Professional Documents

Culture Documents

Relationship Between Capillary Pressure and Resistivity Index

Relationship Between Capillary Pressure and Resistivity Index

Uploaded by

Rosa K Chang HOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Relationship Between Capillary Pressure and Resistivity Index

Relationship Between Capillary Pressure and Resistivity Index

Uploaded by

Rosa K Chang HCopyright:

Available Formats

SCA2005-14

1/12

RELATIONSHIP BETWEEN CAPILLARY PRESSURE AND RESISTIVITY INDEX

Kewen Li*, Stanford University and Yangtz University and Wade Williams, Core Lab, Inc. * Corresponding author This paper was prepared for presentation at the International Symposium of the Society of Core Analysts held in Toronto, Canada, 21-25 August 2005

Abstract

A model has been derived theoretically to correlate capillary pressure and resistivity index. The model is simple and predicts a power law relationship between capillary pressure and resistivity index on a log-log plot. To verify the model, gas-water capillary pressure and resistivity were measured simultaneously at a room temperature in 14 core samples from two formations in an oil reservoir. The permeability of the core samples ranged from 0.028 to over 3000 md. The porosity ranged from less than 8% to over 30%. Capillary pressure curves were measured using a semi-permeable porous-plate technique. The model was tested against the experimental data obtained in this study. The results demonstrated that the model could match the experimental data satisfactorily. Using the model, capillary pressure may be inferred from resistivity data. An existing model was also tested against the experimental data. The results showed that the existing model did not work in most of the cases studied. The new model developed in this study may be useful to evaluate capillary pressure function from resistivity data both in laboratories and reservoirs, especially in the case in which permeability is low.

Introduction

Both capillary pressure and resistivity index are important parameters in reservoir engineering. It is easier to measure resistivity index than capillary pressure in a laboratory, especially for core samples with low permeabilities. One can run resistivity well logging in a well, even in real time, but cannot do this for capillary pressure. It would be useful if a relationship between capillary pressure and resistivity can be found. Resistivity, capillary pressure, and relative permeability have similar features. For example, all are a function of fluid saturation in a porous medium and are influenced by pore structure and heterogeneity. Li and Horne1 derived a model to infer relative permeability from resistivity index. We speculated that capillary pressure may also be derived from resistivity index. Szabo2 proposed a linear model to correlate capillary pressure with resistivity by assuming the exponent of the relationship between capillary pressure and water saturation is equal to that of the relationship between resistivity and water saturation. This assumption may not be reasonable in many cases. The linear model proposed by Szabo2 can be expressed as follows:

SCA2005-14

2/12

Rt = a + bPc R0

(1)

where Ro is the resistivity at a water saturation of 100%, Rt is the resistivity at a specific water saturation of Sw, Pc is the capillary pressure, a and b are two constants. The results from Szabo2 demonstrated that a single straight line, as predicted by the model (Eq. 1), could not be obtained for the relationship between capillary pressure and resistivity index. Longeron et al.3 measured the resistivity index and capillary pressure under reservoir conditions simultaneously. Longeron et al.3 didnt attempt to correlate the two parameters. Literature on the relationship between capillary pressure and resistivity index has been scarce. In this study, a theoretical relationship between capillary pressure and resistivity index was derived. In order to verify the relationship, gas-water capillary pressure and resistivity were measured simultaneously in 14 core samples at a room temperature using a semiporous-plate approach.

Theoretical Background

A theoretical relationship between capillary pressure and resistivity index is derived in this section. The basic idea behind this is that both capillary pressure and resistivity index are a function of the wetting phase saturation and the functions are known from the fractal modeling of a porous medium and are discussed in the following. Toledo et al.4 reported that resistivity obeys the scaling law at low wetting phase saturations:

1

1 ( 3 D f ) ( Sw ) Rt

(2)

where is the exponent in the relation of disjoining pressures and film thickness, Sw is the wetting phase saturation, and Df is the fractal dimension of the surface of the grains in matrix. Toledo et al.4 also reported that capillary pressure follows the scaling law at low wetting phase saturations:

S w ( Pc )

( 3 D f )

(3)

SCA2005-14

3/12

Combining Eqs. 2 and 3, one can obtain:

Pc ( Rt )

(4)

It is known that Rt is equal to Ro when Pc is equal to pe at a water saturation of 100%, which can be expressed as follows using Eq. 4:

pe ( R0 )

(5)

Combining Eqs. 4 and 5:

Pc = pe ( Rt ) R0

(6)

Using the dimensionless form, Eq. 6 can be expressed as follows:

PcD = ( I )

(7)

Where PcD is the dimensionless capillary pressure (Pc/pe); I is the resistivity index and, as a function of the wetting phase saturation, can be represented using the Archies equation5:

I= Rt = Swn R0

(8)

here n is the saturation exponent. R0 depends on the porosity of a porous medium and can be calculated:

FR = R0 = m Rw

(9)

Where Rw is the resistivity of water, m is the cementation exponent, and FR the formation factor. According to Eq. 7, dimensionless capillary pressure can be inferred from the resistivity well logging data once the value of is known. This may provide a new approach to obtain capillary pressure data for reservoir engineering.

SCA2005-14

4/12

Experiments

Experiments were conducted at a room temperature to measure gas-water capillary pressure and resistivity simultaneously. The apparatus, rock and fluid properties are described in this section. Rock and Fluid Properties The properties of the core samples used in this study are listed in Table 1. All the core samples were obtained from one oil reservoir. Group 1 core samples were from one formation with a high permeability and Group 2 were from another formation with a low permeability. The permeability in Group 1 ranged from 437 to 3680 md; the permeability in Group 2 ranged from 0.028 to 387 md. The brine used for Group 1 core samples had a salinity of 90,000 ppm with a resistivity of 0.078 ohm-m at 25C. The brine used for Group 2 core samples had a salinity of 20,000 ppm with a resistivity of 0.308 ohm-m at 25C. Apparatus The schematic of the apparatus used for the combined measurements of gas-water capillary pressure and resistivity is shown in Fig. 1. The outside diameter of each porous plate was painted with silver paint. The resistivity meter was manufactured by Quad Tech and the model was 1730 LCR. The frequency used in this study was 20,000 hz.

Fig. 1: Schematic of experimental apparatus for measuring capillary pressure

Experimental Procedure The samples designated for these analyses were cleaned and dried prior to testing. Permeability and porosity were measured after cleaning. Then the samples were evacuated and saturated with synthetic formation brine. After loading the sample and the

SCA2005-14

5/12

porous plate into the core holder at an appropriate net stress, brine was flushed using a 500 psi back pressure to ensure a complete saturation. Resistivity was measured, followed by injection of several pore volumes of brine. The resistivity at a water saturation of 100% was measured again the following day until stabilized (less than 1% change per day). Formation resistivity factor (FRF) at stress was determined at this point. The sample was desaturated beginning at a low pressure by injecting humidified air at a regulated capillary pressure. The volume and weight of displaced brine were monitored and used to calculate the brine saturation. Resistivity, capillary pressure, and brine saturation were measured daily at each pressure point until saturation was stabilized (less than 1% change per day). This was repeated until no water was produced. At the end of the test, each sample was removed and its weight out was measured. It was Dean-Stark extracted for water, methanol soxhlet extracted for salts, and dried to a constant weight in a vacuum oven at 100C. The final dry weight was measured. DeanStark water extracted was used to confirm the final water saturation.

Results

The experimental data of capillary pressure and resistivity index in core samples from two formations in one oil reservoir were used to test the model (Eq. 6) proposed in this study. The results are presented and discussed in this section. Fig. 2 shows the relationship between formation factor and porosity for all the samples from two formations. The values of cement exponent were calculated using Eq. 9: m is equal to 1.71 for the core samples in Group 1 (formation 1) and is equal to 2.19 for core samples in Group 2 (formation 2).

1000 Group 1 Group 2 Formation Factor 100

10

1 0.01

0.10 Porosity, fraction

1.00

Fig. 2: Relationship between formation factor and porosity for all the samples from two formations

The data of resistivity index vs. water saturation for the core samples in Group 1 (high permeability) are shown in Fig. 3. The data points follow the Archies saturation equation (Eq. 8). The values of saturation exponent were calculated for each core sample using Eq. 8 and the results are shown in Table 1. The value of n ranges from 1.82 to 2.11 and the

SCA2005-14

6/12

average value is about 1.94. The average value was calculated by conducting regression analysis for all of the data points. For the low permeability formation (Group 2), the experimental data of resistivity index are shown in Fig. 4. The values of saturation exponent calculated using Eq. 8 are also listed in Table 1. The value of n ranges from 1.82 to 2.49 and the average value is about 2.13.

1000 No.1 No.3 No.6 Resistivity Index 100 No.8 No.10 No.16 10

1 0.01

0.10 W ater Saturation, fraction

1.00

Fig. 3: Relationship between resistivity index and water saturation for the samples in Group 1

100 No.152 No.153 No.204 Resistivity Index No.299 No.334 10 No.336 No.418 No.479

1 0.10 W ater Saturation, fraction

1.00

Fig. 4: Relationship between resistivity index and water saturation for the samples in Group 2

It is necessary to have the experimental data of capillary pressure to verify the model represented by Eq. 6. The capillary pressure data of the core samples in Group 1 are shown in Fig. 5 and those of Group 2 are shown in Fig. 6. According to Eq. 3, the relationship between capillary pressure and water saturation is linear in the range of small water saturation. Figs. 5 and 6 show such a feature. Note that the range of water

SCA2005-14

7/12

saturation in which the linear relationship exists is very narrow for the No.3 core sample (see Fig. 5). One can see from Figs. 5 and 6 that the range of water saturation in which the linear relationship exists depends upon permeability. For the core samples with a low permeability, the straight line crosses over almost the entire range of water saturation from 1 to Swr (residual water saturation). For the core samples with a high permeability, however, the straight line crosses over only the part with small water saturation.

1000 No.1 No.3 No.6 No.8 No.10 No.16 10

Capillary Pressure, psi

100

1 0.01

0.10 W ater Saturation, fraction

1.00

Fig. 5: Capillary pressure curves of the samples in Group 1 (high permeability)

100

Capillary Pressure, psi

No.152 No.153 10 No.204 No.299 No.334 No.336 No.418 No.479 1 0.10 W ater Saturation, fraction 1.00

Fig. 6: Capillary pressure curves of the samples in Group 2 (low permeability)

SCA2005-14

8/12

The relationships between capillary pressure and resistivity index of Groups 1 and 2 are shown in Figs. 7 and 8 respectively. In Fig. 7, a straight line exists in the range with great capillary pressure and resistivity index (corresponding to small water saturation), as predicted by the model (Eq. 6) derived in this study.

1000 No.1 No.3 No.6 No.8 No.10 No.16 10

Capillary Pressure, psi

100

1 1 10 Resistivity Index

Fig. 7: Relationship between capillary pressure and resistivity index of Group 1 (high permeability)

100

100

1000

Capillary Pressure, psi

No.152 No.153 No.204 10 No.299 No.334 No.336 No.418 No.479 1 1 10 Resistivity Index 100

Fig. 8: Relationship between capillary pressure and resistivity index of Group 2 (low permeability)

SCA2005-14

9/12

Interestingly a straight line exists for almost all of the data points in the core samples with a low permeability (see Fig. 8). This demonstrates that the model (Eq. 6) derived from fractal modeling of a porous medium work satisfactorily. The values of regression coefficient (R), i.e., the goodness of fitting, of the model to the data shown in Figs. 7 and 8 were calculated and are listed in Table 1. One can see that the goodness of fitting is satisfactory. As stated previously, Szabo2 proposed a linear model (Eq. 1) to correlate capillary pressure and resistivity by assuming the exponent of capillary pressure curve is equal to that of the resistivity index curve. To test this model, the experimental data in Figs. 7 and 8 are plotted in Figs. 9 and 10 using a linear scale instead of a logarithmic scale. Comparing the results shown in Figs. 7 and 8 to those plotted in Figs. 9 and 10, one can see clearly that the model (Eq. 6) derived in this study has a better fitting to the experimental data than the linear model (Eq. 1) in the cases studied.

200

160 Capillary Pressure, psi

120 No.1 No.3 No.6 No.8 No.10 No.16 0 0 50 100 Resistivity Index 150 200

80

40

Fig. 9: Relationship between capillary pressure and resistivity index of Group 1 (high permeability) in a linear coordinate plot

SCA2005-14

10/12

70 60 Capillary Pressure, psi No.152 50 40 30 20 10 0 0 5 10 15 Resistivity Index 20 25 30 No.153 No.204 No.299 No.334 No.336 No.418 No.479

Fig. 10: Relationship between capillary pressure and resistivity index of Group 2 (low permeability in a linear coordinate plot)

The values of were calculated using Eq. 6 with the data shown in Figs. 7 and 8. For most of the core samples, the value of is in the range from 1 to 3. The effect of permeability on for the core samples in both Group 1 and 2 is shown in Figs. 11 and 12 respectively.

10

Exponent Between I-Pc

1 Group 1

0 100 1000 Permeability, md 10000

Fig. 11: Effect of permeability on for the core samples in Group 1 (high permeability)

SCA2005-14

11/12

10

Exponent Between I-Pc

Group 2

0 0.01

0.10

1.00

10.00

100.00

1000.00

Permeability, md

Fig. 12: Effect of permeability on for the core samples in Group 2 (low permeability)

In the cases studied, for both Group 1 and 2, the value of decreases with the increase in permeability. The relationship between permeability and is linear in a log-log plot, as shown in Figs. 11 and 12. The values of correlation coefficient for Group 1and 2 are 0.82 and 0.71 respectively.

Discussion

As demonstrated in Fig. 7, the power law model proposed in this study to correlate capillary pressure and resistivity works properly for high values of capillary pressure and resistivity (corresponding to low values of water saturations). At high water saturations, the experimental data deviate the power law model. The possible reason may be that the distribution of water saturation may not be a fractal at high water saturations. This was also pointed out by Toledo et al4. Note that Eqs. 2 and 3 are only suitable for a specific range of water saturation with low values. In the case of low permeability core samples, the number of data points that deviate the power law model is less. This may be due to the fractal property of low permeability core samples. However this is yet to study in more detail. Note that the linear model (Eq. 1) proposed by Szabo2 can fit some experimental data for the high values of capillary pressure, especially in low permeability core samples. However the data point that fit the model are very few.

Conclusions

The following conclusions may be drawn from the present study:

SCA2005-14

12/12

1. A model was developed theoretically to correlate capillary pressure and resistivity index. This model predicts a power law relationship between capillary pressure and resistivity index. 2. The model derived in this study was tested against experimental data in 14 core samples from an oil reservoir. The permeability ranged from 0.028 to over 3000 md. The results demonstrated that the model work satisfactorily. 3. The model works better in core samples with low permeabilities than those with high permeabilities. 4. The experimental results showed that the relationship between capillary pressure and resistivity index is not linear, as the existing model foresees. 5. The value of decreases with the increase in permeability. The relationship between permeability and is linear in a log-log plot in the cases studied.

Acknowledgments

This research was conducted with financial support from the US Department of Energy under grant DE-FG07-02ID14418, the contribution of which is gratefully acknowledged. The authors thank CoreLab for the permission to publish these results.

References

1. Li, K. and Horne, R.N.: A Semianalytical Method to Calculate Relative Permeability from Resistivity Well Logs, SPE 95575, the 2005 SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, October 9-12, 2005. Szabo, M.T.: New Methods for Measuring Imbibition Capillary Pressure and Electrical Resistivity Curves by Centrifuge, SPEJ (June, 1974), 243-252. Longeron, D.G., Argaud, M.J., and Bouvier, L.: Resistivity Index and Capillary Pressure Measurements under Reservoir Conditions using Crude Oil, SPE 19589, presented at the 1989 SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, October 8-11, 1989. Toledo, G.T., Novy, R.A., Davis, H.T. and Scriven, L.E.: Capillary Pressure, Water Relative Permeability, Electrical Conductivity and Capillary Dispersion Coefficient of Fractal Porous Media at Low Wetting Phase Saturation, SPE Advanced Technology Series (SPE23675), 2(1), 136-141, 1994. Archie, G.E.: The Electrical Resistivity Log as an Aid in Determining Some Reservoir Characteristics, AIME Petroleum Tech. (1942), 1-8.

2. 3.

4.

5.

Table 1: Properties of Core Sample

Core No. 1 3 6 8 10 16 152 153 204 299 334 336 418 479 Group 1 (f) 0.272 0.281 0.191 0.227 0.321 0.262 0.114 0.077 0.179 0.185 0.234 0.163 0.211 0.210 k (md) 941 1192 999 3680 437 1916 1.49 0.028 0.560 4.63 387. 35.3 74.0 28.3 g 2.66 2.66 2.65 2.65 2.65 2.66 2.63 2.64 2.69 2.66 2.65 2.66 2.70 2.68 F 10.4 8.41 15.5 11.8 8.00 9.27 122.3 380.9 43.9 40.4 18.5 40.1 26.0 29.9 Swr (f) 0.112 0.116 0.134 0.067 0.167 0.078 0.519 0.796 0.617 0.446 0.222 0.388 0.454 0.560 m 1.80 1.68 1.65 1.67 1.83 1.66 2.21 2.32 2.20 2.19 2.00 2.03 2.09 2.18 n 1.87 1.86 1.82 2.00 2.11 1.97 2.49 2.39 1.82 2.13 2.02 2.23 2.26 1.91 R 0.99 0.99 0.91 0.98 0.96 0.95 0.92 0.98 0.92 0.98 0.98 0.95 0.99 0.98

Group 2

You might also like

- Chapter One 1.1 History and Meaning of SIWESDocument12 pagesChapter One 1.1 History and Meaning of SIWESDahiru Ibrahim100% (1)

- BS EN 16781 BS 8510 Gap AnalysisDocument9 pagesBS EN 16781 BS 8510 Gap AnalysisAshok LakshmananNo ratings yet

- Modeling Cavitating Venturi FlowsDocument8 pagesModeling Cavitating Venturi Flowsorzuririke7703No ratings yet

- Prestige Medical Classic 2100 ManualDocument72 pagesPrestige Medical Classic 2100 Manualwael26724734083No ratings yet

- Fundamental Principles of Ultrafiltration PDFDocument15 pagesFundamental Principles of Ultrafiltration PDFalmutaz9879No ratings yet

- A Microtensiometer Capable of Measuring Water Potentials Below - 10 MPa. - Pagay Et Al. - Lab On A Chip - 2014Document12 pagesA Microtensiometer Capable of Measuring Water Potentials Below - 10 MPa. - Pagay Et Al. - Lab On A Chip - 2014themikemachineNo ratings yet

- A New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexDocument12 pagesA New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexRosa K Chang HNo ratings yet

- 30978Document10 pages30978reza_putra_11No ratings yet

- Spe 12580 MSDocument31 pagesSpe 12580 MSHichem FakhfekhNo ratings yet

- 53 - J. Saien, S. Akbari, J. Chem. Eng. Data 51 (2006) 1832-1835Document4 pages53 - J. Saien, S. Akbari, J. Chem. Eng. Data 51 (2006) 1832-1835Paula GayossoNo ratings yet

- Density and Viscosity of BrineDocument33 pagesDensity and Viscosity of BrineJerrydawangNo ratings yet

- Spe 14234Document13 pagesSpe 14234Roii RoyyNo ratings yet

- A Highly Elastic Constant-Viscosity FluidDocument5 pagesA Highly Elastic Constant-Viscosity FluidhosseinNo ratings yet

- Chapter 17Document20 pagesChapter 17Florina PrisacaruNo ratings yet

- SurfaceTension PDFDocument9 pagesSurfaceTension PDFZayn AhmedNo ratings yet

- 01048935Document4 pages01048935Fari PratomosiwiNo ratings yet

- SPE 158055 Effect of Reservoir Temperature and Pressure On Relative PermeabilityDocument11 pagesSPE 158055 Effect of Reservoir Temperature and Pressure On Relative PermeabilityCristhian GutierrezNo ratings yet

- A Simple Laboratory Experiment To Measure The Surface Tension of A Liquid in Contact With AirDocument9 pagesA Simple Laboratory Experiment To Measure The Surface Tension of A Liquid in Contact With Airmjs9170No ratings yet

- The of in The of Formation, CamposDocument10 pagesThe of in The of Formation, CamposRosa K Chang HNo ratings yet

- A Workflow For Fully Consistent Water Saturation Initialization Without Capillary Pressure ScalingDocument7 pagesA Workflow For Fully Consistent Water Saturation Initialization Without Capillary Pressure ScalingAiwarikiaarNo ratings yet

- SPE 93831 Effect of Temperature On Relative Permeability For Heavy-Oil Diatomite ReservoirsDocument8 pagesSPE 93831 Effect of Temperature On Relative Permeability For Heavy-Oil Diatomite Reservoirsmsmsoft90No ratings yet

- J. Wijmans - R. Baker - The Solution Diffusion Model - A ReviewDocument21 pagesJ. Wijmans - R. Baker - The Solution Diffusion Model - A ReviewNicolasNo ratings yet

- 1 Sca1998 41Document10 pages1 Sca1998 41040884No ratings yet

- Steady-State Relative Permeability Measurements and Interpretation With Account For Capillary EffectsDocument10 pagesSteady-State Relative Permeability Measurements and Interpretation With Account For Capillary EffectsRosa K Chang HNo ratings yet

- Evaluation of Water Saturation From Laboratory To LogsDocument6 pagesEvaluation of Water Saturation From Laboratory To LogsRizwan FaridNo ratings yet

- Stability Comparison of Concentric Tube Bulb Manometer With Conventional U-Shaped ManometerDocument6 pagesStability Comparison of Concentric Tube Bulb Manometer With Conventional U-Shaped ManometerSantiago ChinomeNo ratings yet

- Chapter 5Document37 pagesChapter 5TajTajNo ratings yet

- Marchisio D.L.,Rivautella L.,Gavi E.,Vanni M. - Design of Chemical Reactors For Nano-ParticleDocument8 pagesMarchisio D.L.,Rivautella L.,Gavi E.,Vanni M. - Design of Chemical Reactors For Nano-ParticleJordy CanalesNo ratings yet

- Forty Comparisons of Mercury Injection Data With Oil/Water Capillary Pressure Measurements by The Porous Plate TechniqueDocument13 pagesForty Comparisons of Mercury Injection Data With Oil/Water Capillary Pressure Measurements by The Porous Plate TechniquezoyaNo ratings yet

- Diffusivity Coefficient of HydrogenDocument7 pagesDiffusivity Coefficient of HydrogenJuan Manuel OlivoNo ratings yet

- Mulero Parra 08 1Document16 pagesMulero Parra 08 1Mustapha MaaroufNo ratings yet

- SCA 2015 Technical PapersDocument561 pagesSCA 2015 Technical PaperschikukotwalNo ratings yet

- Eames 1997 International Journal of Heat and Mass TransferDocument12 pagesEames 1997 International Journal of Heat and Mass Transferkhairani najibahNo ratings yet

- Chapter 9: Electrical Properties: F R R ADocument9 pagesChapter 9: Electrical Properties: F R R AJorge SotoNo ratings yet

- Com 2009Document13 pagesCom 2009prakush01975225403No ratings yet

- Sca1998 38Document10 pagesSca1998 38Saroo BastkyNo ratings yet

- From The Laboratory of Pathology, School of Medicine, University of Pennsylvania, Philadelphca, and The Marine Biological Laboratory, Woods Ttole.Document10 pagesFrom The Laboratory of Pathology, School of Medicine, University of Pennsylvania, Philadelphca, and The Marine Biological Laboratory, Woods Ttole.Rizki IsnaennurNo ratings yet

- Theory of Microemulsions: Comparison With Experimental Behavior+Document5 pagesTheory of Microemulsions: Comparison With Experimental Behavior+jagruthimsNo ratings yet

- Hydrostatic Limits of Fluorinert Liquids Used For Neutron and Transport Studies at High PressureDocument5 pagesHydrostatic Limits of Fluorinert Liquids Used For Neutron and Transport Studies at High Pressurejoaosilveira8992No ratings yet

- Thermal Conductivity of NaCl SolutionDocument25 pagesThermal Conductivity of NaCl SolutionlinhNo ratings yet

- Drag Reduction YanuarDocument12 pagesDrag Reduction YanuarBaqi_naval06No ratings yet

- Explicacion K PDFDocument10 pagesExplicacion K PDFLeidy Renteria EstradaNo ratings yet

- Sca1994 28Document10 pagesSca1994 28Rosa K Chang HNo ratings yet

- Well Test Oils andDocument12 pagesWell Test Oils andabdounouNo ratings yet

- L3 Competencies: This One Is Too EasyDocument12 pagesL3 Competencies: This One Is Too Easykrymxen100% (1)

- Atmospheric Correction Factor For Impulse Breakdown Voltage: P. Ortéga, R.T.Waters, A.Haddad, R.Hameed, A.J.DaviesDocument4 pagesAtmospheric Correction Factor For Impulse Breakdown Voltage: P. Ortéga, R.T.Waters, A.Haddad, R.Hameed, A.J.DaviesSriramulu KolliparaNo ratings yet

- Interference and Pulse TestingDocument68 pagesInterference and Pulse TestingRavi Shankar PatelNo ratings yet

- 1 Sca1990 07euro PDFDocument20 pages1 Sca1990 07euro PDFChairul AbdiNo ratings yet

- Elevated Temperature Fatigue of Pressure Vessel SteelsDocument6 pagesElevated Temperature Fatigue of Pressure Vessel SteelsJohnNo ratings yet

- Venturimeter Report PDFDocument7 pagesVenturimeter Report PDFAhmed M. El-DyastyNo ratings yet

- Capillary PressureDocument16 pagesCapillary Pressurezztannguyenzz100% (1)

- Laminar Flow Reactor ProblemDocument6 pagesLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- Spe113510 PDFDocument10 pagesSpe113510 PDFعبدالغفار بيزانNo ratings yet

- Kvamme 1995Document6 pagesKvamme 1995Jagho PraisakaNo ratings yet

- Liquid Phase ReactorDocument22 pagesLiquid Phase Reactorkrishy19s100% (2)

- PHPA As A Frictional Pressure Loss Reducer and Its Pressure Loss EstimationDocument6 pagesPHPA As A Frictional Pressure Loss Reducer and Its Pressure Loss Estimationtariq82aliNo ratings yet

- FRITZLER, 2014. Acetic Anhydryde Hydrolysis at High Acetic Anhydride To Water RatiosDocument10 pagesFRITZLER, 2014. Acetic Anhydryde Hydrolysis at High Acetic Anhydride To Water RatiosAnonymous DMjWxgNo ratings yet

- Electrodilatometry of Liquids, Binary Liquids, and SurfactantsDocument12 pagesElectrodilatometry of Liquids, Binary Liquids, and SurfactantsmilousNo ratings yet

- Properties of Gas and Liquid Experiment ReportDocument18 pagesProperties of Gas and Liquid Experiment ReportFadh At-Tarf67% (3)

- 00071326Document12 pages00071326theoneandonly1No ratings yet

- Physico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentFrom EverandPhysico-Chemistry of Solid-Gas Interfaces: Concepts and Methodology for Gas Sensor DevelopmentNo ratings yet

- How To Run A Nodal Analysis in PipeSIM - 4284982 - 02Document20 pagesHow To Run A Nodal Analysis in PipeSIM - 4284982 - 02Rosa K Chang HNo ratings yet

- Impact of A Novel Scale Inhibitor System On The Wettability of Paleozoic Unayzah Sandstone Reservoir, Saudi ArabiaDocument6 pagesImpact of A Novel Scale Inhibitor System On The Wettability of Paleozoic Unayzah Sandstone Reservoir, Saudi ArabiaRosa K Chang HNo ratings yet

- Sca2013 011Document12 pagesSca2013 011Rosa K Chang HNo ratings yet

- Relative Permeabilities and Transport System in Mixed Wetted Carbonate RocksDocument7 pagesRelative Permeabilities and Transport System in Mixed Wetted Carbonate RocksRosa K Chang HNo ratings yet

- Validating Laboratory Measured Archie Saturation Exponents Using Non-Resistivity Based MethodsDocument6 pagesValidating Laboratory Measured Archie Saturation Exponents Using Non-Resistivity Based MethodsRosa K Chang HNo ratings yet

- LWD IDD Image Derived DensityDocument10 pagesLWD IDD Image Derived DensityRosa K Chang HNo ratings yet

- Freezing of Poorly Consolidated Rock: Method of Stabilization or Alteration?Document6 pagesFreezing of Poorly Consolidated Rock: Method of Stabilization or Alteration?Rosa K Chang HNo ratings yet

- Tight Rock Permeability Measurement by Pressure Pulse Decay and ModelingDocument12 pagesTight Rock Permeability Measurement by Pressure Pulse Decay and ModelingRosa K Chang HNo ratings yet

- An Integrated Approach To Estimate Threshold Capillary Pressure From Core and Log DataDocument12 pagesAn Integrated Approach To Estimate Threshold Capillary Pressure From Core and Log DataRosa K Chang HNo ratings yet

- Fracture Zones Between Overlapping en Echelon Fault Strands Outcrop Analogs Within The Balcones Fault Zone Central TexasDocument9 pagesFracture Zones Between Overlapping en Echelon Fault Strands Outcrop Analogs Within The Balcones Fault Zone Central TexasRosa K Chang HNo ratings yet

- Low-Field Nuclear Magnetic Resonance Characterization of Organic Content in ShalesDocument12 pagesLow-Field Nuclear Magnetic Resonance Characterization of Organic Content in ShalesRosa K Chang HNo ratings yet

- High Resolution Imaging of Porous Geomaterials and Geological Cores With Micro Computed X-Ray TomographyDocument6 pagesHigh Resolution Imaging of Porous Geomaterials and Geological Cores With Micro Computed X-Ray TomographyRosa K Chang HNo ratings yet

- A New Coring Technology To Quantify Hydrocarbon Content and SaturationDocument6 pagesA New Coring Technology To Quantify Hydrocarbon Content and SaturationRosa K Chang HNo ratings yet

- Artificial Lift For High-Volume ProductionDocument15 pagesArtificial Lift For High-Volume ProductionRosa K Chang HNo ratings yet

- 1.1) Geophysics96 VpVs Corr AnalysisDocument13 pages1.1) Geophysics96 VpVs Corr AnalysisRosa K Chang HNo ratings yet

- Pressure, Temperature and Ionic Strength Effects On The Wettability of Co - Brine-Sandstone System: Core-Scale Contact Angle MeasurementsDocument12 pagesPressure, Temperature and Ionic Strength Effects On The Wettability of Co - Brine-Sandstone System: Core-Scale Contact Angle MeasurementsRosa K Chang HNo ratings yet

- Configuring Devices and Device Drivers: This Lab Contains The Following Exercises and ActivitiesDocument11 pagesConfiguring Devices and Device Drivers: This Lab Contains The Following Exercises and ActivitiesColby HumphreyNo ratings yet

- Garden City University College: Department of I.C.TDocument3 pagesGarden City University College: Department of I.C.Trichardmawuli3593No ratings yet

- The Arcgis BookDocument156 pagesThe Arcgis BookCristi Popa100% (2)

- PT Foundations-1Document5 pagesPT Foundations-1YNNo ratings yet

- Specification of 1500v 5.1mva Solar Ware Station - RevaDocument15 pagesSpecification of 1500v 5.1mva Solar Ware Station - Revalilama45-1No ratings yet

- Within Your PresentationDocument2 pagesWithin Your PresentationMUSYOKA KITUKUNo ratings yet

- Hearts of Care Community Hospital Project ProposalDocument33 pagesHearts of Care Community Hospital Project ProposalWALGEN TRADINGNo ratings yet

- Fig. 4. X-Ray Diffraction Pattern of Bio-SynthesizedDocument3 pagesFig. 4. X-Ray Diffraction Pattern of Bio-SynthesizedAfrah MNo ratings yet

- Scorpions Send Me An AngelDocument3 pagesScorpions Send Me An AngelKi J GaborNo ratings yet

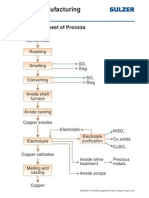

- Copper Manufacturing Process: General Flowsheet of ProcessDocument28 pagesCopper Manufacturing Process: General Flowsheet of ProcessflaviosazevedoNo ratings yet

- Radio Propagation - Large-Scale Path LossDocument68 pagesRadio Propagation - Large-Scale Path LossInvincible 2.0No ratings yet

- Education Research and Development 9sometimes Called ResearchDocument4 pagesEducation Research and Development 9sometimes Called ResearchFirmanNo ratings yet

- Triz 2Document170 pagesTriz 2ravikumarrampurNo ratings yet

- DHCP - DORA Process Call Flow WifiDocument18 pagesDHCP - DORA Process Call Flow WifiArjunAslekarNo ratings yet

- Resume - Alexis GibsonDocument1 pageResume - Alexis Gibsonapi-521009603No ratings yet

- Essentials of Financial Management 3rd Edition Brigham Solutions Manual 1Document18 pagesEssentials of Financial Management 3rd Edition Brigham Solutions Manual 1whitneyreynoldsnzrtkbamfd100% (32)

- Physiology of Normal Pueperium and Its ManagementDocument13 pagesPhysiology of Normal Pueperium and Its ManagementSandhya s100% (3)

- Discussion and Conclusion Travel SpeedDocument4 pagesDiscussion and Conclusion Travel SpeedFahmie FizalNo ratings yet

- Mystical Kashmir Vacation - With Houseboat Stay (14!04!2023T20 - 50) - QuoteId-25446607Document14 pagesMystical Kashmir Vacation - With Houseboat Stay (14!04!2023T20 - 50) - QuoteId-25446607time delhiNo ratings yet

- FOR Approval Specification: Title 32.0" Wuxga TFT LCDDocument36 pagesFOR Approval Specification: Title 32.0" Wuxga TFT LCDСергій НестеровичNo ratings yet

- Avoiding Sentence ErrorsDocument26 pagesAvoiding Sentence Errorsapi-327193447No ratings yet

- ADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPADocument2 pagesADVANCE COPY 20230218 DILG ADVISORY No 02 On The LPABarangay MabuloNo ratings yet

- BRP 40k Second Edition 2col PDFDocument54 pagesBRP 40k Second Edition 2col PDFColin BrettNo ratings yet

- 04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerDocument39 pages04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerMuhammad Saeed100% (2)

- Digital WatermarkingDocument29 pagesDigital WatermarkingAngelNo ratings yet

- Projport For Bhog PurDocument26 pagesProjport For Bhog Purpj singhNo ratings yet

- Experiment 3 - Loss On IgnitionDocument5 pagesExperiment 3 - Loss On IgnitionSeth Aboagye JnrNo ratings yet