Professional Documents

Culture Documents

Equilibrium Stage Processes - Docx Cet

Equilibrium Stage Processes - Docx Cet

Uploaded by

Portia ShilengeCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Lab Report Distillation Column PDFDocument26 pagesLab Report Distillation Column PDFGebrina RizkiaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Au5 Online Operating ManualDocument303 pagesAu5 Online Operating ManualAjesh Babu100% (1)

- Distillation The Theory-Vogelpohl, Alfons PDFDocument165 pagesDistillation The Theory-Vogelpohl, Alfons PDFAlexis Alatorre AlbaNo ratings yet

- Distillation ReportDocument17 pagesDistillation ReportSebastian PinzonNo ratings yet

- Distillation Column Design ReportDocument27 pagesDistillation Column Design ReportUsama Akram100% (1)

- AGE10503, Gas ProcessingDocument34 pagesAGE10503, Gas ProcessingiranmortezaNo ratings yet

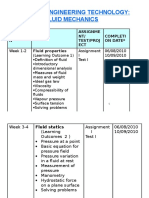

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeNo ratings yet

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengeNo ratings yet

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengeNo ratings yet

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengeNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeNo ratings yet

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengeNo ratings yet

- Kroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFDocument32 pagesKroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFPortia ShilengeNo ratings yet

- Milling Multotec ProjectDocument15 pagesMilling Multotec ProjectPortia ShilengeNo ratings yet

- Derrick Screen ProjectDocument15 pagesDerrick Screen ProjectPortia ShilengeNo ratings yet

- Ball Mills For Blue Ridge PDFDocument2 pagesBall Mills For Blue Ridge PDFPortia ShilengeNo ratings yet

- Preconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterDocument20 pagesPreconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterPortia ShilengeNo ratings yet

- UAE University College of Engineering Training and Graduation Project UnitDocument100 pagesUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeNo ratings yet

- 17-Processing Iron Ore PDFDocument12 pages17-Processing Iron Ore PDFPortia Shilenge100% (1)

- 0204finalreportbrgm PDFDocument88 pages0204finalreportbrgm PDFPortia ShilengeNo ratings yet

- Mini Report of Duties Done in The Ug2 PlantDocument9 pagesMini Report of Duties Done in The Ug2 PlantPortia ShilengeNo ratings yet

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- Report in The Ug2 PlantDocument8 pagesReport in The Ug2 PlantPortia ShilengeNo ratings yet

- Laporan PertaminaDocument51 pagesLaporan PertaminaDeni HermawanNo ratings yet

- Separation ProcessesDocument57 pagesSeparation ProcessesAngelo X0% (1)

- Crude Oil DistillationDocument5 pagesCrude Oil Distillationmahmoud_k_azzamNo ratings yet

- Lecture 4 Reflux Ratio and Column DesignDocument13 pagesLecture 4 Reflux Ratio and Column DesignMohammedTalib100% (1)

- UcucucDocument97 pagesUcucucJV Custodio100% (2)

- DistillationDocument22 pagesDistillationAhmed Omar Amine100% (1)

- 3.1 Mass Transfer Equipment Design: H O CH Cooh CHDocument61 pages3.1 Mass Transfer Equipment Design: H O CH Cooh CHZAINOR SYAHIRA BINTI ZAINAL STUDENTNo ratings yet

- HYSYS Training 2013Document27 pagesHYSYS Training 2013Kokil JainNo ratings yet

- Distillation Is Defined As:: How Does Distillation Work?Document35 pagesDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarNo ratings yet

- Fundamentals Petroleum Refining CourseDocument32 pagesFundamentals Petroleum Refining Coursecivilmechanic100% (2)

- CPE 601 Distillation - Topic 5 Design of Other EquipmentDocument70 pagesCPE 601 Distillation - Topic 5 Design of Other EquipmentRosa SinensisNo ratings yet

- Design QuestionsDocument3 pagesDesign QuestionsTamil SelvanNo ratings yet

- Chemical Technology Subject Code: CH2001Document17 pagesChemical Technology Subject Code: CH2001U SANKAR TEJONo ratings yet

- Alfons Vogelpohl Distillation (2017)Document134 pagesAlfons Vogelpohl Distillation (2017)Lp PerezNo ratings yet

- 6 Crude Oil RefiningDocument57 pages6 Crude Oil RefiningAkashNo ratings yet

- Engineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberDocument7 pagesEngineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberAh WenNo ratings yet

- Shortcut Procedure Simulating Batch Distillation Operations: Suresh Sundaram Lawrence Evans'Document8 pagesShortcut Procedure Simulating Batch Distillation Operations: Suresh Sundaram Lawrence Evans'pippoNo ratings yet

- Selection of Column Type: Plate or PackedDocument52 pagesSelection of Column Type: Plate or Packedsai charanNo ratings yet

- Distillation 2Document20 pagesDistillation 2arslanadeelNo ratings yet

- Refinery All Lectures PDFDocument64 pagesRefinery All Lectures PDFHelin HassanNo ratings yet

- Petroleum Refining Processes1Document73 pagesPetroleum Refining Processes1Arun DasNo ratings yet

- Bitumen ProductionDocument5 pagesBitumen ProductionSanjeev ViswambharanNo ratings yet

- Lecture 1-Petroleum Oil Refinery ProcessesDocument120 pagesLecture 1-Petroleum Oil Refinery Processesdivyansh100% (3)

- Atmospheric Crude Distillation UnitDocument2 pagesAtmospheric Crude Distillation UnitFahmi Ramadhan PutraNo ratings yet

Equilibrium Stage Processes - Docx Cet

Equilibrium Stage Processes - Docx Cet

Uploaded by

Portia ShilengeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equilibrium Stage Processes - Docx Cet

Equilibrium Stage Processes - Docx Cet

Uploaded by

Portia ShilengeCopyright:

Available Formats

Equilibrium Stage Processes Distillation.

Christopher J. Hill, 2000

Back | Exit

Introduction

This course is, in general, concerned with the processes effecting the separation in the outline of a chemical process shown below.

Fig 1: Typical Chemical Process

One example of a separation process, liquid-liquid extraction, may be used to seperate propionic acid from a mixture with kerosine as follows:

Fig 2: Batch liquid-liquid extraction.

For continuous operation,

Fig 3: Continuous liquid-liquid extraction.

The ideal Equilibrium Stage?

The 'Ideal Equilibrium Stage', also known as a 'Theoretical Stage', 'Theoretical Plate' or 'Ideal Stage', is one which has the exit phases/streams in thermodynamic equilibrium, each phase/stream being removed from the stage without entraining any of the other phase / stream.

Binary Distillation

Distillation is a process involving an equilibrium between two phases - liquid and vapour. For a pure compound, in particular a pure ionic compound, a sharp boiling point usually exists. For a mixture, however, a phase equilibrium exists over a range of temperature, as shown below.

Fig 4: Isobaric (Constant Pressure) Temperature Composition Diagram.

The above diagram applies to the system:

Fig 5: Liquid and vapour space in equilibrium.

The first bubble of vapour formed when a liquid (subcooled) is heated is formed at the bubble curve. The first drop of liquid formed when a vapour (superheated) is cooled is formed at the dew curve. x = mole fraction m.v.c. in liquid y = mole fraction m.v.c. in vapour The temperature - composition diagram is used for isobaric conditions. For isothermal (constant temperature) conditions a pressure - composition diagram is used.

Fig 6: Isothermal (constant temperature) Pressure-Composition Diagram.

X-Y Diagrams for Constant Pressure

If the isobaric temperature-composition diagram is drawn or plotted, the x and y data for different temperatures may be utilised to form the x-y diagram (i.e. the plot of y against x). The x-y diagram will correspond to the pressure for which the temperature-composition diagram was plotted.

Fig 7: X-Y Diagram for Constant Pressure.

X-Y Diagrams for Constant Temperature

Fig 8: X-Y Diagram for Constant Temperature.

Pmvc = partial pressure of more volatile component Plvc = partial pressure of less volatile component

Azeotropes

Type A

(e.g. Acetone - CS2, Chloroform - methanol)

Fig 9:

Fig 10:

Fig 11:

Type B

(e.g. Acetone-Chloroform)

Fig 12:

Fig 13:

Fig 14:

Fig 15:

Fig 16:

Flash Distillation

Flash distillation is a process typically used to effect seperation of crude oil. The process involves heating a feed stream and then allowing it to expand into a vessel maintained at low pressure. Partial vaporisation then occurs, and a phase equilibrium is (ideally) reached.

Fig 17: Flash Distillation.

A material balance gives: F = L + V ...1 An m.v.c. balance gives: FZF = Lxe + Vye ...2 Now from 2,

Vye = FZF - Lxe ye = (FZF / V) - (Lxe/V) y = c + mx Putting xe = ZF gives ye = ZF[ (F / V) - (L/V) ] but from 1, (F / V) = (L / V) + 1, so (F / V) - (L / V) = 1 thus ye = ZF when xe = ZF (this is not surprising considering the fact that with a feed of composition ZF and a liquid bottom product of composition ZF the top product cannot be of any composition other than ZF). For the constant pressure at which the flash vessel is operated, a y against x diagram may be plotted and the material balance line (which is straight) is seen to pass through ZF, ZF and xe, ye (corresponding to the temperature Te).

Fig 18:

Simple Differential Distillation

Fig 19: Differential Distillation

The above diagrams represent classical simple laboratory distillation, attributed to Rayleigh, 1903. Heat is applied to vapourise some of the solution. The vapour is condensed and found to contain a high m.v.c. composition (depending on amount vapourised). Now in a small time increment dt, vapour of m.v.c. composition y is given off. The amount of vapour given off is V kmol. Assuming x and y are equilibrium values throughout the process, In time increment dt, dV = -dS m.v.c. balance ydV = -d(Sx) = -Sdx - xdS -ydS = -Sdx - xdS xdS - ydS = -Sdx (x - y) dS = -Sdx

Fig 20:

The last equation above is known as Rayleigh Equation, where S1 = total kmol solution to start with S2 = total kmol solution left in bottoms x1 = starting m.v.c. composition in liquid x2 = finishing m.v.c. composition in liquid

Fig 21:

Continuous Fractionation

The system typically adopted for continuous fractionation is shown below.

Fig 22: Continuous Fractionation.

where, F = Feed flow rate (kmols/hr) xf = m.v.c. composition of feed (mole fraction or mol percentage) V = Vapour flow rate (kmols/hr) L = Reflux flow rate (kmols/hr) D = Top Product flow rate (kmols/hr) xD = m.v.c. composition of top vapour stream, top product, and reflux (mole fraction or mol percentage) V" = Reboiler exit stream flow rate (kmols/hr) W = Bottom-product flow rate (kmols/hr) xW = m.v.c. composition of bottom product and feed to reboiler (mole fraction or mol percentage)

Comparison of Continuous Fractionation with Flash and Rayleigh Distillation

Flash Distillation

Fig 23: Flash Distillation.

Rayleigh Distillation (Simple Differential Distillation)

Fig 24: Rayleigh Distillation.

A single stage of the continuous fractionation column is now considered for comparison.

Continuous Simple Distillation

Fig 25: Continuous Distillation.

Multiple Continuous Simple Distillation

Fig 26: Multiple Continuous Distillation.

Consider a fractionating column of N plates, where the condenser and reboiler are counted as 'plates'. A typical 'nth' plate has the streams shown below associated with it:

Fig 27: Column.

Fig 28: Temperature - Composition Diagram for nth Plate.

M.v.c balance for Nth plate

Fig 29: mvc balance.

VN-1YN-1 + LN+1XN+1 = VNYN + LNXN But XN+1 = XD

VN-1YN-1 + LN+1XD = VNYN + LNXN M.v.c. balance for plates n to N (where n,N in rectifying section)

Fig 30: M.v.c. balance for plates n to N.

(The balance is for the solid red line area) Vn-1Yn-1 + LN+1XN+1 = VNYN + LnXn But XN+1 = XD Vn-1Yn-1 + LN+1XD = VNYN + LnXn M.v.c. balance as above incorporating condenser. (balance as above + dotted red line area) Vn-1Yn-1 = LnXn + DXD

Conditions for Constant Molal Overflow

1. Heat losses negligable (achieved more easily in industrial columns) 2. Negligable heat of mixing 3. Equal or close heats of vaporisation

In general, values of V and L very from stage to stage, and an enthalpy balance over each stage is required to calculate L,V. With constant molal overflow assumption, Ln-1 = Ln = Ln+1 = ... etc. Vn-1 = Vn = Vn+1 = ... etc. M.v.c. balance for plate n to condenser continued. Vn-1Yn-1 = LnXn + DXD Assuming constant molal overflow, Note: V=Vapour from top of column L = reflux D = top-product

VYn-1 = LXn + DXD

Dividing through by V gives

Yn-1 = (L/V)Xn + (D/V)XD Y = m X + c

This material balance equation is called the Upper Operating Line. Note that (L/V) and (D/V) are constants. This linear relationship links the compositions of passing streams between stages.

The Lewis-Sorel Method

This uses the above equilibrium relationship and the operating line equation alternately to step up or down the column. e.g. at the top of the column: YN = XD = (known) Equilibrium XN

Operating Line YN-1 = (L/V)XN + (D/V)XD Equilibrium XN-1

Operating Line YN-2 = (L/V)XN-1 + (D/V)XD etc.

McCabe-Thiele

Recognised the fact that the operating line is straight

simple graphical construction.

On an x-y diagram, the operating line is a straight line of gradient (L/V) and passes through XD, XD

Fig 31:

Fig 32:

Reflux Ratio, R = L / D V=L+D L / V = R / (R + 1) D / V = 1 - (L / V) = (R + 1 - R) / (R + 1) 1 / (R + 1)

Fig 33:

Fig 34:

Fig 35:

Lower Operating Line

L', V' may be different from L, V m.v.c. balance L' xm = V' Ym-1 + W Xw Ym-1 = (L' / V') Xm - (W/V') Xw This material balance is a straight line passing through the point (Xw,Xw) The intersection of the upper and lower operating lines is determined by the feed.

Importance of the feed

The feed should be introduced where the appropriate stream in the column has the same composition as the feed. The thermodynamic state of the feed determines the relationships between L' and L and V' and V

Different States of the Feed

1. Saturated Liquid, i.e. at bubble temperature

2. Saturated Vapour, i.e. at dew temperature

3. Two-Phase Feed

Summary of McCabe Thiele Construction

Fig 39:

Plot equilibrium line Draw 45o line Locate Distillate (XD,XD) Draw Upper Operating Line (gradient R / (R + 1)) between (XD,XD) and (D,XD/(R + 1) ) Locate bottom product (XW,XW) Locate (XF,XF) Draw "q-line" with gradient q / (q - 1) Draw lower operating line (from q-line / upper operating line intersection to (XW,XW) )

Fig 40:

The q-line

For a two phase feed (assumed in equilibrium) F hF = LF hL + VF hv where, hF = specific enthalpy of feed hL = specific enthalpy of saturated liquid hv = specific enthalpy of saturated vapour Generalize by defining q: q = Enthalpy change reqd to vaporise 1 mole of feed (change it to saturated vapour) / molar enthalpy of vaporisation = (hv - hF) / (hv - hL) Increas ing Specifi hv c Enthal hL py Superheated Vapour q<0 Saturated Vapour 2-phase feed Saturated Liquid Sub-cooled Liquid qhv - qhL = hv - hF q=0 0<q<1 q=1 q>1

hF = hv - qhv + qhL = (1-q)hv + qhL FhF = FqhL + F(1-q)hv c.f. FhF = LFhL + VFhV LF = qF and VF = (1 - q)F (q / (q - 1)) = - LF / VF Now V = V' + VF = V' + (1 - q)F and L = L' - LF = L' - qF

Rectifying Operation Line

Vyn-1 = Lxn + DxD Stripping op line V'ym-1 = L'xm - WxW Let intersection occur at ( , ) then (V - V') = (L - L') + DxD + WxW i.e. (V - V') = (L - L') + FzF from 1a, 1b (1 - q)F = -qF + FzF i.e. = (q / (q - 1)) - (zF / (q - 1)) equation of "q-line"

Straight line of gradient q / (q - 1) passing (zF, zF)

Fig 41:

Importance of Reflux Ratio

Fig 42:

Total Reflux

Fig 43:

Minimum Reflux

Fig 44:

Fig 45:

Optimum R is often 1.2 - 1.5 x Rmin

Fig 46:

Relative Volatility

Volatility = y / x Relative Volatility, AB = ( yA / xA ) / ( yB / xB )

Fig 47:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Lab Report Distillation Column PDFDocument26 pagesLab Report Distillation Column PDFGebrina RizkiaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Au5 Online Operating ManualDocument303 pagesAu5 Online Operating ManualAjesh Babu100% (1)

- Distillation The Theory-Vogelpohl, Alfons PDFDocument165 pagesDistillation The Theory-Vogelpohl, Alfons PDFAlexis Alatorre AlbaNo ratings yet

- Distillation ReportDocument17 pagesDistillation ReportSebastian PinzonNo ratings yet

- Distillation Column Design ReportDocument27 pagesDistillation Column Design ReportUsama Akram100% (1)

- AGE10503, Gas ProcessingDocument34 pagesAGE10503, Gas ProcessingiranmortezaNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeNo ratings yet

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengeNo ratings yet

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengeNo ratings yet

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengeNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeNo ratings yet

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengeNo ratings yet

- Kroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFDocument32 pagesKroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFPortia ShilengeNo ratings yet

- Milling Multotec ProjectDocument15 pagesMilling Multotec ProjectPortia ShilengeNo ratings yet

- Derrick Screen ProjectDocument15 pagesDerrick Screen ProjectPortia ShilengeNo ratings yet

- Ball Mills For Blue Ridge PDFDocument2 pagesBall Mills For Blue Ridge PDFPortia ShilengeNo ratings yet

- Preconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterDocument20 pagesPreconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterPortia ShilengeNo ratings yet

- UAE University College of Engineering Training and Graduation Project UnitDocument100 pagesUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeNo ratings yet

- 17-Processing Iron Ore PDFDocument12 pages17-Processing Iron Ore PDFPortia Shilenge100% (1)

- 0204finalreportbrgm PDFDocument88 pages0204finalreportbrgm PDFPortia ShilengeNo ratings yet

- Mini Report of Duties Done in The Ug2 PlantDocument9 pagesMini Report of Duties Done in The Ug2 PlantPortia ShilengeNo ratings yet

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- Report in The Ug2 PlantDocument8 pagesReport in The Ug2 PlantPortia ShilengeNo ratings yet

- Laporan PertaminaDocument51 pagesLaporan PertaminaDeni HermawanNo ratings yet

- Separation ProcessesDocument57 pagesSeparation ProcessesAngelo X0% (1)

- Crude Oil DistillationDocument5 pagesCrude Oil Distillationmahmoud_k_azzamNo ratings yet

- Lecture 4 Reflux Ratio and Column DesignDocument13 pagesLecture 4 Reflux Ratio and Column DesignMohammedTalib100% (1)

- UcucucDocument97 pagesUcucucJV Custodio100% (2)

- DistillationDocument22 pagesDistillationAhmed Omar Amine100% (1)

- 3.1 Mass Transfer Equipment Design: H O CH Cooh CHDocument61 pages3.1 Mass Transfer Equipment Design: H O CH Cooh CHZAINOR SYAHIRA BINTI ZAINAL STUDENTNo ratings yet

- HYSYS Training 2013Document27 pagesHYSYS Training 2013Kokil JainNo ratings yet

- Distillation Is Defined As:: How Does Distillation Work?Document35 pagesDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarNo ratings yet

- Fundamentals Petroleum Refining CourseDocument32 pagesFundamentals Petroleum Refining Coursecivilmechanic100% (2)

- CPE 601 Distillation - Topic 5 Design of Other EquipmentDocument70 pagesCPE 601 Distillation - Topic 5 Design of Other EquipmentRosa SinensisNo ratings yet

- Design QuestionsDocument3 pagesDesign QuestionsTamil SelvanNo ratings yet

- Chemical Technology Subject Code: CH2001Document17 pagesChemical Technology Subject Code: CH2001U SANKAR TEJONo ratings yet

- Alfons Vogelpohl Distillation (2017)Document134 pagesAlfons Vogelpohl Distillation (2017)Lp PerezNo ratings yet

- 6 Crude Oil RefiningDocument57 pages6 Crude Oil RefiningAkashNo ratings yet

- Engineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberDocument7 pagesEngineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberAh WenNo ratings yet

- Shortcut Procedure Simulating Batch Distillation Operations: Suresh Sundaram Lawrence Evans'Document8 pagesShortcut Procedure Simulating Batch Distillation Operations: Suresh Sundaram Lawrence Evans'pippoNo ratings yet

- Selection of Column Type: Plate or PackedDocument52 pagesSelection of Column Type: Plate or Packedsai charanNo ratings yet

- Distillation 2Document20 pagesDistillation 2arslanadeelNo ratings yet

- Refinery All Lectures PDFDocument64 pagesRefinery All Lectures PDFHelin HassanNo ratings yet

- Petroleum Refining Processes1Document73 pagesPetroleum Refining Processes1Arun DasNo ratings yet

- Bitumen ProductionDocument5 pagesBitumen ProductionSanjeev ViswambharanNo ratings yet

- Lecture 1-Petroleum Oil Refinery ProcessesDocument120 pagesLecture 1-Petroleum Oil Refinery Processesdivyansh100% (3)

- Atmospheric Crude Distillation UnitDocument2 pagesAtmospheric Crude Distillation UnitFahmi Ramadhan PutraNo ratings yet