarstDocument4 pagesPatented May 27, 1919.: S. H. GarstKrozeNo ratings yet

- Full Download Ebook PDF Sociology Exploring The Architecture of Everyday Life 11Th Edition Ebook PDF Docx Kindle Full ChapterDocument23 pagesFull Download Ebook PDF Sociology Exploring The Architecture of Everyday Life 11Th Edition Ebook PDF Docx Kindle Full Chapterrobbie.fortney495100% (44)

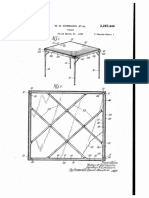

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- 09.14.2018 NgohDocument9 pages09.14.2018 NgohJames LindonNo ratings yet

- Anderson ComplaintDocument15 pagesAnderson ComplaintBasseemNo ratings yet

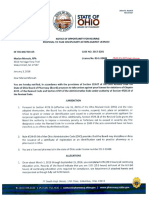

- State Of: Steven W. Schierholt, Esq. Executive Director John R. GaDocument6 pagesState Of: Steven W. Schierholt, Esq. Executive Director John R. GaJames LindonNo ratings yet

- 09.26.2018 LottDocument6 pages09.26.2018 LottJames LindonNo ratings yet

- 09.06.2018 StarmanDocument7 pages09.06.2018 StarmanJames LindonNo ratings yet

- 10.10.2018 GomezDocument5 pages10.10.2018 GomezJames LindonNo ratings yet

- 8.23.18 Better Living Clinic AkronDocument5 pages8.23.18 Better Living Clinic AkronJames LindonNo ratings yet

- State Of: PendingDocument7 pagesState Of: PendingJames LindonNo ratings yet

- James Lindon Attorney, Ph.D. 35104 Saddle Creek Avon, Ohio 44011-4907Document1 pageJames Lindon Attorney, Ph.D. 35104 Saddle Creek Avon, Ohio 44011-4907James LindonNo ratings yet

- Sc-,:iegi?5: in The Matter Of: CASE NO. 2016-1909 License No. 02-1339450Document6 pagesSc-,:iegi?5: in The Matter Of: CASE NO. 2016-1909 License No. 02-1339450James LindonNo ratings yet

- 10.02.2018 MascioDocument6 pages10.02.2018 MascioJames LindonNo ratings yet

- 09.06.2018 Pamela ApplegateDocument6 pages09.06.2018 Pamela ApplegateJames LindonNo ratings yet

- Robert Garrity Prison RecordDocument1 pageRobert Garrity Prison RecordJames LindonNo ratings yet

- Lorain County Government DirectoryDocument53 pagesLorain County Government DirectoryJames LindonNo ratings yet

- 1.25.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonDocument13 pages1.25.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonJames LindonNo ratings yet

- Certification of Micro Entity StatusDocument2 pagesCertification of Micro Entity StatusJames LindonNo ratings yet

- LCBA's 79th President, Andrea Kryszak, Takes Over: Summer, 2015 Volume 10, Issue 3Document21 pagesLCBA's 79th President, Andrea Kryszak, Takes Over: Summer, 2015 Volume 10, Issue 3James LindonNo ratings yet

- Attachment Formulary 2500Document46 pagesAttachment Formulary 2500James LindonNo ratings yet

- 1.3.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonDocument8 pages1.3.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonJames LindonNo ratings yet

- Bilogy Form NotesDocument1 pageBilogy Form NotesFunwi JayNo ratings yet

- Invitation LayoutDocument8 pagesInvitation Layoutrey anne danoNo ratings yet

- Carolina ReaperDocument19 pagesCarolina ReaperKevin AbalosNo ratings yet

- Memorial Day and Other Verse by Helen Leah ReedDocument91 pagesMemorial Day and Other Verse by Helen Leah ReedAndrea SotoNo ratings yet

- Flora and FaunaDocument18 pagesFlora and FaunaTatiana UrsuNo ratings yet

- MangoDocument12 pagesMangothippliNo ratings yet

- Photosynthesis in Higher PlantsDocument5 pagesPhotosynthesis in Higher PlantsGaurav Arun RanaNo ratings yet

- Tom Yum RecipeDocument3 pagesTom Yum Recipeapi-247572990No ratings yet

- 15 - Chapter 5 PDFDocument140 pages15 - Chapter 5 PDFHimanshu YadavNo ratings yet

- IELTS-SPEAKING-SAMPLES-Part-1 & 2-Forecast PDFDocument92 pagesIELTS-SPEAKING-SAMPLES-Part-1 & 2-Forecast PDFThu NguyenNo ratings yet

- Link To Publication in University of Groningen/UMCG Research DatabaseDocument23 pagesLink To Publication in University of Groningen/UMCG Research DatabaseDyah Aji SofyaningtyasNo ratings yet

- TECHNOLOGY LIVELIHOOD EDUCATION 7/8 (Agri-Crop Production)Document7 pagesTECHNOLOGY LIVELIHOOD EDUCATION 7/8 (Agri-Crop Production)Mark Gilbert TandocNo ratings yet

- Short Notes Form 4 Biology Chapter 1 4 PDFDocument6 pagesShort Notes Form 4 Biology Chapter 1 4 PDFTanUeiHorngNo ratings yet

- UntitledDocument56 pagesUntitledahmad bagus muzakkiNo ratings yet

- Blood Circulation and Transport Learning Objective: 2.1 Understanding The Transport System in HumansDocument14 pagesBlood Circulation and Transport Learning Objective: 2.1 Understanding The Transport System in HumansJames WongNo ratings yet

- QuestionsDocument23 pagesQuestionsTayyabNo ratings yet

- 3 - Growing The Best Phalaenopsis Part 4Document6 pages3 - Growing The Best Phalaenopsis Part 4Andrea KojićNo ratings yet

- Novel Food Applications Status enDocument44 pagesNovel Food Applications Status enDanielaLópezNo ratings yet

- 18 Vol 4 No 2Document11 pages18 Vol 4 No 2Syed TabrezNo ratings yet

- Fs Acacia NiloticaDocument2 pagesFs Acacia NiloticaRavi SinghNo ratings yet

- Secondary Metabolite - WikipediaDocument4 pagesSecondary Metabolite - WikipediaAttila Tamas100% (1)

- List of Homeopathic Preparations - Wikipedia PDFDocument15 pagesList of Homeopathic Preparations - Wikipedia PDFsharmadxNo ratings yet

- FilesDocument503 pagesFilesjorgeNo ratings yet

- PhesDocument22 pagesPhesMuhammed Afsal AF Z ALNo ratings yet

- BabugoshaDocument2 pagesBabugoshaVivek SinghNo ratings yet

- Ravello MenuDocument3 pagesRavello MenuFarley ElliottNo ratings yet

- FST 701 Presentation of Samiullah KakarDocument26 pagesFST 701 Presentation of Samiullah KakarS.K. AkhtarzaiNo ratings yet

- Station 1: Time Period B.C.: Student Challenge QuestionsDocument5 pagesStation 1: Time Period B.C.: Student Challenge Questionslouise carinoNo ratings yet

- Recipes Using OrangesDocument27 pagesRecipes Using OrangeskathrynbaxNo ratings yet

- Isolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)Document17 pagesIsolation of Potassium Carbonate From Banana Plant (Musa Balbisiana)zawNo ratings yet