Professional Documents

Culture Documents

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Uploaded by

chompink6900Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Uploaded by

chompink6900Copyright:

Available Formats

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

Zen Toolworks CNC Carving Machine DIY Kit User Installation Manual

Visit Us At:

http://www.zentoolworks.com or http://www.zentoolworks.com/zenwiki/mediawiki

Contact Us At:

zentoolworks@gmail.com

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

P-01, Nema 17 Stepper Motor, 3

P-02, Motor Shaft Flex Coupling, 3

P-03, End Support Ball Bearing, 6

P-04, Anti Backlash Big Falan, 3

P-05, Anti Backlash Small Falan, 3

P-06, Anti Backlash Spring, 3

P-07, Lead screw End Holding Nut, 3

P-08, X, Y Axis Guide Rod, 4

P-09, X, Y Axis Lead Screw, 2

P-10, Z Axis Guide Rod, 2

P-11, Z Axis Lead Screw, 1

P-12, M3 x 20 Screw

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

P-13, M3 Washer

P-14, M3 Machine Screw, 12

P-15, M4 Machine Screw, 18

P-16, M4 Washer

P-17, M4 Lock Washer P-18, M4 Nut

P-19, M6 x 15 Machine Screw, 8

P-20, M6 Washer

P-21, M6 x 20 Machine Screw, 4

P-22, M6 x 25 Machine Screw,4

P-23, M6 Nut,4

P-24, Linear Ball Bearing, 12

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

#01 - Clamping Blocks

#02 - Stepper Motor Base

#03 - End Bearing Block

#04 - Z Axis Upper support

#05 - Z Axis Lower Support

#06 - Gantry Right Support

#07 - Gantry Left Support

#08 - Z Bottom Frame

#09 - Z Top Frame

#10 - Y Axis Higher Support

#11 - Y Axis Lower Support

#12 - Motor Support Block

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

#13 - Y Axis Lower Frame

#14 - Y Alex Top Frame

#15 - Y Alex Side Frame

#16 - Tool Base

#17 - Gantry Left Outer Frame

#18 - Gantry Left Inner Frame

#19 - Gantry Right Outer Frame

#20 - Gantry Right Inner Frame

#21 - Z Axis Base Frame

#22 - Gantry Back Enforce Frame

#23 - Working Table

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

Assemble Instruction:

STEP Y-01

STEP Y-02 First, we need to put the bearing into #3. If you have a bench vise, it will make this job much easier. If not, you can find any equivalent tool that you have the access. Just make sure that when you apply the pressure, it should be even and slow. The bearing should be pushed straight into the block. When it is done, the bearing edge should be flush with the bearing block. Parts: P-03 Frame #3 STEP Y-03 Before push the bearings, make sure the hole is clean from manufacture debris. If not, use a needle file and small tool to clean it.

STEP Y-04 Push the bearing slowly into the bearing block hole.

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-05

User Manual

Here is how it looks like when it is done.

STEP Y-06 We need to push the linear ball bearings into the support frames. Be aware of the orientation during the install. Parts: Frame #10, #11 P-24(4)

STEP Y-07 Again, we are using bench vise for the job.

STEP Y-08 Push it slowly and make sure it is straight.

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-09 Push it till the end.

User Manual

STEP Y-10 Then do the other side. Please take a look at the orientation of two bearings in the picture.

STEP Y-11 Here is how they will look like when it is done.

STEP Y-12 Other side. The bearing's ends flush with the board surface.

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-13

User Manual

Now we need to attach the bearing block (with bearing already installed) onto part #13. Parts: Frame #13, #3 P-15(2) P-16(4) P-18(2)

STEP Y-14 Using M4 machine screw, and put flat washers on both sides.

STEP Y-15 Now it is done.

STEP Y-16 On the other side, we need to put another bearing block onto part #14. The stepper motor will be attached to this frame. Parts: Frame#14, #3 P-15(2) P-16(4) P-18(2)

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-17 Using M4, washers and nuts.

User Manual

STEP Y-18 It is done now.

STEP Y-19 Here is the Y Axis lead screw, and anti backlash nuts assembly. We will need to put them on following the steps as illustrated in the next few picture. Parts: P-09(1) P-04(1) P-05(1) P-06(1)

STEP Y-20 First, put the small falan on. Just make a few turns onto the lead screw.

10

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-21 Now put the spring onto it.

User Manual

STEP Y-22 Finally, put the falan on. Apply some pressure to squeeze both falans together, and then turn the screw into the big falan. You may need to give it a couple of tries. Make sure the anti backlash nuts and lead screw are aligned properly.

STEP Y-23 Turn the anti backlash into the lead screw.

STEP Y-24 Here is the anti backlash nuts installed on the lead screw.

11

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-25

User Manual

The #10 will be attached to the anti backlash nuts using M4 machine screw, with flat washer, lock washer and nuts. Parts: Frame#10 P-15(2) P-16(4) P-17(2) P-18(2)

STEP Y-26 Put the screws on.

STEP Y-27 And then tight them up.

STEP Y-28 Now, we need to put another support frame and guide rods on. Parts: Frame #11 P-08(2)

12

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-29

User Manual

Before we put the guide rod on, please use WD-40 clean the rod thoroughly.

STEP Y-30 Using a paper towel is fine.

STEP Y-31 The rods and #11 are installed.

STEP Y-32 On the other side, we need to first install the motor support blocks on before moving forward. This will make it much easier to access the screws. Parts: Frame#14, #12(2) P-12(4) P-13(4)

13

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-33

User Manual

Using M3 screws to attach the motor support blocks.

STEP Y-34 Using an electrical screwdriver is a good idea.

STEP Y-35 Now the motor support blocks are installed onto the frame #14

STEP Y-36 We are ready to put the rest of the frames of Y Axis together. Parts: Frame#14, #13, #15(2)

14

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-37

User Manual

Push the lead screw shaft through the end ball bearings.

STEP Y-38 The other side, same.

STEP Y-39 It should look like this

STEP Y-40 Using M6x15 for attaching the guide rods to end frames. Parts: P-19(2) P-20(2)

15

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-41 Using a hex key to fasten the screws.

User Manual

STEP Y-42 It is done on one side.

STEP Y-43 Same to the other side of the Y Axis. Parts: P-19 (2) P-20 (2)

STEP Y-44 It is done.

16

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-45

User Manual

Now we are ready to put the side frame on.

STEP Y-46 Using M3 screws provided, M3 flat washers should also be used. Parts: P-12 (6) P-13 (6)

STEP Y-47 Screw them on. Check the squareness often.

STEP Y-48 On the other side, same. Parts: P-12 (6) P-13 (6)

17

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-49

User Manual

Now we finished the M3 screws for the side frames.

STEP Y-50 Finally, we need to fasten the M6 screws on guide rods.

STEP Y-51 It is done.

STEP Y-52 Check whether you can turn the lead screw easily. It should, other wise, you should check where can be the problem. It is always a good idea to identify the issue earlier in the install. Otherwise, you will have to back out many steps to get it fixed.

18

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-53

User Manual

We use a lead screw end holding nut to hold the lead screw to the ball bearing and frame. Parts: P-07(1)

STEP Y-54 To install the nut, you should hold the lead screw and the nut as shown in the picture. Make sure the nut, lead screw and ball bearing; there is no gap in between. Then fasten the setscrews on the nut.

STEP Y-55 Using a hex key to fasten the setscrews on the lead screw end holding nut. After this, check that there should no play between lead screw, bearing and frame.

STEP Y-56 Now we are ready to put the motor on. Parts: P-01(1) Frame #2(1) P-14(4) P-13(4)

19

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-57

User Manual

Use M3 Machine screws provided to attach the stepper motor to the part #2.

STEP Y-58 Now, put the flex coupling onto the lead screw shaft. Parts: P-02 (1)

STEP Y-59 Then put the motor onto the motor support blocks. Parts: P-12 (4) P-13 (4)

STEP Y-60 Here you go.

20

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-61

User Manual

Move the coupling to the middle position.

STEP Y-62 Fasten the setscrews on the flex coupling. Now the motor and lead screw is connected.

STEP Y-63 Be aware of the motor lead orientation; make sure it is easy for your wiring later. For Y Axis, you can either let the wire outlet face up or on the side.

STEP Y-64 Now we are putting the working table onto the support frames for Y Axis. Parts: Frame #23 P-12 (10)

21

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Y-65

User Manual

Now, the Y Axis assembly is done. The picture shows tools we have used, except the bench vise.

STEP Y-66 Tools we have used so far.

STEP X-01 Now let's start Gantry install.

STEP X-02 First thing, we need to prepare the ball bearings and linear bearings. Clean the holes if necessary. Parts: Frame#19,#17

22

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-03

User Manual

Again, we are going to use bench vise. Parts: Frame #19,#17 P-03(2)

STEP X-04 Push it slowly and make sure it is straight. If it is not aligned properly and force the bearing in, it can break the board, so be very careful here.

STEP X-05 Now ball bearings have been pushed into the side frames.

STEP X-06 Now let's install linear bearings to the support frames. Parts: P-24 (4) Frame #7 Frame #8

23

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-07

User Manual

Make sure it is straight, it is important.

STEP X-08 Linear bearings have been installed to Gantry support frames.

STEP X-09 The end of the bearings is flush with the frame surface.

STEP X-10 Again, install the anti backlash nuts to the Gantry lead screw; refer to the install procedure for Y Axis. Parts: P-09 P-04 P-05 P-06

24

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-11

User Manual

The anti backlash nuts are on the lead screw.

STEP X-12 Here is the layout of the main parts for Gantry. Parts: P-08 (2)

STEP X-13 Again, clean the rod using WD-40.

STEP X-14 Attach the anti backlash to the support frame using M4, with lock washers. Parts: P-15(2) P-16(4) P-17(2) P-18(2)

25

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-15 Fasten them using a hex key.

User Manual

STEP X-16 Ready for guide rods.

STEP X-17 Slide the rods on.

STEP X-18 Now, let's prepare the side frames. This two are on the motor side (right). Parts: Frame #19, #20 P-15(2) P-16(4) P-18(2)

26

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-19 Close them up as shown.

User Manual

STEP X-20 Using 2 M4 machine screws.

STEP X-21 Ready to fasten the screws.

STEP X-22 Put the washers and nuts on.

27

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-23 It is done on one side.

User Manual

STEP X-24 Ready for the other side. Parts: Frame #17, #18 P-15(2) P-16(4) P-18(2)

STEP X-25 Be aware of the orientation.

STEP X-26 Close them up.

28

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-27

User Manual

Fasten using M4 screws with washers and nuts.

STEP X-28 Now, we need to put the motor support blocks on. The M3 screws are much easier to access then after put everything together. Parts: Frame #19,#20 P-12(4) P-13(4)

STEP X-29 2 Motor support blocks for Gantry will be inserted into those square holes.

STEP X-30 As shown.

29

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-31 Use M3 screws and washers.

User Manual

STEP X-32 It is done.

STEP X-33 Now we put all Gantry parts together.

STEP X-34 Using M6x20 to connect the gantry side frames and guide rods. Parts: P-21(2) P-20(2)

30

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-35 Done on one side.

User Manual

STEP X-56 Similar to the other side. Parts: P-19(2) P-20(2)

STEP X-37 Using a hex key to fasten the screws.

STEP X-38 Same, install lead screw holding nut. Parts: P-07

31

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-39

User Manual

Squeeze them together; make sure there is no gap between lead screw and ball bearing and holding nut.

STEP X-40 Then fasten the setscrews on the holding nut.

STEP X-41 Put the flex coupling on before the stepper motor. Parts: P-02(1)

STEP X-42 Put the motor onto motor base #2. Parts: P-01 P-14(4) P-13(4) Frame #2

32

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-43 Using M3 machine screws provided.

User Manual

STEP X-44 For gantry motor, you probably want to face the motor leads backward.

STEP X-45 Use screwdriver to fasten the screws.

STEP X-46 Now we need to put the Z Axis base onto the gantry support frames. Parts: Frame #21 P-12(8) P-13(8)

33

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-47 Using M3 screws and washers.

User Manual

STEP X-48 It is done.

STEP X-49 Make sure you can turn the lead screw by hand easily. Check it often and it will save you later.

STEP X-50 Now let's put the gantry back support on. Parts: Frame #22 P-12(16) P-13(16)

34

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-51 Use M3 screws with washers.

User Manual

STEP X-52 No hurry, do it slowly. There are a lot of screws.

STEP X-53 Yes, it is done.

STEP X-54 Here is the finished gantry assembly.

35

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-55

User Manual

Now, let't try to put the gantry and Y Axis base together.

STEP X-56 Using M6 x 25 machines screws. Parts: P-22 (2) P-20(4) P-23(2)

STEP X-57 Finished one side.

STEP X-58 Tight them up.

36

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP X-59 Here is the other side. Parts: P-22 (2) P-20 (4) P-23 (2)

User Manual

STEP X-60 Before you tighten the screws on the other side, use a ruler, check that it is even on both side. You can fine-tune it later, but now, let's just make sure that there is no big error just because ignorance.

STEP X-61 Tight them up.

STEP X-62 Now we have gantry and Y-axis installed. We are ready for putting Z Axis together.

37

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

User Manual

STEP Z-01 Here is a layout of main components of assembling the Z Axis.

STEP Z-02 For Z Axis, we also need to push the ball bearings into bearing blocks. # 3. Parts: P-03 (2) Frame #3 (2)

38

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-03

User Manual

Also, linear bearings will be pushed into support frames. Parts: Frame #3 (2) Frame #4 (2) P-24 (4)

STEP Z-04 Linear bearings have been installed onto Z Axis support frames.

STEP Z-05 Screw the Anti back lash nuts onto the Z Axis lead screw, as demonstrated earlier. Parts: P-11(1) P-4(1) P-5(1) P-6(1)

STEP Z-06 Screw the Anti back lash nuts onto the Z Axis lead screw, as demonstrated earlier. Connect the support frame and anti backlash nuts using M4 machine screw with lock washer, flat washer and nut. Parts: P-15(2) P-16(4) P-17(2) P-18(2)

39

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-07 Close up detail.

User Manual

STEP Z-08 Use a hex key to and a small wrench to fasten M4 screws and nuts.

STEP Z-09 Put the bearing support onto #8 using M4 screws and washers. Parts: Frame#3,#8 P-15(2) P-16(4) P-18(2)

STEP Z-10 On the motor side, we need to put bearing block onto #9 using M4 screws and washers. Parts: Frame#3,#9 P-15(2) P-16(4) P-18(2)

40

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-11

User Manual

Before we put the motor support blocks on, we need to pre insert the M6 x 15 machine screws onto #9. Otherwise, you will not be able to put those screws in. Parts: Frame #9 Frame #12(2) P-19(2) P-20(2) STEP Z-12 Push M6 screws into the #9 frame ...

STEP Z-13 The M6 screws are pre inserted ...

STEP Z-14 Then put the motor support blocks on. Parts: P-13(4) P-12(4)

41

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-15

User Manual

Using M3 screw between #9 and motor support blocks.

STEP Z-16 Now we can put the motor side frame onto the guide rods.

STEP Z-17 Here you can use a hex key to fasten the M6 machine screw.

STEP Z-18 Install another side with M6 x 15 machine screw. Parts: P-19(2) P-20(2)

42

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-19 Looks good?

User Manual

STEP Z-20 Check whether you can easily turn the lead screw by hand. If not, there is an alignment problem, and it is better fix it right now.

STEP Z-21 Put the lead screw holding nut on, squeeze lead screw and holding nut towards the ball bearing. Parts: P-07(1)

STEP Z-22 The lead screw holding nut is installed.

43

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-23

User Manual

Put the flex coupling on before install the motor. Parts: P-02(1)

STEP Z-24 The motor and motor base(#2) Parts: Frame#2 P-01(1) P-14(4) P-13(4)

STEP Z-25 Using M3 machine screws with washers to connect motor and motor base (#2)

STEP Z-26 Put the motor onto the motor support blocks. Parts: P-12(4) P-13(4)

44

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-27 Motor is installed for the Z Axis.

User Manual

STEP Z-28 Fasten the setscrews on the flex coupling.

STEP Z-29 Z Axis assembly is ready to be put on the machine.

STEP Z-30 Use M3 screws and washers to connect the Z Axis to the Z Axis baseboard on the gantry. Parts: P-12(8) P-13(8)

45

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-31 Fasten them up with a screwdriver.

User Manual

STEP Z-32 Don't forget the screws at the bottom.

STEP Z-33 Use a screwdriver to fasten all screws.

STEP Z-34 The Z Axis assembly is installed on the machine now.

46

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

Zen Toolworks CNC Carving Machine DIY Kit

STEP Z-35

User Manual

Now, let's put the tool base #16 to the Z Axis support frames. You can do this step later, if you haven't decided what kind of tool will be used. It is easier to install tool when the base is off. Parts: P-12(8) P-13(8)

STEP Z-36 The tool base has been installed on Z Axis. There are 4 pre-drilled holes on the tool base, which is for your tool holders. Zen Toolworks carries optional spindle motors with tool holders, which can be easily screwed onto this tool base.

STEP Z-37 We have completed the machine assembly. Hope it didn't take you too long and you have enjoyed the process so far. Now it is time to learn stepper motor controller software and design software for the project want to do.

47

Copyright 2010, Zen Toolworks, LLC. All Rights Reserved

You might also like

- Hot Wire Manchine - User Manual-ENDocument41 pagesHot Wire Manchine - User Manual-ENZoliNo ratings yet

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- MyDIYCNC Desktop CNC Machine Kit Assembly InstructionsDocument33 pagesMyDIYCNC Desktop CNC Machine Kit Assembly InstructionsKhairul Yop Azreen100% (1)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- Whyte - 146-T-120-E-120 Supplementary Service Manual Edn1Document16 pagesWhyte - 146-T-120-E-120 Supplementary Service Manual Edn1Jamie WatsonNo ratings yet

- Metal Plus (Model 1412) : Written By: Brook DrummDocument30 pagesMetal Plus (Model 1412) : Written By: Brook DrummEmmanuel LeggeriNo ratings yet

- Rapman v3.0.0 Build ManualDocument83 pagesRapman v3.0.0 Build Manualterence dactylNo ratings yet

- Sample ReportDocument546 pagesSample Reportraviranjan1973No ratings yet

- Zen Toolworks CNC Carving Machine DIY Kit User Installation ManualDocument47 pagesZen Toolworks CNC Carving Machine DIY Kit User Installation ManualMartin SilisqueNo ratings yet

- CNC Machine DIY InstructionDocument65 pagesCNC Machine DIY Instructioncxin168100% (3)

- 3018-Se CNC Router: User ManualDocument27 pages3018-Se CNC Router: User ManualPIXIDOUNo ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- Lead CNC Assembly Instructions v1.0 01 2019Document27 pagesLead CNC Assembly Instructions v1.0 01 2019Bonnelly Peralta AlmanzarNo ratings yet

- PROVerXL 4030V2 User Manual v1.0-202306Document98 pagesPROVerXL 4030V2 User Manual v1.0-202306Salvatore PREITENo ratings yet

- RSX Short Shifter Install GuideDocument11 pagesRSX Short Shifter Install GuideHybrid RacingNo ratings yet

- Arduino 3D Printed CNC Pen PlotterDocument37 pagesArduino 3D Printed CNC Pen Plotterseynif015No ratings yet

- OX Assembly ManualDocument44 pagesOX Assembly ManualMati FernandezNo ratings yet

- Installation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconDocument14 pagesInstallation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconManuel Castro EdiolaNo ratings yet

- Kossel Mini Building GuideDocument43 pagesKossel Mini Building GuideMustafa Liqa-Madiq IV AzoulayeNo ratings yet

- Shapeoko 3 - Assembly GuideDocument37 pagesShapeoko 3 - Assembly GuidePedro RoccaNo ratings yet

- 08 Alpha 160X215Document39 pages08 Alpha 160X215JuanCarlosPRNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- A8 3D Printer Installation Instructions-170111Document44 pagesA8 3D Printer Installation Instructions-170111José R. SilleroNo ratings yet

- BmvwinstallDocument16 pagesBmvwinstallAlejandroO.VargasNo ratings yet

- CNC Programming WRKB Lathe Sample LockedDocument51 pagesCNC Programming WRKB Lathe Sample Lockedkree_bigdaddy100% (1)

- AR3 Robot Manul (163-325)Document163 pagesAR3 Robot Manul (163-325)Alexandre PeixotoNo ratings yet

- Hyundai Accent Sport ShifterDocument13 pagesHyundai Accent Sport ShiftermariuskidNo ratings yet

- Anin RobotDocument21 pagesAnin RobotZall Boed-zilsNo ratings yet

- Installation Instructions: Genuine PartsDocument14 pagesInstallation Instructions: Genuine PartsPascalCoteNo ratings yet

- 3D Printer DIY Whole ProcessDocument14 pages3D Printer DIY Whole Processryan.jane171287No ratings yet

- CNC Machining Center Programming ManualDocument106 pagesCNC Machining Center Programming ManualLight House50% (2)

- T8-Mini CNC Router Complete GuideDocument9 pagesT8-Mini CNC Router Complete GuideRayner MihailovNo ratings yet

- Expert 52 ManualDocument58 pagesExpert 52 ManualDiana ArghirNo ratings yet

- Anet A8 3D Printer Installation InstructionsDocument42 pagesAnet A8 3D Printer Installation InstructionsFabian VázquezNo ratings yet

- Shimano Nexus Inter-7 - Coaster - BrakeDocument12 pagesShimano Nexus Inter-7 - Coaster - BrakeGeorge OrfanidisNo ratings yet

- Instrument Panel and Console TrimDocument33 pagesInstrument Panel and Console TrimGeo AdmNo ratings yet

- Folgertech Prusa I3 Build Manual v1.1Document74 pagesFolgertech Prusa I3 Build Manual v1.1DonutdealerdNo ratings yet

- Prusa I3 Build Document by 3D Printer Czar PDFDocument29 pagesPrusa I3 Build Document by 3D Printer Czar PDFlasersmartNo ratings yet

- Retrofitting of Denford TRIAC CNC Milling MachineDocument25 pagesRetrofitting of Denford TRIAC CNC Milling MachineDivyanshNo ratings yet

- VQ35Document3 pagesVQ35Alejandro MontañoNo ratings yet

- RTD2brace Install InstructionsDocument24 pagesRTD2brace Install InstructionsfjoNo ratings yet

- Anet A8 Printer ManualDocument46 pagesAnet A8 Printer ManualMelku AbebeNo ratings yet

- A8 3D Printer Installation GuideDocument46 pagesA8 3D Printer Installation GuidepepeNo ratings yet

- Anet A8 Installation Guide PDFDocument46 pagesAnet A8 Installation Guide PDFEnrique FernándezNo ratings yet

- A8 3D Printer Installation Instructions-2016!6!30Document46 pagesA8 3D Printer Installation Instructions-2016!6!30Peña EduardoNo ratings yet

- A8 3D Printer Installation GuideDocument46 pagesA8 3D Printer Installation GuideDaniel MejiaNo ratings yet

- A8 3D Printer Installation Instructions 2016 6 30 PDFDocument46 pagesA8 3D Printer Installation Instructions 2016 6 30 PDFAdelaide LoureiroNo ratings yet

- A8 3D Printer Installation Instructions-2016!6!30Document46 pagesA8 3D Printer Installation Instructions-2016!6!30hasanbasri_93No ratings yet

- A8 3D Printer Installation Instructions 2016 6 30 PDFDocument46 pagesA8 3D Printer Installation Instructions 2016 6 30 PDFBendot CeblenkNo ratings yet

- A8 3D Printer Installation GuideDocument46 pagesA8 3D Printer Installation GuideMarcosFenollarNo ratings yet

- A8 3D Printer Installation Instructions 2016 6 30 PDFDocument46 pagesA8 3D Printer Installation Instructions 2016 6 30 PDFvoievodul1No ratings yet

- A8 3D Printer Installation Instructions-2016!6!30Document46 pagesA8 3D Printer Installation Instructions-2016!6!30TheKauti0nNo ratings yet

- A8 3D Printer Installation GuideDocument46 pagesA8 3D Printer Installation GuideMarcosFenollarNo ratings yet

- Prusa I3 Rework Rev1.5 - Assembly InstructionsDocument80 pagesPrusa I3 Rework Rev1.5 - Assembly InstructionsGabor LisakNo ratings yet

- Manual - AR2 Robot Arm AssemblyDocument53 pagesManual - AR2 Robot Arm AssemblyNelson Rey Laura0% (1)

- Genmitsu - 4030XLPROVer MANUALv1.01Document39 pagesGenmitsu - 4030XLPROVer MANUALv1.01abunom48No ratings yet

- Modification Guide CD70 NAVIDocument18 pagesModification Guide CD70 NAVIEduardoEnriqueCadenaLopezNo ratings yet

- A8 3D Printer Installation Instructions-161230Document46 pagesA8 3D Printer Installation Instructions-161230Сергей ЖаркихNo ratings yet

- A8 3D Printer Installation Instructions-161230Document46 pagesA8 3D Printer Installation Instructions-161230Сергей ЖаркихNo ratings yet

- Lifting Beam Cal 4Document1 pageLifting Beam Cal 4dd6077No ratings yet

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- DEF File DescriptionDocument5 pagesDEF File Descriptionchompink6900No ratings yet

- The Ultimate Bee Gees (CD 1)Document1 pageThe Ultimate Bee Gees (CD 1)chompink6900No ratings yet

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- Teklastructures Maintenance Request FormDocument1 pageTeklastructures Maintenance Request Formchompink6900No ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Cover Letter SHEETDocument1 pageCover Letter SHEETchompink6900No ratings yet

- CCK VNT Tank Cal RefDocument2 pagesCCK VNT Tank Cal Refchompink6900No ratings yet

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDocument11 pagesPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900No ratings yet

- Help With Nickel Alloy Welding - GA5Document5 pagesHelp With Nickel Alloy Welding - GA5chompink6900No ratings yet

- Chap. 3 - Split Air Conditioning SystemDocument17 pagesChap. 3 - Split Air Conditioning SystemSparsh ShukalNo ratings yet

- NCII EIM QuestionsDocument5 pagesNCII EIM QuestionsZYJA DLANE MALITNo ratings yet

- HVAC MCQ Question Bank-2020-21Document12 pagesHVAC MCQ Question Bank-2020-21Sayee DeshpandeNo ratings yet

- Ws1081084720 - Emerson Mexico - Cutting Tools Cost BreakdownDocument8 pagesWs1081084720 - Emerson Mexico - Cutting Tools Cost BreakdownalfredNo ratings yet

- Bob Herron Electric LTDDocument8 pagesBob Herron Electric LTDকাফী ওয়াহিদNo ratings yet

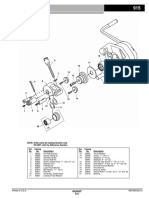

- 915 PartsDocument4 pages915 PartsRobel MTNo ratings yet

- TSP23687 WiringDocument148 pagesTSP23687 WiringEli RochaNo ratings yet

- Cisco LCD 110 Pro 52sDocument3 pagesCisco LCD 110 Pro 52sKyle CobbNo ratings yet

- Manual Slefuitor Cu Vibratii Skil 7347 7348Document108 pagesManual Slefuitor Cu Vibratii Skil 7347 7348Marian BogdanNo ratings yet

- Rekap Spare Part Orderan BearingDocument3 pagesRekap Spare Part Orderan BearingWahyuNo ratings yet

- Pipes DataDocument69 pagesPipes DatafeNo ratings yet

- Manual Rotary Precision Microtome: Design and Manufacturing Made in GermanyDocument6 pagesManual Rotary Precision Microtome: Design and Manufacturing Made in GermanyGiorgio Del Lago MaggioreNo ratings yet

- Designguide Div26 ElectricalDocument81 pagesDesignguide Div26 ElectricalRochelle Espero - IAAANo ratings yet

- Schulte RDX 117 REV 2012 05 SN B11810001201 B11810051311Document40 pagesSchulte RDX 117 REV 2012 05 SN B11810001201 B11810051311Амурдеталь БлаговещенскNo ratings yet

- Mathod Statemenr For Cables and WiresDocument24 pagesMathod Statemenr For Cables and WiresKamran AhmedNo ratings yet

- Owners Manual - Controller Remote - r51 E-30 - New 0Document5 pagesOwners Manual - Controller Remote - r51 E-30 - New 0Makar Va.No ratings yet

- Light Control Switch Circuit: Wiring DiagramDocument3 pagesLight Control Switch Circuit: Wiring DiagramPhang KumwingNo ratings yet

- Series SPITZ: Solid-Rubber Distribution Boxes - MobileDocument1 pageSeries SPITZ: Solid-Rubber Distribution Boxes - MobileTiago PaivaNo ratings yet

- McintoshDocument6 pagesMcintoshayawe888888No ratings yet

- Lathe AccessoriesDocument6 pagesLathe AccessoriesAnand Balaji100% (1)

- Heavy Duty - Fifth Wheel Couplings JSK 38 G1: Advantages at A GlanceDocument2 pagesHeavy Duty - Fifth Wheel Couplings JSK 38 G1: Advantages at A Glancemayadin yadinNo ratings yet

- TolranceDocument18 pagesTolranceDiego MiseNo ratings yet

- COP DetailsDocument98 pagesCOP DetailsGrishma WarkeNo ratings yet

- Catalog PT. WGTDocument22 pagesCatalog PT. WGTRudy AriNo ratings yet

- Samsung TV Blue PrintsDocument36 pagesSamsung TV Blue PrintskakashiryuNo ratings yet

- Eaton Fuller RTLO 14610B Transmission Parts ManualDocument36 pagesEaton Fuller RTLO 14610B Transmission Parts ManualFedericoNo ratings yet

- VT2014B VT2214B Vto2214b VT2514 VT2514 (Od) VT2514B Vto2514b - Cei - Volvo 94 101Document8 pagesVT2014B VT2214B Vto2214b VT2514 VT2514 (Od) VT2514B Vto2514b - Cei - Volvo 94 101جلال الرماحNo ratings yet

- Exporterd DataDocument240 pagesExporterd DatapmnasimNo ratings yet

- Approved Vendor List As On 15.03.2019Document73 pagesApproved Vendor List As On 15.03.2019Satish Kumar AmirishettyNo ratings yet