Professional Documents

Culture Documents

Application of Lime-Flyash Stabilization For Standardization of Urban Road Construction at Surat, South Gujarat

Application of Lime-Flyash Stabilization For Standardization of Urban Road Construction at Surat, South Gujarat

Uploaded by

Maharajan McsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Lime-Flyash Stabilization For Standardization of Urban Road Construction at Surat, South Gujarat

Application of Lime-Flyash Stabilization For Standardization of Urban Road Construction at Surat, South Gujarat

Uploaded by

Maharajan McsCopyright:

Available Formats

APPLICATION OF LIME-FLYASH STABILIZATION FOR STANDARDIZATION OF URBAN ROAD CONSTRUCTION AT SURAT, SOUTH GUJARAT

Ravin M. Tailor

Lecturer, Civil Engineering Department, S.V. National Institute of Technology, Surat 395007 Email: rtailor_1978@yahoo.co.in

Dr. M. D. Desai

Visiting Professor, Applied Mechanics Department, S.V. National Institute of Technology, Surat 395007 Email : earthmdd@yahoo.co.in

ABSTRACT: The City of Surat covered by top strata of Black Cotton soil situated in South Gujarat region in India suffered lots due to expansive behaviour of the soil. This soil being expansive with frequent flood occurrence requires special attention for road construction. The Surat Municipal Corporation (SMC) looking after the road construction activity within the city limits constructed the roads with conventional rubble at subbase layers. The roads did not perform well with the expansive subgrade after rains every year. Also as per IRC: 37-2001 Annexure 4 suggest 0.6 to 1.0 m thick non-expansive cohesive soil (CNS) cushion on the expansive soil for road construction. The old city & drainage of flood did not permit raising formation level of old roads. SMC decided to standardize design with construction procedures for different categories of the roads. The objective was common design and tendering for quick implementation of infrastructure planning of fast growing urban center. Apart from economy and time saved, design was aimed at better performance & durability. The new designs with insitu Lime - Flyash stabilized soil layer as subgrade are prepared with specified construction techniques. The design is performing well with reduction in annual maintenance expenditure of SMC for flexible roads. This design is also utilized by the private developers as standardized design for internal society roads etc. 1.0 INTRODUCTION:

The South West region of India is covered by top soil as black cotton soil. Fig. 1 shows the top soil layer for the country, it indicates that the country has about 40 % top soil as black cotton soil. This soil being the expansive soil requires special attention for pavement design. The IRC: 37 2001 has special recommendations for the pavement on expansive soil in Annexure 4. The city of Surat situated in South Gujarat region of West India is the one of the fastest growing urban centers in India. The city having majority of top soil as black cotton soil, also the city is flooded with frequent floods. The Surat Municipal Corporation (SMC) is looking after the road construction and maintenance activity within

Proceedings of International Conference on Infrastructure Development on Expansive Soils. Index-09 ACE Hosur TN 635109

the city limits. The earlier approach for new road construction was having the different road designs for each proposed road. The city with 6 zones (before 2006) having variety of road design for different roads in different zones. The typical design followed by SMC is shown in Fig. 2. It shows that the design is having rubble soling as sub-base layer, above which the aggregate layer provided as base layer and the bituminous macadam layer with seal coat act as top surfacing. The use of rubble as sub-base layer created lots of problems by sinking in subgrade soil due to impact of traffic and dead load, which caused mud pumping during monsoon. It led to the failure of pavement, formation of potholes, ruts etc. The roads were badly damaged after the every monsoon and the maintenance cost were also higher.

Fig. 1- Map showing the soil deposits in India.

Wearing Coat 20 mm

Macadam Metal

Wearing / Seal Coat 6 % asphalt (Grit + Sand) Grouting 5 kg/sq.mt. Asphalt cover with Grit 0.2 cu.mt./sq.mt.

40 mm 120 mm

Macadam with 4 % Asphalt & Metal (50 %) + Grit (50 %) 40 - 63 mm Metal

Rubble Soling

230 mm

Rubble Soling, > 50 to < 230 mm thickness

Drain

G.L.

Yellow Earth

100 mm

Yellow Earth above natural soil

Fig.2- Sketch showing the typical pavement composition executed by SMC pre 1995.

180

Ravin M. Tailor and Dr. M. D. Desai

During the year 2002 the SMC has decided to form a committee for standardization of road design for different categories. The committee has the experts of road design from Industry as well as Academic Institutes. The committee has decided to prepare the standardized road design for specified categories of roads for city limits. The roads are categorized as, a) Residential Streets, having width less than 12.19 mt (< 40), b) Collector Streets, having width 12.19 to 24.39 mt, Excluding 24.39 mt (4080, Excluding 80), c) Sub Arterial Roads, having width 24.39 to 36.58 mt, Excluding 36.58 mt (80120, Excluding 120) & d) Arterial Roads, having width 36.58 to 60.97 mt (120 to 200). These categories are common for all the zones. All zones have to follow the common design for each category of the road. This helps in maintaining uniformity for different pavement thickness, its composition etc. for roads within different zones of the city. The pavement design with Lime-Flyash stabilized sub-grade, excluding the top surfacing was entrusted to author 2. The top surfacing for different category of the road was decided by the other committee members and it has to be followed while designing new pavement thicknesses. In this paper the standardized pavement design for Residential Streets and Collector Streets are discussed. The practice of pavement construction before monsoon and laying top bituminous surfacing after year was considered in design. 2.0 SUBGRADE:

The Surat city is covered in major part by black cotton soil. It is highly plastic clay (CH group) with high expansive potential / shrinkage potential. Nos. of tests was carried out to get the CBR value of existing subgrade layer. The average value observed was Soaked CBR of 1 to 2 %. The recent study by Jigisha (2008) also shows the Soaked CBR value for South Gujarat region as 1.0 to 2.0 %. The IRC:372001 Annexure 4 suggest 0.6 to 1.0 m thick non-expansive cohesive soil (CNS) cushion on the expansive soil for road construction. The old city area & drainage of flood did not permit raising the formation level of roads. As per new road design it has decided to go for insitu soil stabilization with Lime and Flyash. The stabilization has to be done in following steps. (1) Disk harrowing the existing top 100 to 150 mm soil. (2) Apply 10 kg of slaked lime (CaOH, as per clause 402.2.2 of MoRT&H) per sq.m. area. (3) Apply 50 kg Flyash per sq.m. (4) Thoroughly mix the Lime Flyash with pulverized soil by disk harrowing. (5) Cured the mixed material for 24 hrs with 60 to 70 liter water per sq.m. (6) Compact the cured surface with 8 T static / vibratory rollers as per guidelines of IRC: 37 2001. This stabilized subgrade has the minimum CBR value of 4 %. Hence the subgrade CBR = 4% is adopted for all categories road design. The width of stabilization has to be 1 m more than proposed road width for better performance. However when the pavement is in cutting, this additional 1 m width can be dropped, which would mostly found in SMC case. Also the drainage on roadsides is assumed as well planned. Thus drain will not soak subgrade during the rains and a random check on CBR with tolerance + 5 % has suggested for better quality control.

181

Proceedings of International Conference on Infrastructure Development on Expansive Soils. Index-09 ACE Hosur TN 635109

3.0

TRAFFIC:

The vehicle count survey at different locations was carried out to get the existing traffic condition for each category of the roads. Based on the observed traffic composition and future growth of the city the 0.5 to 1.0 msa and 12 msa were considered as design traffic for Residential Streets and Collector Streets respectively.

4.0

PAVEMENT THICKNESS AND ITS COMPOSITION:

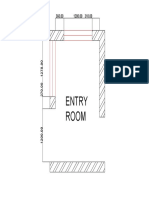

Using the CBR = 4 % and the design traffic for both categories of the roads as discussed in above para the detailed design was carried out referring IRC: 37 2001. Fig. 2 and 3 shows the pavement thickness with its detailed composition and material specification for Residential Streets and Collector Streets respectively.

Road Com ponent G.L.

Bitum inous Surfacing

Thickness, Layers & Com paction

Material &Specification

Form ation level up to Grouting Grouting 5 Kg/SM Asphalt cover with grit 0.03 CM/SM

100 m m

Layer IV Layer III Layer II Layer I

Metal confirm ing to Table 400-7 Grading III of MoRT& H-2001 Metal confirm ing to Table 400-7 Grading II of MoRT& H-2001 / EAF slag as per gradation given in Note (4) Quarry Spoil confirm ing to Table 400-2 Grading I of MoRT& H2001 / EAF slag as per gradation given in Note (4) Disc harrowing insitu Mixing Lim e @10 Kg / SM+ Fly Ash @ 50 Kg / SM & water 60 to 70 Litre / SM,24 hrs curing, Rolling by 8 T static / vibratory roller as per IRC-37:2001 Total 400 m m (Excluding Grouting thickness & Bitum inous Surfacing

Base

100 m m

Sub Base & Subgrade

100 m m 100 m m

Note: (1) Road is in cutting and well drained, Excavation width = Total width + 1.0 mt.

(2) All the above thickness are as compacted. (3) No watering is to be done in Layer II, Layer III & Layer VI. (4) Grading of EAF Slag is as below: Size of Sieve % By weight passing 45 mm 100 22.4 mm 30 - 50 4.75 mm 0-5 (5) Asphalt grade 80 / 100 (6) Lime is Slaked lime (fresh) CaOH as per Clause 402.2.2, MoRT&H. (7) CBR of Layer II materials 30%, Compaction 95% of heavy compation test. (8) - Indicates compaction as per IRC 37:2001 or MORT&H Specification (9) Bituminous Surfacing will be as per the recommondations of the comittee(40mm BM + 25mm SDBC).

Fig.3- Sketch showing the various layers of Roads having width less than 12.19 mt. - Residential Streets, Surat City Limit.

182

Ravin M. Tailor and Dr. M. D. Desai

Road Com ponent G.L.

Bitum inous Surfacing 75 m m Layer IV - B Base 75 m m Layer IV - A 100 m m Layer III Sub Base

&

Thickness, Layers & Com paction

Material & Specification

Form ation level up to Grouting Grouting 5 Kg/SM Asphalt cover with grit 0.03 CM/SM, Rolled

Metal confirm ing to Table 400-7 Grading III of MoRT& H-2001 Metal confirm ing to Table 400-7 Grading II of MoRT& H-2001 Quarry Spoil confirm ing to Table 400-2 Grading I of MoRT& H2001 / EAF slag as per gradation given in Note (4) Disc harrowing insitu Mixing Lim e @10 Kg / SM+ Fly Ash @ 50 Kg / SM & water 60 to 70 Litre / SM,24 hrs curing, Rolling by 8 T static / vibratory roller as per IRC-37:2001

Grouting 2 Kg/SM Asphalt cover with grit 0.03 CM/SM, Rolled Total 630 m m (Excluding Grouting thickness & Bitum inous Surfacing)

90 m m Layer II - B 90 m m Layer II - A 200 m m Layer I

Subgrade

Note: (1) Road is in cutting and well drained, Excavation width = total width + 0.6 to 1.0 mt.

(2) All the above thickness are as compacted. (3) No watering is to be done in Layer II-A, Layer II-B, Layer III & Layer IV-A, Layer IV-B. (4) Grading of EAF Slag is as below: Size of Sieve % By weight passing 45 mm 100 22.4 mm 30 - 50 4.75 mm 0-5 (5) Asphalt grade 80 / 100, Lime is Slaked lime (fresh) CaOH as per Clause 402.2.2, MoRT&H. (6) CBR of compacted Subgrade = 15% after 90 days, Subbase >30% (7) Compaction of Layer I & II A shall be 95% of modified heavy compaction test. (8) Bituminous Surfacing will be as per the recommondations of the comittee(75mm BM + 40mm SDBC). (9) - Indicates compaction as per IRC 37:2001 or MORT&H Specification

Fig.4- Sketch showing the various layers of Roads having width 12.19 mt. & above, but less than 24.39 mt. Collector Roads, Surat City Limit. Based on the budget statement of the SMC it seems that the design is performing well with reduction in annual maintenance expenditure for flexible pavement roads. Also from the local experience and general observation now a days the private developers are also using the same standardized design for internal society roads etc. 5.0 CONCLUSION:

The standardized road width with its specified pavement design will definitely helps the governing authority of any urban area from initial stage of the planning as it has helped to Surat Municipal Corporation. The standardized design has the same cost for construction and it can easily adopted for preliminary planning or tender preparation by any zone or authority for the same city limit. Also the Lime Flyash stabilization has proves the better economy for typical expansive soil in South Gujarat region by reducing the annual maintenance cost. 6.0 REFERENCES:

1. Jigisha Vashi (2008), Review of Geotechnical Parameter: CBR and Modulus of Subgrade Reaction (k) for Rigid Pavements. M.Tech (SMFE) Thesis, SVNIT, Surat. 2. Khanna S.K. & Justo C.E.G.(2001),Highway Engineering,8 th Edition, NemChand & Bros, Roorkee 3. IRC: 37 2001, Guidelines for the Design of Flexible Pavements

183

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- NeomDocument191 pagesNeomMOHAMED SAYED mohamed ali100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AASHTO Guide To Development of Bicycle FacilitiesDocument201 pagesAASHTO Guide To Development of Bicycle FacilitiesLingran Meng100% (1)

- Assignment Traffic EngineeringDocument9 pagesAssignment Traffic EngineeringNadeem YousafzaiNo ratings yet

- A.assessment of Lifting OperationDocument18 pagesA.assessment of Lifting OperationAndika Dwi100% (1)

- Renacon Brochure 1 PDFDocument9 pagesRenacon Brochure 1 PDFMaharajan McsNo ratings yet

- Steel Framed Multi Storey Residential Building Analysis and DesignDocument2 pagesSteel Framed Multi Storey Residential Building Analysis and DesignMaharajan McsNo ratings yet

- MT1 PDFDocument4 pagesMT1 PDFMaharajan McsNo ratings yet

- 3238-Article Text-5879-1-10-20180104Document140 pages3238-Article Text-5879-1-10-20180104Maharajan McsNo ratings yet

- Residential Building With EtabsDocument27 pagesResidential Building With EtabsMaharajan McsNo ratings yet

- Department of Civil EngineeringDocument4 pagesDepartment of Civil EngineeringMaharajan McsNo ratings yet

- Load Calculation From Slab To Beam: M by KN/M KN/M KN/M KN/M KN/M KN/MDocument3 pagesLoad Calculation From Slab To Beam: M by KN/M KN/M KN/M KN/M KN/M KN/MMaharajan McsNo ratings yet

- Anna University: Chennai-600 025: Bonafide CertificateDocument1 pageAnna University: Chennai-600 025: Bonafide CertificateMaharajan McsNo ratings yet

- PSN College of Engineering and Technology (Autonomous) PSN College of Engineering and Technology (Autonomous)Document5 pagesPSN College of Engineering and Technology (Autonomous) PSN College of Engineering and Technology (Autonomous)Maharajan McsNo ratings yet

- Load CalculationDocument3 pagesLoad CalculationMaharajan McsNo ratings yet

- MuthuiahDocument1 pageMuthuiahMaharajan McsNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- Slab Design by ShubhamBabarDocument7 pagesSlab Design by ShubhamBabarMaharajan McsNo ratings yet

- Mind Map: Chemical Substances Found in The OrganismsDocument5 pagesMind Map: Chemical Substances Found in The OrganismsMaharajan Mcs100% (1)

- Building MaterialsDocument3 pagesBuilding MaterialsMaharajan McsNo ratings yet

- Design & Development of Parkinson Gear Tester For Spur Gear To Check The Flank SurfaceDocument6 pagesDesign & Development of Parkinson Gear Tester For Spur Gear To Check The Flank SurfaceMaharajan McsNo ratings yet

- Presenting: Maruti Suzuki India LTDDocument15 pagesPresenting: Maruti Suzuki India LTDjappreet2014No ratings yet

- Utilization of Red Mud As FillerDocument12 pagesUtilization of Red Mud As FillerRam VermaNo ratings yet

- DP80N - DP90N - DP100N - DP120N DP135N - DP150N - DP160N: SpecificationsDocument6 pagesDP80N - DP90N - DP100N - DP120N DP135N - DP150N - DP160N: SpecificationsBiniyam12100% (1)

- Breaking New Ground With Intrafor Stays: The Strand by Strand MethodDocument32 pagesBreaking New Ground With Intrafor Stays: The Strand by Strand MethodDrPadipat ChaemmangkangNo ratings yet

- Envr-203 Site Analysis ReportDocument18 pagesEnvr-203 Site Analysis ReportGeorge GomesNo ratings yet

- 4 Road SupervisionDocument269 pages4 Road SupervisionAnonymous GmbdAQGhNo ratings yet

- Lakes That Have Been Converted For Residential Areas, Bus Stops and Other Such Utilities.Document2 pagesLakes That Have Been Converted For Residential Areas, Bus Stops and Other Such Utilities.Citizen MattersNo ratings yet

- Human Factors Engineering: Kecelakaan Dan Human ErrorsDocument25 pagesHuman Factors Engineering: Kecelakaan Dan Human ErrorsMuhamad NabilNo ratings yet

- Electronic Stability Program (ESP)Document2 pagesElectronic Stability Program (ESP)Kumar Ranjan100% (1)

- InfoServis2018 09 20JointsTruckBusDocument28 pagesInfoServis2018 09 20JointsTruckBusGondangNo ratings yet

- Report On Tactical UrbanismDocument21 pagesReport On Tactical UrbanismIan Ricardo AlbaNo ratings yet

- Essay Outline - China Pakistan Energy Corridor (CPEC)Document2 pagesEssay Outline - China Pakistan Energy Corridor (CPEC)Awais RightsNo ratings yet

- Nawaloka Professional Lighting PresentationDocument23 pagesNawaloka Professional Lighting PresentationAshani100% (1)

- Poetry For The Beat GenerationDocument64 pagesPoetry For The Beat GenerationAdrian BarahonaNo ratings yet

- Use of English: Test MasterDocument2 pagesUse of English: Test MasterAnonymous YaOsE6nNo ratings yet

- Construction of Multi-Purpose Building East Tapinac Elementary School Barangay East Tapinac, Olongapo City, ZambalesDocument6 pagesConstruction of Multi-Purpose Building East Tapinac Elementary School Barangay East Tapinac, Olongapo City, Zambaleszab04148114No ratings yet

- Presentation 2Document97 pagesPresentation 2Irfan ShaikhNo ratings yet

- Traffic Engineering Cec 411-1Document13 pagesTraffic Engineering Cec 411-1Samuel ItopaNo ratings yet

- Site Analysis ChangesDocument2 pagesSite Analysis ChangesAfzal TamboliNo ratings yet

- Rse PPT 02-09-2020Document115 pagesRse PPT 02-09-2020Mohammed Abdul KaleemNo ratings yet

- Fauna by Alissa York (Excerpt)Document30 pagesFauna by Alissa York (Excerpt)Random House of CanadaNo ratings yet

- 2014 Volkswagen PC Price List 20150123Document2 pages2014 Volkswagen PC Price List 20150123Mohamed AhmedNo ratings yet

- About NHDP - National Highways Authority of India, Government of IndiaDocument2 pagesAbout NHDP - National Highways Authority of India, Government of Indiaashish kumarNo ratings yet

- SP Report 2007 08Document64 pagesSP Report 2007 08Gianni MenaNo ratings yet

- LTO Drivers License Examination Reviewer EnglishDocument8 pagesLTO Drivers License Examination Reviewer EnglishFros CatubiganNo ratings yet

- Operator Manual sp4000 Na en PDFDocument21 pagesOperator Manual sp4000 Na en PDFEmmanuel Chavez VargasNo ratings yet