Professional Documents

Culture Documents

Dynaflodrill User Guide

Dynaflodrill User Guide

Uploaded by

Uok RitchieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynaflodrill User Guide

Dynaflodrill User Guide

Uploaded by

Uok RitchieCopyright:

Available Formats

Drillbench Dynaflodrill User Guide Page i

TABLE OF CONTENTS

Page

1. GENERAL 4

1.1 Overview 4

1.2 Areas of application 5

2. MAIN ENVIRONMENT 6

2.1 Overview 6

3. CREATING A CASE FILE 8

3.1 Overview 8

3.2 The data model - DEML 8

3.3 New session (.dml) file 9

3.4 Editing an existing session (.dml) file 10

3.5 Library 10

3.5.1 Library editor 12

4. INPUT PARAMETERS 13

4.1 Description 13

4.2 Survey 14

4.3 Wellbore geometry 17

4.4 String 19

4.5 Surface equipment 22

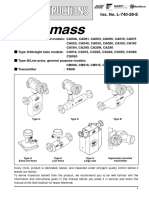

4.6 Injection system 23

4.6.1 Drillstring gas injection 23

4.6.2 Annulus gas injection 24

4.7 Mud 25

4.8 Reservoir 29

4.9 Temperature 33

5. EXPERT INPUT PARAMETERS 34

6. RUN CONFIGURATION 36

6.1 Batch configuration 36

7. MENUS AND TOOLBARS 37

7.1 File 37

7.1.1 New 37

7.1.2 Open 37

7.1.3 Reopen 37

7.1.4 Save 37

7.1.5 Save as 37

7.1.6 Save as template 38

7.1.7 Save library 38

7.1.8 Import 38

7.1.9 Export 38

7.1.10 Exit 39

7.2 Edit 39

7.2.1 Cut 39

7.2.2 Copy 39

7.2.3 Paste 39

Drillbench Dynaflodrill User Guide Page ii

7.2.4 Undo 39

7.3 View 39

7.3.1 Well schematic 39

7.3.2 Survey plot 41

7.3.3 Log view 42

7.3.4 Navigation bar 43

7.3.5 Basic input 43

7.3.6 Expert input 43

7.3.7 Simulation 43

7.4 Simulation 43

7.4.1 Toolbar functionality 43

7.4.2 Start/Pause/Continue 44

7.4.3 Step 44

7.4.4 Reset 44

7.4.5 Load state from file 44

7.4.6 Save state 45

7.5 Results 45

7.5.1 Keep previous results 45

7.5.2 Import results 46

7.5.3 Export results 46

7.5.4 Manage results 47

7.5.5 Add page 47

7.5.6 Current page 47

7.5.7 Load/save layouts 48

7.6 Tools 49

7.6.1 Take snapshot 49

7.6.2 Report 49

7.6.3 Validate parameters 51

7.6.4 Edit unit settings 51

7.6.5 Options 51

7.7 Help 56

7.7.1 About 56

8. RUNNING A SIMULATION 58

8.1 Overview 58

8.2 Controlling a simulation 58

8.3 Simulation window 59

8.4 Interactive simulation mode 60

8.5 Batch simulation mode 61

9. WORKING WITH DYNAFLODRILL RESULTS 63

9.1 Plot page operations 63

9.2 Plot management 63

9.2.1 Set and plot selection 63

9.2.2 Add 64

9.2.3 Reset plot 65

9.2.4 Remove plot 65

9.3 Plot operations 65

9.3.1 Maximize plot 66

9.3.2 Normalize 66

9.3.3 Swap with selected plot 66

9.3.4 Track values 67

9.3.5 Print 67

9.3.6 Import 67

Drillbench Dynaflodrill User Guide Page iii

9.3.7 Export 68

9.3.8 Copy image to clipboard 70

9.3.9 Plot properties 70

9.4 Profile plot operations 71

9.4.1 Take snapshot 71

9.4.2 Create trends at observation points 71

9.5 Curve operations 72

9.5.1 Copy curves 72

9.5.2 Paste as custom curves 73

9.5.3 Clear custom curves 73

9.6 Trend plot switches 73

9.6.1 Show timeline 73

9.6.2 Show previous results 73

9.6.3 Flip axes 74

9.6.4 X axis 74

9.7 Profile plot switches 74

9.7.1 Show pore/fracture pressure 74

9.7.2 Show casing shoe 74

9.7.3 Fade recent results 74

9.7.4 Show minimum/maximum 75

9.7.5 Show previous results 75

9.7.6 Slider 75

9.8 Zooming 75

9.9 3D wellbore plots 76

9.9.1 General functionality 76

9.9.2 Select run 76

9.9.3 Select curve 77

9.9.4 Holdup fraction view 77

9.9.5 Scale palette for entire run 77

9.10 Multiple runs keep results 78

9.11 Improved results view 79

9.12 Well schematic 80

9.13 Create presentation graphics 81

10. RHEOLOGY MODELS 83

10.1 Generalized Newtonian models 83

10.1.1 Bingham plastic model 83

10.1.2 Power law model 83

10.1.3 Robertson-Stiff model 83

10.2 Pressure and temperature dependent rheology 84

10.3 Friction factor 84

10.3.1 Friction factor in laminar flow 84

10.3.2 Friction factor in turbulent flow 84

10.3.3 Transition from laminar to turbulent flow 84

10.3.4 Frictional pressure loss model 85

10.3.5 Beggs and Brill correlation with angle correction for liquid hold-up 85

10.3.6 Semi-empirical pressure loss calculation 85

11. KEYBOARD SHORTCUTS 87

12. ACKNOWLEDGEMENTS 88

Drillbench Dynaflodrill User Guide Page 4

1. GENERAL

1.1 Overview

Underbalanced drilling (UBD) has firmly evolved into a new facet of the oil and gas

industry. Operators are applying this new technology to improve ultimate reservoir

recovery and maximize the economics of production. UBD has been utilized for

specific applications such as limiting lost circulation. A number of developments

took place in the oil industry that caused the present increased interest in

underbalanced drilling.

Underbalanced drilling still has some concerns to be addressed by future

developments in the industry to broaden its applicability. Among those is the

engineering software required for pressure calculations to model well flow and gas

lifting requirement during the design stage. The flow modeling software can be

divided into two categories: steady state (or static) flow modeling and dynamic flow

modeling. The steady state flow modeling is useful for quick sensitivity analyses

and parameters screening exercises. The dynamic flow modeling is required for

simulating the dynamic effects occurring as a result from varying operational

conditions, e.g., drilling and tripping, starting and stopping pumping, drill pipe

connection, and gas injections, BHA deployment and reservoir production.

Designing underbalanced operations ideally require both steady-state and dynamic

tools. Steady-state tools facilitate rapid design, sensitivity studies and dimensioning,

while the dynamic tools are required for checking the operational feasibility of the

steady-state solutions.

Steadyflodrill is a tool designed for the steady-state design phase. It is very fast

with output tailored for the design phase. It is also very closely related to

Dynaflodrill a dynamic tool for underbalanced operations. Starting a design

process in Steadyflodrill, continuing in Dynaflodrill to check feasibility and then

finalizing operational preparations in our training tool Ubitts provides the user with a

very complete and efficient work process.

Drillbench Dynaflodrill User Guide Page 5

1.2 Areas of application

The simulator can be used to design an optimum well program for a given geology,

wellbore configuration and surface equipment. It can also be used to develop

optimum operational procedures to avoid hazards during the drilling operation, and

as a tool for post-analyses of UBD operations. The simulator is also a useful tool

for training and simulation of what-if scenarios.

Example applications of Dynaflodrill:

1. predict whether it is possible to achieve a stable underbalanced condition for the

given system and operational constrains

2. evaluate different scenarios for how to achieve the underbalanced condition

3. predict the amount of injection gas required for the operation

4. design procedures for operations like tripping, starting and stopping circulation

such that excessive wellhead pressures and accidental overbalance situations

are avoided

5. design the operation such that it is in a stable operating range where the

bottomhole pressure is not very sensitive to changes in normal control

parameters

6. post-analysis of underbalanced operation to capture successful procedures and

operational experience and pass them on

7. training of new engineers and other relevant personnel

Drillbench Dynaflodrill User Guide Page 6

2. MAIN ENVIRONMENT

2.1 Overview

By default, the installation creates a Dynaflodrill entry under Programs SPT

Group Drillbench 5.1 in the Start menu. Dynaflodrill is started either by selecting

this shortcut, by clicking a desktop icon or directly from the program installation

directory using the Windows Explorer.

Regardless of the start-up method, the program will look similar to Figure 2-1 when

starting up. The contents of the parameter display may be different depending on

parameter group and selected window.

Figure 2-1. A typical view when starting Dynaflodrill. A summary page gives the

user an overview of the case by showing the most important parameters.

The environment consists of 4 main areas; the menu line and the toolbar at the top

of the window, and the main Dynaflodrill window with a navigation bar to the left and

a data entry and interaction window to the right.

The menu bar

A standard menu bar with File, Edit, View, Simulation, Results, Tools and Help

entries. File operations, view selection and simulation control may be done from

here.

Drillbench Dynaflodrill User Guide Page 7

The toolbar

Frequently used commands, like File New, File Open, Save, Copy, Cut, Paste

and Undo, are placed in a toolbar for easy access. These commands can also be

accessed by standard Windows keyboard shortcuts (Chapter 11). A toolbar for

controlling the simulation with start, pause, single step and reset buttons is placed

next to the normal toolbar. The user can also select the desired type of simulation,

interactive or batch.

Navigation bar

The navigation bar contains:

- Input for specification of the most frequently used input parameters

- Expert input for specification of optional or expert features

- Run configuration for specification of simulation specific parameters

- Simulation for calculation and output of results

Data entry window

Displays either input parameters or simulator output depending on the current

selection in the navigation bar

Drillbench Dynaflodrill User Guide Page 8

3. CREATING A CASE FILE

3.1 Overview

This section briefly describes the data model in Drillbench and how a new case can

be created. All Drillbench applications share the same data model, therefore this

section is similar for all applications.

A new case can be created either by building a new file or by editing an old file. The

data needed for a simulation may be selected from the library or specified on the

input parameter sheets. The input parameter sheets and the library are presented in

more detail in Section 3.5 and Chapter 4.

If you have used older versions of Drillbench, you can open your input files as

normal and you will be notified that your input has been upgraded. Note that this

upgrade is irreversible files saved from this version cannot be loaded in

older versions of Drillbench.

3.2 The data model - DEML

The data model illustrated in Figure 3-1 handles all internal data transfer between

the user interface and the numerical models and stores all the information in XML

files.

The data model is the same for all Drillbench applications, but most applications

only use a subset of the full model. When switching from one application to another,

all applicable data will be used and the user must add only the data specific to the

application in use.

Figure 3-1 Data model in Drillbench

Drillbench Dynaflodrill User Guide Page 9

Data can be collected from several sources. In many cases, companies have some

standards, guidelines or common practices that will remain unchanged from case to

case. Also vendors of tools and fluids may be the same in many cases.

The total amount of data needed to run a Dynaflodrill session may therefore be

divided into case specific data and more standard data that will remain unchanged

or only slightly modified from case to case. The standard data can be defined in the

library to simplify the case definition phase.

Among the case specific data are well trajectory, geometry, operational conditions

and temperature. Typical library entries are fluids, pipes and tools.

3.3 New session (.dml) file

To create a new session file, select File New from the menu bar. The new file

dialog offers choices of starting with a blank file or with predefined templates.

Templates can be defined either for specific well types (i.e. HPHT, deep-water,

extended reach) or for specific fields. The idea behind the templates is that the input

process should be simplified. All the predefined data is available from the user

interface so it is easy to review the data and verify that it fits the case you want to

simulate.

Figure 3-2. New file dialog

The path to the templates is configured in the Tools Options dialog.

Drillbench Dynaflodrill User Guide Page 10

3.4 Editing an existing session (.dml) file

Existing input files are opened by choosing File Open and selecting the file. A

recently used file can also be opened from the File Reopen list. The edit

process is very similar to what you do when you open a template file. After editing

the input file, choose File Save asfrom the menu line and give the input file a

new name. The input file can be saved in any directory.

3.5 Library

All data is entered in the parameter input section. For some data that is typically

entered based on data sheets or from handbooks, an optional library function is

included. The default installation of Drillbench contains a library with values for

pipes & tubulars, tools, fluids etc. The user can easily add information to the library

to define new items.

The entries from the library are selected in the parameter input sections for

Wellbore geometry, String and Mud. The library can be accessed by clicking on the

Name field for the item/component. The items/components that can be found and

stored in the library are:

Riser

Casing/Liner

String components

Bit

Mud (Drilling fluid)

Drillbench Dynaflodrill User Guide Page 11

Figure 3-3. Library browser and filter dialog for casings

To find a specific item or component in the library, there is a filter option to help you

search for the item or component you need. You can set up several different filters

to make your library search more detailed. Click the Add button to add a line in the

filter dialog or press remove if you want to remove a line. Remember to click Apply

filter no filtering is performed before this button is clicked.

To select an item from the list of matching components you can double click on the

element. You will then return to the input screen and can continue to specify other

data.

If you do not find a suitable item or component in the library, you can specify all the

properties of the item or component manually in the input parameter window. The

item or component can then be added to the library by right-clicking on the line in

the table and choosing add item to Library.

Drillbench Dynaflodrill User Guide Page 12

3.5.1 Library editor

There is also a standalone library editor that can be opened from the Start menu

(Start [Program location] Tools Library editor).

Figure 3-4 Library editor

In the Library editor all the information that is stored in the library can be reviewed.

It is possible to add new items or edit the specification of existing items.

Drillbench Dynaflodrill User Guide Page 13

4. INPUT PARAMETERS

The input parameters have been divided into ten main groups:

Summary A brief summary of the most important input data

Description Information about the present study/case

Survey Describes the well trajectory

Wellbore geometry Defines the casing program for the well

String Configuring and defining the drill string and bit

Surface equipment Defines the rig equipment

Injection system Configuring and defining the injection system

Mud Defines the drilling fluid

Reservoir Defines the reservoir properties

Temperature Defines temperatures and temperature model

4.1 Description

Use the Description window to describe the main purpose and key parameters of

the current case. The input is self-explanatory and consists of the most important

parameters needed to identify the case. Use the Description field to distinguish

several computations performed for the same case.

Figure 4-1 Description window

Drillbench Dynaflodrill User Guide Page 14

4.2 Survey

The input data for the survey are measured depth, inclination and azimuth. The

simulator calculates the true vertical depth (TVD) by using the minimum curvature

algorithm. The angle is given as deviation from the vertical, which means that an

angle of 90 indicates the horizontal. The angle between two points is the average

angle between the points. The simulator handles horizontal wells, but angles higher

than 100 are not recommended. This window is optional and the well is assumed

vertical if no data is entered.

Figure 4-2 Specification of survey data

The survey data can be entered manually, copied from a spreadsheet or imported

from an existing survey file. Figure 4-2 shows the survey data table and a 2D sketch

of the well trajectory.

Selecting one or more rows in the survey table will highlight the corresponding part

in the trajectory plot as shown in Figure 4-3.

Drillbench Dynaflodrill User Guide Page 15

Figure 4-3 Highlight sections in well trajectory plot

Inclination data can also be imported from file by choosing File Import Survey

data or RMSwellplan data (

Figure 4-4).

Drillbench Dynaflodrill User Guide Page 16

Figure 4-4 Menu option for survey data import

The RMSwellplan option opens a File open dialog and a *.dwf file can be selected.

The survey data import is different as this option opens a file import tool, shown in

Figure 4-5.

The import tool is very general and can handle different units, different column order

or delimiters. It can also handle any number of header or footer lines.

Figure 4-5 Survey Import window

The survey profile can be previewed in 3D, by selecting View Survey plot.

Drillbench Dynaflodrill User Guide Page 17

Figure 4-6 3D survey plot

4.3 Wellbore geometry

The wellbore geometry section contains the specification of the actual hole. A

typical window appearance is shown in Figure 4-7. The wellbore is divided in two

parts:

- Casing/Liner

- Open hole

Drillbench Dynaflodrill User Guide Page 18

Figure 4-7. Specification of wellbore geometry.

A sketch of the casing program can be displayed for simplifying the input process.

This is opened from the View Well schematic menu. The sketch will be

immediately updated with any changes in casing or open hole specification. Clicking

on a row in the casing table will highlight the corresponding item in the well

schematic as shown in Figure 4-7.

In Dynaflodrill it is only required to specify the inner tube and the annulus, which

makes up the mud flow path. Thus, only the casings that make up the current

annulus must be defined and casings outside may be left out. A complete casing

program can of course be defined if the same case will be used for other

applications that require more details.

The top and bottom position of each pipe (Hanger and Setting depth) must be

specified in measured depth from RKB. Inner and Outer diameter can be typed in

directly or filled out by selecting a casing from the library. The library is optional, but

provides an easy way of entering correct casing data. The library functionality is

described in more detail in Chapter 3.5. Figure 4-8 shows an example of searching

for the desired element. Highlighting an element in the browser and pressing OK

will copy the actual string data to the wellbore geometry window.

Drillbench Dynaflodrill User Guide Page 19

Figure 4-8. Library browser for Casings (database)

To append lines to the table, use the down arrow key. To add or remove lines within

the table use either Ctrl+Ins or Ctrl+Del. Ctrl+Ins with the cursor in the middle of a

table will open a new line above the cursor.

Figure 4-9 Open hole

You specify the open hole section by the length from the last casing shoe to the

bottom of the wellbore along with the open hole diameter.

Planned well depth can be different from the initial length of the open hole section.

4.4 String

Dynaflodrill can use both conventional and coiled tubing. Figure 4-10 shows the

specification of the string data. The specification is done from the bit and up. The

window is divided in two parts specification of the string and specification of the

bit. Also here the casing and string sketch can be displayed to simplify the data

entry process.

Drillbench Dynaflodrill User Guide Page 20

Figure 4-10 String configuration

String

The string specification can either be done by selecting string elements from the

library or by typing directly in the window. The library functionality is described in

Chapter 3.5. The string is specified from the bit and upwards. The section length

and inner and outer diameter are required. The distance from bottom is calculated

and displayed as a reference.

The average stand length is the length drilled before performing a new connection.

During simulation, a message is given in the log window when the pipe joint

reaches the rig floor. The simulator automatically stops pumping when performing

connection.

It is possible to create items with custom dimensions by modifying the diameters of

an already defined item. To add new items to the library, right click on the

component and press Save.

It is also possible to edit/view the properties of the different components by clicking

in the last column of the chosen component. For Dynaflodrill it is important to notice

that the motor is defined as part of the properties dialog.

Figure 4-11 shows the Properties window for the motor. The dimensions and flow

rate interval with corresponding pressure loss can be specified. In the table of flow

rates the minimum and maximum rate is taken as lower and upper motor limitations.

Drillbench Dynaflodrill User Guide Page 21

Figure 4-11 Specification of motor properties

To append lines to the table, use the down arrow key. To add or remove lines within

the table use either Ctrl+Ins or Ctrl+Del.

Clicking on a row in the string table will highlight the corresponding item in the well

schematic as shown in Figure 4-10.

Bit

The bit is defined separately. Select the bit from the library browser by clicking the

ellipsis button. It is possible to edit the bit dimensions and properties by adjusting

the values in the window. The flow area through the nozzles is defined either by

entering the total flow area (TFA) or by entering the diameter of each nozzle. To

add a newly created bit to the library, click the Add to library button.

.

Drillbench Dynaflodrill User Guide Page 22

Figure 4-12 . Bit configuration

If nozzle diameter is selected and it is necessary to specify more than four nozzles,

the extra nozzles can easily be added by pressing the down arrow key at the last

line in the table, or alternatively by pressing Ctrl+Ins.

4.5 Surface equipment

Figure 4-13 Surface equipment window

Choke

The Inner diameter of the choke must be given, together with the minimum time

required to fully close the choke. The simulator automatically adds a surface pipe

Drillbench Dynaflodrill User Guide Page 23

length to the system. The user controls the well pressure by modifying the well head

pressure. In the Choke section the user specifies how to operate the choke by

selecting either Pressure or Opening from the Choke control combo box

The Pressure change parameter is only used if Pressure is selected as choke

control. It defines how much the pressure changes per unit time.

Separator

A Separator working pressure has to be set.

Pump

The Liquid pump rate change defines how fast a new rate can be achieved when

the circulation rate is altered. Example: a Liquid pump rate change of 2000 l/min

means that when circulating at 1000 l/min it takes 0.5 min from the pump is starting

to shut down until it stops flowing.

Correspondingly, the Gas pump rate change defines how fast operational changes

can be achieved for the gas compressors.

Rotary control head

The duration of closure is the time period from the Rotary control head status is

switched to closed in the user interface and until the Rotary control head is fully

closed.

4.6 Injection system

In Figure 4-14 a sample of a gas injection specification is given. The specification is

divided into two parts, Drill string and Annulus injection. There are several options

for annulus gas injection (4.6.2); Parasite annulus, Parasite string and Source point

injection.

A Check valve can be specified to control whether backflow is allowed or not.

Simultaneous injection in both drillpipe and annulus is possible. In this case, the

injection gases may be different, but the check valve status is assumed equal for

both injection lines.

4.6.1 Drillstring gas injection

For drillstring injection it is only necessary to specify the Density of the injection gas

and the mole fraction of the available gas components.

Drillbench Dynaflodrill User Guide Page 24

Figure 4-14 Specification of gas injection properties

4.6.2 Annulus gas injection

There are three options for annulus injection;

- Parasite annulus

- Parasite string

- Source point

Both the parasite annulus and parasite string options require specification of an

inner diameter (for either the annulus casing or the string) and an injection depth

(Length).

It is possible to inject gas or kill mud through the parasite string or parasitic annulus.

If gas injection is modeled, the composition of the injection gas and the gas density

needs to be specified. If kill mud injection is modeled, the mud density must be

given.

It is also required to specify the fluid temperature in the injection line. Figure 4-14

shows the specification for parasitic annulus and Figure 4-15 the specification for

parasitic string. The sketch indicates the layout of the injection system.

Drillbench Dynaflodrill User Guide Page 25

Figure 4-15 Parasitic string

Figure 4-16 shows the specification of the source point injection. Only gas injection

is available. This option only requires an injection depth and the composition of the

injected gas. Injection line temperature is not in use in this option. The source point

option disregards the behavior of the compressible volume in the parasite

string/annulus and represents a simplification of the calculations.

Figure 4-16 Source point gas injection

4.7 Mud

In Figure 4-17 the specification of mud properties is illustrated. Fluids can either be

selected from the library or a new fluid can be defined by entering relevant data in

the window. A fluid can be selected from the available library fluids by clicking on

the button in the Fluid name field. This will open the select fluid dialog shown in

Figure 4-18.

If a fluid similar to the actual fluid is not found, it can be created. This is done by

entering data in the relevant input fields for Component densities, PVT,

Thermophysical properties and Rheology. The newly created drilling fluid can be

added to the library by clicking the Add to library button in the upper right corner.

Drillbench Dynaflodrill User Guide Page 26

Figure 4-17 Mud window

Figure 4-18 Library browser for fluids

Drillbench Dynaflodrill User Guide Page 27

Component densities

Below the drilling fluid entry, the fluid component densities are displayed.

Unless the fluid density is calculated based on data from a field mud, see Measured

PVT model below, a component density model is used. The p, T dependency of

each phase will then be treated separately and a resulting density will be calculated

based on the weight fractions of each phase and the density of the mud at standard

conditions.

Base oil density is specified at standard conditions (1 bar,15C / 14.7 psia and 60

F).

Solids density is the density of the weight material. A solid density of 4.2 sg is

suggested by default, which corresponds to the density of Barite. In these

calculations, the compressibility of solids are assumed to be negligible, an

assumption that in most cases is fairly correct.

Density refers to the density of the whole mud phase and must be specified at the

correct reference temperature and atmospheric pressure.

The last parameter to be specified is the mud Oil water ratio. The ratio is specified

using 'oil%/water%' (e.g. '80/20').

Figure 4-19 Component densities

PVT model

There is an option to choose from two different PVT models, Measured PVT model

or a Black oil PVT model.

Drillbench Dynaflodrill User Guide Page 28

Figure 4-20 PVT model

The Measured PVT model is based on experimental PVT data for elevated

pressure and temperatures. The measured values can be specified by clicking on

the properties button in the PVT section, as shown in Figure 4-21. Clicking the

properties button opens a sub-window with two tab sheets; one for specification of

saturated base oil density and one for specification of gas solubility in the base oil.

This option is suitable only for dry gas influx.

The first row in the gas solubility table should always contain data at 1 bar. This is

used as a reference point in the computations.

Figure 4-21 Specification of PVT data for measured PVT option

For the Black oil PVT model, the mud properties for elevated pressure and

temperature are based on empirical correlations. There are no requirements to the

composition of the base oil.

Fluid type

Fluid type can either be Liquid or Foam.

Drillbench Dynaflodrill User Guide Page 29

The foam quality is a required input when the foam model is used and is defined as

the volume ratio between gas and foam typically in the range from 0.85 to 0.95

(85-95%). The foam model requires that the foam is stable.

Rheology

Three rheology models can be selected; Robertson-Stiff, Power Law and Bingham.

The rheology curve can be specified as a table of shear rate vs. shear stress (Fann

reading). The rheology table is a spreadsheet table and it is possible to use copy

and paste between other programs and Drillbench.

If Robertson-Stiff is chosen as rheology model, where applicable, the table should

contain at least three Fann readings.

Rheology data can also be given in terms of plastic viscosity (PV) and yield point

(YP).

It is assumed that the rheology data entered is valid at atmospheric pressure and

50 C (122 F).

Robertson-Stiff is the recommended model for most situations. The rheology

models are described in more detail in Chapter 10.

4.8 Reservoir

The reservoir properties window is shown in Figure 4-22. The upper part of the

window is a table with characteristics for the reservoir zone, such as depth, pore

pressure, influx rate etc. The lower section contains properties for the reservoir fluid

and the cuttings.

Drillbench Dynaflodrill User Guide Page 30

Figure 4-22 Specification of reservoir properties

Reservoir zone

The name of the reservoir zone is entered in the column Lithology name. Lithology

is used as a term for the material in the surroundings of the well. The reservoir type

can be either fractured or matrix. The type is important for estimating the intensity of

the influx from the reservoir. The columns Top and Bottom define the upper and

lower boundaries of the reservoir zone and are given in metered depth from RKB.

Reservoir top must be between last shoe depth and the bottom of the well. Top

pressure and Top temperature is the pressure and temperature in the reservoir at

the top depth.

The reservoir fluid can either be a pure gas or the user can specify a certain gas oil

ratio (GOR) and water cut (WC). Water cut is the volume fraction of water in the

liquid phase. GOR is specified at standard conditions. Clicking in the Reservoir fluid

column activates the cell for edit and a button appears in the right end of the cell.

Pushing this button opens a dialog, shown in Figure 4-23, where these properties

are specified.

Drillbench Dynaflodrill User Guide Page 31

Figure 4-23 GOR and WC for reservoir fluid

Note that only very lean gases should be regarded as gas only, i.e. dry gas or

leaner. All other fluids should be treated with possibility for oily components as well.

With condensing influx (i.e. not dry gas), the reservoir oil will mix with the mud and

can significantly alter the mud properties. This is an irreversible change, in contrast

to dissolved reservoir gas, which is released from the mud when approaching

surface conditions. Generally, all fluids with the exception of very lean gases should

be treated as oil to capture this effect.

The Influx model defines the rate of influx into the well. Clicking in the Influx column

activates the cell for edit and a button appears in the right end of the cell. Pushing

this button opens a dialog, as shown in Figure 4-24. The selection of models

available depends on which reservoir type and type of fluid is selected.

Figure 4-24 Specification of influx model

Four influx models are available;

- Linear PI: Production depends linearly on the pressure drawdown (i.e. difference

between formation pressure and the flowing bottomhole pressure). This is the PI

model for oil/water reservoir, and the preferred model for high-pressure gas

reservoirs

- Squared PI: Production depends on the difference between the squared reservoir

pressure and the squared well pressure. This is the preferred PI model for low-

pressure gas reservoirs

Drillbench Dynaflodrill User Guide Page 32

- Reservoir model: the influx is based on permeability, porosity, the length of the

reservoir exposed to the well and the drawdown

- Constant: constant influx rate

If the reservoir is a Matrix, the influx rate can be calculated based on a linear PI,

squared PI (gas only) or the reservoir model. The PI is adjusted according to the

length of the reservoir exposed to the well.

If the reservoir is Fractured, the influx rate can be calculated based on a linear PI,

squared PI (gas only) or constant influx rate. For fractured reservoirs the PI will be

independent of the length of the reservoir exposed to the well.

Several reservoir zones can be defined. This makes it possible to specify a

reservoir that consists of a combination of matrix layers and fractures, various influx

rates, etc. The properties for the reservoir fluid are the same for all zones, but

gas/oil ratio and water cut can vary between the zones.

Reservoir fluid

The properties for the reservoir fluid are specified for each phase, as shown in

Figure 4-25.

Figure 4-25 Reservoir fluid specification

The density of the influx gas is specified at standard conditions. If any

contamination is present, the amount of contamination is specified as well (on molar

basis). The available impurity gases are: nitrogen N

2

, carbon dioxide CO

2

and

dihydrogen sulphide H

2

S. The gas density should include the contaminations.

For fluids heavier than very lean gases, properties for the influx gas, influx oil and

water must all be specified. Density and compressibility are given at standard

conditions, while formation volume factor and viscosity are given at reservoir

conditions.

Cuttings

Drillbench Dynaflodrill User Guide Page 33

The cuttings density and either max concentration or minimum relative velocity must

be specified.

4.9 Temperature

Figure 4-26 Temperature input window

Temperature is specified as depth tables for temperatures inside the drillstring and

annulus. Measured depth is entered together with the corresponding temperature.

The number of pairs may be different for annulus and drill string. The first data

points in the tables are the mud temperatures at surface (inlet and outlet).

The program interpolates linearly between the given temperature points when

computing the effective temperature profile.

If measured data is not available, it is recommended to calculate the mud

temperature profile by using the dynamic temperature model in Drillbench

Presmod and copy the result into the tables in Dynaflodrill. A Dynaflodrill input file

can be opened and run in Presmod after adding data for the temperature

calculations.

Drillbench Dynaflodrill User Guide Page 34

5. EXPERT INPUT PARAMETERS

Specification of wellhead pressure, number of grid cells and selection of sub-

models and definition of well observation points are available as optional input.

Figure 5-1 Model parameters

Wellhead pressure

The wellhead pressure represents the reference pressure at surface. This is the

pressure downstream of the choke or any other surface equipment and is the

minimum wellhead annulus outlet pressure. The wellhead pressure is entered as a

constant value. For reference the wellhead pressure is displayed on result plots.

Number of grid cells

The number of grid cells is a numerical parameter. The user specifies the number of

grid cells used to create the underlying mathematical model. More specifically, it

defines the level of detail at which the drillstring and annulus is discretized.

Increasing the number of grid cells will increase the accuracy of the simulation, at

the cost of the computation time. The computation time will at best increase linearly

with respect to the grid cells. To keep the simulation from becoming too time-

consuming, it is recommended to set this parameter between 50 and 100.

Sub-models Pressure loss model

Beggs and Brill, Semi-Empirical and a Mechanistic pressure loss sub-models can

be selected. The mechanistic model is recommended for Newtonian fluids, while

the semi-empirical model is recommended for non-Newtonian fluids.

Drillbench Dynaflodrill User Guide Page 35

Sub-models Gas density model

Hall-Yarborough and Redlich-Kwong can be selected. The Hall-Yarborough

equation of state is the recommended setting.

Friction factor model

The friction factor sub-models shown in Figure 5-2 are available.

Figure 5-2 Friction factor models

For all models except Ed. Technip 1982, steel and open hole roughness must be

specified. Ed. Technip is the recommended friction factor model.

Observation points

Five positions can be specified in the well. At these points, pressure, equivalent

circulating density (ECD) and temperature can be observed during simulation. The

observation point is specified using a measured depth and one of two modes of

operation that affect how the point behaves during string movement. The points

can either be moving or fixed. A moving point is a point that is attached to the

drillstring and moves together with the string. A fixed point refers to a fixed depth,

independent of string movement or bit position.

Drillbench Dynaflodrill User Guide Page 36

6. RUN CONFIGURATION

6.1 Batch configuration

Figure 6-1 shows an example of the batch configuration window. The user specifies

a sequence of time periods where a set of operational conditions are kept constant,

before being changed in the next time period. The operational parameters are the

same as for an interactive simulation.

Figure 6-1. A typical Batch simulation setup.

To make it easier to specify the batch simulation, some parameters like

accumulated time and bit depth at the end of the time period are automatically

calculated and included in the table. This is very useful as reference when setting

up long and complicated batch jobs.

The specification of the operational parameters are stored as part of the case file

when using the File Save option from the menu bar. The batch specification is a

spreadsheet table and can easily be copied to another file or application using

Ctrl+C for copy and Ctrl+V for paste. Changing the entries in the table is done by

placing the cursor in a table cell and typing the desired value.

Drillbench Dynaflodrill User Guide Page 37

7. MENUS AND TOOLBARS

Menus and toolbar icons have standard Windows functionality. We assume that

Dynaflodrill users are familiar with Windows operations, and will only describe the

menu and toolbar functions specially designed for Dynaflodrill.

7.1 File

7.1.1 New

Use File New to create an input file from scratch. This dialog offers choices of

starting with a blank file or with predefined templates. The template path is

configured in the option dialog.

Figure 7-1 New file dialog

7.1.2 Open

Open a file using a standard file selection dialog.

7.1.3 Reopen

Reopen one of the last used files.

7.1.4 Save

Save a file using a standard file selection dialog.

7.1.5 Save as

Drillbench Dynaflodrill User Guide Page 38

Save a file under a new name using a standard file selection dialog.

7.1.6 Save as template

Save the file as a template-file.

7.1.7 Save library

Save all data in the library.

7.1.8 Import

Use File Import to import either a survey file in some ASCII format or survey data

from the RMSwellplan application. When the survey data file has been selected, the

survey data import dialog appears. Select the appropriate column delimiter, the

units used in the survey file and the number of header/footer lines to be skipped.

Figure 7-2. Survey import

The survey file must be in ASCII format with columns for measured depth,

inclination and azimuth. By default, the program assumes that the first column is

used for Measured depth, the second column for Inclination and the third for

Azimuth. If this is not the case, the column headers can be rearranged by drag and

drop: Click and hold the left mouse button on the column header, drag to the correct

position and release the mouse button.

7.1.9 Export

Drillbench Dynaflodrill User Guide Page 39

Use File Export to save the survey data in the RMSwellplan (*.dwf) file format.

7.1.10 Exit

Exits the application.

7.2 Edit

Standard windows functionality.

7.2.1 Cut

Standard windows functionality. In complex input tables the Edit option is not

available. A field must be active for edit before this option is active. To select and

cut a range of spreadsheet cells, highlight the cells and press Ctrl+X.

7.2.2 Copy

Standard windows functionality. In complex input tables the Edit option is not

available. A field must be active for edit before this option is active. To select and

copy a range of spreadsheet cells, highlight the cells and press Ctrl+C.

7.2.3 Paste

Standard windows functionality. In complex input tables the Edit option is not

available. A field must be active for edit before this option is active. To select and

paste a range of spreadsheet cells, highlight the cells, or alternatively the starting

cell for the area to paste, and press Ctrl+V.

7.2.4 Undo

Standard windows functionality.

7.3 View

Used to switch between windows, and to hide or show optional sub-windows and

diagrams.

7.3.1 Well schematic

A schematic plot that includes the riser, seabed, casing/liner program, open hole

and the drill string is shown by selecting View Well schematic or using the well

schematic button in the tool bar. A visual inspection of the well can reveal errors in

the input data. The well schematic has a view properties window to toggle items

and labels to be drawn, which can be opened from the popup menu item

Properties

The well schematic will provide live feedback on changes done in the well

specification by highlighting the well component currently selected for modification,

and by updating geometry changes as they happen.

Drillbench Dynaflodrill User Guide Page 40

Figure 7-3. Well schematic view

Hovering the mouse cursor above elements in the well schematic will highlight the

element under the cursor and show the element name. See Figure 7-4.

Drillbench Dynaflodrill User Guide Page 41

Figure 7-4 Highlight and hint in well schematic

7.3.2 Survey plot

To view a three-dimensional representation of the survey, select View Survey

plot. The default view is in front of the XY-plane. To rotate the view around the well,

move the mouse in the direction of desired rotation while pressing the left mouse

button. To zoom in, move the mouse up while pressing the right mouse button. To

zoom out, move the mouse down while pressing the right mouse button. To move

the figure, move the mouse while pressing the left mouse button and the shift key.

There is a menu line in the survey plot with a File and a View menu. To reset the

view, select View Reset camera from the plots menu line. The plot can be saved

in a variety of formats by selecting File Save As from the plots menu line.

Drillbench Dynaflodrill User Guide Page 42

Figure 7-5. 3D survey plot view

7.3.3 Log view

By default, the log view is located in the lower part of the main window. It displays

errors, warnings and information messages concerning input data and

calculations. Use the check box on the View Log View menu to display or hide

the log. Double-clicking an error or warning leads the user to the input page that

caused the problem. Clicking the right mouse button over the log displays a menu

offering the following commands:

Copy message

This command copies the message on the current line to the clipboard.

Save messages

This command lets you save the log contents to a text file for later review.

Clear messages

This command empties the log.

Hide

Drillbench Dynaflodrill User Guide Page 43

This command hides the log window, and has the same effect as unselecting the

log window check box in the View menu.

Show timestamp

This check box toggles the use of timestamps for the lines in the log. This feature

can be used to distinguish messages from various runs and can be helpful when

the content of the log is saved to a file.

7.3.4 Navigation bar

Toggle the navigation bar on/off. Hiding the navigation bar can be useful to make

more room for the main input or simulation window. The state of this selection is

saved between sessions.

7.3.5 Basic input

Switch to an Input window.

7.3.6 Expert input

Switch to an Expert input window.

7.3.7 Simulation

Switch to a Simulation window.

7.4 Simulation

Simulation control commands can be found both in the menu bar and as a separate

toolbar.

7.4.1 Toolbar functionality

Figure 7-6 The simulation toolbar.

The toolbar has buttons for start/pause, single step and reset of a simulation. You

can also choose from a drop down menu which type of simulation you are going to

run: Interactive simulation, Batch simulation or Dynamic surge and swab simulation.

The simulation is started by clicking Start, and it will continue to run until it is

stopped by the user. When the simulation is started, this button changes to Pause

(Figure 7-7). The simulation can be stopped temporarily by clicking Pause and

resumed by clicking Start. By clicking One step, one time step is performed and the

simulator pauses until Continue or One step is chosen again. To start the simulation

from the very beginning, click the Reset button.

Drillbench Dynaflodrill User Guide Page 44

Figure 7-7 The simulation control while running a simulation

By using Pause, changes in the operational conditions can be made at any time

during the simulation.

Dynaflodrill has several options affecting simulation speed. These options have

been collected into one easy accessible speed control selector.

Figure 7-8 Speed control selection

Selecting speed Maximum the length of each time step is decided by the

simulator. The default is 90 seconds, but can vary depending on the calculations.

Speed type Time constrained allows the user to set the upper limit of the time

step.

7.4.2 Start/Pause/Continue

This menu item is context sensitive, and mimics the button in the toolbar. Used to

start and pause a simulation, and to continue a simulation after a pause.

7.4.3 Step

Run the simulation one step forward. A maximum step length can be specified in

the simulation window.

7.4.4 Reset

Reset the simulation. The simulation will start from the beginning the next time Start

is clicked. Clears all plots, unless keep previous results is active (see 7.5.1).

7.4.5 Load state from file

Load a previous run simulation that was saved as a state file, see below. If keep

previous results is enabled the simulation resumes as new simulation run, i.e., all

plot results will populate new curves; otherwise the plot curves are truncated to the

time stamp the state was saved.

Drillbench Dynaflodrill User Guide Page 45

Figure 7-9: Resuming simulation as a new simulation run.

7.4.6 Save state

The current simulation state may be saved at any time during a simulation. This

way, the simulation can be continued at a later occasion. To save the state, choose

Simulation Save state. A save dialog appears asking for a file name. By default,

the state file is given the extension .pr. Later, the simulation can be continued by

first opening the same input file, then choosing Simulation Load state file. Load

the previously saved restart file and continue the simulation by pressing Start or

Run one time step.

All the results from a simulation are saved in a state file and can be viewed by

loading a state file into the simulator. Thus, Save state can also be used to save

results for later use.

7.5 Results

The Results menu in Dynaflodrill is used for controlling the display of the results.

New plot pages can be opened, renamed or removed.

7.5.1 Keep previous results

You can choose to keep the results from previous simulations and run a new

simulation. The new simulation will be plotted together with the previous

simulation(s). This makes it easier to compare different scenarios or procedures.

Starting a new simulation run with keep previous results disabled will clear out all

previous simulation results.

Drillbench Dynaflodrill User Guide Page 46

Figure 7-10 Results of running two simulations with keep results option on.

7.5.2 Import results

Imports previously saved simulation results. The loaded results will be added as the

oldest runs in the simulation result stack. The simulation results can be imported

across other Drillbench application and do not depend on the input file.

7.5.3 Export results

The simulation results may be saved at any time during a simulation. To save the

results, choose Results Export results. A save dialog appears asking for a file

name. By default, the result file is given the extension .dbr. Later, the results can

be imported independently of the input file and among all Drillbench application

supporting export and import of results, see Figure 7-11; by choosing Results

Import results. The loaded results will be added as the oldest runs in the simulation

result stack.

Drillbench Dynaflodrill User Guide Page 47

Figure 7-11, Import of results across Presmod and Kick

7.5.4 Manage results

Manage results opens a result manager that allows definition of a label for each run

which will show as a prefix in the plot legend. There is also a global option to

disable simulation runs in all result plots, and an option to delete all results of a

simulation run.

Figure 7-12: Result manager

7.5.5 Add page

If you want to add more result pages for custom plots or special plot setups, you

can add a page where you can add new plots. Pages can also be added by typing

Ctrl-T.

7.5.6 Current page

This submenu contains page operations; actions that act upon the currently active

plot page in the simulation view. Some of these operations are only relevant for

custom plot pages, and will be disabled for the default page, which has a fixed

layout. The submenu is unavailable altogether if the simulation view is not active.

The page submenu can also be accessed as a context sensitive popup menu by

right-clicking on a plot page tab.

Drillbench Dynaflodrill User Guide Page 48

7.5.6.1 Rename

You can rename the custom plots pages to organize your plots. Pages can also be

renamed by double-clicking on the page tab.

7.5.6.2 Normalize layout

This will restore the layout of a page with multiple plots to its default state. The

page will be split successively into halves, so all splits will be centered vertically or

horizontally within their region. This corresponds to how plot splits (Add <direction>

operations) will be done before the user applies any manual adjustments.

7.5.6.3 Load and save page layout

Save page layout will save the layout of the current page, along with the page title

and any customizations and axis settings, to a file that can later be imported into

another page or another session using Load page layout.

7.5.6.4 Copy as image to clipboard

An image of the entire plots page will be copied to the system clipboard. This can

be copied into other applications for purposes such as information sharing and

presentations.

7.5.6.5 Clear

This operation removes all plots on the current page, leaving you with an empty plot

page. The page title is retained.

7.5.6.6 Close

Closes and discards the active custom plots page. You can also remove the

current page by hitting Ctrl-F4.

7.5.7 Load/save layouts

Custom chart layout and properties are stored in the DML file. All open plots and

customizations to plots are automatically restored when DML file is opened. Plot

and layout customizations can also be stored and loaded separately to override the

defaults or customizations in a DML. This function can also be used to create

templates for typical plot configurations used in different types of simulations.

The difference between these menu items and the ones in the Current page menu

is that these operations save and load layout and customizations for all plot pages

in the application, which is useful for creating comprehensive templates for typical

plot configurations, while the Current page operations save and load a single page

layout for reuse.

Drillbench Dynaflodrill User Guide Page 49

7.6 Tools

Tools for functionality like reporting, data validation, screen capture of the graphics

window, changing unit settings and program options can be found in the Tools

menu. Some of these tools are used frequently. These have been given a separate

toolbar icon for easy access.

Figure 7-13. Toolbar.

7.6.1 Take snapshot

The snapshot feature places a snapshot of the active plot window on the Clipboard,

which can then be pasted into reports or presentations. Combined with customized

plot layouts this is a very useful tool for presentation of simulation results.

7.6.2 Report

The reports are opened by selecting Tools Report from the menu bar. All reports

use the HTML format. The Input report is a summary report showing the most

important input data. The Current results report includes some input information

and all the result plots that are selected for viewing in the results plot pages in the

simulation window. The tabular results report shows most of the result data as

columns in one big table. Another report, tabular results (printable), shows the same

information, but with the table divided into multiple tables and the table formats

specifically adjusted for printing. Use your web browsers commands to save or

print the report.

Figure 7-14: The Tools menu Report

The reports use standard HTML style sheets (CSS) to define the visual layout. This

makes it easy to customize the format (fonts, colors etc.). Dynaflodrill provides a

default style sheet (ircss.css) which can be edited or replaced to match the users

preferred report style. Figure 7-15 shows the layout of an excerpt from the input

report using the default style sheet. The other reports behave similarly and use the

same layout.

Drillbench Dynaflodrill User Guide Page 50

Figure 7-15: Layout of the Input report

The format of the reports makes it easy to export data to other applications like

Microsoft Excel. The reports can be opened by Excel directly, or the tables can be

copied from the reports to an Excel worksheet by standard copy and paste.

However, if you are using Internet Explorer to view the report, an even simpler way

is available. Data can be exported directly to an Excel sheet by right-clicking on a

table and selecting Export to Microsoft Excel. An Excel sheet will be opened,

containing the data from the selected report table.

Drillbench Dynaflodrill User Guide Page 51

Figure 7-16: Export of Survey data from a report to Excel

7.6.3 Validate parameters

Drillbench has a parameter validation tool. It can be started

by selecting Tools Validate parameters from the menu bar or using the

associated icon on the toolbar.

7.6.4 Edit unit settings

To edit the unit settings, select Tools Edit unit setting from the menu bar, or click

on the unit name in the status bar to pop up the unit menu.

Figure 7-17: Unit menu

The unit menu is allows quick change of unit sets and access to the unit edit page.

7.6.5 Options

Drillbench Dynaflodrill User Guide Page 52

To open the options tab window, select it from Tools Options from the menu bar

or click the associated icon on the toolbar.

This is a dialog that controls the Drillbench program settings. This window is divided

into three tab sheets: General, Appearance and Unit definitions, which are

described below.

Figure 7-18: The Drillbench option dialog.

7.6.5.1 General

Library path

Fluids, casings and string components are selected from a library. The location of

the library file is entered in this field. The library selected here is shared among all

Drillbench applications. Use the arrow in the right corner of the field to select from a

list of previous paths.

Template path

Drillbench Dynaflodrill User Guide Page 53

Path to Drillbench default template files.

At program startup

Reload last used file resumes the session you were working on when exiting

Dynaflodrill the last time.

Remember last selected page

Start at the page you were on when exiting Dynaflodrill the last time.

Reports

Option to indicate whether you want to include the default results in all result

reports. The default is to include.

View

Option to control whether the log window should open automatically when new

messages are produced by Drillbench. The default is to automatically open log.

Input file

Show input read diagnostics

This is an option to enable diagnostic messages when loading an input file. This

should normally not be used. It is only to be used when you have trouble loading an

input file. You may be asked by Drillbench support to turn this option on.

Load plot layout(s)

Custom chart layout and properties are now stored in the DML file. All open plots

and customizations to plots are automatically restored when DML file is opened.

Plot customizations are also preserved when using separate layout files. This option

controls whether Drillbench will load and use the last saved custom result plot

layout.

Load plot style

Drillbench will automatically save to the input file all custom changes to the plots

styles, e.g. line thickness, background colours etc. This option controls whether the

last saved changes are restored.

Drillbench Dynaflodrill User Guide Page 54

7.6.5.2 Appearance

Allow the user to modify colour theme, icon style and tab layout in Dynaflodrill

according to personal preference.

Figure 7-19 Editing color scheme

Drillbench Dynaflodrill User Guide Page 55

Figure 7-20 The Dynaflodrill summary window with different colour settings

7.6.5.3 Unit definitions

The unit settings can be changed by selecting the Unit definitions tab found under

Tools Options in the menu bar, see Figure 6.11. Each unit is defined separately

and saved in a specified unit file. However, predefined sets of units can be selected

from the drop down menu. By default, SI units, metric (European) units and field

units are available. You can create your own set of units by selecting the preferred

units and save to file with a new name.

Drillbench Dynaflodrill User Guide Page 56

7-21 Unit definitions

7.7 Help

To open the Help window in Dynaflodrill you can select it from Help Help topics

or you can open it by pressing F1.

The help window will give you a short description and explanation of all the different

windows in Dynaflodrill.

By pressing F1 from an input window, the help page for the current window will be

displayed.

7.7.1 About

Drillbench Dynaflodrill User Guide Page 57

The Help About option gives you information about Dynaflodrills version number

and the expiry date of the current license.

Figure 7-22. The About window in Dynaflodrill.

Drillbench Dynaflodrill User Guide Page 58

8. RUNNING A SIMULATION

8.1 Overview

Dynaflodrill gives the user an opportunity to perform a detailed design and analysis

of the drilling operation. It is a good approach to start by establishing an operating

range using the steady-state simulator Steadyflodrill, and with this input proceed to

Dynaflodrill to investigate potential dynamic problems.

Two different types of simulations can be performed:

Interactive simulation: Allows the user to modify the operational parameters

manually. During the simulation, messages from the simulator are given to inform

the user about events. The user may change the control parameters during the

simulation

Batch simulation: The changes in operational conditions are specified before

starting the simulator. The whole simulation is performed without any interaction

from the user

8.2 Controlling a simulation

Three buttons for controlling the simulator run are found on the toolbar.

The simulation is started by clicking Start, and it will continue to run until it is

stopped by the user. Immediately after the simulation is started, this button changes

to Pause. Clicking Reset resets all operational parameters so the simulation can be

started from the very beginning. The simulation is stopped temporarily by clicking

Pause and continued after a pause by clicking Start. By clicking Run one time step,

one time step is performed and the simulator pauses until Start or Run one time

step is chosen again.

The simulator proceeds one step at a time with variable time-step length. The step

number and simulated time is updated after the computation in a particular step is

finished. The length of each time step is normally decided by the simulator. The

default is approximately 90 seconds, but can vary depending on the calculations.

The simulation type is selected from the dropdown list on the toolbar

Drillbench Dynaflodrill User Guide Page 59

8.3 Simulation window

The Simulation window is opened by selecting Calculation in the Navigator bar.

Figure 8-1 Simulation window

The Simulation window is divided into two sections:

- Simulation control: The upper part is a panel for information and control of

operational parameters. This panel will change according to which type of

simulation is selected. It can be minimized by clicking the triangle in the

upper left corner of the panel.

- Simulation results: The lower part contains a collection of page views for

display of graphical result plots. Functionality pertaining to plot pages and

result data is described in detail in chapter 9.

Drillbench Dynaflodrill User Guide Page 60

8.4 Interactive simulation mode

Figure 7-6 shows the simulation window when running an interactive simulation.

Changes in the operational conditions can be made prior to simulation start or

whenever the simulation is paused.

Figure 8-2. Interactive simulation

The initial bit depth can either be at the bottom of the wellbore or a distance from

the bottom. The simulator initially suggests the bottom of the wellbore.

The mud circulation rate and gas injection rate, through annulus or a parasite string,

can be modified during the simulation. Kill fluid can be injected through a parasite

string if a well kill scenario is defined in the input parameters (Injection system input

window).

The drilling mode is activated whenever the rate of penetration (ROP) is larger than

0.0. A negative ROP indicates tripping out of the hole.

Acceleration refers to the drillstring acceleration when tripping in and out of hole as

well as the acceleration of drilling velocity. The recommended range is between 0

and 1 m/s

2

(0 - 3 ft/s

2

).

The status of the RCH and Choke can be set to open or closed. The choke is

controlled by interactively setting choke opening or choke pressure during the

simulation, depending on what choke operation mode is selected in the Surface

equipment input parameter window.

To use a shorter time step than the default, activate Max time step and enter the

desired upper limit for time step length.

Drillbench Dynaflodrill User Guide Page 61

During simulation, messages are written to the log window to inform about events.

For instance, a message is given when pipe joints reach the rig floor and it is time to

perform a connection. In this situation, the simulation will automatically pause and

await further input from the user,

8.5 Batch simulation mode

The Batch simulation can be started and controlled by selecting Batch simulation

and using the control buttons in the toolbar. The results are viewed in the

Simulation window. Figure 8-3 shows the simulation window when a batch

simulation is running.

Figure 8-3. Running a batch job in Dynaflodrill

The plot functionality is described in detail in chapter 9.

A progress bar in the bottom right corner shows how far the simulation has come in

the batch job. The progress bar color indicates the state of the simulation: It is

green while running and yellow when simulation is paused. The time period

currently being simulated is also highlighted in the Batch configuration table to give

the user an overview of the progress. This is shown in Figure 8-4.

Drillbench Dynaflodrill User Guide Page 62

Figure 8-4 Highlighting the current simulated batch period

The highlighted line will move while simulation progresses. The highlight is also

connected to the slider in the simulation window so that it shows the corresponding

time period to the slider position.

The user may at all stages in the batch simulation take manual control by switching

to an interactive simulation. This is done by clicking Pause, selecting the Interactive

simulation mode, and carrying on from there with full control over operational

parameters and simulator control.

Drillbench Dynaflodrill User Guide Page 63

9. WORKING WITH DYNAFLODRILL RESULTS

Dynaflodrill includes tools and features that are very valuable for day to day

engineering as well as operation decision support. This chapter describes the

functionality of the plots and plot pages in detail, and provides some usage

examples.

9.1 Plot page operations

Operations that deal with page organization and management are available from

the Results Current page menu on the main menu bar (see section 7.5.6 on

page 47 for a description of these menu items). Right-clicking on one of the page

tabs produces a context-sensitive popup menu (see Figure 9-1) that offers the

same selections as the main menu item.

Figure 9-1: The tab context menu showing page operations.

9.2 Plot management

The different plot windows can be used for displaying the results as the simulation

runs.

The graphical section in the Simulation window is divided into different views or

pages, which are easily configurable. Kick provides a set of commonly used default

plots in the first window. It is possible to customize the plots view according to

personal preference and also to add new custom plots pages.

To view a plot, click on the right mouse button in one of the pages. A context menu

(see Figure 9-2) will appear with a set of operations, including layout, plot

customizations and options, plot selection and more, based on the state of the

page.

9.2.1 Set and plot selection

In an empty page, Set is the only available option. Set has a submenu listing all

available plots, organized into categories. Trend plots are time series. Profile plots

Drillbench Dynaflodrill User Guide Page 64

show current conditions throughout the well, which will change as the simulation

runs. 3D Wellbore is a graphical representation of conditions on the well shown on

a three-dimensional well geometry.

To add a plot to an empty page, navigate the Set submenus and select a plot.

Using Set on an existing plot will replace the plot with the new selection.

Figure 9-2: Plot selection in the plot context menu

9.2.2 Add

To add more plots to a page, use Add. Placement of added plots is determined by

the location of the mouse pointer when you right-click to open the plot context

menu. Drillbench uses diagonal quadrants to determine where the new plot will be

placed. The direction zones are illustrated in Figure 9-3, below. Right-clicking

anywhere within a zone will produce a context menu where the Add item indicates

the direction that corresponds to that zone. Right-clicking in the Above zone will

produce a menu with an Add above item, and so on.

An Add will split the current plot in half, and add the new plot on the appropriate

side of the split.

Add operations offer the same organization and selection of plots as the Set menu

shown above.

Drillbench Dynaflodrill User Guide Page 65

.

Figure 9-3: Direction zones for Add operation

You can add as many plots as you want. You can also use the vertical splitter in a

window that has already been split horizontally. Plots can be resized freely by

dragging the splitters to the desired position.

The configuration of all pages will automatically be saved to the input file. You can

manually export the layout, including plot selections and configurations, in the active

plot page by selecting Save page layout from the Results Current page menu, or

from the page context menu accessed by right-clicking the page tab. The plot page

layout can then later be reused in other simulations by adding a new plot page and

selecting Load page layout. To export the configuration of all custom plot pages to a

single file, select Save layouts in the Results menu (on the main menu bar); select

Load layouts to load or restore all custom plot page configurations.

9.2.3 Reset plot

This menu operation returns the plot to its default configuration. This will delete any

imported curves, undo any customizations (to axes, colors, fonts etc.) and zoom out

to the default full view.

9.2.4 Remove plot

Remove plot will erase the plot and remove its associated splitter frame, and

accordingly reorganize the layout of the plots page.

9.3 Plot operations

The rest of the plot context menu contains operations that mostly act upon a single

plot. Some of these operations are common for all plots.

Drillbench Dynaflodrill User Guide Page 66

9.3.1 Maximize plot

The first of the sizing and placement operations in the Layout submenu will resize

the current plot to the maximum possible size within the constraint of the plot page.

The other plots and splitter walls will still be there, but squashed as much as

possible. This can be useful if you need to focus on details in a particular plot.

9.3.2 Normalize

Normalize, in the Layout submenu, is really a page-wide operation, but is also

available from the plot popup menu because it can be seen as a complement of the

Maximize operation (but not the opposite or reverse). It does the same thing as the

Normalize layout items in the tab popup menu and the Results menu; which is to

restore the layout of a page with multiple plots to its default layout. This involves

adjusting the splitter positions, and thereby the plot size ratios, so that all splits

divides their target pane in half. This is illustrated in Figure 9-4.

Note that the Normalize only returns layout to its default state it does not undo the

specific effects of the Maximize.

Figure 9-4: Normalized layout in a plot page with three splits; a vertical, followed by

a horizontal split in the right pane, then another horizontal split in the top right pane.

9.3.3 Swap with selected plot

The final item in the Layout submenu allows you to reorder plots within a page by

swapping them. If you click a plot on the page, it will get a red border. This

signifies that the plot is now selected. Right-click the other plot you want to switch

around and select Swap with selected plot. The plots will switch place on the page

without otherwise affecting the page setup and plot sizing.

Like other operations that affect plot organization, this operation is only available for

custom plot pages, not for the default plot page. The menu item will also be

unavailable if you have not first clicked another plot to select it.

Drillbench Dynaflodrill User Guide Page 67

9.3.4 Track values

Track values allows you to inspect actual numerical values from a plot. The

indicator line in the plot can be dragged to the desired position. Color coded data

values from all curves in the plot will be continuously updated based on the

indicator position.

Figure 9-5: Track values in action in a pressure plot.

9.3.5 Print

Selecting Print from the plot popup menu will open a print preview dialog, which

allows you to select a device for printing and adjust print options. Some

manipulation of chart characteristics is also possible at this level; the detail level for

axes and the grid can be adjusted, and the plot can be printed as a bitmap

(Smooth) or natively using the device resolution.

9.3.6 Import

Import lets you import curve data for a single curve at a time from a column based