Professional Documents

Culture Documents

Extrusion Die Design

Extrusion Die Design

Uploaded by

Mohammed KhatibOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extrusion Die Design

Extrusion Die Design

Uploaded by

Mohammed KhatibCopyright:

Available Formats

International Training Program (TechnoBiz)

Extrusion Die Design

21 January 2009, Century Park Hotel, Bangkok

The training program presents an intensive introduction to die design for plastic extrusion. The objectives of this program are: to teach the basic principles of die design to demonstrate the application of these principles to the design of the main types of extrusion dies: tubing and pipe dies, wire coating dies, sheet and flat film dies, profile dies, spiral mandrel dies, and coextrusion dies. What the attendees will learn: the flow properties that determine how the material behaves in the die and when it leaves the die the various types of extrusion dies used for different products materials and coating used for extrusion dies simple calculations for die design how computer programs can be used to analyze and design extrusion dies the advantages and disadvantages of various die geometries, e.g. the conventional pipe die versus the spiral mandrel pipe die various die flow problems and how to avoid them

Program Outline

Introduction Die Design Types of extrusion dies, Polymer melt flow in dies, Simple flow calculations, Guidelines for die design, Materials of construction, Complicating factors in die design Plate die, Fully streamlined die, Partially streamlined die, Balancing flow in profile dies, Profile die design examples Draw down ratios, Crosshead vs. in-line dies, Helicoid manifolds, Spiral mandrel manifolds, Tubing and pipe dies, Blown film dies Flat sheet and film dies, Coathanger manifold, Horseshoe manifold, Die flow adjustment Feed block system, Multi-manifold system, Interfacial instabilities Shark skin and melt fracture, Extrudate tearing, Draw resonance, Weld lines, Die lip buildup

Design of Flat Dies

Profile Die Design

Co-extrusion

Die Flow Problems

Tubular Dies

Course Instructor Dr. Chris Rauwendaal

Dr. Chris Rauwendaal - President of Rauwendaal Extrusion Engineering, Inc. since 1990; previously with American Enka Company and Raychem Corporation. Chris received a M.Sc. from Delft University and a Doctorate in Polymer Processing from Twente University in the Netherlands. Chris is a well-known author, lecturer, entrepreneur, and consultant in the field of extrusion. He holds numerous patents and has written more than 200 articles and seven books related to extrusion, mixing, injection molding, and statistical process control. Chris has developed video training courses and interactive training programs on extrusion, injection molding, and SPC. He has been involved in technical meetings of the SPE and PPS for many years as a speaker as well as a technical program chairman. Chris is a Fellow of the Society of Plastics Engineers. Chris is the developer of the CRD and VIP mixing technology that utilizes strong elongational flow to improve mixing in extrusion and molding. CRD mixing devices are successfully used in many extrusion operations. VIP mixers were recently introduced to the plastics processing industry and are gaining rapid acceptance. Work is ongoing to extend this technology to a new generation of extruders and injection molding machines. The most recent development is the HHT (high heat transfer) extruder screw developed to improve cooling in foam tandem extrusion operations.

Course Registration Fee

Registration Fee / Person : 250 US$ (before 15 November 2008) Registration Fee / Person : 350 US$ (after 15 November 2008)

Course fee includes documentation and refreshments.

Group Registration Discounts: If 3 or more than 3 delegates join from the same organization, 10% discount on the registration fee will be offered If 6 delegates join from the same organization, 7th delegate participation is FREE.

Organizer

TechnoBiz Communications LP 300/53, Soi Lardprao 35/1, Lardprao Road, Chandrakasem, Chatuchak, Bangkok 10900 Tel: 66-2-938 2315 Mobile: 66-84-658 1444 Fax: 66-2-513 1301 Email: training@technobiz-asia.com Website : www.technobiz-asia.com

International Training Course

Extrusion Die Design

21 January 2009, Century Park Hotel, Bangkok

Registration Form

Instruction: Please fill all the information in English only

Organization Name .......................... Address ........ .. Tel .Fax ... Email .... Contact Person .... Tel . Email ....... Participant Name Participant 1: . Position Email ......... Participant 2: . Position Email ......... Participant 3: . Position Email ......... Participant 4: . Position Email ......... Registration Fee per Participant: 250 US$ (before 15 Nov 2008) Payment Method Cheque / Draft Payable to TechnoBiz Communications Ltd., Part. Bank Transfer to Bangkok Bank PCL, Ratchada-Latphrao Road Branch, A/C No: 177-0-65819-1 A/C Name: TechnoBiz Communications Ltd., Part., Swift Code: BKKBTHBK Credit Card Visa Master Card 350 US$ (after 15 Nov 2008)

Card Number Cardholder Name . Last 3 digits on signature panel Card Expiry Date . Signature of Cardholder .. Date

Please send completed registration form TechnoBiz Communications Ltd. 300/53, Lardprao Soi 35/1, Lardprao Road, Chandrakasem, Chatuchak, Bangkok 10900 THAILAND Tel: 66-2-938 2315 Mobile: 66-84-658 1444 Fax: 66-2-513 1301 Email: training@technobiz-asia.com Contact Person: Khun Saowalak, Coordinator

You might also like

- I 130 Affidavit Sample PDFDocument2 pagesI 130 Affidavit Sample PDFSangeet VajracharyaNo ratings yet

- Extruding Plastics A Practical Processing Handbook PDFDocument2 pagesExtruding Plastics A Practical Processing Handbook PDFBrian0% (1)

- Contractor Monthly Safety Report: Incidents This Month Total Cause of Injuries This MonthDocument2 pagesContractor Monthly Safety Report: Incidents This Month Total Cause of Injuries This MonthMohammed Khatib100% (4)

- CSEC POB June 2015 P1Document9 pagesCSEC POB June 2015 P1Tia GreenNo ratings yet

- Extrusion Process PDFDocument2 pagesExtrusion Process PDFSamantha50% (2)

- Plastics Processing Data PDFDocument679 pagesPlastics Processing Data PDFElisangelaCordeiro90% (10)

- Extrusion Blow Molding Guidebook PDFDocument308 pagesExtrusion Blow Molding Guidebook PDFNeimar Topanotti Dagostin100% (1)

- NEBOSH International DiplomaDocument2 pagesNEBOSH International DiplomaMohammed Khatib70% (10)

- Padre Pio's Stigmata, Supernatural Miracles and LifeDocument9 pagesPadre Pio's Stigmata, Supernatural Miracles and LifeparanormalmysteryNo ratings yet

- Australian Visa Form 47spDocument26 pagesAustralian Visa Form 47spwhysignupagain100% (1)

- Books10 ExtrusionDocument5 pagesBooks10 ExtrusionThais G Quinones0% (2)

- Design of Extrusion HeadsDocument64 pagesDesign of Extrusion HeadsMohamed HassanNo ratings yet

- Extrusion Technology PDFDocument2 pagesExtrusion Technology PDFMonica100% (1)

- Extrusion Die DesignDocument67 pagesExtrusion Die DesignShubham Chaudhary100% (1)

- Top Injection Molding Problems and Their CountermeasuresDocument7 pagesTop Injection Molding Problems and Their CountermeasuresNaixt CabudzNo ratings yet

- 165-495-1-PB Hal 75-85Document48 pages165-495-1-PB Hal 75-85Tia AdrianyputriNo ratings yet

- About Rotational MoldingDocument7 pagesAbout Rotational MoldingPatel DarshanNo ratings yet

- Moulding Defects 1 PDFDocument158 pagesMoulding Defects 1 PDFAmolPagdal96% (46)

- Plastics Molded ProblemsDocument11 pagesPlastics Molded ProblemsJaynie Lee VillaranNo ratings yet

- Injection Mould Design For PVCDocument7 pagesInjection Mould Design For PVCbile_taseNo ratings yet

- Root Cause Analysis of Polymer Extrusion DefectsDocument5 pagesRoot Cause Analysis of Polymer Extrusion DefectsSBP100% (1)

- Week 9 - Shaping Process For PlasticsDocument139 pagesWeek 9 - Shaping Process For PlasticsFattihi EkhmalNo ratings yet

- Processing of PolymersDocument105 pagesProcessing of PolymersAftaab AlamNo ratings yet

- Setting Process ConditionsDocument10 pagesSetting Process ConditionszaldsonNo ratings yet

- C Polybridge Calculator V25 Feb 09 Office 2003Document58 pagesC Polybridge Calculator V25 Feb 09 Office 2003KodhansNo ratings yet

- KCC Brochure Silicone LSRDocument13 pagesKCC Brochure Silicone LSRrendra syamNo ratings yet

- Extrusion 2012Document100 pagesExtrusion 2012Fernando Lotero100% (4)

- Polymer Extrusion Experimental Report: April 2018Document9 pagesPolymer Extrusion Experimental Report: April 2018Mehmet Sarı100% (1)

- Vishu Shah - Scientific Approach To Injection MoldingDocument52 pagesVishu Shah - Scientific Approach To Injection MoldingStarchyLittleOleMe100% (1)

- Plastic Injection MoldingDocument24 pagesPlastic Injection Moldingmechhandbook100% (1)

- AdditivesDocument62 pagesAdditivesMohsin Alam100% (1)

- Clase 7. Blown Film ExtrusionDocument37 pagesClase 7. Blown Film ExtrusionJuan Carlos Amaro ReyesNo ratings yet

- Extrusion of PlasticsDocument130 pagesExtrusion of PlasticsShubham Chaudhary100% (1)

- Extrusion Moulding Process PDFDocument2 pagesExtrusion Moulding Process PDFKim100% (1)

- Polystyrene Processing GuideDocument4 pagesPolystyrene Processing GuidemadogodNo ratings yet

- Romold Plastic Injection Mold Manufacturing GlossaryDocument8 pagesRomold Plastic Injection Mold Manufacturing Glossarytriya20100% (1)

- 70D Manual BookDocument43 pages70D Manual BookgeorgioNo ratings yet

- Plastic Business GuideDocument101 pagesPlastic Business GuidedanceNo ratings yet

- Plastics Processing TechniquesDocument59 pagesPlastics Processing TechniquesSusmit NimjeNo ratings yet

- Seminar-3 Rubber Transfer MoldingDocument10 pagesSeminar-3 Rubber Transfer MoldingSwapnil AhireNo ratings yet

- D3641 617737-1Document10 pagesD3641 617737-1AndrestorpNo ratings yet

- Basics of Polymers Fabrication and Processing TechnologyDocument108 pagesBasics of Polymers Fabrication and Processing TechnologyneftNo ratings yet

- 14 EXT BR Conical Profile enDocument12 pages14 EXT BR Conical Profile enPankaj KushwahaNo ratings yet

- 7 Factors To Be Considered in Injection Molding Process Cannot Be Ignored. (158) DocxDocument8 pages7 Factors To Be Considered in Injection Molding Process Cannot Be Ignored. (158) DocxGiap NguyenNo ratings yet

- Microinjection Molding of Thermoplastic Polymers: A ReviewDocument14 pagesMicroinjection Molding of Thermoplastic Polymers: A ReviewMario Allesina JuniorNo ratings yet

- Design and Development of Plastic Parts For Car Interior: Project TitleDocument56 pagesDesign and Development of Plastic Parts For Car Interior: Project TitleJyoti KaleNo ratings yet

- Report BengkelDocument11 pagesReport BengkelMuhammad Nasri Zainal AbidinNo ratings yet

- Troubleshooting Guide For Injection MoldingDocument27 pagesTroubleshooting Guide For Injection MoldingMohamedNo ratings yet

- Husky HRPG enDocument136 pagesHusky HRPG envdj85No ratings yet

- Metal Injection Molding Material PropertiesDocument12 pagesMetal Injection Molding Material Propertiesdbfreelancer1195No ratings yet

- Principles of Single Screw ExtrusionDocument44 pagesPrinciples of Single Screw ExtrusionHugo Wizenberg75% (8)

- Mould Theory 2 NoteDocument19 pagesMould Theory 2 Note75Ujwal TDNo ratings yet

- First Internal Question & Answer For Plastic ProcessingDocument17 pagesFirst Internal Question & Answer For Plastic ProcessingSupreeth PremkumarNo ratings yet

- Transfer MoldingDocument2 pagesTransfer MoldingAnuj ReddyNo ratings yet

- Advanced Fine Finishing ProcessesDocument16 pagesAdvanced Fine Finishing Processesnag_rockstar100% (1)

- SSP Pet PD PDFDocument1 pageSSP Pet PD PDF何恭彥No ratings yet

- Powder Injection MouldingDocument45 pagesPowder Injection MouldingAmritanshu SharmaNo ratings yet

- Cleaning ScrewsDocument6 pagesCleaning ScrewsRodolfoAntonioLeónCárdenasNo ratings yet

- Types of Plastic ExtrudersDocument7 pagesTypes of Plastic ExtrudershvadnalaNo ratings yet

- Polymers PPT PDFDocument47 pagesPolymers PPT PDFShivani RajeevNo ratings yet

- Plastic Injection Molding TERMS and GLOSSARYDocument9 pagesPlastic Injection Molding TERMS and GLOSSARYDanny Martinez100% (1)

- (Zheng2012) An Energy Saving Factory-ValidatedDocument6 pages(Zheng2012) An Energy Saving Factory-ValidatedFernando LoteroNo ratings yet

- Rotational Moulding Design GuideDocument14 pagesRotational Moulding Design Guidesushant3240No ratings yet

- Plastics: Surface and FinishFrom EverandPlastics: Surface and FinishS. H. PinnerNo ratings yet

- Broder outline for understandingDocument5 pagesBroder outline for understandingMohammed KhatibNo ratings yet

- Gripple India hanging systems brochure (2)Document18 pagesGripple India hanging systems brochure (2)Mohammed KhatibNo ratings yet

- Fall Prevention PlanDocument6 pagesFall Prevention PlanMohammed KhatibNo ratings yet

- fevicol-sr-998-is-rubber-based-adhesivesDocument2 pagesfevicol-sr-998-is-rubber-based-adhesivesMohammed KhatibNo ratings yet

- Construction Contract Clause DigestDocument81 pagesConstruction Contract Clause Digestchira100% (3)

- Section D GC - Word Version - 3Document36 pagesSection D GC - Word Version - 3Mohammed KhatibNo ratings yet

- Leh Final Tender 19-4-2012Document304 pagesLeh Final Tender 19-4-2012Mohammed KhatibNo ratings yet

- Te 1477 WebDocument81 pagesTe 1477 WebMohammed KhatibNo ratings yet

- 12 Chapter 4Document36 pages12 Chapter 4Mohammed KhatibNo ratings yet

- 07 Dumbrava Iacob-USING PROBABILITY IMPACT MATRIX IN ANALYSIS AND RISK ASSESSMENT PROJECTS PDFDocument21 pages07 Dumbrava Iacob-USING PROBABILITY IMPACT MATRIX IN ANALYSIS AND RISK ASSESSMENT PROJECTS PDFMohammed KhatibNo ratings yet

- Iso 10015 134Document16 pagesIso 10015 134Mohammed KhatibNo ratings yet

- Company Profile - IissDocument16 pagesCompany Profile - IissMohammed KhatibNo ratings yet

- First Aid Proposal DetailsDocument2 pagesFirst Aid Proposal DetailsMohammed KhatibNo ratings yet

- 6 May 09 G00007aDocument1 page6 May 09 G00007aMohammed KhatibNo ratings yet

- Your Boarding Pass To Jakarta - GARUDA INDONESIADocument1 pageYour Boarding Pass To Jakarta - GARUDA INDONESIAdiniatkanibadahNo ratings yet

- Chapter Six - Supply Chain DesignDocument3 pagesChapter Six - Supply Chain DesignPattraniteNo ratings yet

- Kisses PRT 2Document18 pagesKisses PRT 2Kik EtcNo ratings yet

- Detail Judgment of Supreme Court of Pakistan On Contempt of Court Law Pass by The ParlimentDocument148 pagesDetail Judgment of Supreme Court of Pakistan On Contempt of Court Law Pass by The ParlimentMYOB420No ratings yet

- UST-Syllabus For Civil Law REview 1Document53 pagesUST-Syllabus For Civil Law REview 1Gwen Alistaer CanaleNo ratings yet

- On Your Answer Sheet.: San Roque National High School - Senior High SchoolDocument1 pageOn Your Answer Sheet.: San Roque National High School - Senior High SchoolRechelle Mae DualosNo ratings yet

- 1.18.2024 SBFCC Create Morre Eopt Beps 2.0Document70 pages1.18.2024 SBFCC Create Morre Eopt Beps 2.0b86120298alexlinNo ratings yet

- Franchisee Advisory Network (Partner) - Fan (P) Information PaperDocument5 pagesFranchisee Advisory Network (Partner) - Fan (P) Information PaperAditi SinghNo ratings yet

- Key Challenges Facing Public Sector LeadersDocument6 pagesKey Challenges Facing Public Sector LeadersSifa MtashaNo ratings yet

- What The Meaning of LifeDocument2 pagesWhat The Meaning of Life星が輝く夜AdamNo ratings yet

- Angie Ucsp Grade 12 w3Document6 pagesAngie Ucsp Grade 12 w3Princess Mejarito MahilomNo ratings yet

- The Goddess As Role Model - Sita and Radha in Scripture and On Screen PDFDocument577 pagesThe Goddess As Role Model - Sita and Radha in Scripture and On Screen PDFprashant sharma100% (1)

- Economic System PresentationDocument19 pagesEconomic System PresentationVenkatesh NaraharisettyNo ratings yet

- Essential Nutrition ActionDocument36 pagesEssential Nutrition ActionDawud AsnakewNo ratings yet

- Reflection Paper: My Maid Invest in The Stock MarketDocument4 pagesReflection Paper: My Maid Invest in The Stock MarketMarifie PatiuNo ratings yet

- Acc9 Accounting For Special Transactions University of BatangasDocument2 pagesAcc9 Accounting For Special Transactions University of BatangasHannahbea LindoNo ratings yet

- QuizDocument2 pagesQuizNiño SalomesNo ratings yet

- Revision For Mid Term 2Document3 pagesRevision For Mid Term 2Jenni CastroNo ratings yet

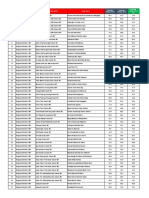

- No. Branch (Mar 2022) Legal Name Organization Level 4 (1 Mar 2022) Average TE/day, 2019 Average TE/day, 2020 Average TE/day, 2021 (A)Document7 pagesNo. Branch (Mar 2022) Legal Name Organization Level 4 (1 Mar 2022) Average TE/day, 2019 Average TE/day, 2020 Average TE/day, 2021 (A)Irfan JauhariNo ratings yet

- 2021 CPT CodesDocument8 pages2021 CPT CodesSundar RamanathanNo ratings yet

- Sample DIARY - CASDocument5 pagesSample DIARY - CASDAN DNANo ratings yet

- Debate HistoryDocument4 pagesDebate Historyheri crackNo ratings yet

- MANVI JAIN BLACKBOOK FinalDocument68 pagesMANVI JAIN BLACKBOOK FinalSunny PalNo ratings yet

- Bruno Lloyd v. Hovensa, LLC Wyatt, V.I., Inc. Bruno Lloyd v. Hovensa, LLC Wyatt, V.I., Inc., 369 F.3d 263, 3rd Cir. (2004)Document15 pagesBruno Lloyd v. Hovensa, LLC Wyatt, V.I., Inc. Bruno Lloyd v. Hovensa, LLC Wyatt, V.I., Inc., 369 F.3d 263, 3rd Cir. (2004)Scribd Government Docs100% (1)

- Rea Ftce Practice Test 2Document14 pagesRea Ftce Practice Test 2kaayyNo ratings yet

- Republic v. Science Park of The Philippines 2021Document13 pagesRepublic v. Science Park of The Philippines 2021f919No ratings yet