Professional Documents

Culture Documents

Flowserve Pump Division Presentation

Flowserve Pump Division Presentation

Uploaded by

George TanasescuCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WHO Monographs On Selected Medicinal Plants3Document390 pagesWHO Monographs On Selected Medicinal Plants3George TanasescuNo ratings yet

- Condensation Recovery of Nitrogen Tetroxide Based On HYSYSDocument7 pagesCondensation Recovery of Nitrogen Tetroxide Based On HYSYSGeorge TanasescuNo ratings yet

- Readme !!! LeggimiDocument6 pagesReadme !!! LeggimiGeorge TanasescuNo ratings yet

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- 1137 - Oferta Chiller TraneDocument3 pages1137 - Oferta Chiller TraneGeorge TanasescuNo ratings yet

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- 2session Technology Ralf HommersDocument29 pages2session Technology Ralf HommersGeorge TanasescuNo ratings yet

- Addmrpt 1 11340 11341Document10 pagesAddmrpt 1 11340 11341PraveenNo ratings yet

- Simplifications PDF Set 5 PDFDocument22 pagesSimplifications PDF Set 5 PDFHriday MittraNo ratings yet

- Service Manual: KDL-52V4100 KDL-52V4100 KDL-52W4100 KDL-52W4100Document114 pagesService Manual: KDL-52V4100 KDL-52V4100 KDL-52W4100 KDL-52W4100Carolina López GonzálezNo ratings yet

- Demage Tolerant Design PDFDocument818 pagesDemage Tolerant Design PDFJoão Júnior LopêsNo ratings yet

- Exercise PlanDocument4 pagesExercise Planj.kendall.reidNo ratings yet

- Basic IUPAC Organic Nomenclature PolyenesDocument2 pagesBasic IUPAC Organic Nomenclature PolyenesMary Joy Lindo BarrogaNo ratings yet

- Ai TS NOTICE FOR CLASS IX XDocument1 pageAi TS NOTICE FOR CLASS IX XVandana SharmaNo ratings yet

- Sex Is Binary EssayDocument6 pagesSex Is Binary EssayAshleigh SchumanNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Number Theory and Public Key Cryptography: SyllabusDocument26 pagesNumber Theory and Public Key Cryptography: SyllabusGeethanjali KotaruNo ratings yet

- Tabel 1. Range Nilai Log SP, Resistivity Dan Gamma Ray No - Litologi Range Nilai Range Nilai Log Range Nilai LogDocument1 pageTabel 1. Range Nilai Log SP, Resistivity Dan Gamma Ray No - Litologi Range Nilai Range Nilai Log Range Nilai Logdody24No ratings yet

- EskimoDocument2 pagesEskimoabdul sorathiyaNo ratings yet

- Figure Skating Spirals in CompetitionDocument2 pagesFigure Skating Spirals in CompetitionAlexandra PurcaroiuNo ratings yet

- Fesen - Space SciencesDocument61 pagesFesen - Space SciencesafosrNo ratings yet

- Chapt 6 - Mauritius Wind SpeedDocument65 pagesChapt 6 - Mauritius Wind SpeedSmr Only100% (1)

- Grade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezDocument1 pageGrade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezRangga NarindraNo ratings yet

- Presentation of Engineering InformationDocument5 pagesPresentation of Engineering InformationDinesh SilvaNo ratings yet

- Beauty Care (Nail Care) Services: Quarter 1, Week 5Document17 pagesBeauty Care (Nail Care) Services: Quarter 1, Week 5Are Pee Etc100% (1)

- Stock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsDocument7 pagesStock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsusamaNo ratings yet

- Chassis EUROCASE ML-5410 Middle Tower Full ATX Mainboard Supported, 7 Slots, PSU InsDocument5 pagesChassis EUROCASE ML-5410 Middle Tower Full ATX Mainboard Supported, 7 Slots, PSU InsGuran MaricioNo ratings yet

- MCQDocument274 pagesMCQgganyan67% (3)

- Seminar PresentationDocument16 pagesSeminar PresentationVinay KurkuriNo ratings yet

- Business Studies Project Class XIIDocument13 pagesBusiness Studies Project Class XIIKanishk Mehrotra67% (15)

- BRAPDocument5 pagesBRAPrkkask01No ratings yet

- Seismic AnalysisDocument6 pagesSeismic AnalysisSharah QuilarioNo ratings yet

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 pagesDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzNo ratings yet

- Kingsley Cv2Document2 pagesKingsley Cv2akwue kingsleyNo ratings yet

- Design ThinkingDocument24 pagesDesign Thinkingapi-302717277No ratings yet

- Iteco-010901-B (0.6 - 1KV TFR-CV Spec)Document9 pagesIteco-010901-B (0.6 - 1KV TFR-CV Spec)Kyaw ThihaNo ratings yet

- THE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweDocument618 pagesTHE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweVasilis AchillesNo ratings yet

Flowserve Pump Division Presentation

Flowserve Pump Division Presentation

Uploaded by

George TanasescuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowserve Pump Division Presentation

Flowserve Pump Division Presentation

Uploaded by

George TanasescuCopyright:

Available Formats

Oil & Gas

Production Pipeline

Offshore Onshore Synthetic Crude Liquid Natural Gas

Pump Division

Pump Supplier To The World Flowserve is the driving force in the global industrial pump marketplace. No other pump company in the world has the depth or breadth of expertise in the successful application of pre-engineered, engineered and special purpose pumps and systems.

Supplier of Choice to the Oil & Gas Industry For over a century and a half, Flowserve has pioneered virtually every significant advancement in petroleum-related pumping technology. The ability to understand the industrys upstream needs and to anticipate its requirements makes Flowserve the supplier of choice for production, pipeline and liquified natural gas (LNG) pumping applications.

Heritage Names of Distinction ACEC Centrifugal Pumps Aldrich Pumps Byron Jackson Pumps Cameron Pumps Durco Pumps Flowserve Pumps IDP Pumps Jeumont-Schneider Pumps Pacific Pumps Pleuger Pumps Scienco Pumps Sier-Bath Rotary Pumps Stork Engineered Pumps United Centrifugal Pumps Western Land Roller Irrigation Pumps Wilson-Snyder Pumps Worthington Pumps Worthington Simpson Pumps

Pump Designs Flowserve offers a wide range of complementary pump types, built to recognized global standards and customer specifications. These include: Single stage process Between bearing single stage Between bearing multistage Vertical Submersible motor Rotary Reciprocating Nuclear Specialty Optional Configurations Sealed and sealless Axially and radially split Volute and diffuser Close coupled and long coupled Single and double casing Dynamic Technologies Few if any pump companies can match Flowserves capabilities in hydraulic and mechanical design or in materials engineering. Among these capabilities are: Computational fluid dynamics Flow visualization Cavitation studies Efficiency optimization Finite element analysis Rapid prototyping Captive alloy foundries Non-metallic materials processing and manufacturing

Market Focused Customer Support Product and industry specialists develop effective proposals and solutions directed toward market and customer preferences. They offer technical advice and assistance throughout each stage of the product life cycle, beginning with the inquiry. Benefits of a pumping partnership with Flowserve include: Advanced technology solutions Order engineering Hydraulic engineering Broad product reliability Worldwide service and support Competitive price and delivery Technology innovation Applications expertise

Offshore

Offshore production presents a host of unique pumping challenges as the hunt for oil and gas has led to deep and often violent seascapes. This has made production much more arduous and hazardous. Flowserve offers extensive products and services to satisfy the pumping needs and specific requirements of offshore platforms and floating production, storage and offloading facilities (FPSOs). These include: Pumps fully compliant with API 610 latest editions and customer specifications Highly engineered, robust and reliable pumps adapted to offshore space and weight concerns, operating and environmental conditions Extended pump mean time between planned maintenance with authorized maintenance service wherever required

Meeting New Challenges New exploration and extraction processes require creative pumping solutions. Flowserve is in the forefront of subsea technology with the application of integrated multiphase pumping and seabed processing systems. In the evolving practice of multiphase pumping, Flowserve is the only manufacturer offering the safety and reliability of shaft seals to API-682. Addressing new challenges is where Flowserves extraordinary experience and capabilities in hydraulic design, submersible motor technology and materials science pay off in pumps that are at home in the depths of the ocean as they are in the bowels of the earth. Production and Pipeline Flowserve produces a complete line of performanceproven pumps for all offshore oil services. These include: submersible motor pumps for sea water lift, ballast rig water services; process pumps to move and handle oil, gas and water; high pressure pumps for sea water injection; high capacity, high pressure pumps for crude oil transportation; and utility and fire protection pumps. Offshore pipelines are carrying an increasing amount of the worlds oil and gas. Pumps for these services must be robust and unfailingly reliable. Flowserve offers pumps for every conceivable pipeline application as well as for storage and transfer, including special cargo stripper pumps for loading and unloading barges and supertankers.

Flowserve is synonymous with oil and gas pumping. This is reflected by Flowserves continuing role in the API Standards Committee... and by its alliance relationships with the worlds most prominent energy companies.

Onshore

Oil- and gas-well drilling continues at a high level of activity worldwide but with ever-increasing difficulties of location, landscape and depth. It is these types of challenges which have made Flowserve a leader in the development and application of advanced pumping technologies for oil and gas applications. Flowserve has made significant contributions to these advancements by designing the first centrifugal pumps for oil-field production along with automatic mainline and booster pipeline stations. Flowserve pioneered secondary recovery through high pressure water injection and first applied submersible motor pumps in crude oil and LPG storage caverns.

Flowserve has earned a pre-eminent position in crude oil and product pipeline pumping.

Production and Pipeline Flowserve provides a broad line of performanceproven, fully compliant API 610 pumps designed for oil-field production services. These include: pumps to transport, handle and separate oil, gas and water brought to the surface; high capacity vertical and horizontal pumps required for high-pressure water injection operations; gas-oil separation plant (GOSP) equipment; scrubber desulfurization pumps; and virtually all ancillary production related applications. Flowserve is a leading manufacturer of petroleum pipeline pumps. The reliability of its single and multistage pumps has made them the products of choice for unattended mainline operation in some of the worlds most inhospitable environments. Low NPSH pumps, in both horizontal and vertical configurations, are offered for booster-station service. And no other manufacturer offers the breadth of pumps for transportation, transfer, storage and cargo stripping.

Its expertise in design, engineered solutions, equipment re-rate and service is without equal.

Synthetic Crude

With new process technologies and techniques, obtaining synthetic crude from the vast tar sand reserves is now economically feasible. To accomplish this, energy producers need pumping flexibility and reliability in both bitumen mining-extraction and the more traditional oil production and pipeline services. And, of course, these pumps must perform in often hostile and quite remote environments. These processes require fully API 610 compliant as well as rugged and reliable Flowserve industrial pumps. General Applications Mining Hard metal slurry and transport pumps Extraction Axially split, multistage pumps for steam assisted gravity drain (SAGD); hard metal froth pumps; low shear, single stage process pumps; hard metal tailings pumps Pipeline API process and pipeline pumps

Converting natural gas leaving the wellhead into liquified natural gas (LNG) is not only good conservation policy but excellent and profitable business policy as well. Regardless of the process used to recover LNG absorption, straight refrigeration or cryogenic liquid expansion Flowserve has the liquid turbine expanders, charge and process pumps, service and utility pumps, and specialty pumps to accomplish the tasks. General Applications Charge and process Petroleum process pumps; between bearing, multistage, singe and double casing axially split, horizontal pumps; single stage, horizontal pumps; vertical, process, can pumps Cryogenic Vertical and horizontal cryogenic pumps, liquid turbine expanders Desulfurization Single and multistage pumps Pipeline and transportation Between bearings single and multistage, horizontal pumps; double casing, horizontal pumps; vertical, process can pumps Safety and utility Between bearings, single stage, axially split, horizontal pumps; vertical turbine and circulator pumps

Liquified Natural Gas

10

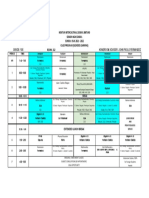

Production Applications

Flowserve oil and gas pumps are fully compliant with API 610 current edition standards.

Sea water lift Submersible motor pumps or vertical line shaft pumps Source water Submersible motor pumps; vertical, deep well, turbine pumps Water injection Horizontal, multistage single and double casing pumps; vertical double casing pumps FPSO positioning Specialty thruster pumps; vertical, double casing pumps Water treatment Submersible motor pumps Utility Single stage, double suction, axially split, horizontal pumps; vertical, in-line process pumps Safety and fire fighting (UL approved package) Single stage, double suction, axially split, horizontal pumps; vertical, turbine pumps Separation Multiphase pumps; single stage process pumps; high pressure, multistage pumps; vertical process pumps; vertical turbine pumps; vertical circulators; and rubber lined or hard metal slurry pumps Gas treating - High pressure, horizontal multistage pumps (BB3 and BB5) and single stage process pumps

11

Deep Well Submersible Motor Pumps

Designed to meet subsurface, deep well or high pressure boosting needs. Liquid ends and water-filled submersible motors to 1830 m (6000 ft) submergence Operating Parameters Flows to 68 000 m3/h (300 000 gpm) Heads to 670 m (2200 ft) Speeds from 2000 to 3600 rpm Motor sizes to 5000 kW (6700 hp)

Production Applications

Between Bearing, Single Stage Pumps (API-BB1)

Horizontal, axially split, single stage, double suction centrifugal pump. Pump configurations include a vertical mounted option and selected sizes of bottom suction models. Both API and non-API designs are available Operating Parameters Flows to 41 000 m3/h (180 000 gpm) Heads to 150 m (500 ft) Pressures to 17 bar (250 psi) Temperatures to 120C (250F)

12

Production Applications

Vertical Turbine Pumps (API-VS1, API-VS6)

Multistage with above or below surface discharge, enclosed or semi-open impellers, open or enclosed lineshafts, single or double casing Operating Parameters Flows to 5680 m3/h (25 000 gpm) Heads to 700 m (2300 ft) Sizes 150 mm (6 in) to 1200 mm (48 in) Settings to 365 m (1200 ft)

Multistage, Double Casing, Diffuser and Volute Design Pumps (API-BB5)

Single and double suction first stage pumps for high pressure services including water injection. Fully compliant with API 610, latest edition Operating Parameters Flows to 4000 m3/h (18 000 gpm) Heads to 4300 m (14 000 ft) Pressures to 400 bar (6000 psi)

13

Multistage, Axially Split Pumps (API-BB3)

Between bearing, axially split, double volute, side suction, side discharge, multistage design. For water injection and disposal, and liquid CO2 injection Operating Parameters Flows to 2950 m3/h (13 000 gpm) Heads to 2130 m (7000 ft) Pressures to 275 bar (4000 psi) Temperatures to 205C (400F)

Production Applications

Horizontal, Overhung Process Pumps (API-OH2)

End suction-top discharge, overhung, centerline mounted configuration. API 682 seal chamber; fully compliant with current edition of API 610 standards Operating Parameters Flows to 2000 m3/h (9000 gpm) Heads to 350 m (1100 ft) Temperatures from -160 C (-250F) to 450 C (850F) Pressures to 80 bar (1160 psi)

Vertical, In-line Process Pumps (API-OH3, API-OH4, API-OH5)

Designed for simplified piping and space savings with in-line suction and discharge nozzles. API 682 seal chamber; fully compliant with current edition of API 610 standards Operating Parameters Flows to 6800 m3/h (28 000 gpm) Heads to 460 m (1100 ft) Pressures to 100 bar (1160 psi) Temperatures to 425C (850F)

14

Pipeline Services

Flowserve pipeline pumps are fully compliant with API 610 current edition standards.

Pipeline and transportation (in series or parallel) Mainline and booster; horizontal, between bearing single and multistage process pumps; vertical process pumps Storage and transfer Horizontal, between bearing, single stage, process pumps; vertical process pumps; submersible motor pumps; vertical, in-line process pumps Terminal Vertical in-line and vertical process pumps On- and offloading - Specialty stripper pumps

Single Stage, Axially Split Pumps (API-BB1)

Axially split, double volute case, double suction pumps for pipeline service and related heavy-duty requirements Operating Parameters Flows to 41 000 m3/h (180 000 gpm) Heads to 150 m (500 ft) Pressures to 17 bar (250 psi) Temperatures to 120C (250F)

Multistage, Axially Split Pumps (API-BB3)

Between bearing, axially split, double volute, side suction, side discharge, multistage design. For high pressure, heavy-duty pipeline applications Operating Parameters Flows to 2950 m3/h (13 000 gpm) Heads to 2130 m (7000 ft) Pressures to 275 bar (4000 psi) Temperatures to 205C (400F)

15

Vertical Turbine, Double Casing Pump (API-VS6)

High pressure, heavy-duty, diffuser type, single or multiple stage pump for continuous duty in pipeline booster and transfer services Operating Parameters Flows to 13 600 m3/h (60 000 gpm) Heads to 1100 m (3500 ft) Pressures to 100 bar (1500 psi) Temperatures to -195C (-320F) to 425C (800F)

Pipeline Services

Vertical, In-line Pumps (API-OH3, API-OH4, API-OH5)

Single suction, double suction, in-line design for high flow, limited NPSHA. Tank farm, transfer and pipeline booster services Operating Parameters Flows to 6800 m3/h (28 000 gpm) Heads to 460 m (1100 ft) Pressures to 100 bar (1160 psi) Temperatures to 425C (850F)

16

Specialty Applications

Hard Metal Slurry Pumps

Horizontal, single stage, end suction design with vertical tangential discharge nozzles for tar sand extraction services including froth and tailings applications Operating Parameters Flows to 10 000 m3/h (44 000 gpm) Heads to 90 m (300 ft) Temperatures to 120C (250F) Pressures to 10 bar (150 psi)

Multiphase Pumps

Two-screw, double suction design with API 682 seal chamber for oil-gas-water separation, subsea service, refining and processing Operating Parameters Flows to 3000 m3/h (13 200 ft) Temperatures to 120C (250F) Pressures to 240 bar (3500 psi) Viscosities to 200 000 000 ssu

17

Cryogenic Liquid Expanders

Double casing, vertical turbine expanders for severe sub-zero temperatures in LNG production. Operating Parameters Temperatures to -180C (-290F) Inlet pressures to 70 bar (1000 psi) (Higher if required) Generator sizes to 2250 kW (3000 hp)

Specialty Applications

Cryogenic Pumps

A full line of pumps, both vertical and single multistage horizontal, for low temperature service in LNG storage and transport. Available in standard designs Operating Parameters Vertical Turbine Pumps - Temperatures from -198C (-325F) to -45C (-50F) - Discharge pressures to 150 bar (2160 psi) - Motor sizes to 1120 kW (1500 hp)

18

Technology, Technical Support and Service

Innovation Through Dynamic Technology Flowserve is without peer in the development, refinement and application of pump technology. This dynamic creativity is reflected in the strength of the companys commitment to: Hydraulic engineering Mechanical design Materials science Intelligent pumping Manufacturing technology All research and technology efforts are directed toward providing customers with greater total value for their investments in Flowserve products and systems. Further, these capabilities enable Flowserve to quickly and accurately provide the best possible solutions to customers specific pumping problems.

19

Pump Improvement Engineering Services The goal of this specialty service is to help plant technical personnel achieve optimal pumping solutions through engineering and technological assistance. Reducing the costs of operation and maintenance while improving overall equipment reliability is achieved through: Field performance testing Vibration analysis Design analysis and root-cause problem solving Material improvements Pump and system audit Advanced technology solutions Nuclear Maintenance Rule support PumpTrac remote pump monitoring and diagnostic services Instruction manual updates Training courses Parts and service Quality OEM parts are readily available from Flowserves worldwide network of service and repair centers, fast response centers and regional parts services offices. All are computer networked to provide as soon as possible response to customers requests for assistance. Customer service technicians are on call around the clock, seven days a week to respond to customer queries, to evaluate and troubleshoot reported pump problems and to provide reliable solutions.

Service and Repair Group Flowserves Service and Repair Group is dedicated to maximizing equipment performance and reliabilitycentered maintenance programs. Pump related services include: Startup and commissioning Diagnostics and prognostics Contract maintenance programs Routine and repair maintenance ANSI and ISO power end exchange program Mechanical seal exchange program Re-rates, upgrades and retrofits Spare parts inventory and management programs Training

Hydraulic Engineering Mechanical Design Materials Science Intelligent Pumping Manufacturing Technology

USA and Canada Flowserve Corporation Pump Division Millennium Center 222 Las Colinas Blvd., 15th Floor Irving, TX 75039-5421 USA Telephone: 1 972 443 6500 Toll Free: 1 800 728 PUMP (7867) Telefax: 1 972 443 6800 Europe, Africa, Middle East Flowserve Ltd. Pump Division Harley House 94 Hare Lane, Claygate, Esher Surrey KT10 ORB, UK Telephone: 44 1372 463700 Telefax: 44 1372 460190

Pump Division

Your local Flowserve representative:

Latin America Flowserve, S.A. de C.V. Avenida Paseo de la Reforma #30 2nd. Floor Colonia Jurez Centro Mxico, D.F. Z.C. 06040 Telephone: 52 5705 5526 Telefax: 52 5705 1125 Asia Pacific Flowserve Pte. Ltd. Pump Division 200 Pandan Loop, #06-03/04 Pantech 21 Singapore 128388 Telephone: 65 6775 3003 Telefax: 65 6779 4607

To find your local Flowserve representative please use the Sales Support Locator System found at www.flowserve.com

Bulletin FPD-3 (E) Printed in U.S.A. March 2002 Flowserve Corporation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WHO Monographs On Selected Medicinal Plants3Document390 pagesWHO Monographs On Selected Medicinal Plants3George TanasescuNo ratings yet

- Condensation Recovery of Nitrogen Tetroxide Based On HYSYSDocument7 pagesCondensation Recovery of Nitrogen Tetroxide Based On HYSYSGeorge TanasescuNo ratings yet

- Readme !!! LeggimiDocument6 pagesReadme !!! LeggimiGeorge TanasescuNo ratings yet

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- 1137 - Oferta Chiller TraneDocument3 pages1137 - Oferta Chiller TraneGeorge TanasescuNo ratings yet

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- 2session Technology Ralf HommersDocument29 pages2session Technology Ralf HommersGeorge TanasescuNo ratings yet

- Addmrpt 1 11340 11341Document10 pagesAddmrpt 1 11340 11341PraveenNo ratings yet

- Simplifications PDF Set 5 PDFDocument22 pagesSimplifications PDF Set 5 PDFHriday MittraNo ratings yet

- Service Manual: KDL-52V4100 KDL-52V4100 KDL-52W4100 KDL-52W4100Document114 pagesService Manual: KDL-52V4100 KDL-52V4100 KDL-52W4100 KDL-52W4100Carolina López GonzálezNo ratings yet

- Demage Tolerant Design PDFDocument818 pagesDemage Tolerant Design PDFJoão Júnior LopêsNo ratings yet

- Exercise PlanDocument4 pagesExercise Planj.kendall.reidNo ratings yet

- Basic IUPAC Organic Nomenclature PolyenesDocument2 pagesBasic IUPAC Organic Nomenclature PolyenesMary Joy Lindo BarrogaNo ratings yet

- Ai TS NOTICE FOR CLASS IX XDocument1 pageAi TS NOTICE FOR CLASS IX XVandana SharmaNo ratings yet

- Sex Is Binary EssayDocument6 pagesSex Is Binary EssayAshleigh SchumanNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Number Theory and Public Key Cryptography: SyllabusDocument26 pagesNumber Theory and Public Key Cryptography: SyllabusGeethanjali KotaruNo ratings yet

- Tabel 1. Range Nilai Log SP, Resistivity Dan Gamma Ray No - Litologi Range Nilai Range Nilai Log Range Nilai LogDocument1 pageTabel 1. Range Nilai Log SP, Resistivity Dan Gamma Ray No - Litologi Range Nilai Range Nilai Log Range Nilai Logdody24No ratings yet

- EskimoDocument2 pagesEskimoabdul sorathiyaNo ratings yet

- Figure Skating Spirals in CompetitionDocument2 pagesFigure Skating Spirals in CompetitionAlexandra PurcaroiuNo ratings yet

- Fesen - Space SciencesDocument61 pagesFesen - Space SciencesafosrNo ratings yet

- Chapt 6 - Mauritius Wind SpeedDocument65 pagesChapt 6 - Mauritius Wind SpeedSmr Only100% (1)

- Grade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezDocument1 pageGrade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezRangga NarindraNo ratings yet

- Presentation of Engineering InformationDocument5 pagesPresentation of Engineering InformationDinesh SilvaNo ratings yet

- Beauty Care (Nail Care) Services: Quarter 1, Week 5Document17 pagesBeauty Care (Nail Care) Services: Quarter 1, Week 5Are Pee Etc100% (1)

- Stock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsDocument7 pagesStock in Transit (GR - IR Regrouping - Reclassification) - SAP BlogsusamaNo ratings yet

- Chassis EUROCASE ML-5410 Middle Tower Full ATX Mainboard Supported, 7 Slots, PSU InsDocument5 pagesChassis EUROCASE ML-5410 Middle Tower Full ATX Mainboard Supported, 7 Slots, PSU InsGuran MaricioNo ratings yet

- MCQDocument274 pagesMCQgganyan67% (3)

- Seminar PresentationDocument16 pagesSeminar PresentationVinay KurkuriNo ratings yet

- Business Studies Project Class XIIDocument13 pagesBusiness Studies Project Class XIIKanishk Mehrotra67% (15)

- BRAPDocument5 pagesBRAPrkkask01No ratings yet

- Seismic AnalysisDocument6 pagesSeismic AnalysisSharah QuilarioNo ratings yet

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 pagesDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzNo ratings yet

- Kingsley Cv2Document2 pagesKingsley Cv2akwue kingsleyNo ratings yet

- Design ThinkingDocument24 pagesDesign Thinkingapi-302717277No ratings yet

- Iteco-010901-B (0.6 - 1KV TFR-CV Spec)Document9 pagesIteco-010901-B (0.6 - 1KV TFR-CV Spec)Kyaw ThihaNo ratings yet

- THE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweDocument618 pagesTHE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweVasilis AchillesNo ratings yet