Professional Documents

Culture Documents

Gatmania Metro

Gatmania Metro

Uploaded by

Gautam SauravCopyright:

Available Formats

You might also like

- Inspection Gauges TypesDocument12 pagesInspection Gauges Typesahsan ali100% (1)

- Eric Cressey Corrective TrainingDocument67 pagesEric Cressey Corrective Trainingberthakey840794% (17)

- EXAVER 2 Paper 1 Sample ExamDocument6 pagesEXAVER 2 Paper 1 Sample ExamMikael Selocs100% (2)

- University of Gondar: Project 1 Titel - Linear MeasurmentDocument9 pagesUniversity of Gondar: Project 1 Titel - Linear Measurmentnahom abrhamNo ratings yet

- Different Types of Mechanical Measuring Tools and GaugesDocument7 pagesDifferent Types of Mechanical Measuring Tools and Gaugescmn_1986No ratings yet

- Chapter One (Sheet Metal)Document27 pagesChapter One (Sheet Metal)mesfin snowNo ratings yet

- Measuring InstrumentsDocument10 pagesMeasuring Instrumentsmohsin931No ratings yet

- Measuring InstrumentsDocument10 pagesMeasuring Instrumentsmohsin931No ratings yet

- Nazim Lab Session 1-15Document48 pagesNazim Lab Session 1-15Hammad SaeedNo ratings yet

- M&M LabDocument39 pagesM&M LabSUSHIL SUSHILNo ratings yet

- Laboratory Report 1 DellosaDocument11 pagesLaboratory Report 1 DellosaAgent PNo ratings yet

- University of North Carolina ManualDocument11 pagesUniversity of North Carolina ManualvysnktNo ratings yet

- TypesDocument14 pagesTypesVishal PatidarNo ratings yet

- Workshop TechnologyDocument105 pagesWorkshop Technologymuneebimran0% (1)

- Group 3 ICT PresentationDocument14 pagesGroup 3 ICT PresentationANNIE ROSE DULANGNo ratings yet

- Caliper: HistoryDocument7 pagesCaliper: HistoryOladimeji TaiwoNo ratings yet

- Dimensional Measurements: Group 22 MembersDocument12 pagesDimensional Measurements: Group 22 MemberscfellowNo ratings yet

- Internship Report: Mecas Engineering LimitedDocument11 pagesInternship Report: Mecas Engineering LimitedHaider AliNo ratings yet

- Lab Session 08 Open Ended Lab: Objective: DiagramDocument5 pagesLab Session 08 Open Ended Lab: Objective: Diagrammeen19111087 KFUEITNo ratings yet

- Lab Report 2 UpdatedDocument9 pagesLab Report 2 UpdatedMalaika KhursheedNo ratings yet

- Measurements & Metrology PracticalDocument91 pagesMeasurements & Metrology PracticalAU Aalim Muhammed Salegh Polytechnic CollegeNo ratings yet

- Measuring ToolsDocument9 pagesMeasuring ToolsWahyu FirmansyahNo ratings yet

- BTM2133-Chapter 4 Measuring InstrumentsDocument61 pagesBTM2133-Chapter 4 Measuring InstrumentsAswaja3130% (1)

- Measuring Tools: Steel RulerDocument4 pagesMeasuring Tools: Steel RulerAnonymous TXTpRqiNo ratings yet

- What Is A Smart InstrumentDocument14 pagesWhat Is A Smart InstrumentJuned LahoriNo ratings yet

- Measurement and Statistical Tasks 1Document8 pagesMeasurement and Statistical Tasks 1Agum GhifariNo ratings yet

- Mechanical Measurement LaboratoryDocument24 pagesMechanical Measurement LaboratoryMahendra SinghNo ratings yet

- Mechanical Instruments and ToolsDocument14 pagesMechanical Instruments and ToolsShakib Shaikh100% (3)

- Study of Measuring Instruments and Gauges PDFDocument7 pagesStudy of Measuring Instruments and Gauges PDFRishabh HanseliaNo ratings yet

- Assignment # 1Document12 pagesAssignment # 1ahsan aliNo ratings yet

- Micrometer CaliperDocument12 pagesMicrometer CaliperallyannanicolemartinNo ratings yet

- Metrology and MeasurementsDocument140 pagesMetrology and MeasurementsVivekanand SriramNo ratings yet

- Tools and Instruments Used in Maritrime EnginneringDocument19 pagesTools and Instruments Used in Maritrime EnginneringSHAHEEN AKBARNo ratings yet

- Introductory Macroeconomics XIIDocument28 pagesIntroductory Macroeconomics XIISnigdha100% (1)

- Various Parameter Measurement - Jan 2022 - R1Document7 pagesVarious Parameter Measurement - Jan 2022 - R1Anih Kishor (RA1911002010062)No ratings yet

- Mechanical Measurements and Measuring DevicesDocument56 pagesMechanical Measurements and Measuring Devicesrizvee.pdb21No ratings yet

- Measuring Instrument and GaugesDocument5 pagesMeasuring Instrument and GaugeskwangsooNo ratings yet

- MQC PDFDocument25 pagesMQC PDFVK DNo ratings yet

- Government Polytechnic Muzaffarpur: Lab Manual of Metrology & Quality Control Lab SUBJECT CODE - 1625506Document25 pagesGovernment Polytechnic Muzaffarpur: Lab Manual of Metrology & Quality Control Lab SUBJECT CODE - 1625506VK D0% (1)

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Metrology and MeasurementsDocument10 pagesMetrology and MeasurementsMUHAMMAD UMAR KAMRANNo ratings yet

- Measurement Techniques - Week 1Document25 pagesMeasurement Techniques - Week 1fhggdhdNo ratings yet

- Measuring MachineDocument19 pagesMeasuring Machinegopir28No ratings yet

- Metrology Assignment 2Document14 pagesMetrology Assignment 2Aadish vikramNo ratings yet

- AAADocument8 pagesAAAmansang.mc62No ratings yet

- Fundamental Techniques of Linear & Angular Measurements in SurveyingDocument15 pagesFundamental Techniques of Linear & Angular Measurements in SurveyingParvez BodhNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- Metrology and Quality AssuranceDocument8 pagesMetrology and Quality Assurancehammad ghaffarNo ratings yet

- The Micrometer: Basic TypesDocument4 pagesThe Micrometer: Basic TypesJofer SantiagoNo ratings yet

- JS01Document9 pagesJS01Fadirul EzwanNo ratings yet

- Vernier To ComparatorDocument78 pagesVernier To ComparatorAtul GaurNo ratings yet

- MCE 286-Engineering Materials and Manufacturing Processes Laboratory Name-Lab 1: Introduction and Metrology 1Document2 pagesMCE 286-Engineering Materials and Manufacturing Processes Laboratory Name-Lab 1: Introduction and Metrology 1Jay PatelNo ratings yet

- Roundness IDocument13 pagesRoundness Ibalasubramani_srinivNo ratings yet

- Vernier Calipper ExperimentSDocument9 pagesVernier Calipper ExperimentSmaylaleibordayNo ratings yet

- Lab Report 1Document5 pagesLab Report 1mamoona noreenNo ratings yet

- Vernier CaliperDocument13 pagesVernier CaliperAbdul AhadNo ratings yet

- Smaw 7 Las q3 w1 w8Document77 pagesSmaw 7 Las q3 w1 w8Rey Mamat LaguraNo ratings yet

- 1537326530linear & Angular MeasurementDocument49 pages1537326530linear & Angular MeasurementAl MamunNo ratings yet

- As Practical Book - Edited TotalDocument285 pagesAs Practical Book - Edited TotalonlyheavenismygoalNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Measurement of Length - Screw Gauge (Physics) Question BankFrom EverandMeasurement of Length - Screw Gauge (Physics) Question BankNo ratings yet

- Ravenloft Gazetteer Volume IVDocument170 pagesRavenloft Gazetteer Volume IVFelipe Barroso100% (1)

- Paragraph TransitionsDocument6 pagesParagraph TransitionsJames ScottNo ratings yet

- TenchuDocument3 pagesTenchuricky_ratedNo ratings yet

- PenthouseDocument8 pagesPenthouseBe SauNo ratings yet

- FOCGB3 Utest VG 3ADocument1 pageFOCGB3 Utest VG 3AGyurácz GyulaNo ratings yet

- Present Simple PDFDocument3 pagesPresent Simple PDFAnni GumiNo ratings yet

- Saiki RanDocument1 pageSaiki RanMadhu Prathipati PNo ratings yet

- Lab Exercise: Microscopy: Care of The MicroscopeDocument13 pagesLab Exercise: Microscopy: Care of The Microscopeblackforest8No ratings yet

- Tracklist Dimitri Vegas & Like Mike Tomorrowland 2013Document2 pagesTracklist Dimitri Vegas & Like Mike Tomorrowland 2013faisal aswinNo ratings yet

- Design of Ogee SpillwayDocument4 pagesDesign of Ogee Spillwaydsananda100% (3)

- Interview QuestionsDocument7 pagesInterview QuestionssangeethadurjatiNo ratings yet

- Technical Specifications of Computed Radiography SystemDocument3 pagesTechnical Specifications of Computed Radiography SystemConrad ConradmannNo ratings yet

- Final Hindu Review May 2019 PDFDocument21 pagesFinal Hindu Review May 2019 PDFAbhishekNo ratings yet

- Bentley SELECT Licensing Program EligibilityDocument13 pagesBentley SELECT Licensing Program EligibilitySanjay SibalNo ratings yet

- Abad, Glenford V - Activity 2Document3 pagesAbad, Glenford V - Activity 2glenford abadNo ratings yet

- Big Magic Secret Ebook FinalDocument107 pagesBig Magic Secret Ebook FinalIntellibrain75% (4)

- Lightpipe DesignDocument22 pagesLightpipe DesignkonshoeNo ratings yet

- 07 - C175Document20 pages07 - C175Ariel Zamora Rodriguez100% (3)

- Elma Metrel A1436 Buletooth Dongle Manual ENDocument10 pagesElma Metrel A1436 Buletooth Dongle Manual ENatianna.paschalNo ratings yet

- Worldbuilding - Fantasy ReligionDocument16 pagesWorldbuilding - Fantasy Religionscottwelchkin100% (2)

- VJJVJVJDocument7 pagesVJJVJVJAnirudh KawNo ratings yet

- Tagore PDFDocument18 pagesTagore PDFjohnyyNo ratings yet

- DmOS 8.2.0 - DatasheetDocument25 pagesDmOS 8.2.0 - DatasheetPaulo Lima CamposNo ratings yet

- Catalogo Cressi Mergulho 2009Document110 pagesCatalogo Cressi Mergulho 2009alexpt2000100% (23)

- Pork16 PDFDocument24 pagesPork16 PDFSean AabergNo ratings yet

- 212 Chapter07Document63 pages212 Chapter07HAU LE DUCNo ratings yet

- R Rec BT.2100 0 201607 I!!pdf eDocument17 pagesR Rec BT.2100 0 201607 I!!pdf eYANo ratings yet

- BNW Character ListDocument2 pagesBNW Character Listapi-279810228No ratings yet

Gatmania Metro

Gatmania Metro

Uploaded by

Gautam SauravCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gatmania Metro

Gatmania Metro

Uploaded by

Gautam SauravCopyright:

Available Formats

Prepared By

Gautam Saurav

Contact (for any assistance)-

gauti12031@hotmail.co.in

www.twitter.com/gauti12031

1 | P a g e

Acknowledgement

I have taken efforts in this term paper. However, it would not have been possible

without the kind support and help of many individuals and organizations. I would

like to extend my sincere thanks to all of them.

I am highly indebted to Mr. Sumit Nijjar for their guidance and constant

supervision as well as for providing necessary information regarding the project &

also for their support in completing the term paper.

My thanks and appreciations also go to my family members and colleague in

developing the term paper and people who have willingly helped me out with their

abilities

Gautam Saurav

2 | P a g e

Contents

Introduction .................................................................................................................................................. 3

Categories of Linear Measurement Instrument ........................................................................................... 3

Linear Measurement .................................................................................................................................... 4

Caliper ........................................................................................................................................................... 4

Micrometer ................................................................................................................................................... 5

Height Gauge ................................................................................................................................................ 6

Depth Gauge ................................................................................................................................................. 7

Bore Gauge.................................................................................................................................................... 8

Use of Instruments for Non-precision Linear Measurement ...................................................................... 9

Non-Precision Linear Measurement Instrument ........................................................................................ 9

Radius Gauges ............................................................................................................................................... 9

Feeler gauges .............................................................................................................................................. 10

Steel Rule .................................................................................................................................................... 11

Firm Joint Type ............................................................................................................................................ 12

Divider......................................................................................................................................................... 12

Engineer's Taper, Wire and Thickness Gauge ............................................................................................. 13

References .................................................................................................................................................. 14

3 | P a g e

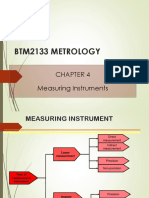

Introduction

Linear measurement just means measurement in a straight line.

Or we can say measurement of length, as distinguished from volume, weight, etc.

A system of measuring length, in which 12 inches = 1 foot or one in which 100 centimeters = 1

meter

Linear measurement includes the measurement of lengths, diameters, heights and thickness. The

basic principle of linear measurement (mechanical type) is that of comparison with standard

dimensions on a suitably engraved instrument or device. Linear measuring instruments are

categorized depending upon their accuracy. The two categories are non-precision instruments

and precision instruments. Non-precision instruments include steel rule, caliper divider, and

telescopic gauge that are used to measure to the line graduations of a rule. Precision instruments

include micrometers, vernier calipers, height gauges and slip gauges. A wide variety of electrical

measuring devices is also available. Electric measuring devices are mainly transducers, i.e. they

transform the displacement into suitable measurable parameter like voltage and current. Some of

the displacement transducers are strain gauges, linear variable differential transformers (LVDT)

and potentiometer.

Categories of Linear Measurement Instrument

1. Precision Instrument

Since modern production processes is concerned with interchangeable products, precise

dimensional control is required in industry. Precision measurement instruments use different

techniques and phenomena to measure distance with accuracy

2. Non-precision Instrument

Non-precision instruments include steel rule, caliper divider, and telescopic gauge that are

used to measure to the line graduations of a rule.

4 | P a g e

Linear Measurement

Caliper

A caliper is a device used to measure the distance between two opposite sides of an object. A

caliper can be as simple as a compass with inward or outward-facing points. The tips of the

caliper are adjusted to fit across the points to be measured, the caliper is then removed and the

distance read by measuring between the tips with a measuring tool, such as a ruler.

Construction Feature:

Outside jaws: used to measure external diameter or width of an object

Inside jaws: used to measure internal diameter of an object

Depth probe: used to measure depths of an object or a hole

Main scale: scale marked every mm

Main scale: scale marked in inches and fractions

Vernier scale gives interpolated measurements to 0.1 mm or better

Vernier scale gives interpolated measurements in fractions of an inch

Retainer: used to block movable part to allow the easy transferring of a measurement

5 | P a g e

Micrometer

A micrometer sometimes known as a micrometer screw gauge, is a device incorporating a

calibrated screw used widely for precise measurement of small distances in mechanical

engineering and machining as well as most mechanical trades, along with

other metrological instruments such as dial, vernier, and digital calipers. Micrometers are often,

but not always, in the form of calipers.

Construction Features:

Frame: The C-shaped body that holds the anvil and barrel in constant relation to each other. It is

thick because it needs to minimize flexion, expansion, and contraction, which would distort the

measurement.

The frame is heavy and consequently has a high thermal mass, to prevent substantial heating up

by the holding hand/fingers. It is often covered by insulating plastic plates which further reduce

heat transference.

Explanation: if you hold the frame long enough so that it heats up by 10C, then the increase in

length of any 10 cm linear piece of steel is of magnitude 1/100 mm. For micrometers this is their

typical accuracy range.

Anvil: The shiny part that the spindle moves toward, and that the sample rests against.

Sleeve / barrel / stock: The stationary round part with the linear scale on it. Sometimes vernier

markings.

Lock nut / lock-ring / thimble lock: The knurled part (or lever) that one can tighten to hold the

spindle stationary, such as when momentarily holding a measurement.

6 | P a g e

Screw: The heart of the micrometer, as explained under operating principles . It is inside the

barrel.

Spindle: The shiny cylindrical part that the thimble causes to move toward the anvil.

Thimble: The part that one's thumb turns. Graduated markings.

Ratchet stop: Device on end of handle that limits applied pressure by slipping at a calibrated

torque.

Height Gauge

A height gauge is a measuring device used either for determining the height of something, or for

repetitious marking of items to be worked on. The former type of height gauge is often used in

doctor's surgeries to find the height of people.

These measuring tools are used in metalworking or metrology to either set or measure vertical

distances; the pointer is sharpened to allow it to act as a scriber and assist in marking out work

pieces.

Construction Features:

They may also be used to measure the height of an object by using the underside of the scriber as

the datum. The datum may be permanently fixed or the height gauge may have provision to

adjust the scale, this is done by sliding the scale vertically along the body of the height gauge by

7 | P a g e

turning a fine feed screw at the top of the gauge; then with the scriber set to the same level as the

base, the scale can be matched to it. This adjustment allows different scribers or probes to be

used, as well as adjusting for any errors in a damaged or resharpened probe.

Depth Gauge

A depth gauge is a pressure gauge that displays the equivalent depth in water. It is a piece

of diving equipment often used by SCUBA divers.

Most modern diving depth gauges have an electronic mechanism and digital display. Older types

used a mechanical mechanism and analogue display.

A diver uses a depth gauge with decompression tables and a watch to avoid decompression

sickness. A common alternative to the depth gauge, watch and decompression tables is a dive

computer. A depth gauge and an oxygen analyser/oxygen sensor can be used to measure

the partial pressure of oxygen of the breathing gas, which is necessary to avoid oxygen toxicity.

Construction Features:

Digital depth gauges commonly also include a timer showing the interval of time that the diver

has been submerged. Some show the diver's rate of ascent and descent, which can be is useful for

avoiding barotrauma.

8 | P a g e

As the gauge only measures water pressure, there is an inherent inaccuracy in the depth

displayed by gauges that are used in both fresh water and seawater due to the difference in

the densities of fresh water and seawater.

Bore Gauge

A dial or vernier bore gauge measures a bore directly. The gauge has three symmetrical anvils

that protrude from the gauge body that are connected to the dial or micrometer mechanism. As

the knob is rotated it moves the anvils in or out with respect to the measurements. The knob

usually has a slipping mechanism to take the feel out of the device and increase reliability

between measurements. The measurement given is the mean diameter of the three anvils, and is

usually good to 0.001 mm

Construction Features:

9 | P a g e

Use of Instruments for Non-precision Linear Measurement

Non-precision instruments are limited to the measurement of parts to a visible line graduation on

the instrument used. There are several non-precision measuring devices. They are used where

high measurement accuracy is not required.

Instruments are use in this case for the measurement of the length or distance between the points

which is not exact but can be use and the measurement may done by wire, rope, hand etc.

Non-Precision Linear Measurement Instrument

Radius Gauges

Wherever two surfaces meet, a radius is generally given to avoid stress concentration. The

radius also plays an important role in case of heat treatment of parts. Thus the proper radius must

be maintained and for checking it, radius gauges are employed. If the curved surface is external,

i.e. male radius it is simply called a 'radius'. If curved surface is internal, i.e, female radius, it is

called a 'fillet'. Radius gauges consist of sets of blades on each of which is stamped the

corresponding radius. On one side we have external radius and on the other side internal radius,

so that it may be suitable for fillets as well a radius. Radius gauges are used with proper light,

placing the work to be gauged between light source and eye. It is only with the passage of light

between gauge and work that radius can be gauged properly.

10 | P a g e

Feeler gauges

These are used to measure the width of the gap between two parallel flat faces e.g., in gauging

of the clearance between the piston and cylinder. A feeler gauge consists of a narrow strip of

sheet steel made to a given thickness. The complete set consists of a number of gauging blades of

different thickness assembled together. Their working depends entirely on the sense of feel. The

feeler blade should neither be forced between the surfaces nor should it slide freely, rather the

correct blade will give a characteristic 'gauge fit' type of feel. If necessary, two blades may be

joined together for noting any dimension.

Feeler gauges generally comprise of a series of gauging blades of different grades and

thicknesses, from 0.03 to 1 mm assembled in protective sheath. The blades are made of heat

treated bright polished tool steel having a tensile strength of about 170 kgf/mm2 for thickness up

to 0.5 mm and about 70 kgf/mm2 for thickness 0.5 mm and above. Generally the blades are

available in overall length of 100 mm. these are 12 mm wide at heel and are tapered for the outer

part of their length so that width at the tip is approximately 6 mm. these are hinged in the sheath

on a screw and nut of such a design that the blades are removable. The nut is in the form of a

bush, passing through both sides of the sheet and forms a hinge upon which the blades may be

rotated. The sheath is so designed as to fully protect the blades when not in use.

11 | P a g e

Steel Rule

Linear measurement includes the measurement of lengths, diameters, heights and thickness. The

basic principle of linear measurement (mechanical type) is that of comparison with standard

dimensions on a suitably engraved instrument or device. Linear measuring instruments are

categorized depending upon their accuracy. The two categories are non-precision instruments

and precision instruments. Non-precision instruments include steel rule, caliper divider, and

telescopic gauge that are used to measure to the line graduations of a rule. Precision instruments

include micrometers, vernier calipers, height gauges and slip gauges. A wide variety of electrical

measuring devices is also available. Electric measuring devices are mainly transducers, i.e. they

transform the displacement into suitable measurable parameter like voltage and current. Some of

the displacement transducers are strain gauges, linear variable differential transformers (LVDT)

and potentiometers.

12 | P a g e

Firm Joint Type

They work on the friction created at the junction of the legs. The two legs are identical in shape

with the contact points equally distant from the fulcrum and are joined together by a rivet. The

component parts of the calipers should be free from seams, cracks and must have smooth bright

finish. The distance between the rivet centre and the extreme working ends of the legs is known

as nominal size and these calipers are available in the nominal size of 100, 150, 200 and 300

mm.

Firm joint calipers are of following types :

(i) Outside caliper

(ii) Inside caliper

(iii) Transfer caliper

(iv) Hermaphrodite caliper

Divider

A divider is similar in construction to a caliper except that both legs are straight with sharp

13 | P a g e

hardened points at the end as shown in Figure 5.8. These are used for scribing arcs and circles

and general layout work. The distance between the fulcrum roller centre and the extreme

working end of one of legs is known as the nominal size Dividers are available in the sizes of

100, 200, 300 mm. In practice, one point is placed in the centre position and the circle or arc may

then be scribed on the job with the other point. A steel scale must be used with this instrument.

Engineer's Taper, Wire and Thickness Gauge

This is a very handy device which contains leaves for taper measurements, wire diameter

measurements and thickness of small gaps

14 | P a g e

References

1. Metrology & Measurement by Anand K Bewoor and Vinay A Kulkarni, TMH

publications. Chapter-3, Linear Metrology, Page No.- 46 to 72.

2. http://nashvillecfi.com/instrument/npiap.html

3. http://www.mtiinstruments.com/products/precisioninstruments.aspx

4. http://telc.tanta.edu.eg/hosting/pro5/containt/L1.htm

5. http://www.indiamart.com/shri-mayank-calibration/linear-measuring-

instruments.html

6. http://www.ignou.ac.in/upload/Unit-5-62.pdf

7. http://en.wikipedia.org/wiki/Measuring_instrument

8. http://www.smi4motion.com/smi2/linear-digital-measuring-device.html

You might also like

- Inspection Gauges TypesDocument12 pagesInspection Gauges Typesahsan ali100% (1)

- Eric Cressey Corrective TrainingDocument67 pagesEric Cressey Corrective Trainingberthakey840794% (17)

- EXAVER 2 Paper 1 Sample ExamDocument6 pagesEXAVER 2 Paper 1 Sample ExamMikael Selocs100% (2)

- University of Gondar: Project 1 Titel - Linear MeasurmentDocument9 pagesUniversity of Gondar: Project 1 Titel - Linear Measurmentnahom abrhamNo ratings yet

- Different Types of Mechanical Measuring Tools and GaugesDocument7 pagesDifferent Types of Mechanical Measuring Tools and Gaugescmn_1986No ratings yet

- Chapter One (Sheet Metal)Document27 pagesChapter One (Sheet Metal)mesfin snowNo ratings yet

- Measuring InstrumentsDocument10 pagesMeasuring Instrumentsmohsin931No ratings yet

- Measuring InstrumentsDocument10 pagesMeasuring Instrumentsmohsin931No ratings yet

- Nazim Lab Session 1-15Document48 pagesNazim Lab Session 1-15Hammad SaeedNo ratings yet

- M&M LabDocument39 pagesM&M LabSUSHIL SUSHILNo ratings yet

- Laboratory Report 1 DellosaDocument11 pagesLaboratory Report 1 DellosaAgent PNo ratings yet

- University of North Carolina ManualDocument11 pagesUniversity of North Carolina ManualvysnktNo ratings yet

- TypesDocument14 pagesTypesVishal PatidarNo ratings yet

- Workshop TechnologyDocument105 pagesWorkshop Technologymuneebimran0% (1)

- Group 3 ICT PresentationDocument14 pagesGroup 3 ICT PresentationANNIE ROSE DULANGNo ratings yet

- Caliper: HistoryDocument7 pagesCaliper: HistoryOladimeji TaiwoNo ratings yet

- Dimensional Measurements: Group 22 MembersDocument12 pagesDimensional Measurements: Group 22 MemberscfellowNo ratings yet

- Internship Report: Mecas Engineering LimitedDocument11 pagesInternship Report: Mecas Engineering LimitedHaider AliNo ratings yet

- Lab Session 08 Open Ended Lab: Objective: DiagramDocument5 pagesLab Session 08 Open Ended Lab: Objective: Diagrammeen19111087 KFUEITNo ratings yet

- Lab Report 2 UpdatedDocument9 pagesLab Report 2 UpdatedMalaika KhursheedNo ratings yet

- Measurements & Metrology PracticalDocument91 pagesMeasurements & Metrology PracticalAU Aalim Muhammed Salegh Polytechnic CollegeNo ratings yet

- Measuring ToolsDocument9 pagesMeasuring ToolsWahyu FirmansyahNo ratings yet

- BTM2133-Chapter 4 Measuring InstrumentsDocument61 pagesBTM2133-Chapter 4 Measuring InstrumentsAswaja3130% (1)

- Measuring Tools: Steel RulerDocument4 pagesMeasuring Tools: Steel RulerAnonymous TXTpRqiNo ratings yet

- What Is A Smart InstrumentDocument14 pagesWhat Is A Smart InstrumentJuned LahoriNo ratings yet

- Measurement and Statistical Tasks 1Document8 pagesMeasurement and Statistical Tasks 1Agum GhifariNo ratings yet

- Mechanical Measurement LaboratoryDocument24 pagesMechanical Measurement LaboratoryMahendra SinghNo ratings yet

- Mechanical Instruments and ToolsDocument14 pagesMechanical Instruments and ToolsShakib Shaikh100% (3)

- Study of Measuring Instruments and Gauges PDFDocument7 pagesStudy of Measuring Instruments and Gauges PDFRishabh HanseliaNo ratings yet

- Assignment # 1Document12 pagesAssignment # 1ahsan aliNo ratings yet

- Micrometer CaliperDocument12 pagesMicrometer CaliperallyannanicolemartinNo ratings yet

- Metrology and MeasurementsDocument140 pagesMetrology and MeasurementsVivekanand SriramNo ratings yet

- Tools and Instruments Used in Maritrime EnginneringDocument19 pagesTools and Instruments Used in Maritrime EnginneringSHAHEEN AKBARNo ratings yet

- Introductory Macroeconomics XIIDocument28 pagesIntroductory Macroeconomics XIISnigdha100% (1)

- Various Parameter Measurement - Jan 2022 - R1Document7 pagesVarious Parameter Measurement - Jan 2022 - R1Anih Kishor (RA1911002010062)No ratings yet

- Mechanical Measurements and Measuring DevicesDocument56 pagesMechanical Measurements and Measuring Devicesrizvee.pdb21No ratings yet

- Measuring Instrument and GaugesDocument5 pagesMeasuring Instrument and GaugeskwangsooNo ratings yet

- MQC PDFDocument25 pagesMQC PDFVK DNo ratings yet

- Government Polytechnic Muzaffarpur: Lab Manual of Metrology & Quality Control Lab SUBJECT CODE - 1625506Document25 pagesGovernment Polytechnic Muzaffarpur: Lab Manual of Metrology & Quality Control Lab SUBJECT CODE - 1625506VK D0% (1)

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Metrology and MeasurementsDocument10 pagesMetrology and MeasurementsMUHAMMAD UMAR KAMRANNo ratings yet

- Measurement Techniques - Week 1Document25 pagesMeasurement Techniques - Week 1fhggdhdNo ratings yet

- Measuring MachineDocument19 pagesMeasuring Machinegopir28No ratings yet

- Metrology Assignment 2Document14 pagesMetrology Assignment 2Aadish vikramNo ratings yet

- AAADocument8 pagesAAAmansang.mc62No ratings yet

- Fundamental Techniques of Linear & Angular Measurements in SurveyingDocument15 pagesFundamental Techniques of Linear & Angular Measurements in SurveyingParvez BodhNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- Metrology and Quality AssuranceDocument8 pagesMetrology and Quality Assurancehammad ghaffarNo ratings yet

- The Micrometer: Basic TypesDocument4 pagesThe Micrometer: Basic TypesJofer SantiagoNo ratings yet

- JS01Document9 pagesJS01Fadirul EzwanNo ratings yet

- Vernier To ComparatorDocument78 pagesVernier To ComparatorAtul GaurNo ratings yet

- MCE 286-Engineering Materials and Manufacturing Processes Laboratory Name-Lab 1: Introduction and Metrology 1Document2 pagesMCE 286-Engineering Materials and Manufacturing Processes Laboratory Name-Lab 1: Introduction and Metrology 1Jay PatelNo ratings yet

- Roundness IDocument13 pagesRoundness Ibalasubramani_srinivNo ratings yet

- Vernier Calipper ExperimentSDocument9 pagesVernier Calipper ExperimentSmaylaleibordayNo ratings yet

- Lab Report 1Document5 pagesLab Report 1mamoona noreenNo ratings yet

- Vernier CaliperDocument13 pagesVernier CaliperAbdul AhadNo ratings yet

- Smaw 7 Las q3 w1 w8Document77 pagesSmaw 7 Las q3 w1 w8Rey Mamat LaguraNo ratings yet

- 1537326530linear & Angular MeasurementDocument49 pages1537326530linear & Angular MeasurementAl MamunNo ratings yet

- As Practical Book - Edited TotalDocument285 pagesAs Practical Book - Edited TotalonlyheavenismygoalNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Measurement of Length - Screw Gauge (Physics) Question BankFrom EverandMeasurement of Length - Screw Gauge (Physics) Question BankNo ratings yet

- Ravenloft Gazetteer Volume IVDocument170 pagesRavenloft Gazetteer Volume IVFelipe Barroso100% (1)

- Paragraph TransitionsDocument6 pagesParagraph TransitionsJames ScottNo ratings yet

- TenchuDocument3 pagesTenchuricky_ratedNo ratings yet

- PenthouseDocument8 pagesPenthouseBe SauNo ratings yet

- FOCGB3 Utest VG 3ADocument1 pageFOCGB3 Utest VG 3AGyurácz GyulaNo ratings yet

- Present Simple PDFDocument3 pagesPresent Simple PDFAnni GumiNo ratings yet

- Saiki RanDocument1 pageSaiki RanMadhu Prathipati PNo ratings yet

- Lab Exercise: Microscopy: Care of The MicroscopeDocument13 pagesLab Exercise: Microscopy: Care of The Microscopeblackforest8No ratings yet

- Tracklist Dimitri Vegas & Like Mike Tomorrowland 2013Document2 pagesTracklist Dimitri Vegas & Like Mike Tomorrowland 2013faisal aswinNo ratings yet

- Design of Ogee SpillwayDocument4 pagesDesign of Ogee Spillwaydsananda100% (3)

- Interview QuestionsDocument7 pagesInterview QuestionssangeethadurjatiNo ratings yet

- Technical Specifications of Computed Radiography SystemDocument3 pagesTechnical Specifications of Computed Radiography SystemConrad ConradmannNo ratings yet

- Final Hindu Review May 2019 PDFDocument21 pagesFinal Hindu Review May 2019 PDFAbhishekNo ratings yet

- Bentley SELECT Licensing Program EligibilityDocument13 pagesBentley SELECT Licensing Program EligibilitySanjay SibalNo ratings yet

- Abad, Glenford V - Activity 2Document3 pagesAbad, Glenford V - Activity 2glenford abadNo ratings yet

- Big Magic Secret Ebook FinalDocument107 pagesBig Magic Secret Ebook FinalIntellibrain75% (4)

- Lightpipe DesignDocument22 pagesLightpipe DesignkonshoeNo ratings yet

- 07 - C175Document20 pages07 - C175Ariel Zamora Rodriguez100% (3)

- Elma Metrel A1436 Buletooth Dongle Manual ENDocument10 pagesElma Metrel A1436 Buletooth Dongle Manual ENatianna.paschalNo ratings yet

- Worldbuilding - Fantasy ReligionDocument16 pagesWorldbuilding - Fantasy Religionscottwelchkin100% (2)

- VJJVJVJDocument7 pagesVJJVJVJAnirudh KawNo ratings yet

- Tagore PDFDocument18 pagesTagore PDFjohnyyNo ratings yet

- DmOS 8.2.0 - DatasheetDocument25 pagesDmOS 8.2.0 - DatasheetPaulo Lima CamposNo ratings yet

- Catalogo Cressi Mergulho 2009Document110 pagesCatalogo Cressi Mergulho 2009alexpt2000100% (23)

- Pork16 PDFDocument24 pagesPork16 PDFSean AabergNo ratings yet

- 212 Chapter07Document63 pages212 Chapter07HAU LE DUCNo ratings yet

- R Rec BT.2100 0 201607 I!!pdf eDocument17 pagesR Rec BT.2100 0 201607 I!!pdf eYANo ratings yet

- BNW Character ListDocument2 pagesBNW Character Listapi-279810228No ratings yet