Professional Documents

Culture Documents

C 46

C 46

Uploaded by

mixajlochkaCopyright:

Available Formats

You might also like

- Ford Think Service Manual - Section 3 PowertrainDocument16 pagesFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNo ratings yet

- Bolens Lawn Tractor RepairDocument46 pagesBolens Lawn Tractor Repairdakehi1188342157% (7)

- Instructions: 6 Speed Transmission Super KitDocument14 pagesInstructions: 6 Speed Transmission Super KitthailanNo ratings yet

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- Database - GPL - LPG - Problem - CarsDocument12 pagesDatabase - GPL - LPG - Problem - CarswwwglroNo ratings yet

- FSR 2010 Pitch FSR ManualDocument16 pagesFSR 2010 Pitch FSR ManualTeguh SanjayaNo ratings yet

- Cablemaster CM - Troubleshooting GuideDocument4 pagesCablemaster CM - Troubleshooting GuideGlendinning Products, LLC.No ratings yet

- Power Sunroof: Calibration & Timing NoteDocument23 pagesPower Sunroof: Calibration & Timing NoteEngine Tuning UPNo ratings yet

- AUMA Valve ActuatorDocument14 pagesAUMA Valve ActuatorSellappan MuthusamyNo ratings yet

- Ea460 Manual enDocument5 pagesEa460 Manual enabuzer1981No ratings yet

- UVR500 Universal Voltage Regulator: Power-Tronics, IncDocument6 pagesUVR500 Universal Voltage Regulator: Power-Tronics, IncPalani VeluNo ratings yet

- Toyota101 VSV AdjustmentDocument11 pagesToyota101 VSV AdjustmentJohn Francis Rosca100% (1)

- Speed Switches: InstructionsDocument3 pagesSpeed Switches: InstructionsmuthakkerNo ratings yet

- 5CKMR Service BullitenDocument7 pages5CKMR Service Bullitenchrist6989No ratings yet

- Testing The Starter On The Engine (1453,1450,1401)Document6 pagesTesting The Starter On The Engine (1453,1450,1401)Cristopher LaosNo ratings yet

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- Ev100manual en PDFDocument13 pagesEv100manual en PDFdragishabl100% (1)

- Test Transmision 420E CatDocument8 pagesTest Transmision 420E CatEdin Raul Yalle RafaelNo ratings yet

- Item 105 AR2 GBDocument8 pagesItem 105 AR2 GBjuan manuel chavezNo ratings yet

- High Voltage: Shutdown SISDocument6 pagesHigh Voltage: Shutdown SISCandiano PopescuNo ratings yet

- Starting Motor System: Shutdown SIS Previous ScreenDocument8 pagesStarting Motor System: Shutdown SIS Previous ScreenSteven ManuputtyNo ratings yet

- PL Starting 8B - 1Document8 pagesPL Starting 8B - 1Pelis CloneNo ratings yet

- Yaesu G450Document12 pagesYaesu G450neosspn100% (1)

- STC Series: Three-Phase Synchronous GeneratorsDocument9 pagesSTC Series: Three-Phase Synchronous GeneratorsReezka PutraNo ratings yet

- Lucas Generator and Control Box Tests 1963Document28 pagesLucas Generator and Control Box Tests 19632humbersNo ratings yet

- Speed Sensor - AdjustDocument6 pagesSpeed Sensor - AdjustЕвгений АбрамовNo ratings yet

- Aq SerieDocument76 pagesAq Serieharold_anilloNo ratings yet

- Interruptor de Parada de Emergencia Motor 3516 MarinoDocument9 pagesInterruptor de Parada de Emergencia Motor 3516 MarinoJoséNo ratings yet

- Troubleshooting The ETR Full Protective System (OP, WT, OS)Document14 pagesTroubleshooting The ETR Full Protective System (OP, WT, OS)Richard ChuaNo ratings yet

- Sqs-Vw-02j-Manual - 27 SecventialDocument7 pagesSqs-Vw-02j-Manual - 27 SecventialciprianNo ratings yet

- Brake Unit Instruction ManualDocument13 pagesBrake Unit Instruction Manuals_barriosNo ratings yet

- Auma ManualDocument17 pagesAuma ManualAhmed EldosokyNo ratings yet

- Lab 8Document6 pagesLab 8Malissa ClarkNo ratings yet

- Atv71 Installation Manual EngDocument43 pagesAtv71 Installation Manual EngsilvaroneNo ratings yet

- Atv71 Installation Manual EngDocument43 pagesAtv71 Installation Manual EngArun SudarsanNo ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box Testsruben_balea100% (1)

- HCB DS-72KV TO 245KV (Manual)Document10 pagesHCB DS-72KV TO 245KV (Manual)Nixon Quispe SanchezNo ratings yet

- Unstable VoltageDocument5 pagesUnstable Voltagevictor laraNo ratings yet

- Testes e Ajustes 01Document4 pagesTestes e Ajustes 01Gustavo PereiraNo ratings yet

- Electrical System: Service ManualDocument4 pagesElectrical System: Service ManualEdin HadzicNo ratings yet

- 07-01 TroubleshootingDocument33 pages07-01 TroubleshootingVinod GuptaNo ratings yet

- Group 14 Starting SystemDocument10 pagesGroup 14 Starting SystemMister_YNo ratings yet

- Switch (Continuous Flow) : TroubleshootingDocument5 pagesSwitch (Continuous Flow) : TroubleshootingjimNo ratings yet

- Phase SequenceDocument3 pagesPhase SequenceSreelekha BasuNo ratings yet

- AVR User's ManualDocument10 pagesAVR User's ManualWilmar ZachawerusNo ratings yet

- Title:To Practically Configuration and Characteristic ofDocument14 pagesTitle:To Practically Configuration and Characteristic ofKelvin YipNo ratings yet

- High VoltageDocument6 pagesHigh Voltagevictor laraNo ratings yet

- Dual Switches HoneywellDocument4 pagesDual Switches Honeywellamirin_kingNo ratings yet

- 6.6 KV BreakerDocument29 pages6.6 KV Breakerdan_geplNo ratings yet

- Governador para Motor PerkinsDocument4 pagesGovernador para Motor Perkinsacere18No ratings yet

- Experiment Laboratory Report No.3 DraftDocument8 pagesExperiment Laboratory Report No.3 DraftSherwin CaringalNo ratings yet

- Newage Sx460 Automatic Voltage RegulatorDocument5 pagesNewage Sx460 Automatic Voltage RegulatorLuis Alberto Lopez100% (1)

- ABB IRB 6400 Wrist Change ManualDocument3 pagesABB IRB 6400 Wrist Change ManualAntonio SanchezNo ratings yet

- Repair of Emerson MW8625W Microwave Oven Timer MotorDocument5 pagesRepair of Emerson MW8625W Microwave Oven Timer MotorRandom73No ratings yet

- Alternator and RegulatorDocument6 pagesAlternator and Regulatorsonny1234No ratings yet

- Piaggio Mp3 400 I.E Service Station Manual-7Document20 pagesPiaggio Mp3 400 I.E Service Station Manual-7H. KeithNo ratings yet

- Cruise ControlDocument14 pagesCruise Controlposlovni2No ratings yet

- Enertork TQ020Document48 pagesEnertork TQ020evilolao50% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Car Cost UpdateDocument11 pagesCar Cost UpdateblithevincentNo ratings yet

- My First Experience To Ride MotorcycleDocument2 pagesMy First Experience To Ride MotorcycleHeri E. AsysyakiriNo ratings yet

- Piaggio Mp3 Yourban EngDocument5 pagesPiaggio Mp3 Yourban EngOceancolourblueNo ratings yet

- Termignoni 2012Document104 pagesTermignoni 2012tallermobexNo ratings yet

- Service Manual Vision Recumbent BikeDocument16 pagesService Manual Vision Recumbent BikeCary BriefNo ratings yet

- Bike Size ChartDocument3 pagesBike Size ChartIshant ChandravnshiNo ratings yet

- Australian Road Rider - Issue 178 - June-July 2024Document132 pagesAustralian Road Rider - Issue 178 - June-July 2024Rexon dela CruzNo ratings yet

- DjagbeDocument6 pagesDjagbeOnanisław Spermacy WyfiutkiewiczNo ratings yet

- KTAG Vehicle Support ListDocument66 pagesKTAG Vehicle Support Listkishan KumarNo ratings yet

- CatalogDocument69 pagesCatalogedwin0207100% (1)

- Yamaha XSDocument5 pagesYamaha XSErnesto Conder100% (1)

- Magura HS 11/33Document16 pagesMagura HS 11/33Nebojša TepićNo ratings yet

- Harley Davidson Sportster (2010) PartsDocument62 pagesHarley Davidson Sportster (2010) PartsjetdedeNo ratings yet

- Iot Ecuwiring PDFDocument38 pagesIot Ecuwiring PDFBruno DuroNo ratings yet

- Kent Gzr700 Road Bike ReviewDocument1 pageKent Gzr700 Road Bike ReviewEliyzia BethNo ratings yet

- Shell MotoGP - The Basics 2023Document28 pagesShell MotoGP - The Basics 2023Jonathan BanksNo ratings yet

- 2 Weel Moter Cycle Industry ProfileDocument6 pages2 Weel Moter Cycle Industry ProfilesaiyuvatechNo ratings yet

- 2009 - Sports - UKDocument90 pages2009 - Sports - UKThunderbird3No ratings yet

- Autos CanDocument5 pagesAutos CanElvisNo ratings yet

- Total Electric Motorcycle ReportDocument18 pagesTotal Electric Motorcycle Reportjprakashus100% (1)

- BikeBiz April 2010 - Issue 51Document80 pagesBikeBiz April 2010 - Issue 51Nu Lucid LabNo ratings yet

- Campus Parking MapDocument2 pagesCampus Parking MapChris McCormickNo ratings yet

- 1hoda AmazeDocument6 pages1hoda AmazeAshok KumarNo ratings yet

- 2008 KX100 ManualDocument233 pages2008 KX100 ManualdkmurrayNo ratings yet

- Muet Essay Writing Test GuideDocument15 pagesMuet Essay Writing Test GuideShaamini100% (1)

- AFM Catalogue 2010 WebDocument76 pagesAFM Catalogue 2010 WebdervalusNo ratings yet

- AerDocument131 pagesAerDolpeo Sedf0% (1)

C 46

C 46

Uploaded by

mixajlochkaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C 46

C 46

Uploaded by

mixajlochkaCopyright:

Available Formats

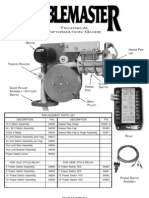

MOTORCYCLE DIVISION

4-STROKE SERVICE BULLETIN GS/GSX/GSX-R/GSF NO. 157A DATE: 3/26/2010

SUBJECT: MODEL:

C46 TROUBLESHOOTING AN INTERMITTENT FI CODE DISPLAY GSX-R600K6, GSX-R750K6, GSX-R1000K3 K8

REFERENCE: GSX-R600 SERVICE MANUAL (P/N 99500-35100-03E) PAGE 6-8 TO 6-10 GSX-R750 SERVICE MANUAL (P/N 99500-37130-03E) PAGE 6-8 TO 6-10 GSX-R1000 SERVICE MANUAL (P/N 99500-39241-03E) PAGE 6-9 TO 6-11 GSX-R1000 SERVICE MANUAL (P/N 99500-39271-03E) PAGE 6-10 TO 6-13 GSX-R1000 SERVICE MANUAL (P/N 99500-39310-03E) PAGE 6-9 TO 6-12 SUBJECT: It has been reported that some GSX-R600/750K6 and GSX-R1000K3K8 models may experience an intermittent "FI" code during normal operation. The engine control module (ECM) on these models continuously monitors the function of the fuel injection system and ignition systems for proper operations, and will display an "FI" warning indicator to the rider if the system detects a malfunction. Field experience has shown that in many cases an intermittent "FI" display on the GSX-R600/ 750K6 and GSX-R1000K3K8 models can often be traced to incorrect adjustment of the Suzuki Exhaust Tuning (SET) cables. This problem can be corrected by readjustment of the cables using the outlined procedure. Problem Verification If an "FI" code is displayed continuously on the LCD panel, place the system in dealer mode using the mode selector switch. This will cause any currently active diagnostic code(s) to be displayed on the LCD panel. Incorrect adjustment of the SET cables typically will result in a C-46 code being displayed.

Mode Selector Switch: 09930-82720

AFTER READING THIS PROCEDURE, TO VIEW A VIDEO OF THIS PROCEDURE,

CLICK HERE

(A COMPUTER SOUND CARD IS REQUIRED FOR THE AUDIO)

- 1/4 -

Continued

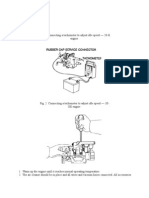

Inspection Inspect the open and close cables to verify that neither cable is pinched or bent and that both cables are properly routed before performing an adjustment. Re-route improperly routed cables and replace cables that are bent or damaged. Make sure to minimize the cable bend at the indicated point 3 . Overtightening the cable clamp will increase cable bend and interfere with smooth cable operation. 1 Close cable 2 Open cable

Figure 1 1 2 3

1 2

Adjustment SET Precautions Always use a mode selector switch to set the drive pulley on the Exhaust Control Valve Actuator (EXCVA) in the ADJUST position before making any adjustments or replacing components. Adjusting cable tension when not in the ADJUST position will damage the actuator gears. Use a wrench to hold the EXCVA drive pulley when loosening or tightening the retaining bolt or the nylon gears inside the EXCVA will be damaged. Do not apply voltage to the EXCVA motor any longer than required when setting the drive pulley to the fully open or closed position. 1) Turn the ignition switch off. Disconnect the EXCVA motor lead wire coupler (P/Gr leads) 1 (Figure 2). Use a 12V battery and harness to set the EXCVA drive pulley to the FULLY OPEN position (Figure 3) by connecting the wires to the terminals as described below. (A harness can be built from connectors in the standard terminal kit.)

Figure 2 valve open position

Figure 3 - 2/4 -

2) Turn the ignition switch ON. Measure the EXCVA position sensor voltage at the Y- B/ Br. The specification for the FULLY OPEN position is 3.7 to 4.5 V. It is normal for the open cable to stretch with use and then the voltage will read high. EXCVA position sensor coupler 2 (Figure 4)

Figure 4 3) If the voltage measurement is out of specification, reconnect the EXCVA motor lead wire coupler and use the mode selector switch to set the drive pulley to the ADJUST position (Figure 5) before adjusting the open cable.

cable adjust position

Figure 5 4) Loosen the lock-nut 3 on the open cable and turn the cable adjuster 4 out approximately one turn. Tighten the lock-nut against the cable adjuster. The EXCVA position sensor voltage will not change in the ADJUST position and must be retested in the FULLY OPEN position. Repeat Steps 1 and 2 to test the voltage after making the adjustment. Make further adjustments following steps 3 and 4 as necessary until the correct voltage specification for the FULLY OPEN position is acheived. 5) Disconnect the EXCVA motor lead wire coupler and use the battery and harness (used in Step 1) to set the EXCVA drive pulley to the FULLY CLOSED position (Fig ure 7) by connecting the wires to the terminals as described below.

Figure 6 valve closed position

Figure 7 - 3/4 -

6) Turn the ignition switch ON. Measure the EXCVA position sensor voltage at the Y- B/ Br. The specification for the FULLY CLOSED position is 0.5 to 1.3 V. It is normal for the close cable to stretch with use and then the voltage will read low.

Figure 8 7) If the voltage measurement is out of specification, set the EXCVA drive pulley in the ADJUST position per the instructions in Step 3. Loosen the lock-nut 3 on the close cable and turn the cable adjuster 4 out approximately one turn. Tighten the lock-nut against the adjuster. The EXCVA position sensor voltage will not change in the ADJUST position and must be retested in the FULLY CLOSED position. Repeat Steps 5 and 6 to test the voltage after making the adjustment. Make further adjustments (following step 7) as necessary until the correct voltage specification for the FULLY CLOSED position is acheived.

Figure 9

8) Test ride the unit thoroughly and verify that the C-46 code does not reappear. If a C-46 code reappears, re-check adjustment. If EXCVA position sensor voltage is still within specification at the FULLY OPEN and FULLY CLOSED positions, inspect the following items (start engine and raise engine speed briefly as necessary): Smooth movement of the SET cables. EXCVA drive pulley reaches fully open and closed positions (see Figure 3 and Figure 7). The EXCVA motor does not make any abnormal noise. The Exhaust Control Valve (EXCV) moves freely.

AFFECTED DEPARTMENTS: The following departments in your dealership should be notified of this information: Management Service Warranty Sales Parts Accessories

American Suzuki Motor Corporation Technical Service Department Motorcycle / ATV / Scooter - 4/4 -

You might also like

- Ford Think Service Manual - Section 3 PowertrainDocument16 pagesFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNo ratings yet

- Bolens Lawn Tractor RepairDocument46 pagesBolens Lawn Tractor Repairdakehi1188342157% (7)

- Instructions: 6 Speed Transmission Super KitDocument14 pagesInstructions: 6 Speed Transmission Super KitthailanNo ratings yet

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- Database - GPL - LPG - Problem - CarsDocument12 pagesDatabase - GPL - LPG - Problem - CarswwwglroNo ratings yet

- FSR 2010 Pitch FSR ManualDocument16 pagesFSR 2010 Pitch FSR ManualTeguh SanjayaNo ratings yet

- Cablemaster CM - Troubleshooting GuideDocument4 pagesCablemaster CM - Troubleshooting GuideGlendinning Products, LLC.No ratings yet

- Power Sunroof: Calibration & Timing NoteDocument23 pagesPower Sunroof: Calibration & Timing NoteEngine Tuning UPNo ratings yet

- AUMA Valve ActuatorDocument14 pagesAUMA Valve ActuatorSellappan MuthusamyNo ratings yet

- Ea460 Manual enDocument5 pagesEa460 Manual enabuzer1981No ratings yet

- UVR500 Universal Voltage Regulator: Power-Tronics, IncDocument6 pagesUVR500 Universal Voltage Regulator: Power-Tronics, IncPalani VeluNo ratings yet

- Toyota101 VSV AdjustmentDocument11 pagesToyota101 VSV AdjustmentJohn Francis Rosca100% (1)

- Speed Switches: InstructionsDocument3 pagesSpeed Switches: InstructionsmuthakkerNo ratings yet

- 5CKMR Service BullitenDocument7 pages5CKMR Service Bullitenchrist6989No ratings yet

- Testing The Starter On The Engine (1453,1450,1401)Document6 pagesTesting The Starter On The Engine (1453,1450,1401)Cristopher LaosNo ratings yet

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- Ev100manual en PDFDocument13 pagesEv100manual en PDFdragishabl100% (1)

- Test Transmision 420E CatDocument8 pagesTest Transmision 420E CatEdin Raul Yalle RafaelNo ratings yet

- Item 105 AR2 GBDocument8 pagesItem 105 AR2 GBjuan manuel chavezNo ratings yet

- High Voltage: Shutdown SISDocument6 pagesHigh Voltage: Shutdown SISCandiano PopescuNo ratings yet

- Starting Motor System: Shutdown SIS Previous ScreenDocument8 pagesStarting Motor System: Shutdown SIS Previous ScreenSteven ManuputtyNo ratings yet

- PL Starting 8B - 1Document8 pagesPL Starting 8B - 1Pelis CloneNo ratings yet

- Yaesu G450Document12 pagesYaesu G450neosspn100% (1)

- STC Series: Three-Phase Synchronous GeneratorsDocument9 pagesSTC Series: Three-Phase Synchronous GeneratorsReezka PutraNo ratings yet

- Lucas Generator and Control Box Tests 1963Document28 pagesLucas Generator and Control Box Tests 19632humbersNo ratings yet

- Speed Sensor - AdjustDocument6 pagesSpeed Sensor - AdjustЕвгений АбрамовNo ratings yet

- Aq SerieDocument76 pagesAq Serieharold_anilloNo ratings yet

- Interruptor de Parada de Emergencia Motor 3516 MarinoDocument9 pagesInterruptor de Parada de Emergencia Motor 3516 MarinoJoséNo ratings yet

- Troubleshooting The ETR Full Protective System (OP, WT, OS)Document14 pagesTroubleshooting The ETR Full Protective System (OP, WT, OS)Richard ChuaNo ratings yet

- Sqs-Vw-02j-Manual - 27 SecventialDocument7 pagesSqs-Vw-02j-Manual - 27 SecventialciprianNo ratings yet

- Brake Unit Instruction ManualDocument13 pagesBrake Unit Instruction Manuals_barriosNo ratings yet

- Auma ManualDocument17 pagesAuma ManualAhmed EldosokyNo ratings yet

- Lab 8Document6 pagesLab 8Malissa ClarkNo ratings yet

- Atv71 Installation Manual EngDocument43 pagesAtv71 Installation Manual EngsilvaroneNo ratings yet

- Atv71 Installation Manual EngDocument43 pagesAtv71 Installation Manual EngArun SudarsanNo ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box Testsruben_balea100% (1)

- HCB DS-72KV TO 245KV (Manual)Document10 pagesHCB DS-72KV TO 245KV (Manual)Nixon Quispe SanchezNo ratings yet

- Unstable VoltageDocument5 pagesUnstable Voltagevictor laraNo ratings yet

- Testes e Ajustes 01Document4 pagesTestes e Ajustes 01Gustavo PereiraNo ratings yet

- Electrical System: Service ManualDocument4 pagesElectrical System: Service ManualEdin HadzicNo ratings yet

- 07-01 TroubleshootingDocument33 pages07-01 TroubleshootingVinod GuptaNo ratings yet

- Group 14 Starting SystemDocument10 pagesGroup 14 Starting SystemMister_YNo ratings yet

- Switch (Continuous Flow) : TroubleshootingDocument5 pagesSwitch (Continuous Flow) : TroubleshootingjimNo ratings yet

- Phase SequenceDocument3 pagesPhase SequenceSreelekha BasuNo ratings yet

- AVR User's ManualDocument10 pagesAVR User's ManualWilmar ZachawerusNo ratings yet

- Title:To Practically Configuration and Characteristic ofDocument14 pagesTitle:To Practically Configuration and Characteristic ofKelvin YipNo ratings yet

- High VoltageDocument6 pagesHigh Voltagevictor laraNo ratings yet

- Dual Switches HoneywellDocument4 pagesDual Switches Honeywellamirin_kingNo ratings yet

- 6.6 KV BreakerDocument29 pages6.6 KV Breakerdan_geplNo ratings yet

- Governador para Motor PerkinsDocument4 pagesGovernador para Motor Perkinsacere18No ratings yet

- Experiment Laboratory Report No.3 DraftDocument8 pagesExperiment Laboratory Report No.3 DraftSherwin CaringalNo ratings yet

- Newage Sx460 Automatic Voltage RegulatorDocument5 pagesNewage Sx460 Automatic Voltage RegulatorLuis Alberto Lopez100% (1)

- ABB IRB 6400 Wrist Change ManualDocument3 pagesABB IRB 6400 Wrist Change ManualAntonio SanchezNo ratings yet

- Repair of Emerson MW8625W Microwave Oven Timer MotorDocument5 pagesRepair of Emerson MW8625W Microwave Oven Timer MotorRandom73No ratings yet

- Alternator and RegulatorDocument6 pagesAlternator and Regulatorsonny1234No ratings yet

- Piaggio Mp3 400 I.E Service Station Manual-7Document20 pagesPiaggio Mp3 400 I.E Service Station Manual-7H. KeithNo ratings yet

- Cruise ControlDocument14 pagesCruise Controlposlovni2No ratings yet

- Enertork TQ020Document48 pagesEnertork TQ020evilolao50% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Car Cost UpdateDocument11 pagesCar Cost UpdateblithevincentNo ratings yet

- My First Experience To Ride MotorcycleDocument2 pagesMy First Experience To Ride MotorcycleHeri E. AsysyakiriNo ratings yet

- Piaggio Mp3 Yourban EngDocument5 pagesPiaggio Mp3 Yourban EngOceancolourblueNo ratings yet

- Termignoni 2012Document104 pagesTermignoni 2012tallermobexNo ratings yet

- Service Manual Vision Recumbent BikeDocument16 pagesService Manual Vision Recumbent BikeCary BriefNo ratings yet

- Bike Size ChartDocument3 pagesBike Size ChartIshant ChandravnshiNo ratings yet

- Australian Road Rider - Issue 178 - June-July 2024Document132 pagesAustralian Road Rider - Issue 178 - June-July 2024Rexon dela CruzNo ratings yet

- DjagbeDocument6 pagesDjagbeOnanisław Spermacy WyfiutkiewiczNo ratings yet

- KTAG Vehicle Support ListDocument66 pagesKTAG Vehicle Support Listkishan KumarNo ratings yet

- CatalogDocument69 pagesCatalogedwin0207100% (1)

- Yamaha XSDocument5 pagesYamaha XSErnesto Conder100% (1)

- Magura HS 11/33Document16 pagesMagura HS 11/33Nebojša TepićNo ratings yet

- Harley Davidson Sportster (2010) PartsDocument62 pagesHarley Davidson Sportster (2010) PartsjetdedeNo ratings yet

- Iot Ecuwiring PDFDocument38 pagesIot Ecuwiring PDFBruno DuroNo ratings yet

- Kent Gzr700 Road Bike ReviewDocument1 pageKent Gzr700 Road Bike ReviewEliyzia BethNo ratings yet

- Shell MotoGP - The Basics 2023Document28 pagesShell MotoGP - The Basics 2023Jonathan BanksNo ratings yet

- 2 Weel Moter Cycle Industry ProfileDocument6 pages2 Weel Moter Cycle Industry ProfilesaiyuvatechNo ratings yet

- 2009 - Sports - UKDocument90 pages2009 - Sports - UKThunderbird3No ratings yet

- Autos CanDocument5 pagesAutos CanElvisNo ratings yet

- Total Electric Motorcycle ReportDocument18 pagesTotal Electric Motorcycle Reportjprakashus100% (1)

- BikeBiz April 2010 - Issue 51Document80 pagesBikeBiz April 2010 - Issue 51Nu Lucid LabNo ratings yet

- Campus Parking MapDocument2 pagesCampus Parking MapChris McCormickNo ratings yet

- 1hoda AmazeDocument6 pages1hoda AmazeAshok KumarNo ratings yet

- 2008 KX100 ManualDocument233 pages2008 KX100 ManualdkmurrayNo ratings yet

- Muet Essay Writing Test GuideDocument15 pagesMuet Essay Writing Test GuideShaamini100% (1)

- AFM Catalogue 2010 WebDocument76 pagesAFM Catalogue 2010 WebdervalusNo ratings yet

- AerDocument131 pagesAerDolpeo Sedf0% (1)