Professional Documents

Culture Documents

Operations

Operations

Uploaded by

Danny LiuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operations

Operations

Uploaded by

Danny LiuCopyright:

Available Formats

S01179768 On my honor, I have not given nor received any unauthorized aid.

Dimmu Burger is a privately owned take-out burger joint in the Southern California region, created by a band of five heavy metal rockers that hail from the freezing shores of Olso, Norway. A take from the word Dimmuborgir, which translates to dark castles in Old Norse, Dimmu Burger prides itself in its dark, gothic, death metal theme, and its literally fresh from the cow, bloody rare hamburgers. While not achieving the same national market share compared to places such as MacDonalds, Wendys, and Burger King, Dimmu Burger has gotten a loyal share of crowds, mostly from hard rockers, goths, and organized cultists around the Sunset Strip in Hollywood. There is only one Dimmu Burger in Los Angeles, and it is the size of a small factory. The lines around Dimmu Burger are packed with loyal and zealous customers, and stretches around for literally blocks. The means by which Dimmu Burger processes the meat comes not from packaged delivered ground meat, but from live cows, supplied via a vendor in Texas who overnights them via airplane. Great care is taken to ensure that the cows are healthy and free of disease. Dimmu Burger believes that, for the highest quality and most brutal hamburger, the cow must die in the most violent matter, and that the hamburgers should come from all parts of the cow, such as brisket, tenderloin, sirloin and ribeye. This gives Dimmu Burger significant differential advantage against other hamburger joints that base their hamburger meat solely on ground chuck (and thus, just order the cheapest ground beef). When they arrive, the cows are then taken to a small processing plant, in which they are literally sacrificed by executioners wearing dark hoods and wielding giant axes. The cows have an average weight of 750 lbs, of which an average of 1/3 of its live weight is allocated towards hamburger meat. Dimmu Burgers hamburger sizes use only single half-pound (or 8 oz) hamburger patties, there are no options for double-patties nor any fluctuations in size. Each cow will contribute an average of 500 hamburgers. Dimmu Burger is open from Monday to Saturday (6 days) from 10AM to 1AM (a 15 hour day), for a total of a 90 hour work week. Processing cows and cooking burgers run throughout the day, and in one hour, the team of executioners can process (which means conducting a sacrificial ritual, beheading the cow by axe, manually stripping the meat from the bone, then chopping the meat to itty bitty pieces while reciting ancient Druid chants, then form the meat into patties) an average of 1 cow. During that same hour, the cooks will use up all the

meat allocated from the cows to make the hamburgers, with none left over. The patties were cooked in a large scale cast iron griddle set on maximum heat to enable a seared crust, for a total of 2 minutes per side (bloody rare) for a total of 4 minutes. In addition, Dimmu Burger patties are taken literally from the cow (who has an average temperature of 101.5 degrees Fahrenheit) and they are not refrigerated, so it takes less time to cook then chilled patties from a refrigerator. Each burger needs a 25 square inch grid (5x5in) of space when cooking. Dimmu Burger keeps a minimum of 2 cast iron 40 x 200 in (8,000 sq in) griddles cooking at anytime, with 2 more on standby in case demand picks up. Normal capacity per cooking cycle is 320 burgers per griddle, with a maximum capacity of 1280 burgers per cooking cycle. During cooking, the patties are seasoned with sea salt and cracked black pepper. The cooking staff are highly efficient to ensure that there is always a constant set of burger patties on the grill, that adhering to the 4 minute cooking cycle means up to 15 cooking cycles can occur in the hour, and that there is no time lost between cycles. The hamburger patty is mated with a bun that was provided as part of a deal with a local bakery; as part of its brutal marketing slogan, Dimmu Burgers are served plain and have no vegetables, condiments, or cheese. Thus the burgers were not cooked to specified order: everyone gets the same Dimmu Burger. Once a customer placed an order, he got the next burger in the inventory/production que. If production exceeds demand, the hamburgers will be left at underneath a heatlamp. If demand exceeds current production, those hamburgers are taken from the heatlamp. Burgers were provided takeout and the customers had very limited eating facilities; Dimmu Burger focused the majority of its facility space on production, cooking, and taking/serving orders. There were always enough booths to serve the longest of lines; the wait was for enough burgers to finish cooking. The customer service was minimal, and it was intentionally so. Much like Pats and Genos Cheesesteak takeouts in Philly, or the Soup Nazi from Seinfeld, the staff played its Brutal customer service very well: they were intentionally rude, mocked customers, and provided the bare minimum of service. And the customers enjoyed every moment of it because people went to Dimmu Burger not just for the food, but for the dark and black metal culture. Revenue wise, all of this bare minimum service this help cut down operating costs. At the end of the day, all hamburgers are thrown out and donated (without revenue) to a non-profit organization dedicated to providing food for homeless Rottweilers. On days that there werent

enough hamburgers to go around, Dimmu Burger will close doors at the end of the work day, and all customers who were in line but didnt get a burger will go home disappointed and hungry. Weekly direct labor costs are around $25,000, weekly direct material costs are $30,000, and overhead costs were $45,000 for a total cost of $100,000. Each labor day will go through 15 cows, or 7,500 hamburgers per day. One week will have production of 45,000 hamburgers. This translates to a cost per burger to be $2.22. Each burger was told for $7, giving a gross margin of $4.78. The original goals declared by Dimmu Burger was to provide the only the most brutal hamburgers while maintaining at least a breakeven net profit, after all the capital investments, overhead, labor, and all operating expenditures were taken into account. All Dimmu Burger management cared about was maintaining a positive net margin on each individual hamburger, no matter how many were sold. Because the founding members of Dimmu Burgers were heavy metal death rockers and not businessmen, they werent exactly customer orientated, nor did they try to streamline or refine production, nor did they even care about the various fluctuations in demand. Whether not enough burgers were made that could have generated extra revenue, or there were burgers made in which there wasnt enough demand, they just casually wrote it off as sunk costs and didnt pay any more attention to that afterwards. Production continued at 7,500 hamburgers a day, and there were various fluctuations in demand. Still, Dimmu Burger didnt take measures to account for this. For the next year, profits started to drop as fixed costs soon outweighed any contribution margins the hamburgers made for the company. In their worse quarter, they had a negative profit margin, among one of their worse performances made. No knowing what to do, they turned over to Galweather and Stern (G&S), a local management consulting firm in Los Angeles, for assistance in what to do. A team from Galweather and Stern, consisting of Marty Kaan, Jeannie van der Hooven, Doug Guggenheim, and Clyde Oberholt, arrived and quickly accessed the situation. The G&S team first started out by estimating the maximum demand. There are approximately 3.8 M people in the city of Los Angeles, covering approximately 500 square miles of land, approximating a 22.3 x 22.3 mile grid. The immediate area of Hollywood approximates to be 28 square miles. Comparing 28 to 500 means that land is 5.6% of Los Angeles, and that maximum Hollywood population would be about 5.6% of the immediate population, of about

212800. But because there would be other customers coming in from all over town, there should be a customer base at least double that of Hollywood, so 212800 would be multipled by three (Hollywood, and double to account for outsiders) to be 638400. Assuming there are three other competitors (McDonalds, Wendys, Burger King, and In-and-Out), Dimmu Burger would have an equal market share (20%), approximately 127,680 customers. Of these customers, they estimated that 80% will fall under a targeted demographics of hamburgers (who doesnt like hamburgers), which means 102144 remaining. Of that, assuming that there are seven days of the week and 4 meals per day (breakfast, lunch, dinner, late nite munches) , it is estimated about 30% would want to eat hamburgers, so 30% of 102144 would mean about 30643 people would want to eat burgers. Taking other factors such as surveys, interviews, and quantitative and qualitative marketing research into account, a metrics analysis conducted by Doug Guggenheim saw that the average mean of people who wanted to eat hamburgers at Dimmu Burger per day was analyzed to be about 15,000 per day, with a standard deviation of 2500. Production was at 7,500 hamburgers per day. The key insight was that while Dimmu Burger was losing money on hamburgers it could not sell when demand wasnt enough, this was a secondary concern. They were losing much greater opportunities by not having enough hamburgers to sell. On top of that, because production couldnt meet demand, the customers base were getting a little disgruntled and several customers were leaving Dimmu Burgers fanbase, in favor of carne asada burritos. Marty Kaan recommended that Dimmu Burger focus a new goal, which was to increase production capacity and win back the customers, and take advantage of the various economies of scale that resulted. First off, the G&S team introduced the Dimmu Burgers leadership to the Theory of Constraints, which was that an organization can be measured and controlled in three metrics. The first was Throughput, which was the rate in which Dimmu Burger generates money through sales (Sales Revenue Raw Material expense). The second is Inventory, the money in which Dimmu Burger spends in products it intends to sell. The last is Operational Expense, the money Dimmu Burger spends to turn the product into Throughput. These translates to Net Product (Throughput Operational Expenses), Rate of Investments (Net Product / Inventory Costs), and Cash flow checklist question (whether income + net working capital is greater than costs).

There was also the theory that any organization would be hindered by at least one constraint; if there were no constraints, throughput would be limitless and thus impossible. If that constraint were to be identified and improved upon, the company will be for the better. The G&S Team told the Dimmu Burger staff that will implement a 5 process checklist: 1) 2) 3) 4) 5) Identify the Constraint Decide how to get the Most out of the Constraint Align the organization to support the Constraint improvement process Make any other changes needed to the Constraint If success, go back to step 1, but continue to check for feedback

The G&S team then took a look at the processing, cooking, storage, and serving facilities, then concluded that the bottleneck constraint was the processing facilities. There was enough cooking space to accommodate more hamburger patties, and there was always enough hamburger buns to go around, but at times there werent enough hamburger meat getting through. The team identified the production facility as the need for improvement, and accessed the cooking facilities and hamburger bun supply chain as non-bottlenecks. The first thing Marty Kaans team did was to have Dimmu Burger upgrade its cow production processing capacity. The cows were no longer airlifted from Texas, they were now delivered by railroad from Nevada, which lowered the material costs. The consulting team also outfitted the executioners with upgraded swords and axes (by chance the G&S team were watching Game of Thrones) that were able to cut and chop the cows much more efficient than before. G&S then installed a processing machine that could separate the meat from the bones before the executioners would chop the meat (apparently, automated meat grinders was something Dimmu Burger refused to allow). Lastly, the C&S team introduced third-party energy drinks (some ingredients were of questionable legal status) and installed a high volume stereo system inside the processing plant. Their logic was that with heavy metal music blaring, the energy drink stimulated executioners would go into a blood frenzy and process more cows with more vigor and enthusiasm then before. The results were phenomenal. By identifying the constraint then elevating the system constraint, Dimmu Burgers executioners were now able to process 2.5 cows (and cook 1250 hamburgers) per hour, which translates to 37.5 cows and 18,750 hamburgers a day. Production week was 112,500 hamburgers a week. The new weekly costs were direct labor costs are around $50,000, weekly direct material costs are $20,000, and weekly overhead costs were $80,000 for a

total cost of $150,000. Cooking facilities were able to keep up with production. New costs per burger was now $1.33, a direct consequence from the economies of scale. Because the G&S team was able to increase production rate and meet the higher demand, the Throughput increased. Because the supply material for the cows was allocated to Nevada now, the Inventory costs decreased. And because the price per burger has now decreased, the Operational Expenses decreased. This three metrics approached turned out to be an effective decision, and soon Dimmu Burger put G&Ss new recommendation into practice. When the consulting team left Dimmu Burger, the five death metal rockers realized an insight behind change management. If they wanted to change Dimmu Burger for the better, they had to know what to change, what to change to, and how to cause that change. In the past year since, Dimmu Burger was able to turn their net profits back in the green, and achieve a higher level than they have previously thought possible. In all situations, Dimmu Burger found that it can now achieve even the highest demand, and it could taper off production at will on those rare occasions of lowered demand. Dimmu Burger has become one of the frontrunners in both market share and volume, and there is talk of them expanding into other parts of California.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Case Analysis: Murphy Stores, Capital ProjectDocument2 pagesCase Analysis: Murphy Stores, Capital Projectariba farrukhNo ratings yet

- Payment of WagesDocument2 pagesPayment of WagesRoizki Edward Marquez100% (1)

- Positions PaperDocument9 pagesPositions Paperapi-238823212100% (1)

- AMS News in The AustralianDocument4 pagesAMS News in The AustralianandrewsaisaiNo ratings yet

- Grapphite IndiaDocument16 pagesGrapphite IndiaShubham KumarNo ratings yet

- QS World University Rankings 2020 - Las Mejores Universidades Mundiales - Universidades PrincipalesDocument36 pagesQS World University Rankings 2020 - Las Mejores Universidades Mundiales - Universidades PrincipalesSamael AstarothNo ratings yet

- Tumasik or Old SingaporeDocument6 pagesTumasik or Old SingaporeAdrian TanNo ratings yet

- Chapter 1Document25 pagesChapter 1Naman PalindromeNo ratings yet

- TimesofindiaDocument30 pagesTimesofindiaGopi GopinathanNo ratings yet

- Teacher's RightDocument39 pagesTeacher's RightLizze Agcaoili ArizabalNo ratings yet

- RPH Final NotesDocument9 pagesRPH Final NotesMariel de LeonNo ratings yet

- Case - Make in IndiaDocument15 pagesCase - Make in IndiaMrinal Mantravadi100% (1)

- Decision Making ModelDocument16 pagesDecision Making ModelprernaNo ratings yet

- Auditing I Chapter FourDocument10 pagesAuditing I Chapter FourDere GurandaNo ratings yet

- Loan SchemesDocument48 pagesLoan SchemesbalwinderNo ratings yet

- Answer Key Language 3 CompherensiveDocument4 pagesAnswer Key Language 3 CompherensiveswarajNo ratings yet

- Municipality of San Narciso Vs Mendez Sr. DigestDocument2 pagesMunicipality of San Narciso Vs Mendez Sr. DigestMark MlsNo ratings yet

- Lzu 1431171 M 7Document24 pagesLzu 1431171 M 7ravitheleoNo ratings yet

- Intercultural Communication Globalization and Social Justice 2nd Edition Sorrells Test Bank 1Document25 pagesIntercultural Communication Globalization and Social Justice 2nd Edition Sorrells Test Bank 1erinbartlettcbrsgawejx100% (34)

- 711 申請書Document2 pages711 申請書Stefanie SusantiNo ratings yet

- Teacher Toolbox Assignment Example From ShaneDocument2 pagesTeacher Toolbox Assignment Example From Shaned0% (1)

- Distributed PowerDocument3 pagesDistributed PowertibvalNo ratings yet

- Ernesto Martínez RamírezDocument2 pagesErnesto Martínez RamírezJavier VillarrealNo ratings yet

- Calificaciones2196790 355f773db07f894Document4 pagesCalificaciones2196790 355f773db07f894Yessika Sanchez BayonaNo ratings yet

- Casper Jensen 2014 Promises of Practice2Document21 pagesCasper Jensen 2014 Promises of Practice2Pedro Neves MarquesNo ratings yet

- Derivative Securities: FINA 3204Document27 pagesDerivative Securities: FINA 3204BillyNo ratings yet

- Test IslamiatDocument3 pagesTest IslamiatWaqas AliNo ratings yet

- Assignment in Psychology of Law EnforcementDocument4 pagesAssignment in Psychology of Law EnforcementKRISTINE DEE L VELASCONo ratings yet

- Alternative DevelopmentDocument28 pagesAlternative DevelopmentOmar100% (1)

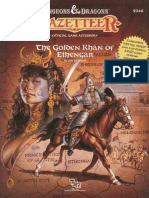

- GAZ12 - Golden Khan of EthengarDocument118 pagesGAZ12 - Golden Khan of EthengarPascal Leroy100% (3)