Professional Documents

Culture Documents

Daily Points To Recall (Day 2) : Professional Training and Consultation

Daily Points To Recall (Day 2) : Professional Training and Consultation

Uploaded by

raobabar21Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Points To Recall (Day 2) : Professional Training and Consultation

Daily Points To Recall (Day 2) : Professional Training and Consultation

Uploaded by

raobabar21Copyright:

Available Formats

Professional Training and Consultation

Dammam

API 653 Preparatory 26 Feb 3 Mar 2005, Page 1 of 5

DAILY POINTS TO RECALL (DAY 2)

1. According to API 653, Repairs means any work necessary to maintain or restore the safe operating conditions (as per original design). Alteration means any work that changes the dimensions and/or configuration of tank (changing original safe operating conditions). Authorized inspection agency is any one of the following (who employ API tank inspector): a. b. c. d. 3. 4. An owner operator Subcontractor to owner operator Inspection organization of jurisdiction Inspection organization of insurance company

2.

Break-over point means area of tank bottom where settlement begins. Change of service means change in fluid stored and having different specific gravity or corrosivity or different temperature or pressure. Critical zone means portion of tank bottom within 3 inches of shell inside and measured radically inwards. Repair organization means any of the following who carries out repairs / alterations according to API 653. a. b. c. Owner-user Subcontractor to owner-user Subcontractor authorized or approved by jurisdiction

5. 6.

7.

Tank roof plates which are so corroded that there are through holes or the average thickness is less than 0.09 inch in any 100 sq. inch area, then plates must be repaired or replaced, i.e., tank cannot be permitted to continue operation.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_5/166701753.doc 8/23/2013 / 21:25:43 a8/p8 /NCD

Professional Training and Consultation

Dammam

API 653 Preparatory 26 Feb 3 Mar 2005, Page 2 of 5

DAILY POINTS TO RECALL (DAY 2)

8.

If tank service is to be changed resulting in increase of internal pressure or operation above 90 C (200 F), then requirements of API Appendix F and M must be fulfilled respectively. If service changes lower temperature then material must be suitable as per impact test requirements of API 650. Tank shell evaluation: 5 step method. a. b. Determine the minimum thickness (t2) at corroded area. Calculate vertical critical length L for tank diameter D (in ft.) L=3.7 c. d.

9.

Dt

or

40 whichever is less

Determine t1 which is minimum of tav (tav is average thickness of at least 5 readings over weakest L) Determine t min by formula, tmin = 2.6 local area. Or tmin = 2.6

DHG for SE

D ( H 1)G for full shell course. SE

Take S from Table 4-1 of API 653 code. e. (i) (ii) Then t1 tmin + (CR x interval), and t2 0.6 x tmin + (CR x interval) if conditions (i) and (ii) are okay accept. If no repair, or replace or reduce the liquid height till repair/ replacement can be done.

10.

Widely scattered pits can be ignored if:

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_5/166701753.doc 8/23/2013 / 21:25:43 a8/p8 /NCD

Professional Training and Consultation

Dammam

API 653 Preparatory 26 Feb 3 Mar 2005, Page 3 of 5

DAILY POINTS TO RECALL (DAY 2)

a. b. No pit depth results in shell thickness being less than half the required thk excluding C. A. Sum of pit dimensions along any vertical line does not exceed 2 inches in a total length of 8.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_5/166701753.doc 8/23/2013 / 21:25:43 a8/p8 /NCD

Professional Training and Consultation

Dammam

API 653 Preparatory 26 Feb 3 Mar 2005, Page 1 of 5

DAILY POINTS TO RECALL (DAY 2)

11. Minimum thickness for bottom plates is given by: a. b. c. 12. Anular plates (product sp. gr. < 1.0): Table 4-3 (API 653) (Product sp. gr. 1.0): Table 3-1 (API 650) Other bottom plates: Table 6-1 (API 653)

Min. thickness in critical zone is smaller of:(but not less than 0.1) a. Half of original bottom thickness in critical zone, and b. Half of tmin for first shell course. Tanks designed prior to API 650 (7th edition, 1980) may be assessed for brittle failure as per Fig. 5.2.

13. 14.

Tanks are not likely to fail in brittle failure if thickness is not more than or shell temperature is not less than 60 F or stress level is less than 7,000 psi. ---------------------------------------- End ------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_5/166701753.doc 8/23/2013 / 21:25:43 a8/p8 /NCD

You might also like

- FM 1614 FRC Pipe and Fittings For UG FP Service 2017Document28 pagesFM 1614 FRC Pipe and Fittings For UG FP Service 2017andyNo ratings yet

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Ipa 510 Ad 2Document3 pagesIpa 510 Ad 2Santiago Cordova AlvaNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Chlorine Liquefaction ReportDocument12 pagesChlorine Liquefaction ReportPavithran50% (2)

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Daily Exam 1 (Open) : Professional Training and ConsultationDocument4 pagesDaily Exam 1 (Open) : Professional Training and ConsultationShaalan AliNo ratings yet

- Api 653 Exam 2018Document21 pagesApi 653 Exam 2018Akram AlhaddadNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocument7 pagesAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.No ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- Api 653 Daily Points To Recall (Day 3)Document2 pagesApi 653 Daily Points To Recall (Day 3)Naveed Ahmed100% (1)

- 4 API 653 AST Inspector CourseDocument4 pages4 API 653 AST Inspector CourseshaajiNo ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhNo ratings yet

- Open Book Testing - API 653Document9 pagesOpen Book Testing - API 653EdisonCorderoNo ratings yet

- Daily Exam 7 (Closed) : Professional Training and ConsultationDocument5 pagesDaily Exam 7 (Closed) : Professional Training and ConsultationCss SfaxienNo ratings yet

- Design and Analysis of Above-Ground Full Containment LNG Storage TanksDocument6 pagesDesign and Analysis of Above-Ground Full Containment LNG Storage TanksrodrigoperezsimoneNo ratings yet

- Daily Points To Recall (Day 3) : API 653 PreparatoryDocument2 pagesDaily Points To Recall (Day 3) : API 653 PreparatoryMohammed ShakilNo ratings yet

- API Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionDocument14 pagesAPI Standard 653, Tank Inspection, Repair, Alteration, and ReconstructionSaqib KhanNo ratings yet

- Prep Material QB-576Document5 pagesPrep Material QB-576Raheem Khan100% (1)

- API 653 PC 15may04 Exam 2 ClosedDocument8 pagesAPI 653 PC 15may04 Exam 2 ClosedShaalan AliNo ratings yet

- Welding Qualification Quiz: Api 653 Preparatory CourseDocument5 pagesWelding Qualification Quiz: Api 653 Preparatory CoursemiteshNo ratings yet

- Daily Points To Recall (Day 1) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 1) : Professional Training and ConsultationshakeelahmadjsrNo ratings yet

- Asme Ix: API 653 PREPARATION/ Question N°08 Close Book ResponsesDocument4 pagesAsme Ix: API 653 PREPARATION/ Question N°08 Close Book ResponseskorichiNo ratings yet

- SP001 03Document14 pagesSP001 03fahad34No ratings yet

- API 510 PC 20 31 Aug05 Mid Session OpenDocument7 pagesAPI 510 PC 20 31 Aug05 Mid Session OpenCss SfaxienNo ratings yet

- 13.2015 Development and Validation of A Leak Before Break Criterion For Cylindrical Pressure VesselsDocument12 pages13.2015 Development and Validation of A Leak Before Break Criterion For Cylindrical Pressure VesselsArun KumarNo ratings yet

- Examen de Evaluación API 510Document10 pagesExamen de Evaluación API 510aecf_13100% (1)

- Ipc2022-87301 The State of Dent Screening and Shape-Based AssessmentsDocument6 pagesIpc2022-87301 The State of Dent Screening and Shape-Based AssessmentsOswaldo MontenegroNo ratings yet

- Chattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFDocument10 pagesChattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFRenan Gustavo PazNo ratings yet

- Sulfuric Acid Sulfur Storage Tank InspectionsDocument36 pagesSulfuric Acid Sulfur Storage Tank InspectionsMohamed ZezoNo ratings yet

- Sodium Leak Through Pin HolesDocument9 pagesSodium Leak Through Pin HolesAvinash ChittellaNo ratings yet

- Api653 Question N°06 ResponsesDocument3 pagesApi653 Question N°06 ResponseskorichiNo ratings yet

- RULE 1160 - BoilerDocument24 pagesRULE 1160 - Boilerteddy tavaresNo ratings yet

- Closed Book PortionDocument5 pagesClosed Book Portionvishal bailurNo ratings yet

- Sandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Document80 pagesSandia National Laboratories API-653 In-Service Tank Inspection and Evaluation TANK ID: 981-A2-T0 (West)Manokaran Ramalingam100% (1)

- API 653 PC 15may04 Exam 3 OpenDocument5 pagesAPI 653 PC 15may04 Exam 3 Openraobabar21No ratings yet

- API 510 Data Sheets - Misc. Oth Quizlet 3Document1 pageAPI 510 Data Sheets - Misc. Oth Quizlet 3ads_1203No ratings yet

- API 510 Exam May 2021Document30 pagesAPI 510 Exam May 2021Ahmed ShakirNo ratings yet

- API 653 Round-2023Document6 pagesAPI 653 Round-2023Mohammed YoussefNo ratings yet

- FILLER WIRE-COuNTRY COMPAREDocument55 pagesFILLER WIRE-COuNTRY COMPAREJR MohanNo ratings yet

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- API 1104 Interpretations July 2022Document45 pagesAPI 1104 Interpretations July 2022FrancoNo ratings yet

- 7030 - Data SheetsDocument12 pages7030 - Data SheetsBrian CaseNo ratings yet

- KubotaDocument12 pagesKubotaFebri Ramdani NugrahaNo ratings yet

- Api 653 Preparatory Important Open Book Questions: Professional Training and ConsultationDocument1 pageApi 653 Preparatory Important Open Book Questions: Professional Training and ConsultationShaalan AliNo ratings yet

- FFS On Nozzles Weld Defect INDOCOR MigasDocument22 pagesFFS On Nozzles Weld Defect INDOCOR MigasRDS FDSNo ratings yet

- Tank SettlementDocument6 pagesTank SettlementkorichiNo ratings yet

- Astm C133Document6 pagesAstm C133Teddy HariyantoNo ratings yet

- Api 653 Quiz-3Document3 pagesApi 653 Quiz-3rajuajiNo ratings yet

- EKS 936 2024 FinalDocument1 pageEKS 936 2024 FinalMohamed HefnyNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument16 pages1 API 653 Memories March 2014 Exammajid100% (1)

- Allowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No ReferenceDocument209 pagesAllowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No Referencejay2kay5793No ratings yet

- BechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiDocument7 pagesBechtBlogNuclear 2-13-17 Repairs ASME XI and PCC-2 George AntakiStephen XuNo ratings yet

- Responsabilities API 510Document8 pagesResponsabilities API 510kataNo ratings yet

- API 653 - Section 650 Flash Card - 36 QuestionsDocument5 pagesAPI 653 - Section 650 Flash Card - 36 QuestionsdanielbellaNo ratings yet

- API 570 - Mockup CB - Paper 2Document16 pagesAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- ApiDocument4 pagesApiMahmoud Alwasif100% (1)

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- Refractory Solution FDocument5 pagesRefractory Solution Fraobabar21No ratings yet

- Pavingexpert - Formwork and ShutteringDocument6 pagesPavingexpert - Formwork and Shutteringraobabar21No ratings yet

- China Coreless IntermediateDocument21 pagesChina Coreless Intermediateraobabar21No ratings yet

- Financial AnalysisDocument16 pagesFinancial Analysisraobabar21No ratings yet

- Bangla Steel Mill RollDocument29 pagesBangla Steel Mill Rollraobabar21No ratings yet

- Compressor ChecklistDocument5 pagesCompressor ChecklistJuanPabloAlvarezNo ratings yet

- Geart Failure LubricationDocument17 pagesGeart Failure Lubricationraobabar21No ratings yet

- Usrcontrol3 Plant Svcs Tcm9 12753Document8 pagesUsrcontrol3 Plant Svcs Tcm9 12753raobabar21No ratings yet

- Texas Commission On Environmental Quality Table 11 InstructionsDocument2 pagesTexas Commission On Environmental Quality Table 11 Instructionsraobabar21No ratings yet

- Capital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter HDocument14 pagesCapital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter Hraobabar21No ratings yet

- MSS SP-115 (1999)Document11 pagesMSS SP-115 (1999)raobabar21No ratings yet

- Agma 9002-A86 Inch Bore and Ansi b17.1Document6 pagesAgma 9002-A86 Inch Bore and Ansi b17.1k21p81100% (2)

- Trainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099Document2 pagesTrainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099raobabar21No ratings yet

- 95000401Document1 page95000401raobabar21No ratings yet

- Rad 1/2 D: 001 C/D M88 DB-950006 00Document1 pageRad 1/2 D: 001 C/D M88 DB-950006 00raobabar21No ratings yet

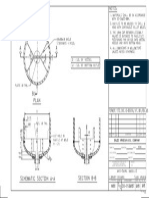

- Notes:: D I.D. of Vessel D I.D. of Bottom OutletDocument1 pageNotes:: D I.D. of Vessel D I.D. of Bottom Outletraobabar21No ratings yet

- Design Notes: 001 D M88 DB-950009 00Document1 pageDesign Notes: 001 D M88 DB-950009 00raobabar21No ratings yet

- Flow Measurement Lecture 1Document37 pagesFlow Measurement Lecture 1Rahul KalraNo ratings yet

- Insulation Material For Arc FurnacesDocument11 pagesInsulation Material For Arc Furnacespranab_473664367No ratings yet

- Jim Hansen - Buried ArcDocument22 pagesJim Hansen - Buried ArcJeff MNo ratings yet

- Introduction To Chemistry: Target: JEE (Main+Advanced)Document5 pagesIntroduction To Chemistry: Target: JEE (Main+Advanced)BaaM TVNo ratings yet

- Physics 30 Formula Sheet NewDocument4 pagesPhysics 30 Formula Sheet NewukhyeonNo ratings yet

- ENPE370 Chapter 01Document7 pagesENPE370 Chapter 01Praise Koobee0% (1)

- This Study Resource Was: Si Units Thermodynamics 6 EditionDocument9 pagesThis Study Resource Was: Si Units Thermodynamics 6 EditionIllion IllionNo ratings yet

- Steel Tables (British) PDFDocument18 pagesSteel Tables (British) PDFdarulrajNo ratings yet

- Lab Report Cee 4200Document5 pagesLab Report Cee 4200Jacob HouNo ratings yet

- 20-Formation Tester PDFDocument11 pages20-Formation Tester PDFEduardo Torres RojasNo ratings yet

- Influence of Diaphragm Wall InstallDocument11 pagesInfluence of Diaphragm Wall InstallMaruda8382No ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Bromide Printing and EnlargingDocument46 pagesBromide Printing and EnlargingGutenberg.orgNo ratings yet

- Fixed Tubesheet Design ConditionDocument1 pageFixed Tubesheet Design ConditionPratik ThakkarNo ratings yet

- Black Body: 400, 0.94 Emissivity, Sensing Size: 120 MM DiaDocument2 pagesBlack Body: 400, 0.94 Emissivity, Sensing Size: 120 MM DiaAsif RazaNo ratings yet

- Modelling Subgrade Modulus Using Deflection of Falling Weight DeflectometerDocument8 pagesModelling Subgrade Modulus Using Deflection of Falling Weight DeflectometerAngga MarditamaNo ratings yet

- Centrifugal ChillersDocument16 pagesCentrifugal ChillersMortal Being100% (2)

- VesicDocument44 pagesVesicLuis MoralesNo ratings yet

- Intro To Organic Reactions Chm457Document52 pagesIntro To Organic Reactions Chm457PUTRI DAYANA BATRIESYA ABDUL HANIFNo ratings yet

- Research On Calculation Method of Wave Load and Mooring Force Based On Time Domain Potential Flow TheoryDocument8 pagesResearch On Calculation Method of Wave Load and Mooring Force Based On Time Domain Potential Flow TheoryAnwarul Shafiq AwalludinNo ratings yet

- Profile ProjectorDocument6 pagesProfile ProjectorAnand Babu100% (1)

- Physics Core 2017 With SolutionDocument62 pagesPhysics Core 2017 With Solutional_helu260% (1)

- Chapter 7Document22 pagesChapter 7comandhurstNo ratings yet

- 覆膜机quotation vacuum membrane press machineDocument7 pages覆膜机quotation vacuum membrane press machiner HariNo ratings yet

- SDGSGDocument5 pagesSDGSGAu NguyenNo ratings yet

- Newton's Law ExperimentDocument22 pagesNewton's Law ExperimentCharlesNo ratings yet

- EBK - LinepipeDocument2 pagesEBK - Linepipeyrdna nawaiteosNo ratings yet

- Exercise-4 Part - 1: Single Option Correct Type: Newton's Laws of MotionDocument23 pagesExercise-4 Part - 1: Single Option Correct Type: Newton's Laws of MotionDebraj SahaNo ratings yet