Professional Documents

Culture Documents

On The Squeeze Film Lubrication of Long Porous Journal Bearings With Couple Stress Fluids

On The Squeeze Film Lubrication of Long Porous Journal Bearings With Couple Stress Fluids

Uploaded by

Hamid MojiryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On The Squeeze Film Lubrication of Long Porous Journal Bearings With Couple Stress Fluids

On The Squeeze Film Lubrication of Long Porous Journal Bearings With Couple Stress Fluids

Uploaded by

Hamid MojiryCopyright:

Available Formats

Feature

On the squeeze lm lubrication of long porous

journal bearings with couple stress uids

N.B. Naduvinamani

Department of Mathematics, Gulbarga University, Gulbarga, India

P.S. Hiremath

Department of Computer Science, Gulbarga University, Gulbarga, India, and

Syeda Tasneem Fathima

Department of Mathematics, Bellary Engineering College, Bellary, India

Abstract

Purpose This paper aims to advance the squeeze lm characteristics of long partial journal bearings with couple stress uid studied by Lin to include

the effect of permeability on the squeeze lm lubrication of long partial porous journal bearings with couple stress uids.

Design/methodology/approach A semi-analytical and semi-numerical solution for the squeeze lm lubrication of long porous partial journal

bearings lubricated with couple stress uid is presented in the paper. The modied Reynolds equation governing the uid lm pressure is derived. The

modied Reynolds equation is solved analytically and closed form expressions for the squeeze lm pressure and load carrying capacity are presented.

The rst-order non-linear equation for the time-height relation is solved numerically with the given initial condition. The effect of couple stresses and

permeability on the squeeze lm characteristics are discussed.

Findings It is found that the effect of couple stresses is to increase the load carrying capacity and to lengthen the squeeze lm time as compared to

the corresponding Newtonian case. The effect of permeability is to reduce the load carrying capacity and to decrease the squeeze lm time as compared

to the corresponding solid case.

Originality/value In the design of porous partial journal bearings, the reduction in the load carrying capacity and the response time can be

compensated by the use of lubricants with proper microstructures by which the bearing life can be increased.

Keywords Lubrication, Fluids

Paper type Research paper

Nomenclature

C radial clearance

e eccentricity

h uid lm thickness, h C 2 e cos u

h non-dimensional lm thickness,

h=C 1 21 cos u

h

0

non-dimensional minimum lm thickness,

h

0

=C 1 21

H

0

thickness of the porous layer

l characteristic material length of the suspended

particles (h/m)

1/2

l couple stress parameter, l/C

p pressure in the lm region

p pressure in the porous region

p non-dimensional pressure pC

2

=mR

2

d1=dt

R radius of the journal

t response time taken by journal centre to move from

1 0 to 1

1

u,v uid velocity components in the x, and y directions,

respectively

u,v uid velocity components in the x and y directions,

respectively, in the porous region.

W load carrying capacity per unit length of the

bearing

W non-dimensional load capacity WC

2

=mR

3

d1=dt

x,y local Cartesian co-ordinates

b ratio of microstructure size to pore size h=m=k

h material constant responsible for couple stress

property

u circumferential co-ordinate

1 eccentricity ratio, e/C

m lubricant viscosity

t dimensionless response time WC

2

t=mR

3

c permeability parameter kH

0

=C

3

The Emerald Research Register for this journal is available at

www.emeraldinsight.com/researchregister

The current issue and full text archive of this journal is available at

www.emeraldinsight.com/0036-8792.htm

Industrial Lubrication and Tribology

57/1 (2005) 1220

q Emerald Group Publishing Limited [ISSN 0036-8792]

[DOI 10.1108/00368790510575941]

The authors acknowledge the nancial support under the Special

Assistance Program DRS project by the University Grants Commission,

New Delhi, India.

12

Introduction

Self-lubricating porous bearings have the advantage of

reducing the need for certain lubricating equipments (oil

pipes, pumps, etc.) as well as reducing other problems related

to lubrication mechanism. One of the advantageous feature of

the porous bearings is that, no external supply of lubricant is

required for running-in. It was Morgan and Cameron (1957)

who rst gave an analytical survey of study of porous bearings

with the aid of hydrodynamic conditions. There have been

numerous studies of various types of porous bearings, such as

slider bearings (Uma, 1977), journal bearings (Prakash and

Vij, 1974), squeeze lms (Wu, 1971) and thrust bearings

(Gupta and Kapur, 1979).

Many of the studies on porous bearings are conned to

Newtonian lubricants. But the use of non-Newtonian uids as

lubricants is of growing interest in recent times. In particular,

the addition of long chain polymer solutions to the lubricant

enhances the bearing performance. These lubricants are uids

with microstructures. The failure of the classical continuum

theory in representing the ow behaviour of such uids

adequately has led to the development of the microcontinuum

theories (Ariman et al., 1973, 1974). One of these theories is

couple stress theory proposed by Stokes (1966), which

account for the polar effects due to the presence of

microstructures in the uid. The Stokes couple stress

model describes adequately the rheological behaviour of the

lubricants with polymer additives. Many of the investigations

for the study of performance characteristics of various bearing

systems with couple stress uid are found in the literature.

The studies by Ramaniah (1979), Ramaniah and Sarkar

(1978), Bujurke and Jayaraman (1982), Bujurke and

Naduvinamani (1990), Lin (1997a b) have shown that the

effect of couple stresses is to increase the load-carrying

capacity and the response time of approach in the squeeze

lms.

Recently, Naduvinamani et al. (2001) have studied the

effect of couple stresses on the squeeze lm lubrication of

short porous journal bearings and conrmed the earlier

ndings of increased load-carrying capacity and delayed time

of approach. In the present study, the squeeze lm

characteristics of long partial journal bearings with

couplestress uid studied by Lin (1997a b) has been

advanced to include the effect of permeability on the

squeeze lm lubrication of long partial porous journal

bearings with couple stress uids.

Analysis

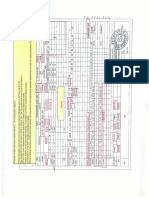

A schematic diagram of the problem under study is shown

in Figure 1. The journal of radius R approaches the

porous bearing surface at a circumferential section u with

velocity V

u

.

The lm thickness h is a function of u and is given by

h C 2 e cos u; 1

where C is the radial clearance and e is the eccentricity of the

journal centre. The lubricant in the lm region and also in the

porous region is assumed to be a Stokes (1966) couple stress

uid.

Under the usual assumptions of uid lm lubrication

applicable to thin lms (Cameron, 1987), the equation of

motion of an incompressible couple stress uid within the lm

region, when the body forces and body couples are absent, are

given by

p

x

m

2

u

y

2

2h

4

u

y

4

; 2

p

y

0; 3

u

x

v

y

0: 4

The ow of couplestress uid in a porous matrix is

governed by the modied Darcy law, which account for the

polar effects

~ q

2k

m1 2b

7p; 5

where ~ q u; v; and b h=m=k:

The ratio (h/m)

1/2

is of dimensional length and hence

characterizes the chain length of the polymer additives. Hence

the parameter b represents the ratio of the microstructure size

to the pore size. The p is the pressure in the porous region.

Owing to continuity, it satises the Laplace equation

2

p

x

2

2

p

y

2

0: 6

The relevant boundary conditions for the velocity

components are:

(1) at the boundary surface y h :

u 0; 7a

2

u

y

2

0; 7b

v 2V

u

: 7c

(2) at the porous journal surface y 0 :

u 0; 8a

2

u

y

2

0; 8b

v 2v

: 8c

The solution of equation (2) subject to the boundary

conditions (7(a) and 7(b)) and (8(a) and 8(b)) is

ux; y

1

2m

p

x

yy 2 h 2l

2

1 2

cosh2y 2 h=2l

coshh=2l

_ _ _ _

;

9

where l h=m

1=2

is the couple stress parameter.

Integrating equation (6) with respect to y over the porous

layer thickness H

0

and using the boundary conditions of solid

bearing

p

y

0

_ _

at y 2H

0

we obtain,

p

y

y0

2

_

0

2H0

2

p

x

2

_ _

dy: 10

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

13

Assuming that the porous layer thickness H

0

is very small and

using the pressure continuity condition p p at the

interface y 0 of porous matrix and uid lm, equation (10)

reduces to

p

y0

2H

0

2

p

x

2

: 11

Then, the vertical component of the modied Darcy velocity,

v at the interface y 0 is given by

v

j

y0

kH

0

1 2b

p

x

2

_ _

: 12

Integrating equation (4) across the uid lm and utilizing

boundary conditions (7(c)) and (8(c)) and expressions in (9)

and (12) in the modied Reynolds type equation is obtained

in the form

x

f h; l

12kH

0

1 2b

_ _

p

x

_ _

212mV

u

; 13

where f h; l h

3

2 12l

2

h 24l

3

tanhh=2l and

V

u

2

dh

dt

C

d1

dt

cos u:

Introducing the non-dimensional quantities:

p

pC

2

mR

2

d1=dt

; u

x

R

;

h

h

C

1 21 cos u;

l

l

C

and c

kH

0

C

3

:

Equation (13) takes the form

u

f

h;

l

12c

1 2b

_ _

p

u

_ _

212 cos u 14

where f

h;

l

h

3

2 12

l

2

h 24

l

3

tanh

h=2

l:

As the permeability parameter c !0; equation (14) reduces

to the corresponding solid case studied by Lin (1997a b).

Squeeze lm pressure

For the 1808 partial journal bearing, the boundary conditions

for the uid lm pressure are

p 0 at u ^

p

2

15a

d p

du

0 at u 0: 15b

Integrating equation (14) with respect to u and the use of

boundary conditions (15(a) and (b)) yield the non-

dimensional uid lm pressure as

p 212

_

uu

u2p=2

sin

2

u

f

h;

l

12c

12b

_ _ du: 16

Load carrying capacity

The load carrying capacity of the 1808 porous partial journal

bearing is evaluated by integrating the uid lm pressure eld

acting on the journal:

W

_

up=2

u2p=2

p cos u Rdu; 17

Figure 1 Physical conguration of porous partial journal bearing

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

14

where W represents the load carrying capacity per unit

length of the porous bearing generated by the squeeze lm

pressure.

The non-dimensional form of equation (17) is

W

WC

2

mR

3

d1=dt

12

_

up=2

u2p=2

sin

2

u

f

h;

l

12c

12b

_ _ du

g1;

l; c: 18

The closed form integration of the integrals appearing in

equations (16) and (18) is not possible and hence they are

obtained numerically.

Time-height relationship

The time taken by the journal centre to move from 1 0 to 1

1

can be obtained from equation (18) as

d1

dt

1

g1;

l; c

; 19

where

t

WC

2

mR

3

t

is the non- dimensional response time.

The rst-order non-linear differential equation (19) is

solved numerically using the fourth-order Runge-Kutta

method (Steven and Reymond, 1998) with the initial

condition

1 0 at t 0: 20

Results and discussion

The effect of permeability on the squeeze lm characteristics

of a long porous journal bearing is observed through the non-

dimensional permeability parameter c and effect of couple

stresses through the non-dimensional couple stress parameter

l: The parameter

l

h=m

_

=C is the ratio of microstructure

size to the radial clearance. Hence

l gives a mechanism of

interaction of uid with the bearing geometry. It is to be noted

that as c !0 the problem reduces to the corresponding solid

case and as

l; b !0 it reduces to the corresponding

Newtonian case.

Squeeze lm pressure

The variation of non-dimensional squeeze lm pressure p as a

function of circumferential co-ordinate u for various values of

l is shown in Figure 2 with the parametric values c 0:01 and

1 0:1:

It is observed that the effect of couple stresses is to increase

the squeeze lm pressure p as compared to the corresponding

Newtonian case. Increase in p is more pronounced for larger

values of

l: The effect of eccentricity ratio parameter 1 on

the variation of p with u is shown in Figure 3 for c 0:01

Figure 2 Non-dimensional lm pressure p as a function of u for different values of l

with c 0.01 and 1 0.1

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

15

and

l 0:2: It is observed that p increases for increasing

values of 1.

Figure 4 shows the variation of p with u for different

values of the permeability parameter c with 1 0:5 and

l 0:2:

The dotted curve in the gure corresponds to the solid case.

The effect of permeability parameter c is to decrease p as

compared to the corresponding solid case. The variation of

maximum pressure p

max

i:e: p at u 0 with c for

different values of

l is shown in Figure 5 with 1 0:5: It is

observed that p

max

increases as c decreases. This increase in

p

max

is more accentuated for larger values of

l:

Load-carrying capacity

Figure 6 shows the variation of non-dimensional load-

carrying capacity

W as a function of the eccentricity ratio

parameter 1 for the different values of

l:

It is found that

W increases for increasing values of 1. The

increase in

W for couplestress uids as compared to the

corresponding Newtonian case is observed and is more

pronounced for larger values of

l: The variation in

W with

l for

different values of c is shown in Figure 7.

It is observed that

W decreases for increasing values of

c and this decrease in

W is more accentuated for larger values

of

l:

Time-height relationship

The response time of squeeze lm is an important factor in

the design of squeeze lm bearings. This is the time elapsed to

reduce the initial lm thickness to the minimum permissible

squeeze lm height. The variation of the non-dimensional

minimum squeeze lm height

h

0

1 21 with the non-

dimensional response time t for the different values of

l is

shown in Figure 8. It is observed that the bearing with

couplestress uid as lubricant have longer response time as

compared to the Newtonian case.

Figure 9 shows the variation of

h

0

with t for different values

of c with

l 0:2: The response time of the squeeze lm t

decreases for increasing values of c. This is due to the

reduction in

W with increasing c.

Conclusions

The squeeze lm lubrication of long porous partial

journal bearings with couplestress uid is presented on the

basis of Stokes microcontinuum theory for couple stress

uids. As the permeability parameter c !0; the squeeze

lm characteristics presented in this paper agrees with

those of solid case studied by Lin (1997a b). It is found

that the effect of permeability is to reduce the non-

dimensional load-carrying capacity and to decrease the

response time as compared to the corresponding solid

case. However, the effect of couple stresses is to enhance

the load carrying capacity and to lengthen the response

time. Hence, in the design of porous partial journal

bearings, the reduction in the load carrying capacity and the

response time can be compensated by the use of lubricants

with proper microstructures by which the bearing life can

be increased.

Figure 3 Non-dimensional lm pressure p as a function of u for different values of 1 with c 0.01 and l

0.2

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

16

Figure 4 Non-dimensional lm pressure p as a function of u for different values of c with 1 0.5 and l

0.2

Figure 5 Maximum lm pressure p

max

vs c for different values of l

with 10.5

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

17

Figure 6 Non-dimensional load-carrying capacity W

vs 1 for different values of l

with c 0.01 and 1 0.1

Figure 7 Non-dimensional load-carrying capacity W

vs l

for different values of c with 1 0.3

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

18

Figure 8 Non-dimensional minimum lm height h

0

vs t for different values of l

with 10.1 and c 0.01

Figure 9 Non-dimensional minimum lm height vs t for different values of c with l

0.2

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

19

References

Ariman, T., Turk, M.A. and Sylvester, N.D. (1973),

Microcontinuum uid mechanics a review, International

Journal of Engineering Science, Vol. 11, pp. 905-30.

Ariman, T., Turk, M.A. and Sylvester, N.D. (1974),

Applications of microcontinuum uid mechanics,

International Journal of Engineering Science, Vol. 12, pp. 273-93.

Bujurke, N.M. and Jayaraman, G. (1982), The inuence of

couplestresses in squeeze lms, International Journal of

Mechanical Science, Vol. 24, pp. 369-76.

Bujurke, N.M. and Naduvinamani, N.B. (1990), The

lubrication of lightly loaded cylinders in combined rolling,

sliding and normal motion with couplestress uid,

International Journal of Mechanical Sciences, Vol. 32,

pp. 969-79.

Cameron, A. (1987), Basic Lubrication Theory, 3rd ed., Wiley

Eastern Ltd, New York, NY.

Gupta, R.S. and Kapur, V.K. (1979), Centrifugal effects in

hydrostatic porous thrust bearing, Journal of Lubrication

Technology, Vol. 101, p. 381.

Lin, J-R. (1997a), Static and dynamic behaviour of pure

squeeze lms in couple stress uids lubricated short journal

bearings, Proceedings of the Institution of Mechanical

Engineers, Vol. 211, pp. 29-36.

Lin, J.R. (1997b), Squeeze lm characteristics of long partial

journal bearings lubricated with couple stress uids,

Tribology International, Vol. 30, pp. 53-8.

Morgan, V.T. and Cameron, A. (1957), Mechanism of

lubrication in porous metal bearings, Proc. Conf. on

Lubrication and Wear, Institution of Mechanical Engineers,

London, pp. 151-7.

Naduvinamani, N.B., Hiremath, P.S. and Gurubasavaraj, G.

(2001), Squeeze lm lubrication of a short porous journal

bearings with couplestress uids, Tribology International,

Vol. 34, pp. 739-47.

Prakash, J. and Vij, S.K. (1974), Analysis of narrow porous

journal bearing using Beavers-Joseph Criteria of velocity

slip, Journal of Applied Mechanics, Vol. 41, pp. 348-54.

Ramanaih, G. (1979), Squeeze lms between nite plates

lubricated by uids with couple stresses, Wear, Vol. 54,

pp. 315-20.

Ramaniah, G. and Sarkar, P. (1978), Optimum load-

capacity of slider bearing lubricated by uids with couple

stresses, Wear, Vol. 49, pp. 61-6.

Steven, C.Chapra and Reymond, P.C. (1998), Numerical

Methods for Engineers with Programming and Software

Applications, 3rd ed., McGraw-Hill International Edition,

New York, NY.

Stokes, V.K. (1966), Couplestresses in uids, Physics of

Fluids, Vol. 9, pp. 1709-15.

Uma, S. (1977), The analysis of double-layered porous

slider bearing, Wear, Vol. 42, pp. 205-15.

Wu, H. (1971), An analysis of the squeeze lm between

porous rectangular plates, Journal of Lubrication

Technology, Paper No. 71-Lub-2.

On the squeeze lm lubrication of long porous journal bearings

N.B. Naduvinamani, P.S. Hiremath and Syeda Tasneem Fathima

Industrial Lubrication and Tribology

Volume 57 Number 1 2005 1220

20

You might also like

- (Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠDocument12 pages(Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠMauricio Solano DiazNo ratings yet

- Assignment 4 - ECE410F Linear Control Systems: Controllability and Stabilization of LTI Systems SolutionsDocument8 pagesAssignment 4 - ECE410F Linear Control Systems: Controllability and Stabilization of LTI Systems SolutionsIsrael JimenezNo ratings yet

- Elsharkawy 1996Document14 pagesElsharkawy 1996Anas SakimNo ratings yet

- Nadu Vina Man I 2001Document9 pagesNadu Vina Man I 2001Anas SakimNo ratings yet

- Nadu Vina Man I 2009Document9 pagesNadu Vina Man I 2009Anas SakimNo ratings yet

- Studies On The Influence of Surface Texture On The Performance of Hydrodynamic Journal Bearing Using Power Law ModelDocument20 pagesStudies On The Influence of Surface Texture On The Performance of Hydrodynamic Journal Bearing Using Power Law Modelatika kabouyaNo ratings yet

- Talaa Ighil PDFDocument6 pagesTalaa Ighil PDFatika kabouyaNo ratings yet

- Ijpapv13n1 13Document8 pagesIjpapv13n1 13shekhawatmahaveerNo ratings yet

- Tribology International: T.V.V.L.N. Rao, A.M.A. Rani, T. Nagarajan, F.M. HashimDocument9 pagesTribology International: T.V.V.L.N. Rao, A.M.A. Rani, T. Nagarajan, F.M. Hashimatika kabouyaNo ratings yet

- A Note On The Lubricating Film in Hydrostatic Mechanical Face SealsDocument9 pagesA Note On The Lubricating Film in Hydrostatic Mechanical Face SealsMansi JoshiNo ratings yet

- Research Article: Design and Experimental Research On Sealing Structure For A Retrievable PackerDocument15 pagesResearch Article: Design and Experimental Research On Sealing Structure For A Retrievable PackerabodolkuhaaNo ratings yet

- 1 s2.0 S0301679X11003707 MainDocument6 pages1 s2.0 S0301679X11003707 MainMert Can AKTAYNo ratings yet

- Très FULLTEXT01Document11 pagesTrès FULLTEXT01atika kabouyaNo ratings yet

- Gas Foil Bearing Analysis and The Effect of Bump Foil Thickness On Its Performance Characteristics Using A Non-Linear Matrix Equation SolverDocument17 pagesGas Foil Bearing Analysis and The Effect of Bump Foil Thickness On Its Performance Characteristics Using A Non-Linear Matrix Equation SolverAnonymous pKuPK3zUNo ratings yet

- 23-04-2021-1619172818-8-IJAMSS-5. IJAMSS - Mathematical Model of Shliomis Model Based Ferrofluid Lubricated Rough Porous Convex PadDocument10 pages23-04-2021-1619172818-8-IJAMSS-5. IJAMSS - Mathematical Model of Shliomis Model Based Ferrofluid Lubricated Rough Porous Convex Padiaset123No ratings yet

- Experimental Investigation of Oil Film Thickness For Hydrodynamic Journal BearingsDocument7 pagesExperimental Investigation of Oil Film Thickness For Hydrodynamic Journal Bearingskishorghatage89No ratings yet

- 11 Bearings2Document0 pages11 Bearings2SreenivasNo ratings yet

- Influence of Surface Texture On The Performance ofDocument14 pagesInfluence of Surface Texture On The Performance ofTao YUNo ratings yet

- Borras PaperDocument5 pagesBorras PaperFarooq NajarNo ratings yet

- DD Gear Lubrication (Post Print)Document25 pagesDD Gear Lubrication (Post Print)soxif94392No ratings yet

- Shape Optimization of A 3D Slider With DimplesDocument9 pagesShape Optimization of A 3D Slider With DimplesTarang MalvaniyaNo ratings yet

- Effect of Lubricant CompressibilityDocument17 pagesEffect of Lubricant CompressibilityTao YUNo ratings yet

- A Comprehensive Fluid-Solid Interaction Analysis of Finite Journal BearingsDocument20 pagesA Comprehensive Fluid-Solid Interaction Analysis of Finite Journal BearingsHarun SarıçamNo ratings yet

- Kha Mari 2021Document19 pagesKha Mari 2021Jitesh DhimanNo ratings yet

- Tribology International: Adesh Kumar Tomar, Satish C. SharmaDocument21 pagesTribology International: Adesh Kumar Tomar, Satish C. Sharmaatika kabouyaNo ratings yet

- Analysis of Misaligned Journal Bearing Lubrication Performance Considering The Effect of Lubricant Couple Stress and Shear ThinningDocument9 pagesAnalysis of Misaligned Journal Bearing Lubrication Performance Considering The Effect of Lubricant Couple Stress and Shear Thinningatika kabouyaNo ratings yet

- Effect of Number and Size of Recess On The Performance of H 2013 Procedia enDocument8 pagesEffect of Number and Size of Recess On The Performance of H 2013 Procedia enMelda RizkaNo ratings yet

- Analysis of Hydrodynamic Journal Bearing Using Fluid Structure Interaction ApproachDocument4 pagesAnalysis of Hydrodynamic Journal Bearing Using Fluid Structure Interaction ApproachseventhsensegroupNo ratings yet

- Tribology International: Jaw-Ren LinDocument6 pagesTribology International: Jaw-Ren LinUdaya Pratap SinghNo ratings yet

- The Effects of Couple Stress Lubricants and Surface Roughness On Squeeze EHL Motion Between Porous Medium Layer and Elastic BallDocument9 pagesThe Effects of Couple Stress Lubricants and Surface Roughness On Squeeze EHL Motion Between Porous Medium Layer and Elastic BallDineshSharmaNo ratings yet

- Experimental Investigations On The Contact Fatigue Life Under Starved ConditionsDocument8 pagesExperimental Investigations On The Contact Fatigue Life Under Starved ConditionsWilmer ContrerasNo ratings yet

- Radulescu 2017 IOP Conf. Ser.: Mater. Sci. Eng. 174 012038Document11 pagesRadulescu 2017 IOP Conf. Ser.: Mater. Sci. Eng. 174 012038gusiNo ratings yet

- Filament Wound PV Optimal DesignDocument8 pagesFilament Wound PV Optimal DesignWaseem GulNo ratings yet

- Finite Element Method For Mixed Elastohydrodynamic Lubrication of Journal-Bearing SystemsDocument32 pagesFinite Element Method For Mixed Elastohydrodynamic Lubrication of Journal-Bearing SystemskishoreNo ratings yet

- Dynamics of A Parallel, High-Speed, Lubricated Thrust Bearing With Navier Slip Boundary ConditionsDocument22 pagesDynamics of A Parallel, High-Speed, Lubricated Thrust Bearing With Navier Slip Boundary ConditionsKunal JoshiNo ratings yet

- 2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsDocument19 pages2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsClaudio BiaginiNo ratings yet

- Rahmatadi PDFDocument8 pagesRahmatadi PDFPuneet MathurNo ratings yet

- Fulltext PDFDocument21 pagesFulltext PDFJogger JamesNo ratings yet

- Effect of Micro-Dimples On Hydrodynamic Lubrication of Textured Sinusoidal Roughness SurfacesDocument8 pagesEffect of Micro-Dimples On Hydrodynamic Lubrication of Textured Sinusoidal Roughness Surfacesatika kabouyaNo ratings yet

- B.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)Document5 pagesB.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)varunNo ratings yet

- Numerical Modelling of Hydrostatic Lift Pockets inDocument9 pagesNumerical Modelling of Hydrostatic Lift Pockets inAli HegaigNo ratings yet

- LOAD INFLUENCE ON HYDROSTATIC OIL FILM JOURNAL BEARING STIFFNESS (PT Film-Rig)Document10 pagesLOAD INFLUENCE ON HYDROSTATIC OIL FILM JOURNAL BEARING STIFFNESS (PT Film-Rig)Alice MarinescuNo ratings yet

- On The Steady Performance of Externally Pressurized Spherical and Conical Bearings: Rabinowitsch Fluid ModelDocument10 pagesOn The Steady Performance of Externally Pressurized Spherical and Conical Bearings: Rabinowitsch Fluid ModelAnsal-TechnicalCampusNo ratings yet

- The Effect of Surface Texturing in Soft Elastohydrodynamic LubricationDocument8 pagesThe Effect of Surface Texturing in Soft Elastohydrodynamic Lubrication1097106323No ratings yet

- IMeche Velocity SlipDocument12 pagesIMeche Velocity SlipPranab SamantaNo ratings yet

- Effect of Strain Rate and Density On Dynamic Behaviour of Syntactic FoamDocument14 pagesEffect of Strain Rate and Density On Dynamic Behaviour of Syntactic Foambenyamin1982100% (1)

- Review On Hydrodynamic Analysis of Journal Bearing Using Computational Fluid DynamicsDocument5 pagesReview On Hydrodynamic Analysis of Journal Bearing Using Computational Fluid DynamicsMuhamad IkhsanNo ratings yet

- Analysis of Hydrodynamic Lubrication in Infinitely Long Journal Bearing With Oscillating VelocityDocument4 pagesAnalysis of Hydrodynamic Lubrication in Infinitely Long Journal Bearing With Oscillating VelocityTarang MalvaniyaNo ratings yet

- Sivam Oh An 1985Document15 pagesSivam Oh An 1985DEGAGA AMENUNo ratings yet

- A Review of Hydrostatic Bearing System: Researches and ApplicationsDocument27 pagesA Review of Hydrostatic Bearing System: Researches and ApplicationsAhmed KhairyNo ratings yet

- Pages 64Document22 pagesPages 64Jaime Magno Gutierrez RamirezNo ratings yet

- Thermohydrodynamic Analysis of A Worn Plain Journal Bearing: M. Fillon, J. BouyerDocument8 pagesThermohydrodynamic Analysis of A Worn Plain Journal Bearing: M. Fillon, J. Bouyeratika kabouyaNo ratings yet

- Static and Dynamic Analysis of Elastohydrodynamic Elliptical Journal-Nair PDFDocument9 pagesStatic and Dynamic Analysis of Elastohydrodynamic Elliptical Journal-Nair PDFPuneet MathurNo ratings yet

- Finite Element Analysis and Improved Design of Large-Scale Belt-Conveyor DrumsDocument16 pagesFinite Element Analysis and Improved Design of Large-Scale Belt-Conveyor DrumsAlejandra Hernandez SanchezNo ratings yet

- NOE0415380416 ch052Document6 pagesNOE0415380416 ch052Umed Abd-alsatarNo ratings yet

- Analysis of Hydrodynamic Journal Bearing: A Review: Priyanka Tiwari and Veerendra KumarDocument7 pagesAnalysis of Hydrodynamic Journal Bearing: A Review: Priyanka Tiwari and Veerendra KumarSridharan SekarNo ratings yet

- Gupta 2010 IJCDocument13 pagesGupta 2010 IJCMurat AltınNo ratings yet

- Bifurcation and Nonlinear Dynamic Analysis of Externally PressurizedDocument21 pagesBifurcation and Nonlinear Dynamic Analysis of Externally PressurizedLuis Alberto FuentesNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Symbolic Solutions For A Class of Partial Differential EquationsDocument10 pagesSymbolic Solutions For A Class of Partial Differential EquationsHamid MojiryNo ratings yet

- v2 PDFDocument20 pagesv2 PDFHamid MojiryNo ratings yet

- Analytical Probability Density Functions For Lms Adaptive Filters Using The Fokker-Planck EquationDocument4 pagesAnalytical Probability Density Functions For Lms Adaptive Filters Using The Fokker-Planck EquationHamid MojiryNo ratings yet

- 337 345 PDFDocument9 pages337 345 PDFHamid MojiryNo ratings yet

- Solution of Nonlinear Oscillators Using Global Error Minimization MethodDocument8 pagesSolution of Nonlinear Oscillators Using Global Error Minimization MethodHamid MojiryNo ratings yet

- A Subclass of Quasi Self Adjoint Lubrication Equations: Conservations LawsDocument8 pagesA Subclass of Quasi Self Adjoint Lubrication Equations: Conservations LawsHamid MojiryNo ratings yet

- Pure Soliton Solutions of Some Nonlinear Partial Differential EquationsDocument8 pagesPure Soliton Solutions of Some Nonlinear Partial Differential EquationsHamid MojiryNo ratings yet

- The Solution of Second-Order Partial Differential EquationsDocument121 pagesThe Solution of Second-Order Partial Differential EquationsHamid MojiryNo ratings yet

- A Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesDocument5 pagesA Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesHamid MojiryNo ratings yet

- M. Tech. Computer Aided DesignDocument42 pagesM. Tech. Computer Aided DesignHamid MojiryNo ratings yet

- A Cartesian Grid Method For Solving The Two-Dimensional Streamfunction-Vorticity Equations in Irregular RegionsDocument45 pagesA Cartesian Grid Method For Solving The Two-Dimensional Streamfunction-Vorticity Equations in Irregular RegionsHamid MojiryNo ratings yet

- High Order Discontinuous Galerkin Method For Elastohydrodynamic Lubrication Line Contact ProblemsDocument7 pagesHigh Order Discontinuous Galerkin Method For Elastohydrodynamic Lubrication Line Contact ProblemsHamid MojiryNo ratings yet

- Prod CoursesofstudyDocument26 pagesProd CoursesofstudyHamid MojiryNo ratings yet

- Ding Shu Tang (IJNME) 2005Document17 pagesDing Shu Tang (IJNME) 2005Hamid MojiryNo ratings yet

- MSP 3407D, MSP 3417D Multistandard Sound Processors: MicronasDocument60 pagesMSP 3407D, MSP 3417D Multistandard Sound Processors: MicronasHamid MojiryNo ratings yet

- Determination of Moisture Content (AOAC, 1999)Document0 pagesDetermination of Moisture Content (AOAC, 1999)Hamid MojiryNo ratings yet

- A Generalized Differential Quadrature Solution For Laminated Composite Shells of RevolutionDocument2 pagesA Generalized Differential Quadrature Solution For Laminated Composite Shells of RevolutionHamid MojiryNo ratings yet

- The Backward-Tracking Lagrangian Particle Method For Transient Viscoelastic FlowsDocument34 pagesThe Backward-Tracking Lagrangian Particle Method For Transient Viscoelastic FlowsHamid MojiryNo ratings yet

- Methods Based On The Differential Quadrature in Vibration Analysis of PlatesDocument17 pagesMethods Based On The Differential Quadrature in Vibration Analysis of PlatesHamid MojiryNo ratings yet

- Efficient Numerical Method For Computation of Thermohydrodynamics of Laminar Lubricating FilmsDocument25 pagesEfficient Numerical Method For Computation of Thermohydrodynamics of Laminar Lubricating FilmsHamid MojiryNo ratings yet

- Ding-Shu (JCP 2005)Document24 pagesDing-Shu (JCP 2005)Hamid MojiryNo ratings yet

- IntroDocument28 pagesIntroHamid MojiryNo ratings yet

- Chen - Shu Et Al (Computers & Structures) 2000Document12 pagesChen - Shu Et Al (Computers & Structures) 2000Hamid MojiryNo ratings yet

- Journal of Computational Physics: J. Wu, C. ShuDocument21 pagesJournal of Computational Physics: J. Wu, C. ShuHamid MojiryNo ratings yet

- CH 09 Part SolutionDocument10 pagesCH 09 Part SolutionHamid MojiryNo ratings yet

- Stock April 2020Document5 pagesStock April 2020roby aldiNo ratings yet

- Detailed Lesson Plan DLP Format DATE LeaDocument4 pagesDetailed Lesson Plan DLP Format DATE LeaPablo JimeneaNo ratings yet

- As 1330-2004 Metallic Materials - Drop Weight Tear Test For Ferritic SteelsDocument7 pagesAs 1330-2004 Metallic Materials - Drop Weight Tear Test For Ferritic SteelsSAI Global - APACNo ratings yet

- 4.3 - B - 7 - Procedure For OHS Management ProgrammeDocument3 pages4.3 - B - 7 - Procedure For OHS Management ProgrammeSASIKUMAR SNo ratings yet

- Theory of Automata and Formal Languages: Instructor: Dr. Muhammad JehanzebDocument27 pagesTheory of Automata and Formal Languages: Instructor: Dr. Muhammad JehanzebKiran ZamanNo ratings yet

- Current Transformer - PACT RCP-4000A-1A-D95 - 2904921: Key Commercial DataDocument4 pagesCurrent Transformer - PACT RCP-4000A-1A-D95 - 2904921: Key Commercial DataЮрий ЛобановNo ratings yet

- VDB3722MA Driver With Microstep Série NovaDocument16 pagesVDB3722MA Driver With Microstep Série NovaJefferson Alcantara GomesNo ratings yet

- Pakistan Studies HSSC-II Model Question PaperDocument6 pagesPakistan Studies HSSC-II Model Question PaperNomikha 4545No ratings yet

- Forensic Chemistry and ToxicologyDocument2 pagesForensic Chemistry and ToxicologyDE GUZMAN VONNo ratings yet

- Earthing Design Calculation 380/110/13.8kV SubstationDocument19 pagesEarthing Design Calculation 380/110/13.8kV Substationhpathirathne_1575733No ratings yet

- Coring Techniques & ApplicationsDocument24 pagesCoring Techniques & ApplicationsSuleiman BaruniNo ratings yet

- Astrolabe Free Chart From HTTP - AlabeDocument2 pagesAstrolabe Free Chart From HTTP - AlabeArijit AcharyaNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- PVC Cable Color Code ChartDocument1 pagePVC Cable Color Code ChartMiabNo ratings yet

- Models Used Must Be Appropriate For Transient Stability AnalysisDocument6 pagesModels Used Must Be Appropriate For Transient Stability AnalysisadauNo ratings yet

- Arun ProformaDocument2 pagesArun ProformaRitesh DassNo ratings yet

- Der DirectoryDocument262 pagesDer DirectoryBenNo ratings yet

- Belzona 1311Document2 pagesBelzona 1311Bobby SatheesanNo ratings yet

- Activity Heal The Environmentpermentilla-Michael-Ray-E.Document1 pageActivity Heal The Environmentpermentilla-Michael-Ray-E.Michael Ray PermentillaNo ratings yet

- Chief Minister's Good Governance Fellowship: Case Study Questions For Shortlisted CandidatesDocument20 pagesChief Minister's Good Governance Fellowship: Case Study Questions For Shortlisted CandidatesRajeev SagiNo ratings yet

- Advancement in Energy Storage DevicesDocument9 pagesAdvancement in Energy Storage Devicesash200459No ratings yet

- Soft StarterDocument7 pagesSoft Starterdvmreddy1232007No ratings yet

- Canal SystemsDocument69 pagesCanal SystemsAnter TsatseNo ratings yet

- Camlin Research MrthodologyDocument17 pagesCamlin Research MrthodologyArnav DuttaNo ratings yet

- EBenefits Life Events White PaperDocument21 pagesEBenefits Life Events White PaperRahul VemuriNo ratings yet

- TE1 Terminal CircuitDocument2 pagesTE1 Terminal Circuitcelestino tuliaoNo ratings yet

- Ives - Stilwell Experiment Fundamentally FlawedDocument22 pagesIves - Stilwell Experiment Fundamentally FlawedAymeric FerecNo ratings yet

- Take Note:: Miracle Light Christian Academy Casilagan, City of Ilagan, Isabela Mathematics 8Document4 pagesTake Note:: Miracle Light Christian Academy Casilagan, City of Ilagan, Isabela Mathematics 8Dennis PacursaNo ratings yet