Professional Documents

Culture Documents

Push Pull PDR Report

Push Pull PDR Report

Uploaded by

Brian AliasgharCopyright:

Available Formats

You might also like

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- G20P-5 MMC2.4 Sb1168e00 PDFDocument798 pagesG20P-5 MMC2.4 Sb1168e00 PDFGORD100% (1)

- 08 Chapter 3Document23 pages08 Chapter 3Sahaya GrinspanNo ratings yet

- Carte Tehnica Ford 3000Document178 pagesCarte Tehnica Ford 3000silviy8582% (11)

- Ergos 15-18-20-25-30-35 D/G: Spare Parts CatalogueDocument108 pagesErgos 15-18-20-25-30-35 D/G: Spare Parts CatalogueRuslan SklokinNo ratings yet

- 207 Handbook User Guide PeugeotDocument250 pages207 Handbook User Guide PeugeotJohn C Wesley-BarkerNo ratings yet

- Wirings Inter 2003Document208 pagesWirings Inter 2003Norman Valle Sáenz93% (14)

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- What We Are Going To UseDocument8 pagesWhat We Are Going To UseSukhmandeep SinghNo ratings yet

- Spring Rates Roll Centers and HandlingDocument9 pagesSpring Rates Roll Centers and HandlingfizznitNo ratings yet

- Steering Prob StatmentDocument8 pagesSteering Prob StatmentDarshanNo ratings yet

- NAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeDocument10 pagesNAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeIndranil BhattacharyyaNo ratings yet

- Glossary of Suspension Terms PDFDocument10 pagesGlossary of Suspension Terms PDFrobinNo ratings yet

- Steer Angles, Ackerman and Tire Slip Angles PDFDocument12 pagesSteer Angles, Ackerman and Tire Slip Angles PDFGeforceCudaNo ratings yet

- Design UprightDocument5 pagesDesign UprightJohn HopkinsNo ratings yet

- Axle ShaftsDocument14 pagesAxle ShaftsAnonymous QiMB2lBCJLNo ratings yet

- Axle ShaftsDocument13 pagesAxle ShaftsankitsarvaiyaNo ratings yet

- Suspension: 1) Wheelbase and TrackwidthDocument8 pagesSuspension: 1) Wheelbase and TrackwidthRaneem khaledNo ratings yet

- 12 Things To Know About Lifted' Suspension EngineeringDocument7 pages12 Things To Know About Lifted' Suspension EngineeringPeter SchmidtNo ratings yet

- Senior Project ReportDocument6 pagesSenior Project ReportRoss Bunnell100% (1)

- See Figures 1 Thru 7: Suspension SystemDocument28 pagesSee Figures 1 Thru 7: Suspension SystembalajigandhirajanNo ratings yet

- 2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel EngineDocument8 pages2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel Engineangelus256No ratings yet

- CH-4 - Part2Document41 pagesCH-4 - Part2Just DearNo ratings yet

- Chasis Lifan 620Document56 pagesChasis Lifan 620lllleonellllNo ratings yet

- Modal and Stress Analysis of Lower Wishbone Arm Along With TopologyDocument7 pagesModal and Stress Analysis of Lower Wishbone Arm Along With TopologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Fourlink Ladderbar TipsDocument5 pagesFourlink Ladderbar TipsmasimalNo ratings yet

- Automotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringDocument22 pagesAutomotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringSenthil Muthu Kumar TNo ratings yet

- METU ME 465 (Automotive) - ch5Document73 pagesMETU ME 465 (Automotive) - ch5Tt OwnsqqNo ratings yet

- A Comparative Study of The SuspensionDocument7 pagesA Comparative Study of The SuspensionSivadanusNo ratings yet

- Independent Suspension SystemDocument28 pagesIndependent Suspension Systemvishnu13141No ratings yet

- Car Suspension Over BumpDocument23 pagesCar Suspension Over BumpVairasivam Karisna KumarNo ratings yet

- Research On Axle HousingsDocument7 pagesResearch On Axle HousingsTushar ChughNo ratings yet

- Module 1-Lesson 2-MEEC 101A PDFDocument7 pagesModule 1-Lesson 2-MEEC 101A PDFDenver NieverasNo ratings yet

- Module 1-Lesson 2-MEEC 101A PDFDocument7 pagesModule 1-Lesson 2-MEEC 101A PDFDenver NieverasNo ratings yet

- Introductory OverviewDocument25 pagesIntroductory OverviewPrachi SinhaNo ratings yet

- t235 1blk9.3 PDFDocument6 pagest235 1blk9.3 PDFRui GavinaNo ratings yet

- SAE Mini BAJA: Suspension and Steering: Project ProgressDocument22 pagesSAE Mini BAJA: Suspension and Steering: Project ProgressVitoria ColliNo ratings yet

- Anti Roll BarDocument27 pagesAnti Roll BarU.S. DubeyNo ratings yet

- Kinematic and Dynamic Analysis of Independent Suspension SystemDocument9 pagesKinematic and Dynamic Analysis of Independent Suspension Systemsiddhartha180987100% (3)

- Calculating Commercial Vehicle Weight DistributionDocument7 pagesCalculating Commercial Vehicle Weight Distributionnaimakruk50% (2)

- Calculating Commercial Vehicle Weight DistributionDocument8 pagesCalculating Commercial Vehicle Weight DistributiondejejuniorNo ratings yet

- Stability of Powered VehiclesDocument4 pagesStability of Powered VehiclesBrianNo ratings yet

- Rear Axle ConstructionDocument19 pagesRear Axle ConstructionMohseen KarcheNo ratings yet

- Design and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFDocument34 pagesDesign and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFKoyyada Kranthikumar100% (1)

- Double Wishbone SuspensionDocument5 pagesDouble Wishbone SuspensionalexmarieiNo ratings yet

- Alignment: Diagnosis, ServiceDocument33 pagesAlignment: Diagnosis, Service2791957No ratings yet

- New Automotive Suspension SystemsDocument30 pagesNew Automotive Suspension SystemsAbubaker MuzayinNo ratings yet

- Suspension Design ProcedureDocument63 pagesSuspension Design ProcedurejalanayushNo ratings yet

- Module 2 SuspensionDocument15 pagesModule 2 SuspensionK R Savin JosephNo ratings yet

- Axle Stability - PrinciplesDocument17 pagesAxle Stability - PrinciplesbagishdxbNo ratings yet

- Unit-Iv Steering SystemDocument20 pagesUnit-Iv Steering SystemMark MubiruNo ratings yet

- Construction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesDocument26 pagesConstruction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesJoshua GrahitaNo ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Ijmet 08 08 019Document8 pagesIjmet 08 08 019achumilemlata48No ratings yet

- A Literature Review On Collapsible Steering ColumnDocument9 pagesA Literature Review On Collapsible Steering ColumnIJIRSTNo ratings yet

- Center of Gravity and Moment ArmDocument6 pagesCenter of Gravity and Moment ArmJam BabNo ratings yet

- Discrete-Time For Traction: RobustDocument7 pagesDiscrete-Time For Traction: RobustfenasikarimNo ratings yet

- A Review On Independent Suspension System of Light Commercial VehicleDocument6 pagesA Review On Independent Suspension System of Light Commercial VehicleKiru CherryNo ratings yet

- Galgotias University: Laboratory ManualDocument52 pagesGalgotias University: Laboratory ManualAgnivesh SharmaNo ratings yet

- VD Exp-8 Q2Document3 pagesVD Exp-8 Q2UMESH HARCHANDANINo ratings yet

- 1 Final Technical Report Mini BajaDocument14 pages1 Final Technical Report Mini BajaLucasNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- F @ (X) X 3-Sin (X) : Third Programming AssignmentDocument1 pageF @ (X) X 3-Sin (X) : Third Programming AssignmentBrian AliasgharNo ratings yet

- Experiment2 DiodesDocument6 pagesExperiment2 DiodesBrian AliasgharNo ratings yet

- Me 335 Exp 2Document8 pagesMe 335 Exp 2Brian AliasgharNo ratings yet

- Time Sheet Brian Aliasghar Week 2Document1 pageTime Sheet Brian Aliasghar Week 2Brian AliasgharNo ratings yet

- VE Immobilizer Description and OperationDocument3 pagesVE Immobilizer Description and Operationraraokt222No ratings yet

- AccessoriesibizaDocument19 pagesAccessoriesibizaCristina BoghianNo ratings yet

- CB650FADocument150 pagesCB650FAlb00572835No ratings yet

- Spare Parts List Catalogo Parti Di Ricambio: AXLE 26.32 ASSALE 26.32Document10 pagesSpare Parts List Catalogo Parti Di Ricambio: AXLE 26.32 ASSALE 26.32Oskars RozefeldsNo ratings yet

- KYMCO AK 550型錄-英文版Document17 pagesKYMCO AK 550型錄-英文版Cornea Vlad DanNo ratings yet

- Japanparts Eco Fuel Filters FC-ECODocument7 pagesJapanparts Eco Fuel Filters FC-ECOPopa DanielNo ratings yet

- 501 11 PDFDocument25 pages501 11 PDFTuan TranNo ratings yet

- Bill Yamaha Royal 2021 JanDocument4 pagesBill Yamaha Royal 2021 JanSubha RahmanNo ratings yet

- Project 1. RockCrawlingDocument2 pagesProject 1. RockCrawlingHải YếnNo ratings yet

- Available Vsi-Di + Vsi-2.0 Di LPG & Direct Liquimax SystemsDocument8 pagesAvailable Vsi-Di + Vsi-2.0 Di LPG & Direct Liquimax SystemssuppholNo ratings yet

- TRUCK - Volvos Steer SystemDocument75 pagesTRUCK - Volvos Steer SystemNuttenNo ratings yet

- 450AJDocument2 pages450AJJose MelgarNo ratings yet

- Maruti (Vwlor: Car BrochureDocument10 pagesMaruti (Vwlor: Car BrochureSiddesh LadNo ratings yet

- 423 Golf 09-1Document32 pages423 Golf 09-1Deepak Chachra50% (2)

- S4 Timing PDFDocument27 pagesS4 Timing PDFTaylor McNamaraNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Safety 116i 118i 120i 130i 118d 120d: S Standard Equipment o Optional Equipment - Not AvailableDocument6 pagesSafety 116i 118i 120i 130i 118d 120d: S Standard Equipment o Optional Equipment - Not AvailableKmt_AeNo ratings yet

- 2016 Peugeot 2008 101601 PDFDocument450 pages2016 Peugeot 2008 101601 PDFKOSTAS PSYRRASNo ratings yet

- BTX - Parts Manual 834H Vol I Feb 2010Document746 pagesBTX - Parts Manual 834H Vol I Feb 2010maneul zambranoNo ratings yet

- VW All ModelsDocument18 pagesVW All ModelsJan ZuffaNo ratings yet

- Body Dimension Drawings: Engine CompartmentDocument8 pagesBody Dimension Drawings: Engine CompartmentmaximchacaNo ratings yet

- Guiadeaplicacionesbujiasvenezuela 151008140628 Lva1 App6892 PDFDocument10 pagesGuiadeaplicacionesbujiasvenezuela 151008140628 Lva1 App6892 PDFRangel AlvarezNo ratings yet

- Ausa Forklift Ch130 Ch150 x4 Spare PartsDocument20 pagesAusa Forklift Ch130 Ch150 x4 Spare Partsdarren100% (52)

- Peugeot 207 1.6 HDI 90 HP Dyno 1Document1 pagePeugeot 207 1.6 HDI 90 HP Dyno 1darthbergmen100% (2)

Push Pull PDR Report

Push Pull PDR Report

Uploaded by

Brian AliasgharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Push Pull PDR Report

Push Pull PDR Report

Uploaded by

Brian AliasgharCopyright:

Available Formats

Push vs.

Pull Rod Suspension The push rod operates in the following manner: when the wheel is in bump, the diagonal member in between the upper and lower control arms gets pushed in toward the chassis of the vehicle. This motion will pivot a bell crank (rocker) which operates about a fixed point, compressing the spring and damper. The push rod suspension configuration is illustrated in Figure X.1.

Figure X.1 Push Rod Suspension The pull rod configuration is very similar to the previous style but simply inverted. During bump, the wheel will pull on the diagonal member which will pivot the bell crank and operate the damper and spring. Figure X.2 shows a diagram of the pull rod suspension style.

Figure X.2 Pull Rod Suspension One of the main reasons teams have chosen to employ the push rod style suspension is the ease of access that comes with it. Since most of the parts are located close to the top of the chassis, adjustments as well as repairs are in easy reach as shown in Figure X.3.

Figure X.3 2012-2013 FSAE Car Front Push Rod Suspension However, with the ease of accessibility comes an increased center of gravity height due to the suspension components placed physically higher up on the chassis of the vehicle. The push rod will also tend to bow outwards during compression but this can be accounted for during the design phase. On the other hand, the pull rod suspension will offer a lower center of gravity as most of the parts are placed on the bottom of the chassis as shown in Figure X.2. But as Figure X.2 also shows, the components will be difficult to reach and will most likely require lifting the vehicle in the air should a need for repairs arise. Another difference between the two types of suspension configurations is in regards to the loads that are passed through the wishbones.

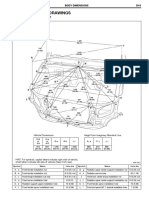

Figure X.4 Reaction Forces of Pull and Push Rod Suspension From Newtons third law, the rods (the diagonal members) must react to the force created by the springs. As Figure X. 4 shows, the forces along the wishbone and the push rod are in the opposite direction of each other meaning they offset each other. With the pull rod configuration, the forces are in the same direction and combine with each other. This difference indicates that the upper control arms of the pull rod suspension style will undergo heavier stresses than the push rod. The extra stress will mean thicker and thus, heavier upper control arms will be required (assuming left and right wishbones are the same material) to safely implement the pull rod style suspension. In order to guide the suspension team on which configuration to choose for the front and rear of the vehicle, a decision matrix was created. This particular decision matrix is based off the scoring rubric of the FSAE competition and is designed to clearly show the choice that would allow the maximum number of points to be awarded.

Figure X.5 Decision Matrix for Push or Pull Rod Suspension The above table shows that pull rod suspension has the most number of points for the front and rear. Certain categories such as resources, efficiency, endurance, acceleration and cost were zeroed out due to the category being irrelevant for the decision or the fact that the scores would be equal between push and pull rod configurations. In the design category, the push rod configuration for the front and rear was given a slightly higher score only due to the packaging issues that arise for the pull rod style. For example, with a push rod style in the front of the car, the shock/spring and bell crank can designed to be placed above all the front components of the car as Figure X.3 shows. However, with the pull rod configuration, the shock/spring and bell crank would be placed toward the bottom of the car where the suspension components need to fit with the pedal assembly and the drivers legs in the nose of the car. Another option is to have the shock/spring and bell crank be positioned under the body of the vehicle but the anti-roll bar and ground clearance issues need to be accounted for. The pull rod configuration was given a slightly higher score in the skid pad and autocross dynamics events. The winning factor for the pull rod style was the lowered center of gravity, which reduces the lateral weight transfer and allows the car to be more level more of the time.

You might also like

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- G20P-5 MMC2.4 Sb1168e00 PDFDocument798 pagesG20P-5 MMC2.4 Sb1168e00 PDFGORD100% (1)

- 08 Chapter 3Document23 pages08 Chapter 3Sahaya GrinspanNo ratings yet

- Carte Tehnica Ford 3000Document178 pagesCarte Tehnica Ford 3000silviy8582% (11)

- Ergos 15-18-20-25-30-35 D/G: Spare Parts CatalogueDocument108 pagesErgos 15-18-20-25-30-35 D/G: Spare Parts CatalogueRuslan SklokinNo ratings yet

- 207 Handbook User Guide PeugeotDocument250 pages207 Handbook User Guide PeugeotJohn C Wesley-BarkerNo ratings yet

- Wirings Inter 2003Document208 pagesWirings Inter 2003Norman Valle Sáenz93% (14)

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- What We Are Going To UseDocument8 pagesWhat We Are Going To UseSukhmandeep SinghNo ratings yet

- Spring Rates Roll Centers and HandlingDocument9 pagesSpring Rates Roll Centers and HandlingfizznitNo ratings yet

- Steering Prob StatmentDocument8 pagesSteering Prob StatmentDarshanNo ratings yet

- NAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeDocument10 pagesNAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeIndranil BhattacharyyaNo ratings yet

- Glossary of Suspension Terms PDFDocument10 pagesGlossary of Suspension Terms PDFrobinNo ratings yet

- Steer Angles, Ackerman and Tire Slip Angles PDFDocument12 pagesSteer Angles, Ackerman and Tire Slip Angles PDFGeforceCudaNo ratings yet

- Design UprightDocument5 pagesDesign UprightJohn HopkinsNo ratings yet

- Axle ShaftsDocument14 pagesAxle ShaftsAnonymous QiMB2lBCJLNo ratings yet

- Axle ShaftsDocument13 pagesAxle ShaftsankitsarvaiyaNo ratings yet

- Suspension: 1) Wheelbase and TrackwidthDocument8 pagesSuspension: 1) Wheelbase and TrackwidthRaneem khaledNo ratings yet

- 12 Things To Know About Lifted' Suspension EngineeringDocument7 pages12 Things To Know About Lifted' Suspension EngineeringPeter SchmidtNo ratings yet

- Senior Project ReportDocument6 pagesSenior Project ReportRoss Bunnell100% (1)

- See Figures 1 Thru 7: Suspension SystemDocument28 pagesSee Figures 1 Thru 7: Suspension SystembalajigandhirajanNo ratings yet

- 2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel EngineDocument8 pages2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel Engineangelus256No ratings yet

- CH-4 - Part2Document41 pagesCH-4 - Part2Just DearNo ratings yet

- Chasis Lifan 620Document56 pagesChasis Lifan 620lllleonellllNo ratings yet

- Modal and Stress Analysis of Lower Wishbone Arm Along With TopologyDocument7 pagesModal and Stress Analysis of Lower Wishbone Arm Along With TopologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Fourlink Ladderbar TipsDocument5 pagesFourlink Ladderbar TipsmasimalNo ratings yet

- Automotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringDocument22 pagesAutomotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringSenthil Muthu Kumar TNo ratings yet

- METU ME 465 (Automotive) - ch5Document73 pagesMETU ME 465 (Automotive) - ch5Tt OwnsqqNo ratings yet

- A Comparative Study of The SuspensionDocument7 pagesA Comparative Study of The SuspensionSivadanusNo ratings yet

- Independent Suspension SystemDocument28 pagesIndependent Suspension Systemvishnu13141No ratings yet

- Car Suspension Over BumpDocument23 pagesCar Suspension Over BumpVairasivam Karisna KumarNo ratings yet

- Research On Axle HousingsDocument7 pagesResearch On Axle HousingsTushar ChughNo ratings yet

- Module 1-Lesson 2-MEEC 101A PDFDocument7 pagesModule 1-Lesson 2-MEEC 101A PDFDenver NieverasNo ratings yet

- Module 1-Lesson 2-MEEC 101A PDFDocument7 pagesModule 1-Lesson 2-MEEC 101A PDFDenver NieverasNo ratings yet

- Introductory OverviewDocument25 pagesIntroductory OverviewPrachi SinhaNo ratings yet

- t235 1blk9.3 PDFDocument6 pagest235 1blk9.3 PDFRui GavinaNo ratings yet

- SAE Mini BAJA: Suspension and Steering: Project ProgressDocument22 pagesSAE Mini BAJA: Suspension and Steering: Project ProgressVitoria ColliNo ratings yet

- Anti Roll BarDocument27 pagesAnti Roll BarU.S. DubeyNo ratings yet

- Kinematic and Dynamic Analysis of Independent Suspension SystemDocument9 pagesKinematic and Dynamic Analysis of Independent Suspension Systemsiddhartha180987100% (3)

- Calculating Commercial Vehicle Weight DistributionDocument7 pagesCalculating Commercial Vehicle Weight Distributionnaimakruk50% (2)

- Calculating Commercial Vehicle Weight DistributionDocument8 pagesCalculating Commercial Vehicle Weight DistributiondejejuniorNo ratings yet

- Stability of Powered VehiclesDocument4 pagesStability of Powered VehiclesBrianNo ratings yet

- Rear Axle ConstructionDocument19 pagesRear Axle ConstructionMohseen KarcheNo ratings yet

- Design and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFDocument34 pagesDesign and Analysis of Front Axle of Heavy Commercial Vehicle 4 GNR PDFKoyyada Kranthikumar100% (1)

- Double Wishbone SuspensionDocument5 pagesDouble Wishbone SuspensionalexmarieiNo ratings yet

- Alignment: Diagnosis, ServiceDocument33 pagesAlignment: Diagnosis, Service2791957No ratings yet

- New Automotive Suspension SystemsDocument30 pagesNew Automotive Suspension SystemsAbubaker MuzayinNo ratings yet

- Suspension Design ProcedureDocument63 pagesSuspension Design ProcedurejalanayushNo ratings yet

- Module 2 SuspensionDocument15 pagesModule 2 SuspensionK R Savin JosephNo ratings yet

- Axle Stability - PrinciplesDocument17 pagesAxle Stability - PrinciplesbagishdxbNo ratings yet

- Unit-Iv Steering SystemDocument20 pagesUnit-Iv Steering SystemMark MubiruNo ratings yet

- Construction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesDocument26 pagesConstruction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesJoshua GrahitaNo ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Ijmet 08 08 019Document8 pagesIjmet 08 08 019achumilemlata48No ratings yet

- A Literature Review On Collapsible Steering ColumnDocument9 pagesA Literature Review On Collapsible Steering ColumnIJIRSTNo ratings yet

- Center of Gravity and Moment ArmDocument6 pagesCenter of Gravity and Moment ArmJam BabNo ratings yet

- Discrete-Time For Traction: RobustDocument7 pagesDiscrete-Time For Traction: RobustfenasikarimNo ratings yet

- A Review On Independent Suspension System of Light Commercial VehicleDocument6 pagesA Review On Independent Suspension System of Light Commercial VehicleKiru CherryNo ratings yet

- Galgotias University: Laboratory ManualDocument52 pagesGalgotias University: Laboratory ManualAgnivesh SharmaNo ratings yet

- VD Exp-8 Q2Document3 pagesVD Exp-8 Q2UMESH HARCHANDANINo ratings yet

- 1 Final Technical Report Mini BajaDocument14 pages1 Final Technical Report Mini BajaLucasNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- F @ (X) X 3-Sin (X) : Third Programming AssignmentDocument1 pageF @ (X) X 3-Sin (X) : Third Programming AssignmentBrian AliasgharNo ratings yet

- Experiment2 DiodesDocument6 pagesExperiment2 DiodesBrian AliasgharNo ratings yet

- Me 335 Exp 2Document8 pagesMe 335 Exp 2Brian AliasgharNo ratings yet

- Time Sheet Brian Aliasghar Week 2Document1 pageTime Sheet Brian Aliasghar Week 2Brian AliasgharNo ratings yet

- VE Immobilizer Description and OperationDocument3 pagesVE Immobilizer Description and Operationraraokt222No ratings yet

- AccessoriesibizaDocument19 pagesAccessoriesibizaCristina BoghianNo ratings yet

- CB650FADocument150 pagesCB650FAlb00572835No ratings yet

- Spare Parts List Catalogo Parti Di Ricambio: AXLE 26.32 ASSALE 26.32Document10 pagesSpare Parts List Catalogo Parti Di Ricambio: AXLE 26.32 ASSALE 26.32Oskars RozefeldsNo ratings yet

- KYMCO AK 550型錄-英文版Document17 pagesKYMCO AK 550型錄-英文版Cornea Vlad DanNo ratings yet

- Japanparts Eco Fuel Filters FC-ECODocument7 pagesJapanparts Eco Fuel Filters FC-ECOPopa DanielNo ratings yet

- 501 11 PDFDocument25 pages501 11 PDFTuan TranNo ratings yet

- Bill Yamaha Royal 2021 JanDocument4 pagesBill Yamaha Royal 2021 JanSubha RahmanNo ratings yet

- Project 1. RockCrawlingDocument2 pagesProject 1. RockCrawlingHải YếnNo ratings yet

- Available Vsi-Di + Vsi-2.0 Di LPG & Direct Liquimax SystemsDocument8 pagesAvailable Vsi-Di + Vsi-2.0 Di LPG & Direct Liquimax SystemssuppholNo ratings yet

- TRUCK - Volvos Steer SystemDocument75 pagesTRUCK - Volvos Steer SystemNuttenNo ratings yet

- 450AJDocument2 pages450AJJose MelgarNo ratings yet

- Maruti (Vwlor: Car BrochureDocument10 pagesMaruti (Vwlor: Car BrochureSiddesh LadNo ratings yet

- 423 Golf 09-1Document32 pages423 Golf 09-1Deepak Chachra50% (2)

- S4 Timing PDFDocument27 pagesS4 Timing PDFTaylor McNamaraNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Safety 116i 118i 120i 130i 118d 120d: S Standard Equipment o Optional Equipment - Not AvailableDocument6 pagesSafety 116i 118i 120i 130i 118d 120d: S Standard Equipment o Optional Equipment - Not AvailableKmt_AeNo ratings yet

- 2016 Peugeot 2008 101601 PDFDocument450 pages2016 Peugeot 2008 101601 PDFKOSTAS PSYRRASNo ratings yet

- BTX - Parts Manual 834H Vol I Feb 2010Document746 pagesBTX - Parts Manual 834H Vol I Feb 2010maneul zambranoNo ratings yet

- VW All ModelsDocument18 pagesVW All ModelsJan ZuffaNo ratings yet

- Body Dimension Drawings: Engine CompartmentDocument8 pagesBody Dimension Drawings: Engine CompartmentmaximchacaNo ratings yet

- Guiadeaplicacionesbujiasvenezuela 151008140628 Lva1 App6892 PDFDocument10 pagesGuiadeaplicacionesbujiasvenezuela 151008140628 Lva1 App6892 PDFRangel AlvarezNo ratings yet

- Ausa Forklift Ch130 Ch150 x4 Spare PartsDocument20 pagesAusa Forklift Ch130 Ch150 x4 Spare Partsdarren100% (52)

- Peugeot 207 1.6 HDI 90 HP Dyno 1Document1 pagePeugeot 207 1.6 HDI 90 HP Dyno 1darthbergmen100% (2)