Professional Documents

Culture Documents

Ultrasonic Thickness Gauge

Ultrasonic Thickness Gauge

Uploaded by

carlosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Thickness Gauge

Ultrasonic Thickness Gauge

Uploaded by

carlosCopyright:

Available Formats

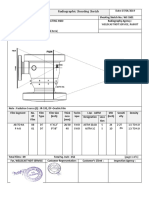

ISO 9001

ULTRASONIC THICKNESS GAUGE TT100/110/120/130

Features:

Portable size and easy operation Suitable for any metallic and non-metallic materials ultrasonic can go through Self-compensating of nonlinearity function is supplied for correction of pickup nonlineasity 10 measuring values recorded optional 2.5MHz, 5MHz and 7MHz transducers are available Clear 4-Digit LCD display with backlight 5 pre-set sound velocities for repeating applications mm / inch selectable TT100 and TT130 are suitable for thickness testing of various materials with sound speed range 1000-9999m/s TT110 and TT120 are easy-operation models with only two keys suitable for thickness testing of steel TT120: high-temperature model with range up to 300

TT100

TT110

TT120

TT130

Technical Specification

TT100 Measuring range Measuring range for steel pipes Diameter of transducer Display resolution Calibration Tolerance Measuring units Sound velocity range Display Surface temperature Battery indicator Power supply Working time Dimensions Weight 126mm 1000-9999m/s 4-Digital LCD with backlight -10 to +60 10 (standard) 0.1mm 4.0mm steel base plate integrated (1%H+0.1) mm (H means the thickness of tested piece) mm/inch 5900 m/s 4-Digital LCD -10 to +300 -10 to +60 1000-9999m/s TT110 TT120 TT130 Standard delivery Main unit 5MHz transducer 5MHz/90 transducer ZW5P high temperature transducer for TT120 Integrated steel calibration plate 4.0mm Batteries AA 1.5V Couplant TIME Certificate Warranty card Instruction manual Optional accessories Optional transducers (See page 29) 1 1 1 1 1 2 1 1 1 1

0.75 -300.00mm (steel) 20 3.0mm 12(optional) 0.01mm

6 (optional)

Low battery voltage indication 2 Pcs. AA batteries 1.5V 250 hours 68mm 23mm

Approx. 250g including batteries 25

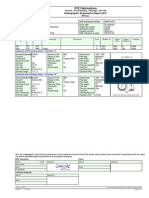

ULTRASONIC THICKNESS GAUGE TT300/300A/310/320/340

Features:

ISO 9001

Advanced handheld ultrasonic thickness gauge Suitable for most metallic and non-metallic materials ultrasonic can go through Auto-calibration of zero point, correction of system error Display current thickness or minimum thickness (menu selectable) Upper-lower limits setting and sound alarm Memory of 500 readings Two point calibration for high accuracy Display resolution 0.1mm/0.01mm selectable TT300/TT300A TT310 Display in mm or inch Large LCD display with adjustable backlight Low battery indicator TT300: Equipped with RS232 interface for connecting with printer and PC with optional software. 5P 10 transducer for normal purpose and optional TSTU32 transducer for casting iron TT300A: Can be equipped with low frequency transducer for thickness testing of thin work piece, and auto-calibration is avaible TT310: Economical model with easy operation TT320: high-temperature model with range up to 300 TT340: equipped with TSTU32 transducer for TT320 TT340 casting iron

Technical Specification

TT300 Measuring range 1.2-225.0mm (steel) TT300A 0.75-225.0mm (steel) TT310 1.2-225.0mm (steel) TT320

1.2-225.0mm (steel) 5.0-80.0mm(steel, high-temp)

TT340 1.2-225.0mm (steel)

Tolerance Measuring range of steel pipes Display resolution Data output Sound velocity Power supply Battery life Sound speed Measuring units Dimensions Weight Surface temperature Dimensions

0.5%H+0.01mm 1% H +0.1mm (H means the thickness (H means the thickness of tested piece) of tested piece) 20mm x 3.0mm 0. 1/0.01mm or 0.01/0.001inch RS232 15mm x 2.0mm 20mm x 3.0mm 0.01mm/0.001inch

1% H +0.1mm (H means the thickness of tested piece)

20mm x 3.0mm 0. 1mm / 0.01inch 1000m/s~9999m/s

2pcs AA batteries (2pcs) 1.5V 100 hours without backlight 1000m/s~9999m/s mm/inch 152mm 370g 250g -10 ~ +60 152mm 26 74mm -10 35mm 74mm 35mm 370g ~ +300 -10 ~ +60

ISO 9001

ULTRASONIC THICKNESS GAUGE TT300/310/320/340

Dataview for TT300

Standard delivery Main unit Transducer 5P 10 Transducer ZW5P for TT320 Transducer TSTU32 for TT340 Rubber jacket Couplant Batteries AA 1.5V Screwdriver Instruction manual TIME certificate Warranty card Optional accessories Optional transducers (See page 29) Printer TA230(see page 47) Dataview software for TT300 1 1 1 1 1 1 2 1 1 1 1

27

ULTRASONIC THICKNESS GAUGE TT500

Features:

ISO 9001

A scan thickness measuring, easy for users to identify the measuring errors by analyzing the waveform on screen Function of echo-echo measurement is available. It is used for measuring the distance between echo to echo, and thus users will get to know the thickness of steel plate even though it is covered by coating, such as inspection of oil tanks Min. and Max. mode function is supplied for users to find out the Min. (or Max.) value from a group of measuring results. it is very useful for inspecting the wall thickness of pipes and pressure vessels D-value mode function. It comprises normal D-value mode and percentage D-values mode. It will enhance operators working efficiency greatly. Specially, users working with exact and changeless process requirements will benefit from TT500 immensely Large memory up to 100 A-scan images and 10000 thickness values Manual gain adjustment/auto gain selectable Up and low limits alarm is available

Technical Specification

Measuring range Sound speed Scanning mode Gain range Rectification Testing mode Resolution Memory Communication Printer 0.75~508.00mm 1000~9999m/s A scan 20~70db step: 1db Positive half wave, negative wave, full wave, and RF Standard mode: testing from primary pulse to the first echo Testing between two echoes Standard: 0.01 low: 0.1 100 A scan graphs and 10000 thickness values in 100 groups RS232 port to PC or printer TP UP-NH-S thermal printer 1. when resolution is 0.01mm and thickness H<10mm, the tolerance is 0.05mm Tolerance (steel) 2. when resolution is 0.01mm and thickness H the tolerance is (0.5%H 0.01mm) 3. when resolution is 0. 1mm, the tolerance is (1%H 0.1mm) 1. 20mm 3.0mm tolerance is less than (resolution =0.01mm, 5MHz transducer) 2. 20mm 3.0mm tolerance is less than (resolution =0. 1mm, 5MHz transducer) 1KHz 0 ~40 127 38mm 234 1Kg 28 0.1mm 0.2mm 10mm, Optional Accessory Optional transducers (See page 29) Printer TP UP-NH Standard Delivery Main unit Battery Couplant Transducer 5P 10 Protection case Instruction manual Warranty card TIME certificate 1 1 1 2 1 1 1 1

Low limits for steel pipes

Pulse frequency Working temperature Dimensions Weight

ISO 9001

ULTRASONIC THICKNESS GAUGE OPTIONAL ACCESSORIES

Optional Transducers

5P 10 for TT1 series and TT3 series

5P 10 /90 for TT1 series

5P 10 /90 for TT3 series

7P 6 for TT1 series

ZW5P for TT120 and TT320

SZ2.5P for TT1 series

TSTU32 for TT300 & TT340

5P 10 for TT500

5P 10 /90

for TT500

7P 6 for TT500

ZW5P for TT500

Transducer Parameters

Transducer 5P 10 5P 10/90 7P 6 ZW5P SZ2.5P TSTU32 Feature Standard straight Standard angle Small diameter High-temperature High penetration High penetration Testing range 1.2~225.0mm(steel) 1.2~225.0mm(steel) 0.75~60mm, 15 2.0mm (steel) 5.0~80.0mm (steel) 3.0~300.3mm (steel) 5.0~40.0mm (cast iron) Contacting diameter 10mm 10mm 6mm 12mm 12mm 22mm Frequency 5MHz 5MHz 7MHz 5MHz 2.5MHz 2MHz Tested surface temperature -10 -10 -10 -10 -10 -10 ~+60 ~+60 ~+60 ~+300 ~+60 ~+60

Guideline to standard velocity in materials Metals (m/sec)

Aluminum Brass Cast iron Copper Cadmium Chromium 6260 4640 4500 4700 2800 6200 Gold Inconel Iron Lead Manganese Magnesium 3240 5720 5900 2200 4700 6310 Nickel Platinum Silver Steel, mild Steel, low carbon Steel, stainless 5630 3960 3600 5900 5850 5790 Tin Titanium Tungsten Zinc Zirconium 3230 6070 5400 4200 4650

Tungsten carbon 5650

Non-metals (m/sec)

Acrylic Resin Ceramic Diamond Epoxy resin Glass 2730 5631 17500 2650 5440 Ice Neoprene Nylon Paraffin Perspex Plexi glass 3980 1600 2620 2200 2850 2700 Polyamide Polyethylene Polyurethane Polystyrene Porcelain PVC 2380 1900 1900 2400 5600 2400 Rubber (butyl) 1900 Rubber (soft) 1450 Rubber (vulc.) 2300 Silicone rubber 948 Teflon Water (20 ) 1350 1480 Aluminum oxide 8700

29

You might also like

- Handbook of Science and Technology Studies Sheila Jasanoff, Gerald E. Markle, James C. Peterson, Trevor J. Pinch (Eds.) - Handbook of Science and Technology Studies-SAGE Publications (2001)Document849 pagesHandbook of Science and Technology Studies Sheila Jasanoff, Gerald E. Markle, James C. Peterson, Trevor J. Pinch (Eds.) - Handbook of Science and Technology Studies-SAGE Publications (2001)Jhon Henry Camargo Aleman100% (2)

- Wheeled Coach2Document2 pagesWheeled Coach2Rachelle Lim-Magtanggol67% (3)

- OPUS SOP - Overall SchematicDocument1 pageOPUS SOP - Overall SchematicValentin Andrenoiu0% (1)

- (Ultrasonic Thickness Gauging) : ProcedureDocument8 pages(Ultrasonic Thickness Gauging) : ProcedureARUNNo ratings yet

- U.T ProcedureDocument10 pagesU.T ProceduretreyX67No ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Ultrasonic Testing Training (UT) : Level-IIDocument8 pagesUltrasonic Testing Training (UT) : Level-IIAn IkhrandiNo ratings yet

- ISO-TC135-SC7-WG9 N0024 Review of ISO TR 25107 ISO TR 2510Document253 pagesISO-TC135-SC7-WG9 N0024 Review of ISO TR 25107 ISO TR 2510jbrizuelasanchez4706No ratings yet

- Weld Scanning ProcedureDocument5 pagesWeld Scanning ProcedureLutfi IsmailNo ratings yet

- Ultrasonic Thickness Gaging: by Tom NelliganDocument4 pagesUltrasonic Thickness Gaging: by Tom NelliganCarlos BustamanteNo ratings yet

- 020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedDocument35 pages020-NDT - TSE - UT - ASME B31.3 - 20 - Ultrasonic, REV 00 (1) - CompressedPT PUTRA SETIAWAN PRIMANo ratings yet

- M022 Jsa For Magnetic Penetration TestDocument4 pagesM022 Jsa For Magnetic Penetration TestYahafis MaulanaNo ratings yet

- B-Scan Buggy Demo ProcedureDocument12 pagesB-Scan Buggy Demo ProcedureJuan Ricardo Villanueva ReañoNo ratings yet

- 4#600 Body RSSDocument1 page4#600 Body RSSRavi patelNo ratings yet

- Beam ToolDocument4 pagesBeam TooldarouichNo ratings yet

- RT Pratical Exam FormulasDocument2 pagesRT Pratical Exam FormulasKartik SharmaNo ratings yet

- RT TechniqueDocument3 pagesRT TechniquesubhashpkdNo ratings yet

- NDT RT NDS1Document46 pagesNDT RT NDS1naganathanNo ratings yet

- Interpretation of EN 1712 Acceptance CriteriaDocument4 pagesInterpretation of EN 1712 Acceptance CriteriaYuzi VengamNo ratings yet

- ASTM-E1961 - 16 (Reapproved 2021)Document7 pagesASTM-E1961 - 16 (Reapproved 2021)Mohamed AboelkhierNo ratings yet

- Radiation Safety Program 2Document16 pagesRadiation Safety Program 2Ahmed shabanNo ratings yet

- Inspection Technologies Brochure English 5Document19 pagesInspection Technologies Brochure English 5Agus WiyantoNo ratings yet

- Linearity of Equipment GainDocument4 pagesLinearity of Equipment GainReezman MalkeNo ratings yet

- FCPG-00000-CPP143-00-QA-6050-00011-002 - RT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00011-002 - RT Procedurem.rasheed400010No ratings yet

- 23-10-16 UT Thickness Fire ExtinguisherDocument1 page23-10-16 UT Thickness Fire ExtinguisherAmranNo ratings yet

- Partial List of ISO SpecificationsDocument4 pagesPartial List of ISO Specificationsskynyrd75No ratings yet

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- QA-NDT-12 ET DNV Classification Note 7Document13 pagesQA-NDT-12 ET DNV Classification Note 7Colin-James Lowe100% (1)

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Cal BlocksDocument2 pagesCal BlocksRamy HusseinNo ratings yet

- Iso 12715:2014-06 (E)Document1 pageIso 12715:2014-06 (E)thejusNo ratings yet

- PAUTDocument2 pagesPAUTAnonymous tBFZZ5UDNo ratings yet

- Gray Shades PDFDocument1 pageGray Shades PDFbgonzalez1981No ratings yet

- E428Document6 pagesE428valentinNo ratings yet

- AC7114-4 Rev M Final EDITORIAL 2DECDocument60 pagesAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneNo ratings yet

- ATTAR Student Handbook LatestDocument13 pagesATTAR Student Handbook LatestRahul PatelNo ratings yet

- Pentrmeter SpecificationDocument30 pagesPentrmeter SpecificationJayeshNo ratings yet

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingGulfnde Industrial ServicesNo ratings yet

- NDTSNTDocument20 pagesNDTSNTEugenia Le FosseNo ratings yet

- Procedure Qualification Requirements For Flaw SizingDocument2 pagesProcedure Qualification Requirements For Flaw SizingAngelTinocoNo ratings yet

- Inspection Trends (January 2013 Vol. 16 No. 1)Document28 pagesInspection Trends (January 2013 Vol. 16 No. 1)Patrick DominguezNo ratings yet

- TFM SNT Level 2 CourseDocument1 pageTFM SNT Level 2 Courserichard ortegaNo ratings yet

- Testing by Radiography On Welded Mild Steel (NDT Method)Document5 pagesTesting by Radiography On Welded Mild Steel (NDT Method)IJSTENo ratings yet

- Defect Examples of AUT ScanDocument17 pagesDefect Examples of AUT ScanLương Hồ VũNo ratings yet

- 08 Omniscan ConventionsDocument11 pages08 Omniscan ConventionsLương Hồ VũNo ratings yet

- 0455e - Welding Inspector Visual Acuity Record PDFDocument1 page0455e - Welding Inspector Visual Acuity Record PDFAbu HanifaNo ratings yet

- SIUI Industrial Ultrasonic Products PDFDocument13 pagesSIUI Industrial Ultrasonic Products PDFShahbaz AhmadNo ratings yet

- DMS 2 Thickness Gauge TrainingDocument34 pagesDMS 2 Thickness Gauge TrainingcarlosNo ratings yet

- En 14096-1 Final DraftDocument11 pagesEn 14096-1 Final Draftrizwankhanzhi100% (1)

- Regulatory Guide: June, 2019 PNRA-RG-904.06 (Rev.0)Document40 pagesRegulatory Guide: June, 2019 PNRA-RG-904.06 (Rev.0)Shahbaz AhmadNo ratings yet

- To FDDocument4 pagesTo FDDong Hyun KangNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- Epoch 650Document8 pagesEpoch 650andrewgeorgecherianNo ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Ultrasonic Angle-Beam Contact Testing: Standard Practice ForDocument9 pagesUltrasonic Angle-Beam Contact Testing: Standard Practice ForNubia BarreraNo ratings yet

- Se 213Document6 pagesSe 213S.K.AGRAWALNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- Ultra Conic Thickness Gauge Tt110Document3 pagesUltra Conic Thickness Gauge Tt110kmats7770No ratings yet

- Coating Thickness GaugeDocument5 pagesCoating Thickness GaugecarlosNo ratings yet

- HOMMEL TESTER T500 Technical DataDocument1 pageHOMMEL TESTER T500 Technical DataJageNo ratings yet

- Zetec Ultravision EC DatasheetDocument2 pagesZetec Ultravision EC Datasheetcarlos0% (1)

- Winter 2018 Registration FormDocument1 pageWinter 2018 Registration FormcarlosNo ratings yet

- Aero Fab Catalog 2014Document23 pagesAero Fab Catalog 2014carlosNo ratings yet

- HDV Accessories: Videoscope Camera Probes & AccessoriesDocument1 pageHDV Accessories: Videoscope Camera Probes & AccessoriescarlosNo ratings yet

- Eddyliner PX User ManualDocument146 pagesEddyliner PX User ManualcarlosNo ratings yet

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- RotoUTscan v8Document2 pagesRotoUTscan v8carlosNo ratings yet

- VM Products Gain Test Box2Document16 pagesVM Products Gain Test Box2carlos100% (1)

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedDocument6 pagesSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- AAR Manual of StandardsDocument40 pagesAAR Manual of StandardsKristian Marchena100% (3)

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 pagesSetup Guide No 4 Weld Inspection WeldcheckcarlosNo ratings yet

- NDT MarketplaceDocument1 pageNDT MarketplacecarlosNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- 4.omniscan Setup - Min-Wheel Encoder SetupDocument13 pages4.omniscan Setup - Min-Wheel Encoder SetupcarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- OmniSX MX2 Training 4B Phased Array ProbesDocument49 pagesOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- 55 Demag PipeDocument2 pages55 Demag PipecarlosNo ratings yet

- OmniSX MX2 Training 4C Phased Array WedgesDocument37 pagesOmniSX MX2 Training 4C Phased Array WedgescarlosNo ratings yet

- 2.a.omniscan Setup - Calibration For Sectorial ScanDocument34 pages2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- OmniSX MX2 Training 4A PA Calculator OverviewDocument10 pagesOmniSX MX2 Training 4A PA Calculator OverviewcarlosNo ratings yet

- Model BLR-1™ Blue Light RadiometerDocument1 pageModel BLR-1™ Blue Light RadiometercarlosNo ratings yet

- OmniSX MX2 Training 7 UT ConfigurationDocument29 pagesOmniSX MX2 Training 7 UT Configurationcarlos100% (2)

- ISONIC UtPod Operating Manual Revision 1 - 12Document72 pagesISONIC UtPod Operating Manual Revision 1 - 12carlosNo ratings yet

- PA Probes Specs Zion NDTDocument1 pagePA Probes Specs Zion NDTcarlosNo ratings yet

- Hobart AWS Auto Wrapper Operator ManualDocument72 pagesHobart AWS Auto Wrapper Operator ManualRic WagonerNo ratings yet

- Isl 88731Document1 pageIsl 88731JahmoNo ratings yet

- Change ManagementDocument130 pagesChange ManagementAnum Akmal67% (3)

- Samsung DVD-E232 - 235 - 335 - 435Document12 pagesSamsung DVD-E232 - 235 - 335 - 435videoson100% (1)

- M/E Item Qty Unit: MBU BUDGET 2020-2021Document13 pagesM/E Item Qty Unit: MBU BUDGET 2020-2021Shiftmanager PICTNo ratings yet

- Pre Test StructureDocument6 pagesPre Test Structurespawn19840% (1)

- Current Information and Advancement About The Solar SystemDocument6 pagesCurrent Information and Advancement About The Solar SystemEnz Ognilla71% (7)

- rsm370h1f 20169 (R20160901)Document17 pagesrsm370h1f 20169 (R20160901)bilalNo ratings yet

- Standards of MeasurementDocument12 pagesStandards of MeasurementShubham KheraNo ratings yet

- Package QueryDocument51 pagesPackage QuerySiddiq MohammedNo ratings yet

- TSC List of Correspondents 2019 - SHIPPING 2Document191 pagesTSC List of Correspondents 2019 - SHIPPING 2Alvin BernardoNo ratings yet

- ht26rt oDocument280 pagesht26rt oمحمد مباركNo ratings yet

- New Part CatalogueDocument68 pagesNew Part CatalogueDimas Hani Nurfalah100% (1)

- P180 Vs K350 PiaggioDocument2 pagesP180 Vs K350 PiaggiototalityNo ratings yet

- Belt FrictionDocument5 pagesBelt FrictionShah NawazNo ratings yet

- Power Plant Control and Instrumentation SpecificationDocument119 pagesPower Plant Control and Instrumentation SpecificationpingoliaNo ratings yet

- PV 48Document12 pagesPV 48thierrylindoNo ratings yet

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Deloitte Digital - Front-End DeveloperDocument3 pagesDeloitte Digital - Front-End DeveloperLolNo ratings yet

- Two Stroke AircraftDocument10 pagesTwo Stroke AircraftVinti Bhatia100% (1)

- Vane Motors - 21,6 To 37,5 CM /R (1.32 To 2.29 in /R) : Characteristics EfficiencyDocument7 pagesVane Motors - 21,6 To 37,5 CM /R (1.32 To 2.29 in /R) : Characteristics EfficiencysyediliyassikandarNo ratings yet

- Mongolia RS - GIS International Conference AgendaDocument3 pagesMongolia RS - GIS International Conference AgendaMGiSNo ratings yet

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Golay CodesDocument50 pagesGolay CodesdshgjklopNo ratings yet

- ZD Company PresentationDocument38 pagesZD Company Presentationcheng xinxianNo ratings yet

- Data Structures Through C++: Chapter - 1 1.1. C++ Class Overview-Basic Oop ConceptsDocument31 pagesData Structures Through C++: Chapter - 1 1.1. C++ Class Overview-Basic Oop ConceptsajNo ratings yet

- Navy Children School Class Xii (Physics) Holiday HomeworkDocument2 pagesNavy Children School Class Xii (Physics) Holiday HomeworkAditya JyotiNo ratings yet