Professional Documents

Culture Documents

Preventive and Predictive Maintenance: Chapter - 8

Preventive and Predictive Maintenance: Chapter - 8

Uploaded by

Gajanan JagtapCopyright:

Available Formats

You might also like

- Hino J05C-TD Workshop ManualDocument168 pagesHino J05C-TD Workshop ManualHữuLộcÂu83% (24)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Installation, Operating and Maintenance Manual Water Heater ElectricDocument105 pagesInstallation, Operating and Maintenance Manual Water Heater ElectricalexNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Pumps and Seals PDFDocument1,024 pagesPumps and Seals PDFBung TromixNo ratings yet

- Operating-manual-SKIT S DEB SPS 1.2 12Document50 pagesOperating-manual-SKIT S DEB SPS 1.2 12Val ShaNo ratings yet

- Acson Cassette Fan CoilDocument204 pagesAcson Cassette Fan CoilmikcomiNo ratings yet

- STANFORD Fault Finding ManualDocument29 pagesSTANFORD Fault Finding ManualRaul E. SoliNo ratings yet

- CTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportDocument20 pagesCTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportSriNo ratings yet

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Industrial TrainingDocument24 pagesIndustrial TrainingAshish Dwivedi100% (2)

- Training Program 25.01.2014Document144 pagesTraining Program 25.01.2014waleedNo ratings yet

- Operation and Maintenance of 220KV Receiving SubstationDocument5 pagesOperation and Maintenance of 220KV Receiving SubstationPrakash Chavan100% (1)

- Maquet Servo I Service ManualDocument84 pagesMaquet Servo I Service ManualkokyongcNo ratings yet

- 3 HV Sub Station Maint - Tranasformer Part2Document121 pages3 HV Sub Station Maint - Tranasformer Part2matshah9889No ratings yet

- Course-Energy Conservation and AuditDocument18 pagesCourse-Energy Conservation and AuditMahesh ChaudhariNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document7 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Maintenance of Transformers (A Detailed Checklist) - Electrical4UDocument11 pagesMaintenance of Transformers (A Detailed Checklist) - Electrical4Umadantiwari2000% (1)

- L6-TGN-072 (Rev 1) Power SuppliesDocument10 pagesL6-TGN-072 (Rev 1) Power SuppliesTomasPavlovicNo ratings yet

- Toolbox Meeting Template 1Document5 pagesToolbox Meeting Template 1pepenapao1217No ratings yet

- Microcontroller Based Low Cost Controlled Rectifiers Training Module For Power Electronics LaboratoryDocument4 pagesMicrocontroller Based Low Cost Controlled Rectifiers Training Module For Power Electronics LaboratoryJubari FikriNo ratings yet

- LC3050 Level Controller-Installation Maintenance ManualDocument32 pagesLC3050 Level Controller-Installation Maintenance ManualSharmin SultanaNo ratings yet

- Substaion MaintenanceDocument9 pagesSubstaion MaintenanceChandana K R 4UB20EE010No ratings yet

- HT SWBD Test ScheduleDocument24 pagesHT SWBD Test SchedulesbpathiNo ratings yet

- Substation ReportDocument12 pagesSubstation ReportAmandeep KhereNo ratings yet

- Manuale NanoVIP2 Rel. 1.4 en-UKDocument58 pagesManuale NanoVIP2 Rel. 1.4 en-UKECNo ratings yet

- Slection of Motor Starter PDFDocument4 pagesSlection of Motor Starter PDFArun GuptaNo ratings yet

- Chapter 6: Electrical and Instrumentation FacilitiesDocument47 pagesChapter 6: Electrical and Instrumentation FacilitiesBhausaheb PatilNo ratings yet

- Electrical System Comm ProcedureDocument60 pagesElectrical System Comm Procedurevaithy1990No ratings yet

- Energy Audit ReportDocument11 pagesEnergy Audit ReportshailNo ratings yet

- MP - Conference Paper - Lifetime Extension Services For Static Var CompensatorsDocument15 pagesMP - Conference Paper - Lifetime Extension Services For Static Var CompensatorsJawad AziziNo ratings yet

- Study and Analysis of Systems For Monitoring in Power SubstationsDocument3 pagesStudy and Analysis of Systems For Monitoring in Power SubstationsIsrael DanielNo ratings yet

- MPEB Summer Training ReportDocument24 pagesMPEB Summer Training ReportKeshav Chadha88% (8)

- 323Document22 pages323Sridhar Raja AluriNo ratings yet

- Chaprer TwoDocument28 pagesChaprer Twowintabiniam43No ratings yet

- Condition Monitoring Notes-Unit 2Document11 pagesCondition Monitoring Notes-Unit 2MaheswariRVNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersAshwani RanaNo ratings yet

- Vibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSDocument8 pagesVibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSweerasinghekNo ratings yet

- There Are 3 Key Elements To A ContactorDocument3 pagesThere Are 3 Key Elements To A ContactorSharath KotaNo ratings yet

- As 60156 KV-CL20 RC Um 960129-2Document330 pagesAs 60156 KV-CL20 RC Um 960129-2Emmanuel Rodríguez OrdazNo ratings yet

- Manual Inglés APM - V3.6Document73 pagesManual Inglés APM - V3.6Implementación OLCNo ratings yet

- ACS 1000W PMWorkInstDocument22 pagesACS 1000W PMWorkInstJinNo ratings yet

- Measuring and Monitoring Relays - ABBDocument76 pagesMeasuring and Monitoring Relays - ABBpevareNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersramaNo ratings yet

- Siemens Kion - Service ManualDocument207 pagesSiemens Kion - Service Manualversilia0% (1)

- Condition Monitoring DocumentationDocument49 pagesCondition Monitoring DocumentationSanthosh Penugonda0% (1)

- NCL ReportDocument20 pagesNCL ReportSwati Tripathi33% (3)

- Project Report On Transformer Protection Using Numerical RelayDocument85 pagesProject Report On Transformer Protection Using Numerical RelayIhsan Ullah100% (4)

- Fault Finding Manual 8Document29 pagesFault Finding Manual 8Jovan KosticNo ratings yet

- Internship ReportDocument6 pagesInternship ReportEngr Syed Numan ShahNo ratings yet

- Automatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsDocument65 pagesAutomatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsYassine.G ChipLabNo ratings yet

- Liebert APM With Modular Battery User Manual v2.9Document72 pagesLiebert APM With Modular Battery User Manual v2.9truong_hoangvanNo ratings yet

- Avr 100s IngleseDocument65 pagesAvr 100s IngleseVedran GaćeNo ratings yet

- Service Note - ABB Life Expectancy Analysis Program - SM101 - EN - Rev B - 2010Document2 pagesService Note - ABB Life Expectancy Analysis Program - SM101 - EN - Rev B - 2010Jor BillacisNo ratings yet

- Sudhanshu - UPPCLDocument23 pagesSudhanshu - UPPCLShivendu PandeyNo ratings yet

- Samsung t190 ltw19hs ltw19gsDocument56 pagesSamsung t190 ltw19hs ltw19gsMARCELO BetucciNo ratings yet

- Fault and Abnormal 1Document71 pagesFault and Abnormal 1Mahesh PushpakumaraNo ratings yet

- ELEC105Document3 pagesELEC105Joemon HenryNo ratings yet

- PSP Manual 13Document10 pagesPSP Manual 13Muhammad AnsNo ratings yet

- A#4 G4 Romero Bsee-1fDocument7 pagesA#4 G4 Romero Bsee-1fRomero, Ken Angelo B.No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- Internship Report: University of The Punjab (Lahore)Document18 pagesInternship Report: University of The Punjab (Lahore)Abdullah NasirNo ratings yet

- Testing and CommissioningDocument4 pagesTesting and CommissioningMitesh Gandhi100% (2)

- Project ReportDocument13 pagesProject ReportAbhinav ChauhanNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Power Electronics: Lecture Notes of Power Electronics CourseFrom EverandPower Electronics: Lecture Notes of Power Electronics CourseNo ratings yet

- Unit-2 Tripping 28 - 03 - 2009Document1 pageUnit-2 Tripping 28 - 03 - 2009Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Chandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedDocument1 pageChandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedGajanan JagtapNo ratings yet

- Unit-1 Tripping 28-3-2009Document1 pageUnit-1 Tripping 28-3-2009Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument2 pagesEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Ana U#6-2006Document32 pagesEvent Ana U#6-2006Gajanan JagtapNo ratings yet

- U3 Tripping 12 - 02 - 2009 - ADocument2 pagesU3 Tripping 12 - 02 - 2009 - AGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Officers Recreation Centre Urjanagar ChandrapurDocument2 pagesOfficers Recreation Centre Urjanagar ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Ana U#7,2006 - CompletedDocument31 pagesEvent Ana U#7,2006 - CompletedGajanan JagtapNo ratings yet

- Event Analysis Card SlipDocument2 pagesEvent Analysis Card SlipGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Unit-2 Non Tripping 4-02-2009OLDDocument1 pageUnit-2 Non Tripping 4-02-2009OLDGajanan JagtapNo ratings yet

- Event Analysis Report: 198 A, B, D, E, F NILDocument1 pageEvent Analysis Report: 198 A, B, D, E, F NILGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Format For Oil Gun: Month/Year November 2012Document2 pagesFormat For Oil Gun: Month/Year November 2012Gajanan JagtapNo ratings yet

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Unit-1 Tripping 30-01-2009 Mod FormataDocument1 pageUnit-1 Tripping 30-01-2009 Mod FormataGajanan JagtapNo ratings yet

- A - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFDocument27 pagesA - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFAnonymous hxV81ITD8kNo ratings yet

- Pump Replacement Guide A5 0413 LRDocument16 pagesPump Replacement Guide A5 0413 LRmohammudaphNo ratings yet

- PS8 Metal EomDocument28 pagesPS8 Metal EomROY RIVERANo ratings yet

- Variable Speed Fluid Couplings - Brochure 2014 (Voith)Document20 pagesVariable Speed Fluid Couplings - Brochure 2014 (Voith)RudanekNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Topic 2 Testing-And-Commissioning-In-PlumbingDocument56 pagesTopic 2 Testing-And-Commissioning-In-PlumbingRODEL YUNTINGNo ratings yet

- Flow Transmitter Promag BA055DENDocument178 pagesFlow Transmitter Promag BA055DENcysautsNo ratings yet

- (Triveni) Rajashri Power 10 MW For ACC byDocument32 pages(Triveni) Rajashri Power 10 MW For ACC bynogeshwar50% (2)

- M VACDocument98 pagesM VACLuis Alberto Perez ParedesNo ratings yet

- Instruction Manual TLC SprayerDocument9 pagesInstruction Manual TLC SprayerBea Andre Trecho TupasNo ratings yet

- Gv222ti - Gas Natural GLP PDFDocument2 pagesGv222ti - Gas Natural GLP PDFdaniloreisrochaNo ratings yet

- Electronic Fuel Injection ComponentsDocument50 pagesElectronic Fuel Injection ComponentsDani-meganeboyNo ratings yet

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNo ratings yet

- Understanding Compressors Article PDFDocument14 pagesUnderstanding Compressors Article PDFdantesosaNo ratings yet

- Zamil DY - Series PDFDocument23 pagesZamil DY - Series PDFgagokapalaNo ratings yet

- Kamewa Steel Series WaterjetsDocument2 pagesKamewa Steel Series WaterjetsAnkit singhNo ratings yet

- Vantage BoilerDocument2 pagesVantage BoilerjarNo ratings yet

- Honda WX10 ManualDocument68 pagesHonda WX10 ManualBogdan BurcheciNo ratings yet

- Cyl Im PLS 011122Document3 pagesCyl Im PLS 011122rohanNo ratings yet

- Curso Cat d6r III STMGDocument73 pagesCurso Cat d6r III STMGSilas F Pimenta90% (20)

- Solar Water Pumping SystemDocument78 pagesSolar Water Pumping SystemvehiclesalesbeaekaNo ratings yet

- Uht Pasteurization FinalDocument4 pagesUht Pasteurization FinalZacky Husada AchmadNo ratings yet

- Variable Displacement Pump A7V: Extract From RE 92210/05.95Document2 pagesVariable Displacement Pump A7V: Extract From RE 92210/05.95Joana Meller100% (1)

Preventive and Predictive Maintenance: Chapter - 8

Preventive and Predictive Maintenance: Chapter - 8

Uploaded by

Gajanan JagtapOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preventive and Predictive Maintenance: Chapter - 8

Preventive and Predictive Maintenance: Chapter - 8

Uploaded by

Gajanan JagtapCopyright:

Available Formats

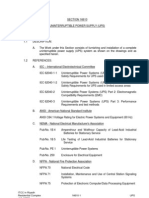

Chapter 8

PREVENTIVE AND PREDICTIVE MAINTENANCE

Preventive maintenance of all HT & LT auxiliaries motors various instruments and valves used in the power station are scheduled and carried out b respective sections as follows. 1. HT & LT motors - Electrical Maintenance Department. 2. Pumps & Turbine Auxiliaries and valves Turbine maintenance Department. 3. Pumps and Boiler auxiliaries and valves (Coal Mill etc)- Boiler Maintenance Department. 4. Various Types of Instrument Testing, Instrumentation & Control (TIC) Section. Preventive maintenance of all T & LT auxiliaries, Motors, Various Instruments & Valves helps in minimizing the break down of the power station unit and thus achieving the energy conservation purpose. Similarly predictive maintenance schedule is prepared and carries out regularly. Under this schedule, vibration of all HT auxiliaries of Boiler and Turbine such as ID & FD Fans Coal Mills PA Fans, Boiler Feed Pumps etc are measured and if it is in the danger zone / category, then that auxiliary is withdrawn/ stopped. The cause of vibrations is found out and rectify and then it again taken into service. This predictive maintenance avoids the sudden emergency breakdown of the auxiliaries and hence the breakdown of the Unit, thus achieving the energy conservation purpose. The non destructive test and residual life assessment stud is carried out for non moving auxiliaries as a p[art of preventive maintenance. Recently CSTPS has carried out energy audit of 500 MW units to explore possibility of energy conservation. Being an ISO 9000:2000 unit QMS is scrupulously followed and higher objectives are set and achieved by all sections of CSTPS. Calibrations of all Instruments are carried out as per prescribed calibration schedule and sensitivity and accuracy is maintained. Efficient operation required continuous monitoring that too with accurate measurement. 8.1 ELCB (EARTH LEAKAGE CIRCUIT BREAKER): -

ELCB of various required rated sensitivities has been incorporated in the electric supply systems at all locations. Also it is made compulsory

to fit the ELCB in temporary extension electric supplies at various places at the time of maintenance work. ELCB is a device which cut-off the supply when there is a leakage current flows in the circuit. Thus, it acts as a safety device and also it serves as a device to reduce the losses of electricity due to leakage current and drawing of over current by auxiliaries. ELCB has been incorporated in ever-domestic supply in the colon also. ------

You might also like

- Hino J05C-TD Workshop ManualDocument168 pagesHino J05C-TD Workshop ManualHữuLộcÂu83% (24)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Installation, Operating and Maintenance Manual Water Heater ElectricDocument105 pagesInstallation, Operating and Maintenance Manual Water Heater ElectricalexNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Pumps and Seals PDFDocument1,024 pagesPumps and Seals PDFBung TromixNo ratings yet

- Operating-manual-SKIT S DEB SPS 1.2 12Document50 pagesOperating-manual-SKIT S DEB SPS 1.2 12Val ShaNo ratings yet

- Acson Cassette Fan CoilDocument204 pagesAcson Cassette Fan CoilmikcomiNo ratings yet

- STANFORD Fault Finding ManualDocument29 pagesSTANFORD Fault Finding ManualRaul E. SoliNo ratings yet

- CTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportDocument20 pagesCTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportSriNo ratings yet

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Industrial TrainingDocument24 pagesIndustrial TrainingAshish Dwivedi100% (2)

- Training Program 25.01.2014Document144 pagesTraining Program 25.01.2014waleedNo ratings yet

- Operation and Maintenance of 220KV Receiving SubstationDocument5 pagesOperation and Maintenance of 220KV Receiving SubstationPrakash Chavan100% (1)

- Maquet Servo I Service ManualDocument84 pagesMaquet Servo I Service ManualkokyongcNo ratings yet

- 3 HV Sub Station Maint - Tranasformer Part2Document121 pages3 HV Sub Station Maint - Tranasformer Part2matshah9889No ratings yet

- Course-Energy Conservation and AuditDocument18 pagesCourse-Energy Conservation and AuditMahesh ChaudhariNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document7 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Maintenance of Transformers (A Detailed Checklist) - Electrical4UDocument11 pagesMaintenance of Transformers (A Detailed Checklist) - Electrical4Umadantiwari2000% (1)

- L6-TGN-072 (Rev 1) Power SuppliesDocument10 pagesL6-TGN-072 (Rev 1) Power SuppliesTomasPavlovicNo ratings yet

- Toolbox Meeting Template 1Document5 pagesToolbox Meeting Template 1pepenapao1217No ratings yet

- Microcontroller Based Low Cost Controlled Rectifiers Training Module For Power Electronics LaboratoryDocument4 pagesMicrocontroller Based Low Cost Controlled Rectifiers Training Module For Power Electronics LaboratoryJubari FikriNo ratings yet

- LC3050 Level Controller-Installation Maintenance ManualDocument32 pagesLC3050 Level Controller-Installation Maintenance ManualSharmin SultanaNo ratings yet

- Substaion MaintenanceDocument9 pagesSubstaion MaintenanceChandana K R 4UB20EE010No ratings yet

- HT SWBD Test ScheduleDocument24 pagesHT SWBD Test SchedulesbpathiNo ratings yet

- Substation ReportDocument12 pagesSubstation ReportAmandeep KhereNo ratings yet

- Manuale NanoVIP2 Rel. 1.4 en-UKDocument58 pagesManuale NanoVIP2 Rel. 1.4 en-UKECNo ratings yet

- Slection of Motor Starter PDFDocument4 pagesSlection of Motor Starter PDFArun GuptaNo ratings yet

- Chapter 6: Electrical and Instrumentation FacilitiesDocument47 pagesChapter 6: Electrical and Instrumentation FacilitiesBhausaheb PatilNo ratings yet

- Electrical System Comm ProcedureDocument60 pagesElectrical System Comm Procedurevaithy1990No ratings yet

- Energy Audit ReportDocument11 pagesEnergy Audit ReportshailNo ratings yet

- MP - Conference Paper - Lifetime Extension Services For Static Var CompensatorsDocument15 pagesMP - Conference Paper - Lifetime Extension Services For Static Var CompensatorsJawad AziziNo ratings yet

- Study and Analysis of Systems For Monitoring in Power SubstationsDocument3 pagesStudy and Analysis of Systems For Monitoring in Power SubstationsIsrael DanielNo ratings yet

- MPEB Summer Training ReportDocument24 pagesMPEB Summer Training ReportKeshav Chadha88% (8)

- 323Document22 pages323Sridhar Raja AluriNo ratings yet

- Chaprer TwoDocument28 pagesChaprer Twowintabiniam43No ratings yet

- Condition Monitoring Notes-Unit 2Document11 pagesCondition Monitoring Notes-Unit 2MaheswariRVNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersAshwani RanaNo ratings yet

- Vibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSDocument8 pagesVibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSweerasinghekNo ratings yet

- There Are 3 Key Elements To A ContactorDocument3 pagesThere Are 3 Key Elements To A ContactorSharath KotaNo ratings yet

- As 60156 KV-CL20 RC Um 960129-2Document330 pagesAs 60156 KV-CL20 RC Um 960129-2Emmanuel Rodríguez OrdazNo ratings yet

- Manual Inglés APM - V3.6Document73 pagesManual Inglés APM - V3.6Implementación OLCNo ratings yet

- ACS 1000W PMWorkInstDocument22 pagesACS 1000W PMWorkInstJinNo ratings yet

- Measuring and Monitoring Relays - ABBDocument76 pagesMeasuring and Monitoring Relays - ABBpevareNo ratings yet

- P P O I : Roject Rofile N NvertersDocument11 pagesP P O I : Roject Rofile N NvertersramaNo ratings yet

- Siemens Kion - Service ManualDocument207 pagesSiemens Kion - Service Manualversilia0% (1)

- Condition Monitoring DocumentationDocument49 pagesCondition Monitoring DocumentationSanthosh Penugonda0% (1)

- NCL ReportDocument20 pagesNCL ReportSwati Tripathi33% (3)

- Project Report On Transformer Protection Using Numerical RelayDocument85 pagesProject Report On Transformer Protection Using Numerical RelayIhsan Ullah100% (4)

- Fault Finding Manual 8Document29 pagesFault Finding Manual 8Jovan KosticNo ratings yet

- Internship ReportDocument6 pagesInternship ReportEngr Syed Numan ShahNo ratings yet

- Automatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsDocument65 pagesAutomatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsYassine.G ChipLabNo ratings yet

- Liebert APM With Modular Battery User Manual v2.9Document72 pagesLiebert APM With Modular Battery User Manual v2.9truong_hoangvanNo ratings yet

- Avr 100s IngleseDocument65 pagesAvr 100s IngleseVedran GaćeNo ratings yet

- Service Note - ABB Life Expectancy Analysis Program - SM101 - EN - Rev B - 2010Document2 pagesService Note - ABB Life Expectancy Analysis Program - SM101 - EN - Rev B - 2010Jor BillacisNo ratings yet

- Sudhanshu - UPPCLDocument23 pagesSudhanshu - UPPCLShivendu PandeyNo ratings yet

- Samsung t190 ltw19hs ltw19gsDocument56 pagesSamsung t190 ltw19hs ltw19gsMARCELO BetucciNo ratings yet

- Fault and Abnormal 1Document71 pagesFault and Abnormal 1Mahesh PushpakumaraNo ratings yet

- ELEC105Document3 pagesELEC105Joemon HenryNo ratings yet

- PSP Manual 13Document10 pagesPSP Manual 13Muhammad AnsNo ratings yet

- A#4 G4 Romero Bsee-1fDocument7 pagesA#4 G4 Romero Bsee-1fRomero, Ken Angelo B.No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- Internship Report: University of The Punjab (Lahore)Document18 pagesInternship Report: University of The Punjab (Lahore)Abdullah NasirNo ratings yet

- Testing and CommissioningDocument4 pagesTesting and CommissioningMitesh Gandhi100% (2)

- Project ReportDocument13 pagesProject ReportAbhinav ChauhanNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Power Electronics: Lecture Notes of Power Electronics CourseFrom EverandPower Electronics: Lecture Notes of Power Electronics CourseNo ratings yet

- Unit-2 Tripping 28 - 03 - 2009Document1 pageUnit-2 Tripping 28 - 03 - 2009Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Chandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedDocument1 pageChandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedGajanan JagtapNo ratings yet

- Unit-1 Tripping 28-3-2009Document1 pageUnit-1 Tripping 28-3-2009Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument2 pagesEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Ana U#6-2006Document32 pagesEvent Ana U#6-2006Gajanan JagtapNo ratings yet

- U3 Tripping 12 - 02 - 2009 - ADocument2 pagesU3 Tripping 12 - 02 - 2009 - AGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Officers Recreation Centre Urjanagar ChandrapurDocument2 pagesOfficers Recreation Centre Urjanagar ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Ana U#7,2006 - CompletedDocument31 pagesEvent Ana U#7,2006 - CompletedGajanan JagtapNo ratings yet

- Event Analysis Card SlipDocument2 pagesEvent Analysis Card SlipGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Unit-2 Non Tripping 4-02-2009OLDDocument1 pageUnit-2 Non Tripping 4-02-2009OLDGajanan JagtapNo ratings yet

- Event Analysis Report: 198 A, B, D, E, F NILDocument1 pageEvent Analysis Report: 198 A, B, D, E, F NILGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Format For Oil Gun: Month/Year November 2012Document2 pagesFormat For Oil Gun: Month/Year November 2012Gajanan JagtapNo ratings yet

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Unit-1 Tripping 30-01-2009 Mod FormataDocument1 pageUnit-1 Tripping 30-01-2009 Mod FormataGajanan JagtapNo ratings yet

- A - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFDocument27 pagesA - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFAnonymous hxV81ITD8kNo ratings yet

- Pump Replacement Guide A5 0413 LRDocument16 pagesPump Replacement Guide A5 0413 LRmohammudaphNo ratings yet

- PS8 Metal EomDocument28 pagesPS8 Metal EomROY RIVERANo ratings yet

- Variable Speed Fluid Couplings - Brochure 2014 (Voith)Document20 pagesVariable Speed Fluid Couplings - Brochure 2014 (Voith)RudanekNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Topic 2 Testing-And-Commissioning-In-PlumbingDocument56 pagesTopic 2 Testing-And-Commissioning-In-PlumbingRODEL YUNTINGNo ratings yet

- Flow Transmitter Promag BA055DENDocument178 pagesFlow Transmitter Promag BA055DENcysautsNo ratings yet

- (Triveni) Rajashri Power 10 MW For ACC byDocument32 pages(Triveni) Rajashri Power 10 MW For ACC bynogeshwar50% (2)

- M VACDocument98 pagesM VACLuis Alberto Perez ParedesNo ratings yet

- Instruction Manual TLC SprayerDocument9 pagesInstruction Manual TLC SprayerBea Andre Trecho TupasNo ratings yet

- Gv222ti - Gas Natural GLP PDFDocument2 pagesGv222ti - Gas Natural GLP PDFdaniloreisrochaNo ratings yet

- Electronic Fuel Injection ComponentsDocument50 pagesElectronic Fuel Injection ComponentsDani-meganeboyNo ratings yet

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNo ratings yet

- Understanding Compressors Article PDFDocument14 pagesUnderstanding Compressors Article PDFdantesosaNo ratings yet

- Zamil DY - Series PDFDocument23 pagesZamil DY - Series PDFgagokapalaNo ratings yet

- Kamewa Steel Series WaterjetsDocument2 pagesKamewa Steel Series WaterjetsAnkit singhNo ratings yet

- Vantage BoilerDocument2 pagesVantage BoilerjarNo ratings yet

- Honda WX10 ManualDocument68 pagesHonda WX10 ManualBogdan BurcheciNo ratings yet

- Cyl Im PLS 011122Document3 pagesCyl Im PLS 011122rohanNo ratings yet

- Curso Cat d6r III STMGDocument73 pagesCurso Cat d6r III STMGSilas F Pimenta90% (20)

- Solar Water Pumping SystemDocument78 pagesSolar Water Pumping SystemvehiclesalesbeaekaNo ratings yet

- Uht Pasteurization FinalDocument4 pagesUht Pasteurization FinalZacky Husada AchmadNo ratings yet

- Variable Displacement Pump A7V: Extract From RE 92210/05.95Document2 pagesVariable Displacement Pump A7V: Extract From RE 92210/05.95Joana Meller100% (1)