Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

49 viewsSuper Air Knife Installation & Maintenance: Compressed Air Line Sizes

Super Air Knife Installation & Maintenance: Compressed Air Line Sizes

Uploaded by

kresimir.mikoc9765The document provides guidelines for installing and maintaining Super Air Knives. It recommends sizing compressed air lines and manifolds properly based on air knife length to avoid pressure drops. It also suggests using filtration and separation equipment no more than 15 feet from air knives to prevent contamination. The document describes how to position and adjust air knives for different applications and clean them if clogged.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Double DumpDocument2 pagesDouble Dumpkresimir.mikoc9765No ratings yet

- Eastar SpecificationsDocument2 pagesEastar SpecificationsUmar ShamsudinNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- W01 358 7751Document29 pagesW01 358 7751MROstop.comNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6910Document29 pagesW01 358 6910MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- Description Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsDocument30 pagesDescription Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7091Document29 pagesW01 358 7091MROstop.comNo ratings yet

- W01 358 7092Document29 pagesW01 358 7092MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 9106Document29 pagesW01 358 9106MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Air System ComponentsDocument6 pagesAir System ComponentsEliasNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 9048Document29 pagesW01 358 9048MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 2132Document29 pagesW01 358 2132MROstop.comNo ratings yet

- W01 358 7609Document29 pagesW01 358 7609MROstop.comNo ratings yet

- W02 M58 3019Document30 pagesW02 M58 3019MROstop.comNo ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- W01 358 7902Document30 pagesW01 358 7902MROstop.com100% (1)

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W02 M58 3001Document30 pagesW02 M58 3001MROstop.comNo ratings yet

- W01 358 8048Document29 pagesW01 358 8048MROstop.comNo ratings yet

- W01 358 7327Document29 pagesW01 358 7327MROstop.comNo ratings yet

- Static Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesDocument29 pagesStatic Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesMROstop.comNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Continius Level Measurment of Bulk Material PDFDocument8 pagesContinius Level Measurment of Bulk Material PDFkresimir.mikoc9765No ratings yet

- Berlinerluft Air Conduction Ducts Web 052016 PDFDocument30 pagesBerlinerluft Air Conduction Ducts Web 052016 PDFkresimir.mikoc9765100% (1)

- PB EU ManiFlowSelectorValves (MSV) R3 2016-11Document12 pagesPB EU ManiFlowSelectorValves (MSV) R3 2016-11kresimir.mikoc9765No ratings yet

- Spray Rinse & Steam HandlingDocument8 pagesSpray Rinse & Steam Handlingkresimir.mikoc9765No ratings yet

- Cryogenic Globe Valves: Model BSDocument4 pagesCryogenic Globe Valves: Model BSkresimir.mikoc9765No ratings yet

- B1-Screw Hose CouplingsDocument10 pagesB1-Screw Hose Couplingskresimir.mikoc9765No ratings yet

- Or Series: Rivers WellsDocument4 pagesOr Series: Rivers Wellskresimir.mikoc9765No ratings yet

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionDGWNo ratings yet

- Ash and Slag HandlingDocument4 pagesAsh and Slag Handlingkresimir.mikoc9765No ratings yet

- Vacu ValveDocument2 pagesVacu Valvekresimir.mikoc9765No ratings yet

- FC 1013 FCIPumpPaperDocument4 pagesFC 1013 FCIPumpPaperkresimir.mikoc9765No ratings yet

- Aerodyne BaghouseMaintenanceDocument1 pageAerodyne BaghouseMaintenancekresimir.mikoc9765No ratings yet

- Power Generation From Pressure Reduction in The Natural Gas Supply Chain in BangladeshDocument7 pagesPower Generation From Pressure Reduction in The Natural Gas Supply Chain in Bangladeshkresimir.mikoc9765100% (1)

- Electricity Production With Zero Emission and Its Distribution To The GridDocument5 pagesElectricity Production With Zero Emission and Its Distribution To The Gridkresimir.mikoc9765No ratings yet

- Grade 2205 DuplexDocument9 pagesGrade 2205 Duplexkresimir.mikoc9765No ratings yet

- Sandvik 1500SAF: Super Duplex Stainless SteelDocument2 pagesSandvik 1500SAF: Super Duplex Stainless Steelkresimir.mikoc9765No ratings yet

- F2103033842Document5 pagesF2103033842Matin AhmedNo ratings yet

- Listen To The Following Words Carefully and Write Them. (Any Three)Document9 pagesListen To The Following Words Carefully and Write Them. (Any Three)Anonymous wfZ9qDMNNo ratings yet

- Frampton AntithesispedagogyDocument2 pagesFrampton AntithesispedagogyJohann WieseNo ratings yet

- HR304Document3 pagesHR304Tanmoy MondalNo ratings yet

- Deflocculation of Concentrated Aqueous Clay Suspensions With SodDocument5 pagesDeflocculation of Concentrated Aqueous Clay Suspensions With SodkhosrosaneNo ratings yet

- Fun With Magnets PDFDocument4 pagesFun With Magnets PDFMohamed SoudhNo ratings yet

- Spatial Modulation - Optimal Detection and Performance AnalysisDocument3 pagesSpatial Modulation - Optimal Detection and Performance AnalysisAliakbar AlastiNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Test Bank For Clinical Nursing Skills 8th Edition SmithDocument7 pagesTest Bank For Clinical Nursing Skills 8th Edition Smithnoumenalskall0wewNo ratings yet

- Vacant Seats: 5-Year Integrated M.Sc. (Hons.) ProgrammesDocument2 pagesVacant Seats: 5-Year Integrated M.Sc. (Hons.) Programmesmana khantNo ratings yet

- En0389 (Utilities Ii) PDFDocument127 pagesEn0389 (Utilities Ii) PDFGabriel GabrielNo ratings yet

- 12B TB Book PDF-1 PDFDocument113 pages12B TB Book PDF-1 PDFامل العودة طالب100% (1)

- Manual de Partes-HISTER 9 Ton.Document556 pagesManual de Partes-HISTER 9 Ton.Juan PabloNo ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- 1st Quarter ToolkitDocument6 pages1st Quarter ToolkitDimple BolotaoloNo ratings yet

- Elements Cmpds Mix Ws-AnswersDocument2 pagesElements Cmpds Mix Ws-Answerseric sivaneshNo ratings yet

- ContractionsDocument2 pagesContractionsAlexander Vargas TorresNo ratings yet

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- CBRDocument3 pagesCBRJunita PasaribuNo ratings yet

- SOP - Internal FAT-MachineDocument12 pagesSOP - Internal FAT-MachineSarvesh DaradeNo ratings yet

- SAP Kernel 720Document24 pagesSAP Kernel 720rajaraobhmNo ratings yet

- Virtual Synchronous Control For Grid-Connected DFIG-Based Wind TurbinesDocument13 pagesVirtual Synchronous Control For Grid-Connected DFIG-Based Wind TurbinesWILLIAM FERNEY RINCON MELONo ratings yet

- Selection Post IX Graduation 08-02-2022 EngDocument156 pagesSelection Post IX Graduation 08-02-2022 EngVijay singh TomarNo ratings yet

- English Project CompileDocument33 pagesEnglish Project CompileAbdul QayyumNo ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- Lesson Plan in English 8Document66 pagesLesson Plan in English 8Mhairo Akira100% (1)

- CHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Document2 pagesCHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Karthika SNo ratings yet

Super Air Knife Installation & Maintenance: Compressed Air Line Sizes

Super Air Knife Installation & Maintenance: Compressed Air Line Sizes

Uploaded by

kresimir.mikoc97650 ratings0% found this document useful (0 votes)

49 views0 pagesThe document provides guidelines for installing and maintaining Super Air Knives. It recommends sizing compressed air lines and manifolds properly based on air knife length to avoid pressure drops. It also suggests using filtration and separation equipment no more than 15 feet from air knives to prevent contamination. The document describes how to position and adjust air knives for different applications and clean them if clogged.

Original Description:

11Exair

Original Title

11Exair

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides guidelines for installing and maintaining Super Air Knives. It recommends sizing compressed air lines and manifolds properly based on air knife length to avoid pressure drops. It also suggests using filtration and separation equipment no more than 15 feet from air knives to prevent contamination. The document describes how to position and adjust air knives for different applications and clean them if clogged.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views0 pagesSuper Air Knife Installation & Maintenance: Compressed Air Line Sizes

Super Air Knife Installation & Maintenance: Compressed Air Line Sizes

Uploaded by

kresimir.mikoc9765The document provides guidelines for installing and maintaining Super Air Knives. It recommends sizing compressed air lines and manifolds properly based on air knife length to avoid pressure drops. It also suggests using filtration and separation equipment no more than 15 feet from air knives to prevent contamination. The document describes how to position and adjust air knives for different applications and clean them if clogged.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 0

LIT 2103

2010 EXAIR Corporation

SUPER AIR KNIFE INSTALLATION & MAINTENANCE

COMPRESSED AIR LINE SIZES

Compressed air lines should be sized to hold pressure drops to a minimum. Do not use restrictive fittings or undersized lines that can starve the

Super Air Knife by causing excessive line pressure drop.

The following table (below left) shows the recommended infeed pipe sizes. If compressed air hose is used, always go one size larger than the

recommended pipe size due to the smaller I.D. of hose. (Example: Consider 1/2" I.D. hose the equivalent of 3/8" pipe.)

For 24" (610mm) and longer Air Knives, it is best to supply both ends. Model 9076 and 9077 Universal Air Knife Plumbing Kits (sold separately)

provide the appropriate size hose and fittings for coupling inlets on the same Super Air Knife. The standard gap setting is .002" (.05mm). For

larger gap settings, it is best to supply both ends of the Air Knife in order to maintain uniform flow. (see Super Air Knife Shim Set)

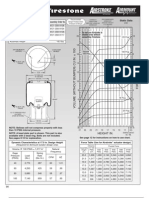

SUPER AI R KNIFE

RECOMMENDED INFEED PIPE SIZES

Si ngl e Ai r Kni fe Inst al l ati on

SUPER AI R KNIFE RECOMMENDED

MANI FOLD AND INFEED PIPE SIZES

Mul ti pl e Ai r Kni fe Instal l ati on

Super

Air Knife

Length

Model Numbers

Infeed Pipe Size

Length of Run

Web

Width

Min.

Manifold

Size

Infeed Pipe Size

Length of Run

10'

(3m)

50'

(15.2m)

100'

(30.5m)

10'

(3m)

50'

(15.2m)

100'

(30.5m)

3" (76mm) 110003, 110003SS, 110003SS-316, 110003-PVDF 1/4" 3/8" 1/2" 60" (1.5M) 1" 1" 1-1/4" 1-1/4"

6" (152mm) 110006, 110006SS, 110006SS-316, 110006-PVDF 1/4" 3/8" 1/2" 84" (2.13M) 1" 1" 1-1/4" 1-1/2"

9" (229mm) 110009, 110009SS, 110009SS-316, 110009-PVDF 3/8" 1/2" 3/4" 102" (2.6M) 1-1/4" 1-1/4" 1-1/4" 1-1/2"

12" (305mm) 110012, 110012SS, 110012SS-316, 110012-PVDF 3/8" 1/2" 3/4" 120" (3M) 1-1/4" 1-1/4" 1-1/2" 2"

18" (457mm) 110018, 110018SS, 110018SS-316, 110018-PVDF 1/2" 3/4" 1"

24" (610mm) 110024, 110024SS, 110024SS-316, 110024-PVDF 1/2" 3/4" 1"

30" (762mm) 110030, 110030SS, 110030SS-316, 110030-PVDF 3/4" 1" 1"

36" (914mm) 110036, 110036SS, 110036SS-316, 110036-PVDF 3/4" 1" 1-1/4"

42" (1067mm) 110042, 110042SS, 110042SS-316, 110042-PVDF 3/4" 1" 1-1/4"

48" (1219mm) 110048, 110048SS, 110048SS-316, 110048-PVDF 3/4" 1" 1-1/4"

54" (1372mm) 110054, 110054SS, 110054SS-316, 110054-PVDF 3/4" 1" 1-1/4"

MANIFOLD SYSTEMS

Sometimes, a long continuous sheet of air is needed. When the required length exceeds the standard Super Air Knife lengths, they can be

manifolded. Inlets in the bottom of the Super Air Knife are provided for this purpose. The table (above right) shows the recommended manifold

sizes for various web lengths.

COMPRESSED AIR SUPPLY

The Super Air Knife has compressed air inlets on each end and on the bottom. Lengths 24" (610mm) and longer should be supplied at two inlets

(opposite ends) to maintain a balanced airflow. An additional center inlet is provided on the bottom of the 48" (1219mm) and 54" (1372mm)

lengths.

With proper filtration and separation of dirt, moisture and oil from the compressed air supply, the Super Air Knife will operate for years with no

maintenance required. Use a 5 micron or smaller filter separator on the compressed air supply. Use Model 9001 Automatic Drain Filter Separator

11510 Goldcoast Drive Cincinnati, OH, USA 45249-1621

(513) 671-3322 FAX (513) 671-3363 E-mail: techelp@exair.com

LIT 2103

2010 EXAIR Corporation

for units up to 12" (305mm), Model 9032 for 18" (457mm) & 24" (610mm) units and Model 9002 for all other units larger than 24" (610mm). To

prevent problems associated with oil, use an oil removal filter. Use a 0.03 micron or smaller oil removal filter on the compressed air supply. Use

Model 9005 Oil Removal Filter for units up to 6"(152mm), Model 9006 Oil Removal Filter for units longer than 6" (152mm). The oil removal

filter should be used downstream from the automatic drain filter separator. Filters should be used close to each Super Air Knife, within 10 to 15'

(3 to 4.6m) is best.

The Super Air Knife is designed to use normal shop air supplies up to 100 PSIG (6.9 BAR, 689 kPa). For infinite control of flow and force,

pressure may be regulated. Use Model 9008 Pressure Regulator for lengths up to 12" (305mm), Model 9033 Pressure Regulator for 18" (457mm)

and 24" (610mm) lengths and Model 9009 Pressure Regulator for lengths over 24" (610mm). Super Air Knives are designed for 250 PSIG

(17.2 BAR, 1.72 MPa) Max.

If air preparation units other than EXAIR models are being used, please note the following:

PRESSURE REGULATORS Must be pressure relieving and rated for a supply pressure of 250 PSIG (17.2 BAR, 1.72 MPa). Suggested

operating pressure is 5-125 PSIG (0.3-8.6 BAR, 34-862 kPa). For models 12" (305mm) and under, flow should be minimum 50 SCFM

(1416 SLPM). For models over 12" (305mm) and up to 24" (610mm), flow should be minimum 90 SCFM (2549 SLPM). For models over 24"

(610mm), flow should be minimum 185 SCFM (5239 SLPM).

AUTO DRAIN FILTER SEPARATORS Must be rated for a supply pressure of 250 PSIG (17.2 BAR, 1.72 MPa) and have 5 micron

filtration. For models 12" (305mm) and under, flow should be minimum 50 SCFM (1416 SLPM). For models over 12" (305mm) and up to

24" (610mm), flow should be minimum 90 SCFM (2549 SLPM). For models over 24" (610mm), flow should be minimum 185 SCFM

(5239 SLPM).

OIL REMOVAL FILTERS Must be rated for a supply pressure of 250 PSIG (17.2 BAR, 1.72 MPa) and have 0.03 micron filtration. For

models 6" (152mm) and under, flow should be minimum 37 SCFM (1048 SLPM). For models over 6" (152mm), flow should be minimum

185 SCFM (5239 SLPM).

USING THE SUPER AIR KNIFE

The Model 9060 Universal Air Knife Mounting System (included in deluxe kits or sold separately) can be articulated into any position to provide

secure, precise positioning for any air knife. The Super Air Knife can also be supported by the compressed air pipe or by using the -20 threaded

holes on the bottom.

The force (combination of mass flow and velocity) of a Super Air Knife is reasonably constant up to a 12" (305mm) distance. Force is lower at

distances greater than 12" (305mm). However, many applications are successful at 18" (457mm), 24" (610mm) or more.

The high velocity airstream thickens as it flows away from the Super Air Knife. At 6" (152mm), it is 3" (76mm) thick and at a 12" (305mm)

distance, 5" (127mm) thick. If the application requires a thin knife of air, mount the Super Air Knife close. This gives a high velocity, thin sheet

of air that has lower mass flow. As the distance from the product surface to the Super Air Knife increases, the thickness of the sheet of air

increases, velocity decreases and mass flow increases. By moving the Super Air Knife in and out from the material, the optimum operating

distance may be determined.

Note: Sharp edges might be present on any of these products. Please take appropriate precautions when handling.

SUPER AIR KNIFE SHIM SET

Force and flow through the Super Air Knife may be easily increased by adding shims to open the air gap. The Super Air Knife is supplied with a

.002" thick shim installed. It sets the air slot to a .002" opening. To increase the air gap, use a shim set (included with the Super Air Knife Kits).

A shim set includes shims of .001" (.03mm), .003" (.08mm) and .004" (.1mm) thickness for aluminum models or (3) .002" (.05mm) thickness

shims for stainless steel models. By changing and stacking them, gaps may be set from .001" to .010" (.03 to .25mm) for aluminum Super Air

Knives and .002" to .008" (.05 to .20mm) for stainless steel. Individual shims are available. When increasing the air gap, be sure the piping, valves,

filter and regulator is sized to meet the new air volume requirement (SCFM/SLPM).

To change shims, remove the assembly bolts. Inspect the Super Air Knife and shim(s) to assure no dust, dirt or chips are on matching surfaces or

in the plenum chamber. Replace or add a shim(s), and re-tighten bolts to 7.5 ft. lbs. Note that mating parts (body & cap) do not align flush. The

flat surface of the cap extends past the body to direct the airflow in a perfectly straight line. The air opening cannot be dead-ended, which meets

OSHA requirements.

TROUBLESHOOTING & MAINTENANCE

If There Is A Reduction In Flow Or Force From The Super Air Knife, check the pressure by installing a gauge in one of the unused inlets.

Large pressure drops are possible due to undersized lines, restrictive fittings and clogged filter elements.

For replacement or repair filter and regulator parts, contact EXAIR at 1-800-903-9247 or techelp@exair.com. Call (513) 671-3322 for

outside the US and Canada.

CLEANING

If contaminants have clogged the Super Air Knife, inspect the unit by disassembling. The Super Air Knife consists of two component parts and

between them is a shim that sets the gap the compressed air exhausts through. This shim is usually .002" (.05mm) thick although thicker shims

can be used. Inspect each part for dust or dirt contamination and a possible oil film in the area of the slotted nozzle. Clean each part and re-tighten

bolts.

Occasionally, there is a build up which occurs on the face of the Super Air Knife as a result of vapors in the atmosphere. Clean this surface with a

solvent and a clean rag. To prevent contaminants from getting pushed back into the slot, perform this procedure with a small amount of

compressed air passing through the Super Air Knife.

If you have any questions or problems, please contact an EXAIR Application Engineer at:

Toll Free: 1-800-903-9247 (U.S. & Canada) Telephone: 513 671-3322 outside of U.S. & Canada

Toll Free Fax: 866-329-3924 (U.S. & Canada) FAX: 513 671-3363 outside of U.S. & Canada

E-mail: techelp@exair.com Website: www.exair.com

You might also like

- Double DumpDocument2 pagesDouble Dumpkresimir.mikoc9765No ratings yet

- Eastar SpecificationsDocument2 pagesEastar SpecificationsUmar ShamsudinNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- W01 358 7751Document29 pagesW01 358 7751MROstop.comNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6910Document29 pagesW01 358 6910MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- Description Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsDocument30 pagesDescription Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7091Document29 pagesW01 358 7091MROstop.comNo ratings yet

- W01 358 7092Document29 pagesW01 358 7092MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 9106Document29 pagesW01 358 9106MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Air System ComponentsDocument6 pagesAir System ComponentsEliasNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 9048Document29 pagesW01 358 9048MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 2132Document29 pagesW01 358 2132MROstop.comNo ratings yet

- W01 358 7609Document29 pagesW01 358 7609MROstop.comNo ratings yet

- W02 M58 3019Document30 pagesW02 M58 3019MROstop.comNo ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- W01 358 7902Document30 pagesW01 358 7902MROstop.com100% (1)

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W02 M58 3001Document30 pagesW02 M58 3001MROstop.comNo ratings yet

- W01 358 8048Document29 pagesW01 358 8048MROstop.comNo ratings yet

- W01 358 7327Document29 pagesW01 358 7327MROstop.comNo ratings yet

- Static Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesDocument29 pagesStatic Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesMROstop.comNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Continius Level Measurment of Bulk Material PDFDocument8 pagesContinius Level Measurment of Bulk Material PDFkresimir.mikoc9765No ratings yet

- Berlinerluft Air Conduction Ducts Web 052016 PDFDocument30 pagesBerlinerluft Air Conduction Ducts Web 052016 PDFkresimir.mikoc9765100% (1)

- PB EU ManiFlowSelectorValves (MSV) R3 2016-11Document12 pagesPB EU ManiFlowSelectorValves (MSV) R3 2016-11kresimir.mikoc9765No ratings yet

- Spray Rinse & Steam HandlingDocument8 pagesSpray Rinse & Steam Handlingkresimir.mikoc9765No ratings yet

- Cryogenic Globe Valves: Model BSDocument4 pagesCryogenic Globe Valves: Model BSkresimir.mikoc9765No ratings yet

- B1-Screw Hose CouplingsDocument10 pagesB1-Screw Hose Couplingskresimir.mikoc9765No ratings yet

- Or Series: Rivers WellsDocument4 pagesOr Series: Rivers Wellskresimir.mikoc9765No ratings yet

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionDGWNo ratings yet

- Ash and Slag HandlingDocument4 pagesAsh and Slag Handlingkresimir.mikoc9765No ratings yet

- Vacu ValveDocument2 pagesVacu Valvekresimir.mikoc9765No ratings yet

- FC 1013 FCIPumpPaperDocument4 pagesFC 1013 FCIPumpPaperkresimir.mikoc9765No ratings yet

- Aerodyne BaghouseMaintenanceDocument1 pageAerodyne BaghouseMaintenancekresimir.mikoc9765No ratings yet

- Power Generation From Pressure Reduction in The Natural Gas Supply Chain in BangladeshDocument7 pagesPower Generation From Pressure Reduction in The Natural Gas Supply Chain in Bangladeshkresimir.mikoc9765100% (1)

- Electricity Production With Zero Emission and Its Distribution To The GridDocument5 pagesElectricity Production With Zero Emission and Its Distribution To The Gridkresimir.mikoc9765No ratings yet

- Grade 2205 DuplexDocument9 pagesGrade 2205 Duplexkresimir.mikoc9765No ratings yet

- Sandvik 1500SAF: Super Duplex Stainless SteelDocument2 pagesSandvik 1500SAF: Super Duplex Stainless Steelkresimir.mikoc9765No ratings yet

- F2103033842Document5 pagesF2103033842Matin AhmedNo ratings yet

- Listen To The Following Words Carefully and Write Them. (Any Three)Document9 pagesListen To The Following Words Carefully and Write Them. (Any Three)Anonymous wfZ9qDMNNo ratings yet

- Frampton AntithesispedagogyDocument2 pagesFrampton AntithesispedagogyJohann WieseNo ratings yet

- HR304Document3 pagesHR304Tanmoy MondalNo ratings yet

- Deflocculation of Concentrated Aqueous Clay Suspensions With SodDocument5 pagesDeflocculation of Concentrated Aqueous Clay Suspensions With SodkhosrosaneNo ratings yet

- Fun With Magnets PDFDocument4 pagesFun With Magnets PDFMohamed SoudhNo ratings yet

- Spatial Modulation - Optimal Detection and Performance AnalysisDocument3 pagesSpatial Modulation - Optimal Detection and Performance AnalysisAliakbar AlastiNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Test Bank For Clinical Nursing Skills 8th Edition SmithDocument7 pagesTest Bank For Clinical Nursing Skills 8th Edition Smithnoumenalskall0wewNo ratings yet

- Vacant Seats: 5-Year Integrated M.Sc. (Hons.) ProgrammesDocument2 pagesVacant Seats: 5-Year Integrated M.Sc. (Hons.) Programmesmana khantNo ratings yet

- En0389 (Utilities Ii) PDFDocument127 pagesEn0389 (Utilities Ii) PDFGabriel GabrielNo ratings yet

- 12B TB Book PDF-1 PDFDocument113 pages12B TB Book PDF-1 PDFامل العودة طالب100% (1)

- Manual de Partes-HISTER 9 Ton.Document556 pagesManual de Partes-HISTER 9 Ton.Juan PabloNo ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- 1st Quarter ToolkitDocument6 pages1st Quarter ToolkitDimple BolotaoloNo ratings yet

- Elements Cmpds Mix Ws-AnswersDocument2 pagesElements Cmpds Mix Ws-Answerseric sivaneshNo ratings yet

- ContractionsDocument2 pagesContractionsAlexander Vargas TorresNo ratings yet

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- CBRDocument3 pagesCBRJunita PasaribuNo ratings yet

- SOP - Internal FAT-MachineDocument12 pagesSOP - Internal FAT-MachineSarvesh DaradeNo ratings yet

- SAP Kernel 720Document24 pagesSAP Kernel 720rajaraobhmNo ratings yet

- Virtual Synchronous Control For Grid-Connected DFIG-Based Wind TurbinesDocument13 pagesVirtual Synchronous Control For Grid-Connected DFIG-Based Wind TurbinesWILLIAM FERNEY RINCON MELONo ratings yet

- Selection Post IX Graduation 08-02-2022 EngDocument156 pagesSelection Post IX Graduation 08-02-2022 EngVijay singh TomarNo ratings yet

- English Project CompileDocument33 pagesEnglish Project CompileAbdul QayyumNo ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- Lesson Plan in English 8Document66 pagesLesson Plan in English 8Mhairo Akira100% (1)

- CHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Document2 pagesCHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Karthika SNo ratings yet