Professional Documents

Culture Documents

Axle FG

Axle FG

Uploaded by

vkmsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axle FG

Axle FG

Uploaded by

vkmsCopyright:

Available Formats

Axle (Fuel gauge)

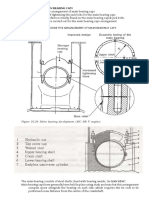

Function /Purpose 1. Its function is to transmit torque developed by resultant of magnetic field created by coils and magnet of fuel gauge assembly. 2. It rotates with a torque proportional to resultant voltage developed by variable resistance.The fuel level in the tank varies the resistance and thus voltage is developed in the coils proportional to fuel level. 3. Axle is held in the magnet by press fit arrangement. 4. Fuel gauge pointer is mounted on the axle. Possible Modes of Failure: 1. Torsional failure while transmitting torque. 2. Possibility of bending of axle during its fitment with magnet. 3. Possibility of bending of magnet while mounting of pointer on axle. 4. Magnet may come out of axle during working of gauge. 5. Pointer axle rotation in non concentric (oval) manner. 6. Pointer may come out from axle. 7. Flickering of pointer. 8. Pointer axle loose in bobbin. 9. Axle may get jam in the bobbin top or bottom cover. 10. Interference of axle with bobbin assembly. 11. Rusting of axle due to environmental effects. Design Procedure: 1. Determine diameter of axle depending upon torque to be transmitted by axle. 2. The diameter of axle should not be uniform but of varying diameter to get inserted in magnet and pointer. 3. Press fit between axle and magnet should be assured. 4. Also press fit between axle and pointer bush should be assured. 5. Determine its length depending upon height of fuel gauge dial from bottom face of lower bobbin. 6. Specifically mention instruction on the drawing so as to control concentricity. 7. Provide adequate clearance between axle and hole provided in the bobbin assembly. 8. Provide adequate clearance between axle and inner face of lower bobbin. 9. Interference between pointer axle and bobbin assembly should be avoided. 10. Anti corrosive coating should be applied on axle surface to prevent its corrosion. 11. Provide diameter to assure press fit between magnet- axle and pointer axle. 12. The material should be selected based on its torsional strength, its machinability, corrosion resistance, elastic strength required for press fit. 13. Mention specifically on drawing for nickel plating if steel is used as material for manufacture. Nickel plating ensures protection from corrosion. 14. Provide surface finish required after nickel coating. 15. ID of magnet to be controlled and checked by gauge to avoid pointer flickering. Material: Free Cutting Steel. Properties of Material: TENSILE STRENGTH (Kgf/mm2) P 0.06 44-54 TENSILE STRENGTH (Kgf/mm2) P 0.06 60-65 7-10 % 212 38 YIELD STRENGTH (Kgf/mm2) 22 % ELONGATION 137 HARDNESS (BRINNEL) YIELD STRENGTH (Kgf/mm2)

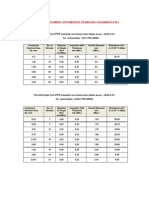

Properties Of Free cutting Steel 14mNS14 C 0.10.18 Mn 1.21.5 Si 0.050.3 S 0.10.18

% ELONGATION

HARDNESS (BRINNEL)

Properties Of Free cutting Steel 40Mn2S12 C 0.350.45 Mn 1.31.7 Si 0.025 S 0.080.15

You might also like

- X30592Document16 pagesX30592CTN2010No ratings yet

- Referance For Marine Engineers by Min Zar TarDocument208 pagesReferance For Marine Engineers by Min Zar Tarmgboune100% (2)

- Astm c1513Document4 pagesAstm c1513Ramón RocaNo ratings yet

- Brenco - CTRBMDocument48 pagesBrenco - CTRBMDevendra SinghNo ratings yet

- Diesel Engine ComponentDocument22 pagesDiesel Engine ComponentRahul KumarNo ratings yet

- ME 1302 - MACHINE DESIGN (5th Mech)Document7 pagesME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNo ratings yet

- Kestrel builders v6Document42 pagesKestrel builders v6Andrea FigianiNo ratings yet

- Final 1Document43 pagesFinal 1cejoshua42No ratings yet

- Attachment 3-Tower DesignCalculation Book (English)Document44 pagesAttachment 3-Tower DesignCalculation Book (English)Alam SyahNo ratings yet

- MAN ShaftErrosion SL2008-498Document18 pagesMAN ShaftErrosion SL2008-498flipflop12100% (1)

- Plain Bearings Failure Mode and RectificationDocument13 pagesPlain Bearings Failure Mode and RectificationengrsurifNo ratings yet

- Dom Gtu ImpDocument8 pagesDom Gtu ImpSwastik PanchalNo ratings yet

- Main BearingDocument28 pagesMain BearingCadet Aviral Jha [9335]100% (1)

- CN Maintenance Practices IIDocument10 pagesCN Maintenance Practices IIavijayakumar_1964No ratings yet

- DME Unit 3 Threaded Joints PDFDocument42 pagesDME Unit 3 Threaded Joints PDFsachinroy8638No ratings yet

- Instruction Manual: PFC-1609 Reaction Hammer CrusherDocument9 pagesInstruction Manual: PFC-1609 Reaction Hammer CrusherabdulfetahNo ratings yet

- Md-Ii 2Document11 pagesMd-Ii 2Vishal ZalaNo ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- Heavy Weld ShopDocument6 pagesHeavy Weld Shopyogendra singhNo ratings yet

- SRI-Installation Anchor-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBIDocument9 pagesSRI-Installation Anchor-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBIDito NarendraNo ratings yet

- Ijser: Parameters Influencing Connecting Rod: A ReviewDocument9 pagesIjser: Parameters Influencing Connecting Rod: A ReviewNurul'Ain Haniyun Mohamad FodziNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaNo ratings yet

- ME6503-Design of Machine ElementsDocument15 pagesME6503-Design of Machine ElementsBas RamuNo ratings yet

- Chassis Desgin Univ 2 MarksDocument7 pagesChassis Desgin Univ 2 Markspavanrane67% (3)

- Fatigue Failure of an Idle Gear Shaft of a GearboxDocument9 pagesFatigue Failure of an Idle Gear Shaft of a GearboxGuilherme BandeiraNo ratings yet

- B Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1Document6 pagesB Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1suneel kumar rathoreNo ratings yet

- 2014 RMB Tech Manual Rev Apr 8Document71 pages2014 RMB Tech Manual Rev Apr 8muzNo ratings yet

- 072 - ME8593, ME6503 Design of Machine Elements DEM - NotesDocument190 pages072 - ME8593, ME6503 Design of Machine Elements DEM - NotesR Raj Singh SinghNo ratings yet

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDocument9 pagesIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNo ratings yet

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDocument9 pagesIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNo ratings yet

- Shaft Strain Gaging Guide v4Document11 pagesShaft Strain Gaging Guide v4craigNo ratings yet

- Cylinder Block and Crank Mechanism Inspection and ServiceDocument29 pagesCylinder Block and Crank Mechanism Inspection and ServiceGetachew TikueNo ratings yet

- Brakes, Clutch and CoplingDocument35 pagesBrakes, Clutch and CoplingJohnNo ratings yet

- Assembly and Tensioning of High Strength Bolts andDocument14 pagesAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNo ratings yet

- Month Marine Engineering at The Operational LevelDocument79 pagesMonth Marine Engineering at The Operational LevelMum ZetaNo ratings yet

- Pinion and Bull Gear IDocument11 pagesPinion and Bull Gear ImailbkraoNo ratings yet

- DME QuestionsDocument15 pagesDME QuestionsjerinNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Discussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramDocument11 pagesDiscussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramMani RajNo ratings yet

- QJY Car Lift 6328693Document12 pagesQJY Car Lift 6328693Ildikó BodnárNo ratings yet

- pdf&rendition=1Document6 pagespdf&rendition=1siraj.safetyNo ratings yet

- Iv RepotDocument16 pagesIv Repotneethurj9No ratings yet

- Design of Castelleated Beam by British CodeDocument8 pagesDesign of Castelleated Beam by British Codemsn sastryNo ratings yet

- Wollo University Kiot: Designinig of Bushed Pin CouplingDocument16 pagesWollo University Kiot: Designinig of Bushed Pin CouplingBirhanu AsfawNo ratings yet

- STC TRS Conventional 02Document419 pagesSTC TRS Conventional 02battery sectionNo ratings yet

- Industrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentDocument19 pagesIndustrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentVeer PatelNo ratings yet

- ST7203 Steel Structures Question BankDocument12 pagesST7203 Steel Structures Question BankFinney WilsonNo ratings yet

- Me6503 Dme Mech VST Au Unit IIDocument37 pagesMe6503 Dme Mech VST Au Unit IISiva Raman100% (2)

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- ME602MCDDocument23 pagesME602MCDspideyr9No ratings yet

- 2. Rewinding of single-phase induction motors (1)Document9 pages2. Rewinding of single-phase induction motors (1)JayaprasadGollaNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- Hacksaw PDFDocument40 pagesHacksaw PDFturuceluNo ratings yet

- Service Bulletin: Subject: Installation & Inspection of Flexible Metal Hose AssembliesDocument17 pagesService Bulletin: Subject: Installation & Inspection of Flexible Metal Hose AssembliesjussmeeeNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- MIL DTL 17 Cable DescriptionsDocument1 pageMIL DTL 17 Cable DescriptionsvkmsNo ratings yet

- PVF Pps-Mesh en 2017Document2 pagesPVF Pps-Mesh en 2017vkmsNo ratings yet

- Mil DTL 22759,16Document1 pageMil DTL 22759,16vkmsNo ratings yet

- Bare Solid Soft Drawn Copper WireDocument1 pageBare Solid Soft Drawn Copper WirevkmsNo ratings yet

- Application: Business Group Automotive CablesDocument1 pageApplication: Business Group Automotive CablesvkmsNo ratings yet

- HDPE - Specification and DetailsDocument1 pageHDPE - Specification and DetailsvkmsNo ratings yet

- Standard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)Document1 pageStandard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)vkmsNo ratings yet

- Standard Wire & Cable Co.: Air PlenumDocument1 pageStandard Wire & Cable Co.: Air PlenumvkmsNo ratings yet

- Econoseal J Series (Mark II+)Document1 pageEconoseal J Series (Mark II+)vkmsNo ratings yet

- 4 - JASO D 611 Auto CablesDocument1 page4 - JASO D 611 Auto CablesvkmsNo ratings yet

- HDPE Vs LDPE ArticleDocument2 pagesHDPE Vs LDPE ArticleJanene DenilaNo ratings yet

- GM Connectors A13: 56 SeriesDocument1 pageGM Connectors A13: 56 SeriesvkmsNo ratings yet

- Process Engineers - CONCEPT DETAILS (Plating)Document1 pageProcess Engineers - CONCEPT DETAILS (Plating)vkmsNo ratings yet

- Schools Physical Ancillary FacilitiesDocument548 pagesSchools Physical Ancillary FacilitiesThejesh GNNo ratings yet

- Scotchlok Connectors A15: Pictures Are Not Actual SizeDocument1 pageScotchlok Connectors A15: Pictures Are Not Actual SizevkmsNo ratings yet

- Precision and Bias: Measurement - Method and ProcessDocument2 pagesPrecision and Bias: Measurement - Method and ProcessvkmsNo ratings yet

- Iso Octane Toluene 50 50 Astm d471Document4 pagesIso Octane Toluene 50 50 Astm d471vkmsNo ratings yet

- What Is It?: Symbols To Indicate Critical Features On A Part DrawingDocument1 pageWhat Is It?: Symbols To Indicate Critical Features On A Part DrawingvkmsNo ratings yet

- Nylon Tie-Raps A17: Marine Fuel Line ApplicationDocument1 pageNylon Tie-Raps A17: Marine Fuel Line ApplicationvkmsNo ratings yet

- White Paper On Solving Quality Issues GDandDocument2 pagesWhite Paper On Solving Quality Issues GDandvkmsNo ratings yet

- SleeplessDocument2 pagesSleeplessmarieangeluNo ratings yet

- September: Earth, Wind & Fire (Original Key: A Major)Document3 pagesSeptember: Earth, Wind & Fire (Original Key: A Major)claudioNo ratings yet

- 0 - Touchless Touch Screen TechnologyDocument16 pages0 - Touchless Touch Screen Technologyjeedimadla vishalNo ratings yet

- Yamaha RX-797Document83 pagesYamaha RX-797venkatNo ratings yet

- Pony The Orangutan - Google SearchDocument1 pagePony The Orangutan - Google Searchj55xwz5c6xNo ratings yet

- GP3 Prelim ManualDocument18 pagesGP3 Prelim ManualGillouATTNo ratings yet

- WWW Quickfunnel Live Special Aid 2974567Document20 pagesWWW Quickfunnel Live Special Aid 2974567Faruk hossainNo ratings yet

- YourSpex - Brochure DesignDocument44 pagesYourSpex - Brochure DesignShashi DubeyNo ratings yet

- Feng Yu Jiu Tian Vol 12 PDFDocument84 pagesFeng Yu Jiu Tian Vol 12 PDFJussa Leilady Alberba100% (6)

- The Way of The World PowerPoint Presentation SSDocument15 pagesThe Way of The World PowerPoint Presentation SSmorebandu2483No ratings yet

- Mate in One 1Document2 pagesMate in One 1bhavya modiNo ratings yet

- GCE Advanced Level - ICT - E COMMERCEDocument12 pagesGCE Advanced Level - ICT - E COMMERCEsamindu lakshanNo ratings yet

- Best PneumaticsDocument16 pagesBest PneumaticsAshok DevarajNo ratings yet

- Chess ScriptDocument125 pagesChess ScriptLucía Durá SanchisNo ratings yet

- Spring 2016 U6 Week 5Document1 pageSpring 2016 U6 Week 5Giovanni AlemaoNo ratings yet

- Smartclass Ethernet Tester: Download Manager and Upgrade InstructionsDocument6 pagesSmartclass Ethernet Tester: Download Manager and Upgrade InstructionsAnonymous 1OlQQ3cWNo ratings yet

- Maldives BrochureDocument2 pagesMaldives Brochureapi-389035187No ratings yet

- Easy Whipped Ricotta Toast Recipe 5498683Document2 pagesEasy Whipped Ricotta Toast Recipe 5498683asia lilyNo ratings yet

- How Retailers Can Embrace ANew EraDocument19 pagesHow Retailers Can Embrace ANew ErachinmayNo ratings yet

- LV1 Anglais ES-SDocument3 pagesLV1 Anglais ES-SLetudiant.frNo ratings yet

- Peking Opera: Prepared By: Joel E. Matematico Jr. Music Faculty Junior High School DepartmentDocument7 pagesPeking Opera: Prepared By: Joel E. Matematico Jr. Music Faculty Junior High School DepartmentNaomi AceroNo ratings yet

- Sample Music Curriculum For 9-12 Choir ProgramsDocument11 pagesSample Music Curriculum For 9-12 Choir Programsapi-372392951No ratings yet

- SEJ BoardDocument2 pagesSEJ BoardShodhan M AminNo ratings yet

- 917 PaperpublishedDocument17 pages917 PaperpublishedTrixy013No ratings yet

- Lecture 25Document72 pagesLecture 25Akash Deep GoelNo ratings yet

- Stop MessageDocument26 pagesStop MessageVivek BalachandranNo ratings yet

- Brother PT-9200pc Service ManualDocument93 pagesBrother PT-9200pc Service ManualDuplessisNo ratings yet

- American Road TripDocument24 pagesAmerican Road TripluluvinoliaNo ratings yet

- Palm Mall KorbaDocument13 pagesPalm Mall Korbanetfreak12No ratings yet

- Exploring The Staves in A Christmas Carol Stave 1: Main EventsDocument9 pagesExploring The Staves in A Christmas Carol Stave 1: Main EventseqewqwqaNo ratings yet