Professional Documents

Culture Documents

03 Welding Imperfections 29-11-03

03 Welding Imperfections 29-11-03

Uploaded by

bizhanjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 Welding Imperfections 29-11-03

03 Welding Imperfections 29-11-03

Uploaded by

bizhanjCopyright:

Available Formats

THE WELDING INSTITUTE

Welding Imperfections:

What are welding imperfections?

Welding imperfections are material discontinuities caused by, or during, the process of welding. All things contain imperfections, but it is only when they fall outside of a level of acceptance that they should be termed defects, as they may render the product defective, or unfit for its purpose. As welds can be considered as castings they may contain all kinds of imperfections associated with the casting of metals, plus any other particular imperfections associated with the specific welding process being used. Welding imperfections can be classified as follows: 1) 3) 5) 7) Cracks Solid inclusions Surface and profile Misalignment 2) 4) 6) Gas pores and cavities Lack of fusion Mechanical/Surface damage

1)

Cracks:

Cracks sometimes occur in welded materials, and may be caused by a great number of factors. Generally, we can say that for any crack like imperfection to occur in a material, there are 3 criteria that must be present: a) A force b) Restraint c) A weakened structure

Typical types of hot and cold cracks that will be discussed later in the course are: 1) H2 Cracks 2) Solidification Cracks 3) Lamellar Tears

A Materials likelihood to crack during welding can be evaluated under the term Weldability. This may be defined as: The ease with which materials may be welded by the common welding processes All cracks have sharp edges, which produce high stress concentrations. This generally results in rapid progression, however this also depends on the properties of the metal. Cracks are classed as planar imperfections as they generally have only 2 visible, or measurable dimensions i.e. length and depth. Most fall into the defects category, though some standards will allow a degree of so called crater, or star cracking.

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 1

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

2)

Gas pores, porosity and cavities:

Gas pores: These are defined as singular gas filled cavities < 1.6mm diameter, which are created during final solidification by expulsion of gases from solution in solidifying weld metal. Porosity: Porosity is a term used to describe a collection, or area of gas pores. These areas may be classified by their number, size and grouping of the pores within the area. (i.e. Fine, or coarse cluster porosity) Porosity is mainly produced when welding improperly cleaned plate, or when using damp welding consumables. Gases may also be formed by the breakdown of paints, oil based products, corrosion or anti corrosion products that have been left on the plates to be welded. A singular gas filled cavity = or > 1.6mm diameter is termed a blow hole Porosity can be frequently formed during the MIG or TIG process by the temporary loss of gas shield, and ingress of air into the arc column. This may be caused by movement of the surrounding atmosphere, or wind. Porosity may also be caused by improper settings of shielding gas flow rate. Gas pores may also be break the welds surface where they are collectively known as surface porosities. Porosity may also found in deep Sub Arc welds due to the distance that trapped gases formed in the root area need to travel to escape from the surface, and may also occur when using damp MMA welding electrodes, or damp Sub Arc Fluxes. Porosity may be prevented by correct cleaning of materials, correct setting and shielding when using the TIG or MIG welding processes, and using dry welding consumables. Porosity may generally be identified on a radiograph as a spherical imperfection that has varying density shades, from highest in the centre, decreasing to its outer edges i.e. Surface breaking cluster porosity Coarse cluster porosity Blow hole > 1.6 mm

Shrinkage cavity Fine cluster porosity

Hollow root bead Shrinkage cavities: These are internal voids, or cavities that are formed during the solidification of single welds of high depth to width ratio (d:w) as with SAW or MIG. They may be defined as a hot plastic tears caused by opposing contractional strains. Shrinkage cavities produce high stress concentrations at their sharp edges, and are thus generally treated as cracks.

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 2

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

3)

Solid inclusions:

Solid inclusions include metallic and non-metallic inclusions that may be trapped in the weld during the process of welding. The type of solid inclusion that may be expected is really dependant on the welding process being used. In welding processes that use fluxes to form all the required functions of shielding and chemical cleaning, such as MMA and Submerged Arc welding, slag inclusions may occur. Other welding processes such as MIG and TIG use silicon, aluminium and other elements to de-oxidise the weld. These may form silica, or alumina inclusions. Any of these non-metallic compounds may be trapped inside a weld during welding. This often happens after slag traps, such as undercut have been formed. Slag traps are mostly caused by incorrect welding technique. Metallic inclusions include tungsten inclusions that may be produced during TIG welding by a poor welding technique, an incorrect tungsten vertex angle, or too high amperage for the diameter of tungsten being used. Copper inclusions may be caused during MIG/MAG welding by a lack of welding skill, or incorrect settings in mechanised, or automated MIG welding. (Mainly welding Aluminium alloys) Other welding phenomena such arc blow or the deviation of the electric arc by magnetic forces, can cause solid inclusions to be trapped in welds. The locations of these inclusions may be within the centre of a deposited weld, or between welds where the result causes Lack of inter-run fusion, or at the sidewall of the weld preparation causing Lack of side wall fusion Generally solid internal inclusions may be caused by: 1) 2) 3) 4) 5) 6) Lack of welder skill. (Incorrect welding technique) Poor manipulation of the welding process, or electrode. Incorrect parameter settings, i.e. voltage, amperage, speed of travel. Magnetic arc blow. Incorrect positional use of the process, or consumable. Incorrect inter-run cleaning.

Surface breaking solid inclusion Internal solid inclusion causing a lack of inter-run Internal solid inclusion causing fusion a lack of sidewall fusion

Internal solid Solid inclusions from base metal undercut in the root run, or hot pass (Slag traps)

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 3

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

4)

Lack of fusion:

Lack of fusion imperfections, are defined as a lack of union between two adjacent areas of material. This may be accompanied, or caused by other imperfections as explained in the last section. Lack of fusion can be considered a serious imperfection, as like cracks, they produce areas of high stress concentration. Lack of fusion, or overlap (a form of lack of fusion) may occur in the weld face area during positional welding caused by the action of gravity and incorrect use of the process. Arc blow is a prime cause of lack of fusion imperfections, particularly when using high current processes, such as Sub Arc using high direct electric currents. (DC+ or DC -) Lack of fusion may also be formed in the root area of the weld where it may be found on one, or both plate edges. It may also be accompanied by incomplete root penetration. Lack of fusion is also a common imperfection in Dip transfer MIG welding of metals over 3mm thickness, especially when welding vertically down. This is caused by the inherent coldness of this form of metal transfer, and the action of gravity. Like solid inclusions, lack of fusion imperfections may be caused by: 1) 2) 3) 4) 5) 6) 7) Lack of welder skill. (Incorrect welding technique) Poor manipulation of the welding process, or electrode. Incorrect parameter settings, i.e. voltage, amperage, speed of travel. Magnetic arc blow. Incorrect positional use of the process, or consumable. Incorrect inter-run cleaning. Incorrect or non-feathered tack welds. (Lightly ground prior to welding)

Lack of sidewall fusion (Also causing an Incompletely filled groove)

Overlap (Causing a Cold laps)

Lack of inter-run Lack of sidewall fusion Lack of root fusion

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 4

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

5)

Surface and profile:

Surface and profile imperfections are generally caused by poor welding techniques. This includes the use of incorrect welding parameters, electrode/blowpipe sizes and/or manipulation and joint set up. This category may be split into two further groups of weld face and weld root. Surface and profile imperfections are shown pictorially in A & B below:

A:

Spatter is not a major factor in lowering the weldments strength, though it may mask other imperfections, and should therefore be cleaned off before inspection. Spatter may also hinder NDT and be detrimental to coatings. It can also cause micro cracking or hard spots in some materials due to the localised heating/quenching effect. An incompletely filled groove may bring the weld below its DTT. It is a major stress concentration when accompanied by lack of sidewall fusion. Lack of root fusion causes a serious stress concentration to occur in the root. It may also render the root area more susceptible to corrosion in service

Spatter An Incompletely filled groove

Lack of root fusion

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 5

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

B:

A bulbous contour is an imperfection as it causes sharp stress concentrations at the toes of individual passes and may also contribute to overall poor toe blend Arc strikes, Stray-arcing, or Stray flash may cause many problems including several types of cracks to occur. They can also cause depressions in the plate bringing it below its DTT. Arc strikes would normally be NDT inspected and then repaired. Incomplete root penetration may be caused by too small a root gap, insufficient amperage, or poor welding technique. It also causes high stress concentrations to occur. It also generally produces a weld with less throat thickness than the DTT of the joint.

Bulbous contour Arc Strikes Poor toe blend

Incomplete root penetration bead

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 6

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

C: An irregular bead width is a surface imperfection, which is often referenced in application standards as. The weld bead should be regular along its linear length

Undercut: Undercut can be defined as a depression at the toe of a weld in a previous deposited weld, or base metal, caused by welding. Undercut is generally caused by incorrect welding technique, including the use of too high a current for the electrode being used, and the welding position. It is often caused in the top toe of fillet welds when attempting to produce a large leg length fillet weld in one run. Undercut can also be considered a serious imperfection particularly if it is sharp, as again it causes high stress concentrations. It is gauged in severity by its length, depth and sharpness. Parent metal, surface undercut

Parent metal, top toe undercut

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 7

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

Weld metal, surface undercut

Root Run or Hot Pass undercut

Shrinkage grooves: Shrinkage grooves may occur in the root area and are caused by contractional forces pulling on the hot plastic base metal in the root area. It is often mistakenly termed as root undercut. Shrinkage grooves

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 8

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

Root concavity: (Suck back) This may be caused when using too high a gas backing pressure in purging. It may also be produced when welding with too large a root gap and depositing too thin a root bead, when the hot pass may pull back the root bead through contractional strains.

Root concavity

Excess penetration: Often caused by using too high a welding current, and/or, slow travel speed, coupled with a large root gap, and/or a small root face for the current or process being used. It is often accompanied by burn through, which can be defined as a local collapse of the weld puddle causing a hole, or depression in the final weld root bead. Root oxidation: Root oxidation may take place when welding re-active metals such as stainless steels with contaminated, or inadequate purging gas flow. Incompletely fused Tack Welds: It is often a procedural requirement for tack welds to be feathered (Lightly ground and blended) prior to welding. This requirement is mainly dependent upon the class of work. Feathering should enable the tack welds to be more easily fused and thus more smoothly blended into the root/penetration bead during welding. Failure to achieve this correctly may result in a degree of lack of root fusion/penetration occurring in the weld root run. An un-feathered root tack weld Adjacent un-smooth area showing a lack of root fusion and/or root penetration

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 9

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

Crater pipes: This often occurs during TIG welding in the crater at the end of a weld run during final solidification. It is caused by insufficient filler material to meet the solidification process and can be eliminated by applying adequate filler metal, or using a slope out control.

Crater pipe

Root oxidation in Stainless Steel

Excess root penetration bead This may lead to a burn through A local collapse of the weld pool leaving a hole in the root area.

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 10

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

To summarize, we can list surface or profile welding imperfections as follows: 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) Incompletely filled grove/lack of fusion. Spatter. Arc strikes. (Stray arcs) Incomplete root penetration. Lack of root fusion. Bulbous or irregular contour. Poor toe blend. Irregular bead width. Undercut. (Weld and Base metal) Root concavity. Root shrinkage grooves. Excess penetration. Burn through. Root oxidation.

6)

Mechanical/Surface damage:

Mechanical/Surface damage: This can be defined as any surface material damage caused during the manufacturing process, or in-service conditions. This can include damage caused by: 1) 3) 5) 7) Grinding. Hammering. Chiselling. Corrosion. 2) 4) 6) Chipping. Braking off welded attachments by hammering. Using needle guns to compress weld capping runs.

As with the stray arcing, the above imperfections can be detrimental as they reduce the through thickness dimension of the plate in that area. They can cause local stress concentrations and should be repaired prior to completing the job.

Chisel Marks

Pitting Corrosion

Grinding Marks

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 11

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

7)

Misalignment:

There are 2 main forms of misalignment in plate materials, which are termed: 1) Linear misalignment. 2) Angular misalignment.

Linear misalignment: can be controlled during weld set up by the correct use/control of the weld set up technique i.e. tacking, bridging, clamping etc. Excess weld metal height and the root penetration bead are always measured from the lowest plate to the highest point of the weld metal, as shown below. Excess weld metal height

3 mm Linear misalignment measured in mm Angular misalignment: may be controlled by the correct application of distortion control techniques, i.e. balanced welding, offsetting, or use of jigs, clamps, etc.

15 Angular misalignment measured in degrees

Hi-Lo is a term that is generally used to describe the unevenness across the root faces between pipes found during setting up for welding. This unevenness is often caused by an un-matching and/or irregular wall thickness, or between pipes having any degree of ovality. It is not a term that should be used when describing misalignment in plates.

Hi-Lo

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 12

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

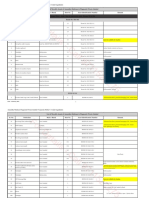

Summary of Welding Imperfections:

Group

1) Cracks

Type

Centreline H2 Lamellar Tears Porosity Gas pore < 1.6mm Blow hole > 1.6mm Shrinkage cavity Slag MMA/SAW Silica TIG/MAG(Fe steels) Tungsten TIG Copper (MIG/MAG) Lack of side wall fusion (Can be surface breaking) Lack of root fusion Cold lapping Poor toe blend Arc Strikes Incomplete penetration Incompletely filled groove Spatter Bulbous contour Undercut: Surface and internal Shrinkage groove (Root) Root concavity Excess Penetration Burn through Crater Pipes (Mainly TIG) Hammer/Grinding marks etc. Angular Misalignment () Linear Misalignment (mm) Hi-Lo (mm) Only in pipe

Causes/Location

Weld Metal Weld Metal & HAZ Base metal Damp electrodes Un-cleaned plates/pipes Loss of gas shield Weld metal (high d:w) Poor Inter-run cleaning Slag traps. Arc blow Dipping tungsten in pool Dipping contact tip in pool Arc Blow Incorrect welding technique Non feathering of tack welds Positional welding technique Incorrect welding technique Poor welding technique < Root gap/Amps. > Root face Incorrect welding technique Damp consumables Incorrect welding technique Too high an amperage Poor welding technique Contractional strains Too high gas pressure > Root gap/Amps < Root face Incorrect current decay Poor workmanship Poor fit-up. Distortion Poor fit-up. Irregular pipe wall, or ovality

2) Porosity/Cavities

3) Solid Inclusions

4) Lack of Fusion

5) Surface & Profile

6) Mechanical damage 7) Misalignment

Notes: The causes given in the above table should not be considered as the only possible causes of the imperfection given, but as an example of a probable cause. Good working practices and correct welder training will minimise the occurrence of unacceptable welding imperfections, or welding defects.

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 13

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

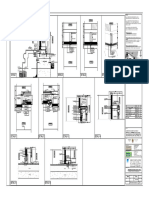

Identify and name the following Welding Imperfections:

(As indicated within the ovals) 1 A 2 A

3 A

4 A

5 A

6 A

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 14

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

9 A

10

11 A

12 A B

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 15

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

13

14

A A

15 A

16

17 A B

18

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 16

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

THE WELDING INSTITUTE

Solutions:

Page 3:14

1. 2. 3. 4. 5a. 6a. Weld metal undercut Lack of root fusion Root concavity Incomplete root penetration Lack of sidewall fusion Slag inclusion 5b 6a Cold lap (Bulbous contour) Base metal undercut

Page 3:15

7. 8. 9. 10. Pitting Corrosion Lack of sidewall fusion with an incompletely filled groove Spatter Bulbous contour with a Poor toe blend 11b. 12b. Lack of root fusion Weld metal undercut

11a. Arc strikes 12a. Base metal undercut

Page 3:16

13. 14. 15. 16. Chisel marks Incompletely filled groove with a bulbous contour Shrinkage grooves Burn through 17b. 18b. Undercut (In the top toe) Burn through

17a. Spatter 18a. Excess root penetration bead

Welding Inspection of Steels WIS 5 Section 03 Welding Imperfections Rev 09-09-03 Copyright 2003, TWI Ltd

3. 17

WORLD CENTRE FOR MATERIALS JOINING TECHNOLOGY

You might also like

- A Study Into The Effects of Residual Stresses and Hot Dip GalvanizingDocument4 pagesA Study Into The Effects of Residual Stresses and Hot Dip GalvanizingSteve HornseyNo ratings yet

- Welddefects As Per Iso 5817Document40 pagesWelddefects As Per Iso 5817shruthiNo ratings yet

- A General Review of Geometric Shape ImperfectionsDocument12 pagesA General Review of Geometric Shape Imperfectionsbipete69No ratings yet

- Welding Imperfection Part 1Document18 pagesWelding Imperfection Part 1amit4709No ratings yet

- Chemical Composition - Is 2062 - Anx - BDocument2 pagesChemical Composition - Is 2062 - Anx - BTuhin Subhra Mondal100% (4)

- Wis5 TermsDocument29 pagesWis5 Termsravi00098No ratings yet

- Hashemite University - NDT Overview PDFDocument7 pagesHashemite University - NDT Overview PDFgeorgescribd1103No ratings yet

- Visual TestingDocument1 pageVisual TestingAnonymous GE8mQqxNo ratings yet

- Weld GaugesDocument15 pagesWeld GaugesHaleemUrRashidBangashNo ratings yet

- Welding NotesDocument39 pagesWelding NotesSabir JadejaNo ratings yet

- Welding Gauges PDFDocument4 pagesWelding Gauges PDFsopan kharcheNo ratings yet

- Impact Hardness TestDocument7 pagesImpact Hardness TestAse Sharew100% (1)

- 008a.rtfi - AbbrevationsDocument2 pages008a.rtfi - AbbrevationsVivekanandan JNo ratings yet

- The Importance of Visual Welding InspectionDocument4 pagesThe Importance of Visual Welding Inspectionhekayat71No ratings yet

- Qap Wo 7 r0 (Ion Exchange)Document1 pageQap Wo 7 r0 (Ion Exchange)KailasNo ratings yet

- Welding R1Document49 pagesWelding R1proxywarNo ratings yet

- Welding Gauge: Crown Height Fillet Weld Leg HeightDocument1 pageWelding Gauge: Crown Height Fillet Weld Leg Heightabhics67No ratings yet

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- Control Distortion During Design StageDocument5 pagesControl Distortion During Design StagebalamuruganNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipeashokkahirwar100% (1)

- Ultrasonic NotesDocument5 pagesUltrasonic NotesannapoornaavulaNo ratings yet

- How To Read Welding GaugesDocument8 pagesHow To Read Welding Gaugeservikas34No ratings yet

- Weldingdefects 150915053459 Lva1 App6892Document22 pagesWeldingdefects 150915053459 Lva1 App6892Star GlacierNo ratings yet

- Casting Material CA15BASD PDFDocument4 pagesCasting Material CA15BASD PDFAditya GuptaNo ratings yet

- Is 2062Document2 pagesIs 2062niketpatel3121No ratings yet

- Weld DefectsDocument47 pagesWeld DefectsPratikNo ratings yet

- Defects - Solidification Cracking - Job Knowledge 44Document3 pagesDefects - Solidification Cracking - Job Knowledge 44tuanNo ratings yet

- TDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticDocument6 pagesTDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticPrakash RajNo ratings yet

- Welding Procedures (Overview)Document11 pagesWelding Procedures (Overview)Luis LugoNo ratings yet

- Preheating and Post Weld Heat TreatmentsDocument3 pagesPreheating and Post Weld Heat TreatmentssubrataNo ratings yet

- Job Knowledge 68Document8 pagesJob Knowledge 68Mehmet Soysal100% (1)

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayNo ratings yet

- Shielded Metal Arc Welding Electrodes: Chapter ObjectivesDocument8 pagesShielded Metal Arc Welding Electrodes: Chapter ObjectivesWilly UioNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- Preheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Document6 pagesPreheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Rakesh RanjanNo ratings yet

- How To Prevent Control Welding DistortionDocument2 pagesHow To Prevent Control Welding DistortionNilesh DalviNo ratings yet

- The ASME Impact Test RequirementDocument7 pagesThe ASME Impact Test Requirementrosli2503No ratings yet

- Arc - Wleding Final ExamDocument13 pagesArc - Wleding Final ExamJhonalyne Estioco CamachoNo ratings yet

- Pressure Test Report: Observation Inspection Checked Reviewed Cleared ResultsDocument1 pagePressure Test Report: Observation Inspection Checked Reviewed Cleared ResultsKarthikNo ratings yet

- Welding Notes 1Document4 pagesWelding Notes 1api-440145703No ratings yet

- HeadDocument1 pageHeadabdulloh_99No ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- MTI Friction Welding Brochure PDFDocument60 pagesMTI Friction Welding Brochure PDFemirNo ratings yet

- Measuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInDocument5 pagesMeasuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInnkvonNo ratings yet

- NDT-Basic-FormulaeDocument3 pagesNDT-Basic-FormulaeJayeshNo ratings yet

- ABout Preheat Before WeldingDocument2 pagesABout Preheat Before WeldingHary Olya AdriansyahNo ratings yet

- Defects and Discontinuities: Boiler and Mechanical PowerDocument78 pagesDefects and Discontinuities: Boiler and Mechanical PowerthejusNo ratings yet

- All 24.05.16Document139 pagesAll 24.05.16Siva Prasad100% (1)

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- Distortion Prevent and ControlDocument14 pagesDistortion Prevent and ControlTheAnh TranNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- WeldingDocument193 pagesWeldingavutu_kunduruNo ratings yet

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 pageGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNo ratings yet

- Normalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionDocument3 pagesNormalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionAnonymous izrFWiQNo ratings yet

- Chap 9-SMAW Beads Fillet WeldsDocument47 pagesChap 9-SMAW Beads Fillet WeldsSally Java SenayoNo ratings yet

- 03 Welding Imperfections 30-03-07 (2Document20 pages03 Welding Imperfections 30-03-07 (2geokovoorNo ratings yet

- Welding Defects Causes & SolutionsDocument30 pagesWelding Defects Causes & SolutionsAkshay Kumar100% (1)

- Significance of Defects in WeldsDocument9 pagesSignificance of Defects in Weldsssk48100% (1)

- Welding Defect: Hydrogen EmbrittlementDocument8 pagesWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinNo ratings yet

- Updating BaselinesDocument1 pageUpdating BaselinesbizhanjNo ratings yet

- Updating Activities Using Apply Actuals / Update ProgressDocument5 pagesUpdating Activities Using Apply Actuals / Update ProgressbizhanjNo ratings yet

- Weld Defects TWIDocument96 pagesWeld Defects TWISabir Shabbir100% (7)

- PronunciationDocument166 pagesPronunciationSteven Donahue94% (52)

- Primavera P6 ManualDocument230 pagesPrimavera P6 ManualDionne Solito MonteloyolaNo ratings yet

- Introduction To L Tex: A Document Preparation System: Produced With L TEX by G Baker and G MoloneyDocument34 pagesIntroduction To L Tex: A Document Preparation System: Produced With L TEX by G Baker and G MoloneybizhanjNo ratings yet

- Business Process Modeling Notation (BPMN)Document18 pagesBusiness Process Modeling Notation (BPMN)Sophia HasanNo ratings yet

- Tools For Systems Thinking and Modeling: Dynamics: Graphs Over Time Structure: Causal-Loop DiagramsDocument38 pagesTools For Systems Thinking and Modeling: Dynamics: Graphs Over Time Structure: Causal-Loop DiagramsbizhanjNo ratings yet

- Systems Causal LoopsDocument44 pagesSystems Causal LoopsbizhanjNo ratings yet

- SD2Document23 pagesSD2bizhanjNo ratings yet

- ABM by Helbing and BaliettiDocument47 pagesABM by Helbing and BaliettibizhanjNo ratings yet

- TQM-Literature Review by Ahire Et Al 1995Document30 pagesTQM-Literature Review by Ahire Et Al 1995bizhanj100% (2)

- Ar 2030 Kte 9 TXDocument4 pagesAr 2030 Kte 9 TXbizhanjNo ratings yet

- Coverage CalculationDocument1 pageCoverage CalculationbizhanjNo ratings yet

- SAErotorsDocument2 pagesSAErotorsRAHUL_AGRAWALNo ratings yet

- IARPA - Catalyst Entity Extraction & Disambiguation StudyDocument122 pagesIARPA - Catalyst Entity Extraction & Disambiguation StudyImpello_TyrannisNo ratings yet

- Operating System AdministrationDocument6 pagesOperating System AdministrationRahulsrivasNo ratings yet

- Dynamic PumpsDocument38 pagesDynamic PumpsShayn Shayn100% (3)

- ME 180 OB CurriculumDocument179 pagesME 180 OB CurriculumOm GujarNo ratings yet

- Sr. No. Particulars Make / Brand Item No. Asset Identification Number Remark List of Movable Assets of Anoushka Medicare & Diagnostic Private LimitedDocument49 pagesSr. No. Particulars Make / Brand Item No. Asset Identification Number Remark List of Movable Assets of Anoushka Medicare & Diagnostic Private LimitedAJEET KUMARNo ratings yet

- BOL1219 A Leaflet190109Document2 pagesBOL1219 A Leaflet190109servicibsNo ratings yet

- Factsheet M21Document8 pagesFactsheet M21TANASEGMIHAINo ratings yet

- Difference Between Struts 1 and Struts 2 FrameworkDocument3 pagesDifference Between Struts 1 and Struts 2 FrameworkmihirhotaNo ratings yet

- CC-VT230W QS-M ENG v1 PDFDocument18 pagesCC-VT230W QS-M ENG v1 PDFSunil RaoNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- SD.010 S D: XXX - InventoryDocument67 pagesSD.010 S D: XXX - InventoryNitaiChand DasNo ratings yet

- Hyster H05 BrochureDocument8 pagesHyster H05 BrochureAziz DarwishNo ratings yet

- Latex CodeDocument10 pagesLatex CodeNakulGhateNo ratings yet

- Scheme & Cost of Gis ProjectDocument2 pagesScheme & Cost of Gis Projectahmad idhanNo ratings yet

- Example Problems (Chapter-5)Document22 pagesExample Problems (Chapter-5)Updirahman MohamoudNo ratings yet

- Setup Thunder Bird Using Davmail To Access Outlook Web AccessDocument12 pagesSetup Thunder Bird Using Davmail To Access Outlook Web Accessegrodrig20082275No ratings yet

- SrilankaDocument17 pagesSrilankamax0% (1)

- Ground Floor GW 07Document1 pageGround Floor GW 07MiteshSuneriyaNo ratings yet

- Books4career - Full List (15.10.2012)Document173 pagesBooks4career - Full List (15.10.2012)matsiengNo ratings yet

- Example Beam ProblemDocument2 pagesExample Beam ProblemxicaodocetNo ratings yet

- 3.3 Heat and Humidity - Psychrometers and Psychrometric CalculationsDocument14 pages3.3 Heat and Humidity - Psychrometers and Psychrometric CalculationsDeepakKattimaniNo ratings yet

- 31 Waves ReflectionDocument2 pages31 Waves Reflectioneltytan100% (1)

- 1 s2.0 S2214785323023027 MainDocument5 pages1 s2.0 S2214785323023027 MainArun KarthickNo ratings yet

- Installation and Operation Manual: Proact™ Itb Integrated Actuator and Throttle BodyDocument26 pagesInstallation and Operation Manual: Proact™ Itb Integrated Actuator and Throttle BodyNimNo ratings yet

- Wilo 455160Document2 pagesWilo 455160Reya Medical DesignNo ratings yet

- Mountain and Agricultural SettlementsDocument66 pagesMountain and Agricultural SettlementsArianne Joy Quiba DullasNo ratings yet

- ABB Electrical Wiring AccessoriesDocument2 pagesABB Electrical Wiring Accessoriesവർഗീസ് ജോസഫ്0% (1)

- LUBCON Printing ServicesDocument2 pagesLUBCON Printing ServicesOmin PostingNo ratings yet

- Field Test - Vane Shear TestDocument2 pagesField Test - Vane Shear Testhavocsnsd0% (1)