Professional Documents

Culture Documents

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Uploaded by

cool_rdCopyright:

Available Formats

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- EJ501 T2 Logical Sensor and ActuatorDocument53 pagesEJ501 T2 Logical Sensor and ActuatorLoga HSNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Frequently Asked Questions: tSEN-190Document1 pageFrequently Asked Questions: tSEN-190Venkat DeepakNo ratings yet

- PNP NPN SensorsDocument9 pagesPNP NPN Sensorsraj kharatNo ratings yet

- See What Is Going On! Capacitive Sensor For More TransparencyDocument9 pagesSee What Is Going On! Capacitive Sensor For More TransparencyJanfel LimboNo ratings yet

- Interfacing With Proximity SensorDocument21 pagesInterfacing With Proximity SensorYupniatsNo ratings yet

- Magnetic Proximity SwitchDocument9 pagesMagnetic Proximity SwitchSagar ChachondiaNo ratings yet

- Sensors PaperworkDocument22 pagesSensors PaperworkShawn TaladhayNo ratings yet

- Inductive Sensor: PrincipleDocument47 pagesInductive Sensor: Principletheone_415No ratings yet

- 电感接近开关的选择和使用 - VOICE OF STEVEDocument3 pages电感接近开关的选择和使用 - VOICE OF STEVEapi-19795268No ratings yet

- Semester: V Class / Branch: TE ITDocument6 pagesSemester: V Class / Branch: TE ITKaustubh SawantNo ratings yet

- Sensor Material !Document6 pagesSensor Material !Emmanuel__KNo ratings yet

- Tuan2 - Digital SensorsDocument19 pagesTuan2 - Digital SensorsNguyen Thanh LauNo ratings yet

- PLC Level 1Document46 pagesPLC Level 1Mohamed MamdouhNo ratings yet

- Discrete Automatic SensorsDocument9 pagesDiscrete Automatic SensorsAyase ManamiNo ratings yet

- Sensors and ActuatorsDocument109 pagesSensors and ActuatorsDr-Amit Kumar Singh100% (2)

- Assignment: Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesAssignment: Course Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Everything You Need To Know About Proximity Sensor CircuitDocument11 pagesEverything You Need To Know About Proximity Sensor CircuitjackNo ratings yet

- Case Study On Inductive Proximity SwitchesDocument4 pagesCase Study On Inductive Proximity SwitchesMANASNo ratings yet

- Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesCourse Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Capacitive Proximity SensorsDocument22 pagesCapacitive Proximity SensorsYahia NassarNo ratings yet

- Rolling Mill AutomationDocument23 pagesRolling Mill AutomationMohamed AlkharashyNo ratings yet

- Mr5103 Sensors and Signal Conditioning: Assignment - IDocument40 pagesMr5103 Sensors and Signal Conditioning: Assignment - ISamuel AbraghamNo ratings yet

- Basics of Sensors - Siemens WW (Industrial Automation Sensors)Document112 pagesBasics of Sensors - Siemens WW (Industrial Automation Sensors)VanNinh TNNo ratings yet

- Basics of SensorsDocument112 pagesBasics of SensorsAnshul ShambhavNo ratings yet

- Proximity Sensor Inductive, Capacitive Photoelectric.Document27 pagesProximity Sensor Inductive, Capacitive Photoelectric.Vikas KumarNo ratings yet

- Sensor Tech. PresentationDocument8 pagesSensor Tech. PresentationVaibhav AwareNo ratings yet

- Proximity Sensor: I. Prereading QuestionsDocument7 pagesProximity Sensor: I. Prereading QuestionsPamungkasNo ratings yet

- Notes - Unit - 4Document25 pagesNotes - Unit - 4shubhtrip4No ratings yet

- Proximity Sensor: Types of Sensor Circuits IR SensorsDocument5 pagesProximity Sensor: Types of Sensor Circuits IR SensorsgobimohanNo ratings yet

- Industrial Sensors: Programmable Logic Controllers Industrial ControlsDocument22 pagesIndustrial Sensors: Programmable Logic Controllers Industrial ControlsVenkat RajNo ratings yet

- Elements of Technology (Eot) : Assignment 3Document38 pagesElements of Technology (Eot) : Assignment 3nikitaNo ratings yet

- ch3 - Sensor TechnologyDocument58 pagesch3 - Sensor TechnologyOla JamesNo ratings yet

- Module 2Document61 pagesModule 2yashpalsingh80726No ratings yet

- البحث الاولDocument15 pagesالبحث الاولMohamed ElzabalawyNo ratings yet

- 1.) RESISTIVE SENSORS: The Resistive Sensors Can Be Defined As The Resistance of A Sensor Can BeDocument3 pages1.) RESISTIVE SENSORS: The Resistive Sensors Can Be Defined As The Resistance of A Sensor Can BeSanjana SehrawatNo ratings yet

- 4 Sensor Communication DesignDocument60 pages4 Sensor Communication DesignAdam AndualemNo ratings yet

- Chapter 2 Logical SensorDocument33 pagesChapter 2 Logical SensorMuhammad AniqNo ratings yet

- Lecture-2 Sensors and ActuatorsDocument39 pagesLecture-2 Sensors and ActuatorsDeepak TendolkarNo ratings yet

- Inductive Proximity Sensor Interfaced With ArduinoDocument6 pagesInductive Proximity Sensor Interfaced With ArduinoIJSTENo ratings yet

- Balba, King Patrick V. ME-5202Document3 pagesBalba, King Patrick V. ME-5202King Patrick BalbaNo ratings yet

- TechCorner 20 - Sensor OverviewDocument3 pagesTechCorner 20 - Sensor OverviewQuantumAutomationNo ratings yet

- Logical SensorsDocument7 pagesLogical SensorssohiravleensinghNo ratings yet

- Inductive SensorDocument7 pagesInductive Sensorr.vishalvibhakarNo ratings yet

- WSN FileDocument9 pagesWSN FileleezaNo ratings yet

- Proximity Sensor: Name: Tarun Kumar VTU No.: 14026 Subject: Sensor and ActuatorsDocument8 pagesProximity Sensor: Name: Tarun Kumar VTU No.: 14026 Subject: Sensor and ActuatorsTarun KumarNo ratings yet

- Transducers 3Document15 pagesTransducers 3Rudra MishraNo ratings yet

- Types of Sensor and Their ApplicationDocument6 pagesTypes of Sensor and Their Applicationpogisimpatiko0% (1)

- Proximity SensorDocument4 pagesProximity SensormunugotisumanthraoNo ratings yet

- Lab - 13 - PhotoInterupter and Proximity SensorDocument9 pagesLab - 13 - PhotoInterupter and Proximity SensorRahman ShafiqueNo ratings yet

- Inductive Proximity Sensors Lec3Document28 pagesInductive Proximity Sensors Lec3Hakije LakherNo ratings yet

- Handbook of Ultra-Wideband Short-Range Sensing: Theory, Sensors, ApplicationsFrom EverandHandbook of Ultra-Wideband Short-Range Sensing: Theory, Sensors, ApplicationsNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Textbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationFrom EverandTextbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationNo ratings yet

- Overview of Indian Hazardous Location SystemDocument7 pagesOverview of Indian Hazardous Location Systemcool_rdNo ratings yet

- Sasol Synfuels Success StoryDocument3 pagesSasol Synfuels Success Storycool_rdNo ratings yet

- Lucius Learning Series - MOV Seismic Weak LinkDocument20 pagesLucius Learning Series - MOV Seismic Weak Linkcool_rdNo ratings yet

- Vegason 61 63-EnDocument32 pagesVegason 61 63-Encool_rd100% (1)

- Basic Safety Publications: International Electrotechnical CommissionDocument4 pagesBasic Safety Publications: International Electrotechnical Commissioncool_rdNo ratings yet

- FC 0113 Ashcroft SelectionDocument2 pagesFC 0113 Ashcroft Selectioncool_rdNo ratings yet

- Template - Control ValveDocument7 pagesTemplate - Control Valvecool_rd0% (1)

- Application Guide: Selection of Type EnclosuresDocument20 pagesApplication Guide: Selection of Type Enclosurescool_rdNo ratings yet

- Technical Brief - IP RatingsDocument2 pagesTechnical Brief - IP Ratingscool_rdNo ratings yet

- DCSandPLC Cement PlantsDocument12 pagesDCSandPLC Cement PlantsWaqar Abdul GhaffarNo ratings yet

- FC 0313 SpirePaperDocument8 pagesFC 0313 SpirePapercool_rdNo ratings yet

- Wiring Diagram For NPN and PNP 3 Wire Sensors With The D2-16ND3-2Document1 pageWiring Diagram For NPN and PNP 3 Wire Sensors With The D2-16ND3-2cool_rdNo ratings yet

- Ins and Outs of I/P Transducers: General DescriptionDocument7 pagesIns and Outs of I/P Transducers: General Descriptioncool_rdNo ratings yet

- Form No.16A: Tax Information Network of Income Tax Department Certificate No.: GVVIPLDocument2 pagesForm No.16A: Tax Information Network of Income Tax Department Certificate No.: GVVIPLcool_rdNo ratings yet

- TNB Electricity System - Tenaga Nasional BerhadDocument2 pagesTNB Electricity System - Tenaga Nasional BerhadNor IdayuNo ratings yet

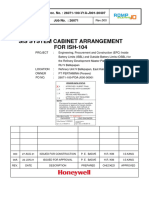

- 26071-100-V1a-J001-20407 - 000 Sis System Cabinet Arrangement For Ish-104Document10 pages26071-100-V1a-J001-20407 - 000 Sis System Cabinet Arrangement For Ish-104widionosucipto29No ratings yet

- TV Flyback Transformer Datasheet List - Belajar SEODocument5 pagesTV Flyback Transformer Datasheet List - Belajar SEOempeeno10% (1)

- Routine Test Vs Type Test Report PDFDocument3 pagesRoutine Test Vs Type Test Report PDFMuhammad SyarifNo ratings yet

- L&T - Tech Article - Motorised Changeover Connection Logic and ApplicationDocument3 pagesL&T - Tech Article - Motorised Changeover Connection Logic and ApplicationIshwar ranawatNo ratings yet

- bc141 PDFDocument5 pagesbc141 PDFVonalOrduNo ratings yet

- Catalog enDocument292 pagesCatalog enSella KumarNo ratings yet

- EHX 12ay7 Mic PreDocument1 pageEHX 12ay7 Mic Prepmacs10No ratings yet

- Power Transmission Over Long Distances With CablesDocument8 pagesPower Transmission Over Long Distances With CablesramsesiNo ratings yet

- Bom For Sb1 Annexure ODocument9 pagesBom For Sb1 Annexure ONilanjan GuhaNo ratings yet

- 0100 Motor Start Cat enDocument190 pages0100 Motor Start Cat enVõ Thạch BảoNo ratings yet

- JNTUK R19 I-Year-ECE-Syllabus-30-31Document2 pagesJNTUK R19 I-Year-ECE-Syllabus-30-31ramiNo ratings yet

- MTPL-OM-PPM-CL-007 - PPM Checklist For TrackerDocument2 pagesMTPL-OM-PPM-CL-007 - PPM Checklist For TrackerVeerendra YduvanshiNo ratings yet

- © by Tony Van RoonDocument24 pages© by Tony Van RoonBagavath Singh100% (1)

- Klockner Moeller HPL0211-2004 - 11 - IZM - GBDocument79 pagesKlockner Moeller HPL0211-2004 - 11 - IZM - GBMario Penelo RivaNo ratings yet

- DR K B Singh Lecture Notes PG III Sem TTLDocument3 pagesDR K B Singh Lecture Notes PG III Sem TTLAbhijith PrabhaNo ratings yet

- Villa Smart 2 Solar Power Back Up SystemDocument4 pagesVilla Smart 2 Solar Power Back Up SystemCamaNo ratings yet

- ELA1501-2023-S1-Major Test 2Document4 pagesELA1501-2023-S1-Major Test 2Ayanda AyoNo ratings yet

- CatalogueNEX24NEW SchneiderDocument26 pagesCatalogueNEX24NEW Schneidermaniking1No ratings yet

- TS Synchronous CondenserDocument8 pagesTS Synchronous CondenserAndré LuizNo ratings yet

- An 2236Document3 pagesAn 2236georgesmaccarioNo ratings yet

- A McMurray InverterDocument2 pagesA McMurray Inverteranshu71% (7)

- Arteche Ds Acd-17 enDocument2 pagesArteche Ds Acd-17 enSolidNo ratings yet

- Littelfuses Switch DiagramsDocument2 pagesLittelfuses Switch DiagramsRicardo VilhenaNo ratings yet

- Building GroundingDocument11 pagesBuilding Groundinggerrzen64No ratings yet

- Overgangsliste Fra Compact NS Til NSXDocument48 pagesOvergangsliste Fra Compact NS Til NSXKais AbichouNo ratings yet

- sr2b201jd PDFDocument6 pagessr2b201jd PDFMircea MurarNo ratings yet

- Metal Detectors LagfgfgnDocument1 pageMetal Detectors LagfgfgnLan HoangNo ratings yet

- Next Generation Alternative Energy Storage Application With Super Capacitors or Ultra CapacitorsDocument16 pagesNext Generation Alternative Energy Storage Application With Super Capacitors or Ultra CapacitorsHaritha HariNo ratings yet

- Com RS485Document7 pagesCom RS485Alexandra CăpraruNo ratings yet

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Uploaded by

cool_rdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Frequently Asked Questions: Directlogic PLC Modules (Except 305

Uploaded by

cool_rdCopyright:

Available Formats

Frequently Asked Questions

How do inductive proximity switches work?

Inductive proximity switches are used to detect the presence of metallic objects without actually contacting the object. Their high-speed switching and small size make them indispensable in automation applications. Inductive proximity switches consist of a coil driven by an oscillator. The oscillator creates an electromagnetic field which appears at the active face of the switch. If a metal target enters this area, the electromagnetic field is reduced and the switch turns on or off. Some typical inductive sensor applications are: counting metallic objects, monitoring the position of elements in a machine, sensing the presence of metallic parts like screws, etc., and measuring the rotational speed of axial detecting cams.

Company Information Systems Overview

What output do I need? NPN or PNP?

This is determined by the device you are connecting the sensor to. Most DirectLOGIC PLC modules (except 305 series) allow NPN or PNP sensors to be connected. This is determined by how the sensor is wired to the PLC.

Do AutomationDirect supplied sensors operate on AC or DC voltage?

The majority of AutomationDirect supplied sensors operate on 10-30 VDC. However, we do offer the VT1, VK1, and VM1 series that operate on 20-253VAC.

Programmable Controllers

Field I/O Software C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights Process Relays/ Timers Comm. Terminal Blocks & Wiring Power

How do I choose between normally open (N.O.) and normally closed (N.C.)?

N.O. sensors do not pass power to the PLC until an object is detected. N.C. sensors always pass power to the PLC until an object is detected. The majority of Centsable sensors are N.O.; however, some sensors offer the option of N.C., such as PKW, PMW and CT1 series.

Can my sensor be installed in a washdown area?

Yes. All AutomationDirect supplied proximity sensors carry an IP67 or IP68 enclosure rating. This rating allows temporary submersion of the sensor into water.

What does switching frequency mean to my application?

This is how fast your sensor can sense an object, reset, and sense another object. For example, if a sensor has a switching frequency of 100 Hz or 100 cycles per second, the sensor can sense a maximum of 100 objects per second. This is very critical in many applications such as gear rotation measurement.

What is the difference between inductive and capacitive sensors?

The primary difference is sensing material. Inductive sensors only detect metallic objects while capacitive sensors will detect materials such as wood, paper, liquids, cardboard, etc.

When do I want quick disconnects (Q/D) versus embedded cable output?

There is a slight cost increase to purchase a sensor and a Q/D cable compared to only purchasing a sensor with a preattached cable. However, the Q/D output allows easy replacement of a failed sensor. This is important in minimizing machine or operation downtime.

Can the sensor be put into a vibrating environment?

Yes. Frequency range of 10-55 Hz, maximum amplitude of 1mm. Duration in any axis a maximum of 30 minutes.

How do I know what size proximity sensor I need?

It depends on two factors: mounting space and sensing distance. Each application has a specific space available for the sensor and each application has a requirement for how close the sensor can be mounted to the sensed object.

What is the difference between 2wire, 3-wire, and 4-wire sensors?

2-wire sensors: allows either NPN or PNP outputs (don't have to select). 3-wire sensors: standard sensors. When ordering, you must choose between NPN and PNP output. 4-wire sensors: Allow either N.O. or N.C. outputs (don't have to select). Must still select NPN or PNP output.

What is the temperature range of the sensors?

Most sensors operate between -25F and 70F. However, check the specifications for exact ranges.

What is the difference between shielded and unshielded?

With a shielded proximity sensor, the face of the sensor may be mounted flush with metal, whereas an unshielded sensor may NOT be mounted flush with metal (otherwise the sensor will always be ON). In many applications, flush mounting is a requirement. Also, unshielded proximity sensors allow for greater sensing distances.

If I wire my proximity sensor wrong, will it damage it?

Possibly. All sensors contain polarity reversal, short-circuit and transient noise protection. However, the transient protection is only effective under 30 VDC.

Circuit Protection Enclosures Tools Pneumatics Appendix Product Index Part # Index

Volume 13

w w w. a u to m at i o n d i re c t . c o m / p rox i m i ty

Sensors

e18-77

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- EJ501 T2 Logical Sensor and ActuatorDocument53 pagesEJ501 T2 Logical Sensor and ActuatorLoga HSNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Frequently Asked Questions: tSEN-190Document1 pageFrequently Asked Questions: tSEN-190Venkat DeepakNo ratings yet

- PNP NPN SensorsDocument9 pagesPNP NPN Sensorsraj kharatNo ratings yet

- See What Is Going On! Capacitive Sensor For More TransparencyDocument9 pagesSee What Is Going On! Capacitive Sensor For More TransparencyJanfel LimboNo ratings yet

- Interfacing With Proximity SensorDocument21 pagesInterfacing With Proximity SensorYupniatsNo ratings yet

- Magnetic Proximity SwitchDocument9 pagesMagnetic Proximity SwitchSagar ChachondiaNo ratings yet

- Sensors PaperworkDocument22 pagesSensors PaperworkShawn TaladhayNo ratings yet

- Inductive Sensor: PrincipleDocument47 pagesInductive Sensor: Principletheone_415No ratings yet

- 电感接近开关的选择和使用 - VOICE OF STEVEDocument3 pages电感接近开关的选择和使用 - VOICE OF STEVEapi-19795268No ratings yet

- Semester: V Class / Branch: TE ITDocument6 pagesSemester: V Class / Branch: TE ITKaustubh SawantNo ratings yet

- Sensor Material !Document6 pagesSensor Material !Emmanuel__KNo ratings yet

- Tuan2 - Digital SensorsDocument19 pagesTuan2 - Digital SensorsNguyen Thanh LauNo ratings yet

- PLC Level 1Document46 pagesPLC Level 1Mohamed MamdouhNo ratings yet

- Discrete Automatic SensorsDocument9 pagesDiscrete Automatic SensorsAyase ManamiNo ratings yet

- Sensors and ActuatorsDocument109 pagesSensors and ActuatorsDr-Amit Kumar Singh100% (2)

- Assignment: Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesAssignment: Course Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Everything You Need To Know About Proximity Sensor CircuitDocument11 pagesEverything You Need To Know About Proximity Sensor CircuitjackNo ratings yet

- Case Study On Inductive Proximity SwitchesDocument4 pagesCase Study On Inductive Proximity SwitchesMANASNo ratings yet

- Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesCourse Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Capacitive Proximity SensorsDocument22 pagesCapacitive Proximity SensorsYahia NassarNo ratings yet

- Rolling Mill AutomationDocument23 pagesRolling Mill AutomationMohamed AlkharashyNo ratings yet

- Mr5103 Sensors and Signal Conditioning: Assignment - IDocument40 pagesMr5103 Sensors and Signal Conditioning: Assignment - ISamuel AbraghamNo ratings yet

- Basics of Sensors - Siemens WW (Industrial Automation Sensors)Document112 pagesBasics of Sensors - Siemens WW (Industrial Automation Sensors)VanNinh TNNo ratings yet

- Basics of SensorsDocument112 pagesBasics of SensorsAnshul ShambhavNo ratings yet

- Proximity Sensor Inductive, Capacitive Photoelectric.Document27 pagesProximity Sensor Inductive, Capacitive Photoelectric.Vikas KumarNo ratings yet

- Sensor Tech. PresentationDocument8 pagesSensor Tech. PresentationVaibhav AwareNo ratings yet

- Proximity Sensor: I. Prereading QuestionsDocument7 pagesProximity Sensor: I. Prereading QuestionsPamungkasNo ratings yet

- Notes - Unit - 4Document25 pagesNotes - Unit - 4shubhtrip4No ratings yet

- Proximity Sensor: Types of Sensor Circuits IR SensorsDocument5 pagesProximity Sensor: Types of Sensor Circuits IR SensorsgobimohanNo ratings yet

- Industrial Sensors: Programmable Logic Controllers Industrial ControlsDocument22 pagesIndustrial Sensors: Programmable Logic Controllers Industrial ControlsVenkat RajNo ratings yet

- Elements of Technology (Eot) : Assignment 3Document38 pagesElements of Technology (Eot) : Assignment 3nikitaNo ratings yet

- ch3 - Sensor TechnologyDocument58 pagesch3 - Sensor TechnologyOla JamesNo ratings yet

- Module 2Document61 pagesModule 2yashpalsingh80726No ratings yet

- البحث الاولDocument15 pagesالبحث الاولMohamed ElzabalawyNo ratings yet

- 1.) RESISTIVE SENSORS: The Resistive Sensors Can Be Defined As The Resistance of A Sensor Can BeDocument3 pages1.) RESISTIVE SENSORS: The Resistive Sensors Can Be Defined As The Resistance of A Sensor Can BeSanjana SehrawatNo ratings yet

- 4 Sensor Communication DesignDocument60 pages4 Sensor Communication DesignAdam AndualemNo ratings yet

- Chapter 2 Logical SensorDocument33 pagesChapter 2 Logical SensorMuhammad AniqNo ratings yet

- Lecture-2 Sensors and ActuatorsDocument39 pagesLecture-2 Sensors and ActuatorsDeepak TendolkarNo ratings yet

- Inductive Proximity Sensor Interfaced With ArduinoDocument6 pagesInductive Proximity Sensor Interfaced With ArduinoIJSTENo ratings yet

- Balba, King Patrick V. ME-5202Document3 pagesBalba, King Patrick V. ME-5202King Patrick BalbaNo ratings yet

- TechCorner 20 - Sensor OverviewDocument3 pagesTechCorner 20 - Sensor OverviewQuantumAutomationNo ratings yet

- Logical SensorsDocument7 pagesLogical SensorssohiravleensinghNo ratings yet

- Inductive SensorDocument7 pagesInductive Sensorr.vishalvibhakarNo ratings yet

- WSN FileDocument9 pagesWSN FileleezaNo ratings yet

- Proximity Sensor: Name: Tarun Kumar VTU No.: 14026 Subject: Sensor and ActuatorsDocument8 pagesProximity Sensor: Name: Tarun Kumar VTU No.: 14026 Subject: Sensor and ActuatorsTarun KumarNo ratings yet

- Transducers 3Document15 pagesTransducers 3Rudra MishraNo ratings yet

- Types of Sensor and Their ApplicationDocument6 pagesTypes of Sensor and Their Applicationpogisimpatiko0% (1)

- Proximity SensorDocument4 pagesProximity SensormunugotisumanthraoNo ratings yet

- Lab - 13 - PhotoInterupter and Proximity SensorDocument9 pagesLab - 13 - PhotoInterupter and Proximity SensorRahman ShafiqueNo ratings yet

- Inductive Proximity Sensors Lec3Document28 pagesInductive Proximity Sensors Lec3Hakije LakherNo ratings yet

- Handbook of Ultra-Wideband Short-Range Sensing: Theory, Sensors, ApplicationsFrom EverandHandbook of Ultra-Wideband Short-Range Sensing: Theory, Sensors, ApplicationsNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Textbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationFrom EverandTextbook of Urgent Care Management: Chapter 35, Urgent Care Imaging and InterpretationNo ratings yet

- Overview of Indian Hazardous Location SystemDocument7 pagesOverview of Indian Hazardous Location Systemcool_rdNo ratings yet

- Sasol Synfuels Success StoryDocument3 pagesSasol Synfuels Success Storycool_rdNo ratings yet

- Lucius Learning Series - MOV Seismic Weak LinkDocument20 pagesLucius Learning Series - MOV Seismic Weak Linkcool_rdNo ratings yet

- Vegason 61 63-EnDocument32 pagesVegason 61 63-Encool_rd100% (1)

- Basic Safety Publications: International Electrotechnical CommissionDocument4 pagesBasic Safety Publications: International Electrotechnical Commissioncool_rdNo ratings yet

- FC 0113 Ashcroft SelectionDocument2 pagesFC 0113 Ashcroft Selectioncool_rdNo ratings yet

- Template - Control ValveDocument7 pagesTemplate - Control Valvecool_rd0% (1)

- Application Guide: Selection of Type EnclosuresDocument20 pagesApplication Guide: Selection of Type Enclosurescool_rdNo ratings yet

- Technical Brief - IP RatingsDocument2 pagesTechnical Brief - IP Ratingscool_rdNo ratings yet

- DCSandPLC Cement PlantsDocument12 pagesDCSandPLC Cement PlantsWaqar Abdul GhaffarNo ratings yet

- FC 0313 SpirePaperDocument8 pagesFC 0313 SpirePapercool_rdNo ratings yet

- Wiring Diagram For NPN and PNP 3 Wire Sensors With The D2-16ND3-2Document1 pageWiring Diagram For NPN and PNP 3 Wire Sensors With The D2-16ND3-2cool_rdNo ratings yet

- Ins and Outs of I/P Transducers: General DescriptionDocument7 pagesIns and Outs of I/P Transducers: General Descriptioncool_rdNo ratings yet

- Form No.16A: Tax Information Network of Income Tax Department Certificate No.: GVVIPLDocument2 pagesForm No.16A: Tax Information Network of Income Tax Department Certificate No.: GVVIPLcool_rdNo ratings yet

- TNB Electricity System - Tenaga Nasional BerhadDocument2 pagesTNB Electricity System - Tenaga Nasional BerhadNor IdayuNo ratings yet

- 26071-100-V1a-J001-20407 - 000 Sis System Cabinet Arrangement For Ish-104Document10 pages26071-100-V1a-J001-20407 - 000 Sis System Cabinet Arrangement For Ish-104widionosucipto29No ratings yet

- TV Flyback Transformer Datasheet List - Belajar SEODocument5 pagesTV Flyback Transformer Datasheet List - Belajar SEOempeeno10% (1)

- Routine Test Vs Type Test Report PDFDocument3 pagesRoutine Test Vs Type Test Report PDFMuhammad SyarifNo ratings yet

- L&T - Tech Article - Motorised Changeover Connection Logic and ApplicationDocument3 pagesL&T - Tech Article - Motorised Changeover Connection Logic and ApplicationIshwar ranawatNo ratings yet

- bc141 PDFDocument5 pagesbc141 PDFVonalOrduNo ratings yet

- Catalog enDocument292 pagesCatalog enSella KumarNo ratings yet

- EHX 12ay7 Mic PreDocument1 pageEHX 12ay7 Mic Prepmacs10No ratings yet

- Power Transmission Over Long Distances With CablesDocument8 pagesPower Transmission Over Long Distances With CablesramsesiNo ratings yet

- Bom For Sb1 Annexure ODocument9 pagesBom For Sb1 Annexure ONilanjan GuhaNo ratings yet

- 0100 Motor Start Cat enDocument190 pages0100 Motor Start Cat enVõ Thạch BảoNo ratings yet

- JNTUK R19 I-Year-ECE-Syllabus-30-31Document2 pagesJNTUK R19 I-Year-ECE-Syllabus-30-31ramiNo ratings yet

- MTPL-OM-PPM-CL-007 - PPM Checklist For TrackerDocument2 pagesMTPL-OM-PPM-CL-007 - PPM Checklist For TrackerVeerendra YduvanshiNo ratings yet

- © by Tony Van RoonDocument24 pages© by Tony Van RoonBagavath Singh100% (1)

- Klockner Moeller HPL0211-2004 - 11 - IZM - GBDocument79 pagesKlockner Moeller HPL0211-2004 - 11 - IZM - GBMario Penelo RivaNo ratings yet

- DR K B Singh Lecture Notes PG III Sem TTLDocument3 pagesDR K B Singh Lecture Notes PG III Sem TTLAbhijith PrabhaNo ratings yet

- Villa Smart 2 Solar Power Back Up SystemDocument4 pagesVilla Smart 2 Solar Power Back Up SystemCamaNo ratings yet

- ELA1501-2023-S1-Major Test 2Document4 pagesELA1501-2023-S1-Major Test 2Ayanda AyoNo ratings yet

- CatalogueNEX24NEW SchneiderDocument26 pagesCatalogueNEX24NEW Schneidermaniking1No ratings yet

- TS Synchronous CondenserDocument8 pagesTS Synchronous CondenserAndré LuizNo ratings yet

- An 2236Document3 pagesAn 2236georgesmaccarioNo ratings yet

- A McMurray InverterDocument2 pagesA McMurray Inverteranshu71% (7)

- Arteche Ds Acd-17 enDocument2 pagesArteche Ds Acd-17 enSolidNo ratings yet

- Littelfuses Switch DiagramsDocument2 pagesLittelfuses Switch DiagramsRicardo VilhenaNo ratings yet

- Building GroundingDocument11 pagesBuilding Groundinggerrzen64No ratings yet

- Overgangsliste Fra Compact NS Til NSXDocument48 pagesOvergangsliste Fra Compact NS Til NSXKais AbichouNo ratings yet

- sr2b201jd PDFDocument6 pagessr2b201jd PDFMircea MurarNo ratings yet

- Metal Detectors LagfgfgnDocument1 pageMetal Detectors LagfgfgnLan HoangNo ratings yet

- Next Generation Alternative Energy Storage Application With Super Capacitors or Ultra CapacitorsDocument16 pagesNext Generation Alternative Energy Storage Application With Super Capacitors or Ultra CapacitorsHaritha HariNo ratings yet

- Com RS485Document7 pagesCom RS485Alexandra CăpraruNo ratings yet